Experimental Analysis of Fiber Reinforcement Rings’ Effect on Tensile and Flexural Properties of Onyx™–Kevlar® Composites Manufactured by Continuous Fiber Reinforcement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

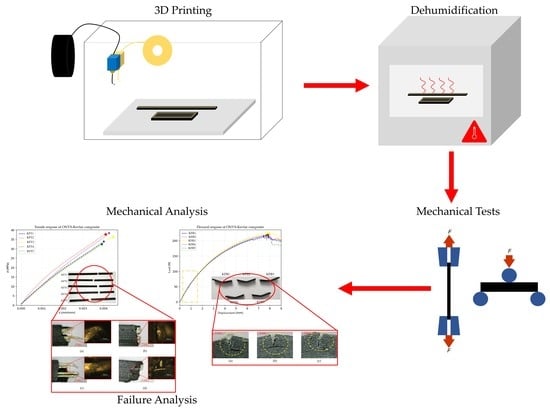

2.2. Methods

2.2.1. Printing of Onyx™–Kevlar® Samples

2.2.2. Mechanical Analysis

2.2.3. Dehumidification Process

2.2.4. Density Analysis

3. Results and Discussion

3.1. Tensile Properties

3.2. Flexural Properties

3.3. Printing Defects

3.4. Density Test

4. Conclusions

- The addition of of fiber volume as Kevlar® reinforcement rings to Onyx™ with 50% of rectangular infill resulted in an increment of almost 400% of pure Onyx™ elastic modulus. A value of was obtained with lower fiber volume compared with other studies that go from to using to of fiber volume.

- The addition of of fiber volume as Kevlar® reinforcement rings to Onyx™ with 50% of rectangular infill resulted in an increment of almost 140% of pure Onyx™ flexural modulus. A flexural modulus of was obtained, and similar results were obtained using 19% of fiber volume and triangular infill.

- A specific elastic modulus of was obtained and a specific flexural modulus of was obtained for Onyx™–Kevlar® CFRC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Askeland, D.; Fulay, P.P.; Wright, W. The Science and Engineering of Materials, 6th ed.; Altieri, T., Ed.; Cengage Learning: Stamford, CT, USA, 2010; ISBN 978-0-495-29602-7. [Google Scholar]

- Gay, D.; Hoa, S.V. Composite Materials Design and Applications, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2007; ISBN 1420045199. [Google Scholar]

- Li, Y.; Zhang, F.; Liu, Y.; Leng, J. 4D Printed Shape Memory Polymers and Their Structures for Biomedical Applications. Sci. China Technol. Sci. 2020, 63, 545–560. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; Yu, Y.; Wang, X.; Wang, Q.; Shang, L. Cellular Fluidic-Based Vascular Networks for Tissue Engineering. Eng. Regen. 2021, 2, 171–174. [Google Scholar] [CrossRef]

- Zhao, M.; Geng, Y.; Fan, S.; Yao, X.; Zhu, M.; Zhang, Y. 3D-Printed Strong Hybrid Materials with Low Shrinkage for Dental Restoration. Compos. Sci. Technol. 2021, 213, 108902. [Google Scholar] [CrossRef]

- Pratama, L.K.; Santosa, S.P.; Dirgantara, T.; Widagdo, D. Design and Numerical Analysis of Electric Vehicle Li-Ion Battery Protections Using Lattice Structure Undergoing Ground Impact. World Electr. Veh. J. 2021, 13, 10. [Google Scholar] [CrossRef]

- Li, C.; Kim, I.Y.; Jeswiet, J. Conceptual and Detailed Design of an Automotive Engine Cradle by Using Topology, Shape, and Size Optimization. Struct. Multidiscip. Optim. 2015, 51, 547–564. [Google Scholar] [CrossRef]

- Muvunzi, R.; Mpofu, K.; Daniyan, I. An Evaluation Model for Selecting Part Candidates for Additive Manufacturing in the Transport Sector. Metals 2021, 11, 765. [Google Scholar] [CrossRef]

