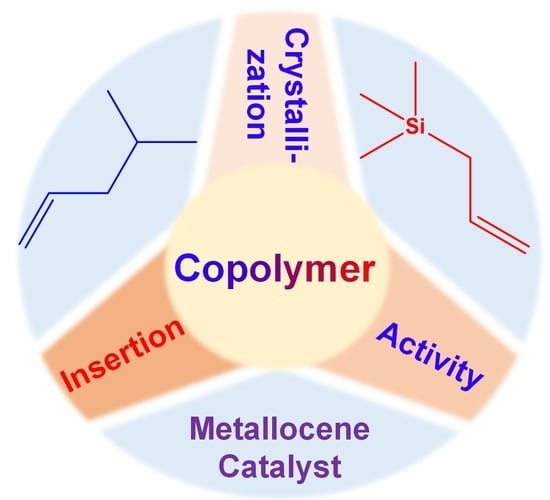

Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.; Rempel, G.L. Ziegler-Natta catalysts for olefin polymerization: Mechanistic insights from metallocene systems. Prog. Polym. Sci. 1995, 20, 459–526. [Google Scholar] [CrossRef]

- Alt, H.G.; Alexander, K. Effect of the nature of metallocene complexes of Group IV metals on their performance in catalytic ethylene and propylene polymerization. Chem. Rev. 2000, 100, 1205–1221. [Google Scholar] [CrossRef]

- Singh, R.P. Recent developments in the degradation and stabilization of poly(1-butene). Prog. Polym. Sci. 1985, 11, 201–219. [Google Scholar] [CrossRef]

- Day, M.R. “TPX” [4-methyl-1-pentene] methylpentene polymers. Plast. Polym. 1968, 36, 101–108. [Google Scholar]

- Hanifpour, A.; Bahri-Laleh, N.; Nekoomanesh-Haghighi, M.; Poater, A. Coordinative chain transfer polymerization of 1-decene in the presence of a Ti-based diamine bis(phenolate) catalyst: A sustainable approach to produce low viscosity PAOs. Green Chem. 2020, 22, 4617–4626. [Google Scholar] [CrossRef]

- Hu, J.; Li, Z.; Hu, Z.-D.; Wu, J.; Wang, J. Achieving super resolution lithography based on bulk plasmon polaritons of hyperbolic metamaterials. Opt. Mater. 2022, 130, 112536. [Google Scholar] [CrossRef]

- Wang, C.; Cui, Z.; Song, J.; Wang, Z. Molecular simulation study on the separation of CO2 and N2 in poly(4-methyl-1-pentene) membrane. J. Mol. Liq. 2022, 359, 119376. [Google Scholar] [CrossRef]

- Markova, S.Y.; Dukhov, A.V.; Pelzer, M.; Shalygin, M.G.; Vad, T.; Gries, T.; Teplyakov, V.V. Designing 3D Membrane Modules for Gas Separation Based on Hollow Fibers from Poly(4-methyl-1-pentene). Membranes 2022, 12, 36. [Google Scholar] [CrossRef]

- Markova, S.Y.; Pelzer, M.; Shalygin, M.G.; Vad, T.; Gries, T.; Teplyakov, V.V. Gas separating hollow fibres from Poly(4-methyl-1-pentene): A new development. Sep. Purif. Technol. 2022, 278, 119534. [Google Scholar] [CrossRef]

- Tan, X.; Liu, T.-H.; Zhou, W.; Yuan, Q.; Ying, J.; Yan, Q.; Lv, L.; Chen, L.; Wang, X.; Du, S.; et al. Enhanced Electromagnetic Shielding and Thermal Conductive Properties of Polyolefin Composites with a Ti3C2Tx MXene/Graphene Framework Connected by a Hydrogen-Bonded Interface. ACS Nano 2022, 16, 9254–9266. [Google Scholar] [CrossRef]

- Abetz, C.; Georgopanos, P.; Pistidda, C.; Klassen, T.; Abetz, V. Reactive Hydride Composite Confined in a Polymer Matrix: New Insights into the Desorption and Absorption of Hydrogen in a Storage Material with High Cycling Stability. Adv. Mater. Technol. 2022, 7, 2101584. [Google Scholar] [CrossRef]

- Fukuda, M.; Furuya, T.; Sadano, K.; Tokumine, A.; Mori, T.; Saomoto, H.; Sakai, K. Electron Microscopic Confirmation of Anisotropic Pore Characteristics for ECMO Membranes Theoretically Validating the Risk of SARS-CoV-2 Permeation. Membranes 2021, 11, 529. [Google Scholar] [CrossRef] [PubMed]

