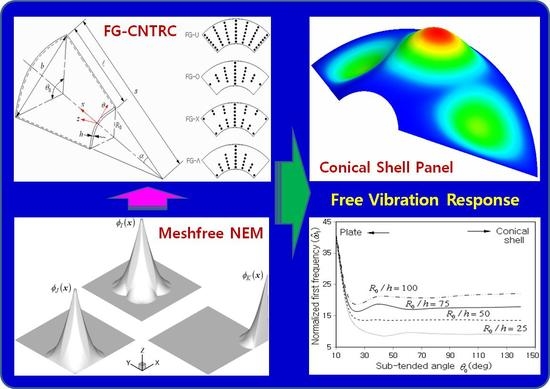

Free Vibration Responses of Functionally Graded CNT-Reinforced Composite Conical Shell Panels

Abstract

:1. Introduction

2. Modeling of FG-CNTRC Conical Shell Panel

3. Analysis of Free-Vibration Using 2-D NEM

4. Results and Discussion

4.1. Verification

4.2. Parametric Investigation

5. Conclusions

- The numerical method reliably and effectively solves the free vibration of FG-CNTRC conical shell panels without causing shear locking with the maximum relative difference of less than 5% to the reference solutions, even for coarse and 2-D planar NEM grids.

- The normalized first frequency increases proportional to the CNT volume fraction , but it uniformly decreases with increasing the values of semi-vertex angle and shell radius .

- To the sub-tended angle , the does not show remarkable change except for slight fluctuation until the decrease of to a certain value. However, a further decrease of causes the sudden increase of , except for CFCF. The increased intensity is dependent on the boundary condition, but it is not sensitive to .

- The uniformly increases with thickness and length owing to the calibration, but actually, its non-calibrated value uniformly decreases proportional to these two parameters.

- In the symmetric sandwich FG-CNTRC conical shell panels, for the PMMA core slightly increases and then drops remarkably proportional to , and vice versa for the CNTRC core.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ke, L.L.; Yang, J.; Kitipornchai, S. Nonlinear free vibration of functionally graded carbon nanotube-reinforced composite beams. Compos. Struct. 2010, 92, 676–683. [Google Scholar] [CrossRef]

- Cho, J.R.; Ahn, Y.J. Investigation of mechanical behaviors of functionally graded CNT-reinforced composite plates. Polymers. 2022, 14, 2664. [Google Scholar] [CrossRef]

- Shen, S.H. Nonlinear bending of functionally graded carbon nanotube-reinforced composite plates in thermal environments. Compos. Struct. 2009, 19, 9–19. [Google Scholar] [CrossRef]

- Cho, J.R.; Oden, J.T. Functionally graded material: A parametric study on thermal-stress characteristics using the Crank-Nicolson-Galerkin scheme. Comput. Methods Appl. Mech. Eng. 2000, 188, 17–38. [Google Scholar] [CrossRef]

- Kou, X.Y.; Parks, G.T.; Tan, S.T. Optimal design of functionally graded materials using a procedural model and paricle swarm optimization. Comput. Aided Des. 2012, 44, 300–310. [Google Scholar] [CrossRef]

- Liew, K.M.; Pan, Z.; Zhang, L.W. The recent progress of functionally graded CNT reinforced composites and structures. Sci. China Phys. Mech. Astronomy. 2020, 63, 234601. [Google Scholar] [CrossRef]

- Barbaros, I.; Yang, Y.; Safaei, B.; Yang, Z.; Qin, Z.; Asmael, M. State-of-the-art review of babrication, application, and mechanical properties of cunctionally graded porous nanocomposite materials. Nanotechnol. Rev. 2022, 11, 321–371. [Google Scholar] [CrossRef]

- Cho, J.R. Nonlinear bending analysis of FG-CNTRC plate resting on elastic foundation by natural element method. Eng. Anal. Boundary Elem. 2022, 141, 65–74. [Google Scholar] [CrossRef]