- Burkhart, M.; Aurich, J.C. Framework to Predict the Environmental Impact of Additive Manufacturing in the Life Cycle of a Commercial Vehicle. Procedia CIRP 2015, 29, 408–413. [Google Scholar] [CrossRef]

- Bari, K.; Bollenbach, L. Spiderweb Cellular Structures Manufactured via Additive Layer Manufacturing for Aerospace Application. J. Compos. Sci. 2022, 6, 133. [Google Scholar] [CrossRef]

- Adumitroaie, A.; Antonov, F.; Khaziev, A.; Azarov, A.; Golubev, M.; Vasiliev, V.V. Novel Continuous Fiber Bi-Matrix Composite 3-D Printing Technology. Materials 2019, 12, 3011. [Google Scholar] [CrossRef] [Green Version]

- Adin, M.Ş.; Kılıçkap, E. Strength of Double-Reinforced Adhesive Joints. Mater. Test. 2021, 63, 176–181. [Google Scholar] [CrossRef]

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. 3D and 4D Printing: From Innovation to Evolution. Adv. Colloid Interface Sci. 2021, 294, 102482. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for Additive Manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Blanco, I. The Use of Composite Materials in 3d Printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- ADİN, H.; SAĞLAM, Z.; ADİN, M.Ş. Numerical Investigation of Fatigue Behavior of Non-Patched and Patched Aluminum/Composite Plates. Eur. Mech. Sci. 2021, 5, 168–176. [Google Scholar] [CrossRef]

- Yeong, W.Y.; Goh, G.D. 3D Printing of Carbon Fiber Composite: The Future of Composite Industry? Matter 2020, 2, 1361–1363. [Google Scholar] [CrossRef]

- Cersoli, T.; Yelamanchi, B.; MacDonald, E.; Carrillo, J.G.; Cortes, P. 3D Printing of a Continuous Fiber-Reinforced Composite Based on a Coaxial Kevlar/PLA Filament. Compos. Adv. Mater. 2021, 30, 263498332110000. [Google Scholar] [CrossRef]

- Dong, K.; Ke, H.; Panahi-Sarmad, M.; Yang, T.; Huang, X.; Xiao, X. Mechanical Properties and Shape Memory Effect of 4D Printed Cellular Structure Composite with a Novel Continuous Fiber-Reinforced Printing Path. Mater. Des. 2021, 198, 109303. [Google Scholar] [CrossRef]

- Pagliarulo, V.; Russo, P.; Leone, G.; D’Angelo, G.A.; Ferraro, P. A Multimodal Optical Approach for Investigating 3D-Printed Carbon PEEK Composites. Opt. Lasers Eng. 2022, 151, 106888. [Google Scholar] [CrossRef]

- Díaz, J.G.; León-Becerra, J.; Pertuz, A.D.; González-Estrada, O.A.; Jaramillo-Gutiérrez, M.I. Evaluation Through SEM Image Processing of the Volumetric Fiber Content in Continuos Fiber-Reinforced Additive Manufacturing Composites. Mater. Res. 2021, 24. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material Extrusion Additive Manufacturing of Continuous Fibre Reinforced Polymer Matrix Composites: A Review and Outlook. Compos. B Eng. 2021, 224, 109143. [Google Scholar] [CrossRef]

- Hunt, C.J.; Morabito, F.; Grace, C.; Zhao, Y.; Woods, B.K.S. A Review of Composite Lattice Structures. Compos. Struct. 2022, 284, 115120. [Google Scholar] [CrossRef]

- Chabaud, G.; Castro, M.; Denoual, C.; le Duigou, A. Hygromechanical Properties of 3D Printed Continuous Carbon and Glass Fibre Reinforced Polyamide Composite for Outdoor Structural Applications. Addit. Manuf. 2019, 26, 94–105. [Google Scholar] [CrossRef]

- Papa, I.; Silvestri, A.T.; Ricciardi, M.R.; Lopresto, V.; Squillace, A. Effect of Fibre Orientation on Novel Continuous 3D-Printed Fibre-Reinforced Composites. Polymers 2021, 13, 2524. [Google Scholar] [CrossRef] [PubMed]