- Lopez, L.C.; Wilkes, G.L.; Stricklen, P.M.; White, S.A. Synthesis, structure, and properties of poly(4-methyl-1-pentene). J. Macromol. Sci. Rev. Macromol. Chem. Phys. 1992, C32, 301–406. [Google Scholar] [CrossRef]

- Sung, Y.-C.; Huang, P.-S.; Huang, S.-H.; Chiang, Y.-W.; Tsai, J.-C. Syndiotactic Poly(4-methyl-1-pentene)-Based Stereoregular Diblock Copolymers: Synthesis and Self-Assembly Studies. Polymers 2022, 14, 4815. [Google Scholar] [CrossRef] [PubMed]

- Descour, C.; Duchateau, R.; Mosia, M.R.; Gruter, G.M.; Severn, J.R.; Rastogi, S. Catalyst behavior for 1-pentene and 4-methyl-1-pentene polymerization for C2-, Cs- and C1-symmetric zirconocenes. Polym. Chem. 2011, 2, 2261–2272. [Google Scholar] [CrossRef]

- Wang, W.; Hou, L.; Sheng, J.; Ren, M.; Tang, Y. Copolymerization of 4-methyl-1-pentene with α,ω-alkenols. Express Polym. Lett. 2016, 10, 1026–1033. [Google Scholar] [CrossRef]

- Wang, W.; Hou, L.; Sheng, J. Syndiotactic Polymer of Allylcyclopentane by A Metallocene Catalyst. ChemCatChem 2016, 8, 3218–3223. [Google Scholar] [CrossRef]

- Kirshenbaum, I.; Feist, W.C.; Isaacson, R.B. Properties of semicrystalline polyolefins. IV. Crystallization phenomena in poly(3-methyl-1-butene). J. Appl. Polym. Sci. 1965, 9, 3023–3031. [Google Scholar] [CrossRef]

- Hu, W.; Hagihara, H.; Miyoshi, T. Microstructure and Thermal Property of Isotactic Poly(3-methyl-1-butene) Obtained Using the C2-Symmetrical Zirconocene/MAO Catalyst System. Macromolecules 2007, 40, 1763–1766. [Google Scholar] [CrossRef]

- Liu, J.; Nomura, K. Efficient functional group introduction into polyolefins by copolymerization of ethylene with allyltrialkylsilane using nonbridged half-titanocenes. Macromolecules 2008, 41, 1070–1072. [Google Scholar] [CrossRef]

- Kawakami, T.; Ito, S.; Nozaki, K. Iron-catalyzed homo- and copolymerization of propylene: Steric influence of bis(imino)pyridine ligands. Dalton Trans. 2015, 44, 20745–20752. [Google Scholar] [CrossRef] [PubMed]

- Zeigler, R.; Resconi, L.; Balbontin, G.; Guerra, G.; Venditto, V.; De Rosa, C. Allyltrimethylsilane polymers from metallocene catalysts: Tacticity and structural characterization. Polymer 1994, 35, 4648–4655. [Google Scholar] [CrossRef]

- De Rosa, C.; Auriemma, F.; Tarallo, O.; Malafronte, A.; Di Girolamo, R.; Esposito, S.; Piemontesi, F.; Liguori, D.; Morini, G. The “Nodular” α Form of Isotactic Polypropylene: Stiff and Strong Polypropylene with High Deformability. Macromolecules 2017, 50, 5434–5446. [Google Scholar] [CrossRef]

- De Rosa, C.; Auriemma, F.; Tarallo, O.; Di Girolamo, R.; Troisi, E.M.; Esposito, S.; Liguori, D.; Piemontesi, F.; Vitale, G.; Morini, G. Tailoring the properties of polypropylene in the polymerization reactor using polymeric nucleating agents as prepolymers on the Ziegler-Natta catalyst granule. Polym. Chem. 2017, 8, 655–660. [Google Scholar] [CrossRef]

- Habaue, S.; Baraki, H.; Okamoto, Y. Polymerization and asymmetric oligomerization of allylsilanes using chiral ethylenebis(4,5,6,7-tetrahydro-1-indenyl)zirconium and -hafnium complexes. Macromol. Chem. Phys. 1998, 199, 2211–2215. [Google Scholar] [CrossRef]