- Nguyen, D.; Nguyen, P.D. The dynamic response and vibration of functionally graded carbon nanotube-reinforced composite (FG-CNTRC) truncated conical shells resting on elastic foundations. Mater. 2017, 10, 1194. [Google Scholar] [CrossRef]

- Kiani, Y.; Dimitri, R.; Tornabene, F. Free vibration study of composite conical panels reinforced with FG-CNTs. Eng. Struct. 2018, 172, 472–482. [Google Scholar] [CrossRef]

- Sofiyev, A.H.; Esencan Turkaslan, B.; Bayramov, R.P.; Salamci, M.U. Analytical solution of stability of FG-CNTRC conical shells under external pressures. Thin-Walled Struct. 2019, 144, 106338. [Google Scholar] [CrossRef]

- Chan, D.Q.; Nguyen, P.D.; Quang, V.D.; Anh, V.T.T.; Duc, N.D. Nonlinear buckling and post-buckling of functionally graded CNTs reinforced composite truncated conical shells subjected to axial load. Steel Compos. Struct. 2019, 31, 243–259. [Google Scholar]

- Ansari, R.; Hasrati, E.; Torabi, J. Nonlinear vibration response of higher-order shear deformable FG-CNTRC conical shells. Compos. Struct. 2019, 222, 110906. [Google Scholar] [CrossRef]

- Qin, B.; Zhong, R.; Wang, T.; Wang, Q.; Xu, Y.; Hu, Z. A unified Fourier series solution for vibration analysis of FG-CNTRC cylindrical, conical shells and annular plates with arbitrary boundary conditions. Compos. Struct. 2020, 232, 111549. [Google Scholar] [CrossRef]

- Talebitooti, M.; Soreshjani, A.H.; Pakravan, I.; Telebitooti, R. Frequency study on panle type of FG-CNTRC joined conical-conical structures. Compos. Struct. 2021, 259, 113241. [Google Scholar] [CrossRef]

- Fu, T.; Wu, X.; Xiao, Z.; Chen, Z. Dynamic instability analysis of FG-CNTRC laminated conical shells surrounded by elastic foundations with FSDT. Euro. J. Mech. A/Solids. 2012, 85, 104139. [Google Scholar] [CrossRef]

- Xiang, P.; Xia, Q.; Jiang, L.Z.; Peng, L.; Yan, J.W.; Liu, X. Free vibration analysis of FG-CNTRC conical shell panels using the kernel particle Ritz element-free method. Compos. Struct. 2021, 255, 112987. [Google Scholar] [CrossRef]

- Hou, S.; Zheng, Y.; Zandi, Y.; Khadimallah, M.A.; Ebtekar, A. The free vibration analysis of carbon nanotubes-reinforced deep conical shells with an intermediate ring support under various boundary conditions. Eng. Struct. 2022, 263, 114291. [Google Scholar] [CrossRef]

- Rezaiee-Pajand, M.; Sobhani, E.; Masoodi, A.R. Vibration behavior of exponentially graded joined conical-conical shells. Steel Compos. Struct. 2022, 43, 603–623. [Google Scholar]

- Lee, Y.; Lee, P.-S.; Bathe, K.-J. The MITC3+shell finite element and its performance. Comput. Struct. 2014, 138, 12–23. [Google Scholar] [CrossRef]

- Lyly, M.; Stenberg, R.; Vihinen, T. A stable bilinear element for the Reissner-mindlin plate model. Comput. Meth. Appl. Mech. Engrg. 1993, 110, 343–357. [Google Scholar] [CrossRef]

- Rezaiee-Pajand, M.; Sobhani, E.; Masoodi, A.R. Nonlinear vibration analysis of carbon nanotube reinforced composite plane structures. Steel Compos. Struct. 2019, 30, 493–516. [Google Scholar]