- Cheng, M.; Chen, W.; Weerasooriya, T. Mechanical Properties of Kevlar® KM2 Single Fiber. J. Eng. Mater. Technol. Trans. ASME 2005, 127, 197–203. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; ISBN 9781493921133. [Google Scholar]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Vaško, M.; Sága, M.; Majko, J.; Vaško, A.; Handrik, M. Impact Toughness of FRTP Composites Produced by 3D Printing. Materials 2020, 13, 5654. [Google Scholar] [CrossRef]

- Nayak, S.M.; Balachandra Shetty, P.; Mishra, R.K.; Reddy, S.; Viraj, G.R. Failure Analysis of Additive Manufactured Fiber-Reinforced Thermoplastics. J. Fail. Anal. Prev. 2019, 19, 471–475. [Google Scholar] [CrossRef]

- Díaz-Rodríguez, J.G.; Pertúz-Comas, A.D.; González-Estrada, O.A. Mechanical Properties for Long Fibre Reinforced Fused Deposition Manufactured Composites. Compos. B Eng. 2021, 211, 108657. [Google Scholar] [CrossRef]

- Yogeshvaran, R.N.; Liu, B.G.; Farukh, F.; Kandan, K. Out-of-Plane Compressive Response of Additively Manufactured Cross-Ply Composites. J. Mech. 2020, 36, 197–211. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, X.; Zhao, W.; Wang, G.; Liu, B. An Overview of Research on FDM 3D Printing Process of Continuous Fiber Reinforced Composites. J. Phys. Conf. Ser. 2019, 1213, 052037. [Google Scholar] [CrossRef]

- Struzziero, G.; Barbezat, M.; Skordos, A.A. Consolidation of Continuous Fibre Reinforced Composites in Additive Processes: A Review. Addit. Manuf. 2021, 48, 102458. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Wang, H.; Fu, K.; Ye, L. 3D Printed Continuous CF/PA6 Composites: Effect of Microscopic Voids on Mechanical Performance. Compos. Sci. Technol. 2020, 191, 108077. [Google Scholar] [CrossRef]

- Korkees, F.; Allenby, J.; Dorrington, P. 3D Printing of Composites: Design Parameters and Flexural Performance. Rapid Prototyp. J. 2020, 26, 699–706. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Fidan, I. Tensile Performance of 3D-Printed Continuous Fiber-Reinforced Nylon Composites. J. Manuf. Mater. Process. 2021, 5, 68. [Google Scholar] [CrossRef]

- Huang, Y.; Tian, X.; Zheng, Z.; Li, D.; Malakhov, A.V.; Polilov, A.N. Multiscale Concurrent Design and 3D Printing of Continuous Fiber Reinforced Thermoplastic Composites with Optimized Fiber Trajectory and Topological Structure. Compos. Struct. 2022, 285, 115241. [Google Scholar] [CrossRef]

- Giarmas, E.; Tsongas, K.; Tzimtzimis, E.K.; Korlos, A.; Tzetzis, D. Mechanical and FEA-Assisted Characterization of 3D Printed Continuous Glass Fiber Reinforced Nylon Cellular Structures. J. Compos. Sci. 2021, 5, 313. [Google Scholar] [CrossRef]

- Qian, X.; Wang, H.; Zhang, D.; Wen, G. High Strain Rate Out-of-Plane Compression Properties of Aramid Fabric Reinforced Polyamide Composite. Polym. Test. 2016, 53, 314–322. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Venezia, C.; Badini, C. Experimental Characterization and Modeling of 3D Printed Continuous Carbon Fibers Composites with Different Fiber Orientation Produced by FFF Process. Polymers 2022, 14, 426. [Google Scholar] [CrossRef]

- Heitkamp, T.; Girnth, S.; Kuschmitz, S.; Klawitter, G.; Waldt, N.; Vietor, T. Continuous Fiber-Reinforced Material Extrusion with Hybrid Composites of Carbon and Aramid Fibers. Appl. Sci. 2022, 12, 8830. [Google Scholar] [CrossRef]