- Sugie, K.; Yamada, T.; Yamaji, T. Novel silicon-containing copolymer, ultrathin solid membrane composed of said copolymer, use of said solid membrane for concentrating a specified gas in a gaseous mixture, and process for producing said solid membrane. U.S. Patent 4393113A, 12 July 1983. [Google Scholar]

- Kaminsky, W.; Kuelper, K.; Brintzinger, H.H.; Wild, F.R.W.P. Polymerization of propene and butene with a chiral zirconocene and methylaluminoxane as cocatalyst. Angew. Chem. 1985, 97, 507–508. [Google Scholar] [CrossRef]

- Ewen, J.A.; Jones, R.L.; Razavi, A.; Ferrara, J.D. Syndiospecific propylene polymerizations with Group IVB metallocenes. J. Am. Chem. Soc. 1988, 110, 6255–6256. [Google Scholar] [CrossRef] [PubMed]

- Ewen, J.A. Mechanisms of stereochemical control in propylene polymerizations with soluble Group 4B metallocene/methylalumoxane catalysts. J. Am. Chem. Soc. 1984, 106, 6355–6364. [Google Scholar] [CrossRef]

- Wang, W.; Hou, L.; Zhang, T. Integrated Effect of Comonomer and Catalyst on Copolymerization of Ethylene with Allylcyclopentane or Allylcyclohexane by Using Metallocene Catalysts. ChemistrySelect 2020, 5, 7581–7585. [Google Scholar] [CrossRef]

- Razavi, A.; Atwood, J.L. Preparation and crystal structures of the cyclopentadienylfluorenyldiphenylmethane zirconium and hafnium complexes (η5-C5H4CPh2-η5-C13H8)MCl2 (M = Zr, Hf) and the catalytic formation of high molecular weight high tacticity syndiotactic polypropylene. J. Organomet. Chem. 1993, 459, 117–123. [Google Scholar] [CrossRef]

- Piemontesi, F.; Camurati, I.; Resconi, L.; Balboni, D.; Sironi, A.; Moret, M.; Zeigler, R.; Piccolrovazzi, N. Crystal Structures and Solution Conformations of the Meso and Racemic Isomers of Ethylenebis(1-indenyl))zirconium Dichloride. Organometallics 1995, 14, 1256–1266. [Google Scholar] [CrossRef]

- Wang, L.; Li, D.; Ren, H.; Wang, Y.; Wu, W.; Gao, Y.; Wang, X.; Gao, H. Isoselective 4-methylpentene polymerization by pyridylamido hafnium catalysts. Polym. Chem. 2021, 12, 3556–3563. [Google Scholar] [CrossRef]

- Li, Y.; Guo, Z.; Xue, M.; Yan, S. Epitaxial Recrystallization of IPBu in Form II on an Oriented IPS Film Initially Induced by Oriented Form I IPBu. Macromolecules 2019, 52, 4232–4239. [Google Scholar] [CrossRef]

- Diez-Rodriguez, T.M.; Blazquez-Blazquez, E.; Perez, E.; Cerrada, M.L. Influence of Content in D Isomer and Incorporation of SBA-15 Silica on the Crystallization Ability and Mechanical Properties in PLLA Based Materials. Polymers 2022, 14, 1237. [Google Scholar] [CrossRef]

- De Rosa, C.; Venditto, V.; Guerra, G.; Corradini, P. Chain conformation and unit cell in the crystalline phase of syndiotactic poly(4-methyl-1-pentene). Macromolecules 1992, 25, 6938–6942. [Google Scholar] [CrossRef]

- Jeon, K.; Palza, H.; Quijada, R.; Alamo, R.G. Effect of Comonomer Type on the Crystallization Kinetics of Random Isotactic Propylene 1-Alkene Copolymers. Polymer 2009, 50, 832–844. [Google Scholar] [CrossRef]

- Hosier, I.L.; Alamo, R.G.; Esteso, P.; Isasi, J.R.; Mandelkern, L. Formation of the Alpha and Gamma Polymorphs in Random Metallocene Copolymers. Effect of Concentration and Type of Comonomer. Macromolecules 2003, 36, 5623–5636. [Google Scholar] [CrossRef]

- Alamo, R.G.; Ghosal, A.; Chatterjee, J.; Thomson, K.L. Linear Growth Rates of Random Propylene Ethylene Copolymers. The Changeover from γ Dominated Growth to Mix (α + γ) Polymorphic Growth. Polymer 2005, 46, 8774–8789. [Google Scholar] [CrossRef]

- De Rosa, C. Crystal Structure of Form II of Isotactic Poly(4-methyl-1-pentene). Macromolecules 2003, 36, 6087–6094. [Google Scholar] [CrossRef]