- Tran, T.T.; Pham, Q.H.; Nguyen-Thoi, T. Static and free vibration analyses of functionally graded porous variable-thickness plates using an edge-based smoothed finite element method. Defence Technol. 2021, 17, 971–986. [Google Scholar] [CrossRef]

- Chau-Dinh, T. Analysis of shell structures by an improved 3-node triangular flat shell element with a bubble function and cell-based smoothing. Thin-Wall. Struct. 2023, 182, 110222. [Google Scholar] [CrossRef]

- Sukumar, N.; Moran, B.; Belytschko, T. The natural element method in solid mechanics. Int. J. Numer. Methods Engng. 1998, 43, 839–887. [Google Scholar] [CrossRef]

- Cho, J.R.; Lee, H.W. A Petrov-Galerkin natural element method securing the numerical integration accuracy. J. Mech. Sci. Technol. 2006, 20, 94–109. [Google Scholar] [CrossRef]

- Chinesta, F.; Cescotto, S.; Cueto, E.; Lorong, P. Natural Element Method for the Simulation of Structures and Processes; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Cho, J.R.; Oden, J.T. Locking and boundary layer in hierarchical models for thin elastic structures. Comput. Meth. Appl. Mech. Engrg. 1997, 149, 33–48. [Google Scholar] [CrossRef]

- Pitkaranta, J. The problem of membrane locking in finite element analysis of cylindrical shells. Numer. Math. 1992, 61, 523–542. [Google Scholar] [CrossRef]

- Baker, E.B.; Oden, J.T.; Carey, G.F. Finite Elements: An Introoduction, Vol. 1; Prentice-Hall: Hoboken, NJ, USA, 1981. [Google Scholar]

- Nguyen-Thoi, T.; Phung-Van, P.; Thai-Hoang, C.; Nguyen-Xuan, H. A cell-based smoothed discrete shear gap method (CS-DSG3) using triangular elements for static and free vibration analyses of shell structures. Int. J. Mech. Sci. 2013, 74, 32–45. [Google Scholar] [CrossRef]

- Li, Z.M.; Qiao, P. On an exact bending curvature model for nonlinear free vibration analysis shear deformable anisotropic laminated beams. Compos. Struct. 2014, 108, 243–258. [Google Scholar] [CrossRef]

- Bardell, N.S.; Dunsdon, J.M.; Langley, R.S. Free vibration of thin, isotropic, open, conical panels. J. Sound Vib. 1998, 217, 297–320. [Google Scholar] [CrossRef]

- Au, F.T.K.; Cheung, Y.K. Free vibration and stability analysis of shells by the isoparametric spline finite strip method. Thin-Wall. Struct. 1996, 24, 53–82. [Google Scholar] [CrossRef]

- Lim, C.W.; Liew, K.M. Vibratory behaviour of shallow conical shells by a global Ritz formulation. Eng. Struct. 1995, 17, 63–70. [Google Scholar] [CrossRef]

- Cho, J.R. Natural element approximation of hierarchical models of plate-like elastic structures. Finite Elem. Anal. Des. 2020, 180, 103439. [Google Scholar] [CrossRef]

- Han, Y.; Elliott, J. Molecular dynamics simulations of the elastic properties of polymer/carbon nanotube composites. Comput. Mater. Sci. 2007, 39, 315–323. [Google Scholar] [CrossRef]