- Saidane, E.H.; Arnold, G.; Louis, P.; Pac, M.-J. 3D Printed Continuous Glass Fibre-Reinforced Polyamide Composites: Fabrication and Mechanical Characterisation. J. Reinf. Plast. Compos. 2022, 41, 284–295. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of Continuous Carbon, Glass and Kevlar Fibre Reinforced Polymer Composites Using Additive Manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- Yelamanchi, B.; MacDonald, E.; Gonzalez-Canche, N.; Carrillo, J.; Cortes, P. The Fracture Properties of Fiber Metal Laminates Based on a 3D Printed Glass Fiber Composite. J. Thermoplast. Compos. Mater. 2020, 36, 815–835. [Google Scholar] [CrossRef]

- Wang, K.; Chen, Y.; Long, H.; Baghani, M.; Rao, Y.; Peng, Y. Hygrothermal Aging Effects on the Mechanical Properties of 3D Printed Composites with Different Stacking Sequence of Continuous Glass Fiber Layers. Polym. Test. 2021, 100, 107242. [Google Scholar] [CrossRef]

- Yavas, D.; Zhang, Z.; Liu, Q.; Wu, D. Fracture Behavior of 3D Printed Carbon Fiber-Reinforced Polymer Composites. Compos. Sci. Technol. 2021, 208, 108741. [Google Scholar] [CrossRef]

- Parmiggiani, A.; Prato, M.; Pizzorni, M. Effect of the Fiber Orientation on the Tensile and Flexural Behavior of Continuous Carbon Fiber Composites Made via Fused Filament Fabrication. Int. J. Adv. Manuf. Technol. 2021, 114, 2085–2101. [Google Scholar] [CrossRef]

- Bárnik, F.; Vaško, M.; Handrik, M.; Dorčiak, F.; Majko, J. Comparing Mechanical Properties of Composites Structures on Onyx Base with Different Density and Shape of Fill. Transp. Res. Procedia 2019, 40, 616–622. [Google Scholar] [CrossRef]

- Saeed, K.; McIlhagger, A.; Harkin-Jones, E.; McGarrigle, C.; Dixon, D.; Ali Shar, M.; McMillan, A.; Archer, E. Characterization of Continuous Carbon Fibre Reinforced 3D Printed Polymer Composites with Varying Fibre Volume Fractions. Compos. Struct. 2022, 282, 115033. [Google Scholar] [CrossRef]

- Ekoi, E.J.; Dickson, A.N.; Dowling, D.P. Investigating the Fatigue and Mechanical Behaviour of 3D Printed Woven and Nonwoven Continuous Carbon Fibre Reinforced Polymer (CFRP) Composites. Compos. B Eng. 2021, 212, 108704. [Google Scholar] [CrossRef]

- Um, H.-J.; Lee, J.-S.; Shin, J.-H.; Kim, H.-S. 3D Printed Continuous Carbon Fiber Reinforced Thermoplastic Composite Sandwich Structure with Corrugated Core for High Stiffness/Load Capability. Compos. Struct. 2022, 291, 115590. [Google Scholar] [CrossRef]

- Avanzini, A.; Battini, D.; Giorleo, L. Finite Element Modelling of 3D Printed Continuous Carbon Fiber Composites: Embedded Elements Technique and Experimental Validation. Compos. Struct. 2022, 292, 115631. [Google Scholar] [CrossRef]

- Morales, U.; Esnaola, A.; Iragi, M.; Aretxabaleta, L.; Aurrekoetxea, J. The Effect of Cross-Section Geometry on Crushing Behaviour of 3D Printed Continuous Carbon Fibre Reinforced Polyamide Profiles. Compos. Struct. 2021, 274, 114337. [Google Scholar] [CrossRef]

- Li, W.; Guo, S.; Giannopoulos, I.K.; Lin, M.; Xiong, Y.; Liu, Y.; Shen, Z. 3D-Printed Thermoplastic Composite Fasteners for Single Lap Joint Reinforcement. Compos. Struct. 2022, 282, 115085. [Google Scholar] [CrossRef]