- De Rosa, C.; Capitani, D.; Cosco, S. Solid-state 13C nuclear magnetic resonance spectra of four crystalline forms of isotactic poly(4-methyl-1-pentene). Macromolecules 1997, 30, 8322–8331. [Google Scholar] [CrossRef]

| Run | ATMS (mmol) | 4M1P (mmol) | Polymer (g) | Conv (wt%) | Tm b (°C) | ΔHm b (J/g) | Mw c (k) | pdi c | ATMS Incorp. d (mol%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 19.7 | 0.56 | 34 | 149 | 8.3 | 26.5 | 1.90 | 0 |

| 2 | 3.8 | 15.8 | 0.28 | 15 | -- e | -- e | 25.4 | 1.85 | -- f |

| 3 | 7.6 | 11.8 | 0.30 | 15 | -- e | -- e | 37.3 | 1.78 | -- f |

| 4 | 11.3 | 7.9 | 0.41 | 19 | -- e | -- e | 28.8 | 1.80 | 89.0 |

| 5 | 15.1 | 3.9 | 0.55 | 23 | 236 | 2.7 | 34.6 | 1.84 | -- f |

| 6 | 18.9 | 0 | 0.77 | 30 | 246 | 6.8 | 46.3 | 1.83 | 100 |

| 7 | 0 | 19.7 | 1.62 | 98 | 208 | 45.1 | 8.5 | 1.94 | 0 |

| 8 | 3.8 | 15.8 | 1.56 | 85 | 159 | 25.2 | 4.7 | 1.69 | -- f |

| 9 | 7.6 | 11.8 | 1.15 | 53 | -- e | -- e | 5.0 | 1.71 | 66.0 |

| 10 | 11.3 | 7.9 | 0.96 | 48 | 251 | 1.7 | 6.2 | 1.85 | 81.5 |

| 11 | 15.1 | 3.9 | 0.71 | 30 | 273 | 16.5 | 7.5 | 1.69 | -- f |

| 12 | 18.9 | 0 | 0.69 | 27 | 281 | 19.4 | 6.1 | 1.75 | 100 |

| Ph2(Cp)(Flu)ZrCl2 [31] (cat 1) | rac-EBIZrCl2 [32] (cat 2) | |||

|---|---|---|---|---|

| Bond length (Å) | Zr-Cl | 2.424(2) | Zr-Cl | 2.3884(5) |

| Zr-C(1) | 2.417(8) | Zr-C(1) | 2.438(2) | |

| Zr-C(2) | 2.513(6) | Zr-C(2) | 2.443(2) | |

| Zr-C(3) | 2.680(6) | Zr-C(3) | 2.531(2) | |

| Zr-C(27) | 2.452(8) | Zr-(C3a) | 2.624(2) | |

| Zr-C(28) | 2.450(6) | Zr-(C7a) | 2.553(2) | |

| Zr-C(29) | 2.523(6) | |||

| Bond angles (°) | Flu-Zr-Cp | 118.2 | Ind-Zr-Ind | 125.3(1) |

| Cl-Zr-Cl | 95.6 | Cl-Zr-Cl′ | 99.09(3) | |

| C1-C14-C27 | 99.6 | C(1)-C(8)-C(8′)-C(1′) | 45.6(3) | |

| ||||

| Polymer | Chemical Shift of Carbon (ppm) | ||||

|---|---|---|---|---|---|

| e | c | d | b | a | |

| iso-PMP | 44.84 | 41.38 | 30.19 | 24.68 | 22.33 |

| syndio-PMP | 44.75 | 41.80 | 30.36 | 24.67 | 22.25 |

| iso-PATMS | 45.47 | 28.48 | 22,72 | -- | -0.89 |

| syndio-PATMS | 45.70 | 28.25 | 22,78 | -- | -1.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Ren, M.; Hou, L.; Qu, S.; Li, X.; Guo, Z. Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts. Polymers 2023, 15, 2038. https://doi.org/10.3390/polym15092038

Wang W, Ren M, Hou L, Qu S, Li X, Guo Z. Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts. Polymers. 2023; 15(9):2038. https://doi.org/10.3390/polym15092038

Chicago/Turabian StyleWang, Wei, Minqiao Ren, Liping Hou, Shuzhang Qu, Xinwei Li, and Zifang Guo. 2023. "Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts" Polymers 15, no. 9: 2038. https://doi.org/10.3390/polym15092038