- Shen, H.S.; Xiang, Y. Nonlinear analysis of nanotube-reinforced composite beams resting on elastic foundations in thermal environments. Eng. Struct. 2013, 56, 698–708. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Woinowsky-Krieger, S. Theory of Plates and Shells; McGraw-Hill: New York, NY, USA, 1959. [Google Scholar]

| Mode | Grid Density | |||||

|---|---|---|---|---|---|---|

| 1 | 219.21 | 215.60 | 213.55 | 212.27 | 211.41 | 210.80 |

| 2 | 270.25 | 263.52 | 260.02 | 258.14 | 257.12 | 256.55 |

| 3 | 321.33 | 316.65 | 314.07 | 312.49 | 311.44 | 310.70 |

| 4 | 358.66 | 353.54 | 350.94 | 349.74 | 349.24 | 349.06 |

| Mode | Bardell et al., 1998 [33] | Au and Cheung, 1996 [34] | Xiang et al., 2021 [17] | Present | Without Locking Suppression |

|---|---|---|---|---|---|

| 1 | 209.84 | 213.4 | 207.31 | 211.41 | 459.36 |

| 2 | 257.11 | 262.5 | 255.11 | 257.12 | 495.22 |

| 3 | 307.90 | 314.7 | 305.62 | 311.44 | 555.35 |

| 4 | 351.90 | 358.6 | 349.75 | 349.24 | 619.71 |

| Mode | Bardell et al., 1998 [33] | Xiang et al., 2021 [17] | Lim and Liew, 1995 [35] | Present | Without Locking Suppression |

|---|---|---|---|---|---|

| 1 | 235.35 | 233.39 | 239.10 | 236.03 | 337.67 |

| 2 | 247.45 | 245.43 | 251.32 | 248.84 | 361.29 |

| 3 | 258.64 | 256.59 | 262.61 | 260.52 | 397.98 |

| 4 | 269.32 | 267.23 | 273.37 | 269.30 | 457.46 |

| Materials | Young’s Moduli (GPa) | Poisson’s Ratios | Shear Moduli (GPa) | Density (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CNT | 5646.6 | 7080.0 | 7080.0 | 0.175 | - | - | 1944.5 | - | - | 1400 |

| PMMA | 2.5 | 0.34 | 0.9328 | 1150 | ||||||

| 0.12 | 0.137 | 1.022 | 0.715 |

| 0.17 | 0.142 | 1.626 | 1.138 |

| 0.28 | 0.141 | 1.585 | 1.109 |

| Method | B.C. | CNT Distribution Pattern | ||||

|---|---|---|---|---|---|---|

| FG-U | FG-O | FG-X | FG-Λ | |||

| Ritz [17] | SSSS | 25 | 7.1582 | 6.8063 | 7.5283 | 6.8247 |

| 50 | 10.9383 | 10.6914 | 11.2019 | 10.6209 | ||

| 100 | 16.6892 | 16.3410 | 16.9865 | 16.3520 | ||

| CCCC | 25 | 10.2580 | 9.3196 | 11.1090 | 9.6157 | |

| 50 | 14.0268 | 13.1407 | 14.8966 | 13.3853 | ||

| 100 | 19.9495 | 19.1304 | 20.8134 | 19.3277 | ||

| Present | SSSS | 25 | 7.4946 | 7.1102 | 7.4803 | 7.1495 |

| 50 | 10.8709 | 10.4183 | 11.0825 | 10.4999 | ||

| 100 | 17.2480 | 16.9044 | 17.5377 | 16.9233 | ||

| CCCC | 25 | 10.0308 | 9.1407 | 10.7619 | 9.4352 | |

| 50 | 13.6482 | 12.7137 | 14.1845 | 12.9821 | ||

| 100 | 19.9310 | 19.1746 | 20.7438 | 19.3556 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, J.-R. Free Vibration Responses of Functionally Graded CNT-Reinforced Composite Conical Shell Panels. Polymers 2023, 15, 1987. https://doi.org/10.3390/polym15091987

Cho J-R. Free Vibration Responses of Functionally Graded CNT-Reinforced Composite Conical Shell Panels. Polymers. 2023; 15(9):1987. https://doi.org/10.3390/polym15091987

Chicago/Turabian StyleCho, Jin-Rae. 2023. "Free Vibration Responses of Functionally Graded CNT-Reinforced Composite Conical Shell Panels" Polymers 15, no. 9: 1987. https://doi.org/10.3390/polym15091987