- Prajapati, A.R.; Dave, H.K.; Raval, H.K. Influence of fiber rings on impact strength of 3D printed fiber reinforced polymer composite. Int. J. Mod. Manuf. Technol. 2020, XII, 2067–3604. [Google Scholar]

- Wang, K.; Li, S.; Wu, Y.; Rao, Y.; Peng, Y. Simultaneous Reinforcement of Both Rigidity and Energy Absorption of Polyamide-Based Composites with Hybrid Continuous Fibers by 3D Printing. Compos. Struct. 2021, 267, 113854. [Google Scholar] [CrossRef]

- Cofaru, N.F.; Pascu, A.; Oleksik, M.; Petruse, R. Tensile Properties of 3D-Printed Continuous-Fiber-Reinforced Plastics. Mater. Plast. 2022, 58, 271–282. [Google Scholar] [CrossRef]

- Ansari, A.A.; Kamil, M. Performance Study of 3D Printed Continuous Fiber-Reinforced Polymer Composites Using Taguchi Method. J. Mater. Eng. Perform. 2022. [Google Scholar] [CrossRef]

- Pertuz-Comas, A.D.; Díaz, J.G.; Meneses-Duran, O.J.; Niño-Álvarez, N.Y.; León-Becerra, J. Flexural Fatigue in a Polymer Matrix Composite Material Reinforced with Continuous Kevlar Fibers Fabricated by Additive Manufacturing. Polymers 2022, 14, 3586. [Google Scholar] [CrossRef]

- Ojha, K.K.; Gugliani, G.; Francis, V. Tensile Properties and Failure Behaviour of Continuous Kevlar Fibre Reinforced Composites Fabricated by Additive Manufacturing Process. Adv. Mater. Process. Technol. 2022, 1–15. [Google Scholar] [CrossRef]

- Markforged Material Datasheet Composites 2022, 2. Available online: https://www-objects.markforged.com/craft/materials/CompositesV5.2.pdf (accessed on 13 October 2022).

- Zeng, C.; Liu, L.; Bian, W.; Liu, Y.; Leng, J. 4D Printed Electro-Induced Continuous Carbon Fiber Reinforced Shape Memory Polymer Composites with Excellent Bending Resistance. Compos. B Eng. 2020, 194, 108034. [Google Scholar] [CrossRef]

- Pascual-González, C.; Iragi, M.; Fernández, A.; Fernández-Blázquez, J.P.; Aretxabaleta, L.; Lopes, C.S. An Approach to Analyse the Factors behind the Micromechanical Response of 3D-Printed Composites. Compos. B Eng. 2020, 186, 107820. [Google Scholar] [CrossRef]

- Pai, C.-C.; Jeng, R.-J.; Grossman, S.J.; Huang, J.-C. Effects of Moisture on Thermal and Mechanical Properties of Nylon-6,6. Adv. Polym. Technol. 1989, 9, 157–163. [Google Scholar] [CrossRef]

- Hetrick, D.R.; Sanei, S.H.R.; Ashour, O. Void Content Reduction in 3D Printed Glass Fiber-Reinforced Polymer Composites through Temperature and Pressure Consolidation. J. Compos. Sci. 2022, 6, 128. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive Manufacturing of Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- Saeed, K.; McIlhagger, A.; Harkin-Jones, E.; McGarrigle, C.; Dixon, D.; Archer, E. Elastic Modulus and Flatwise (Through-Thickness) Tensile Strength of Continuous Carbon Fibre Reinforced 3D Printed Polymer Composites. Materials 2022, 15, 1002. [Google Scholar] [CrossRef]

- Rijckaert, S.; Daelemans, L.; Cardon, L.; Boone, M.; van Paepegem, W.; de Clerck, K. Continuous Fiber-Reinforced Aramid/PETG 3D-Printed Composites with High Fiber Loading through Fused Filament Fabrication. Polymers 2022, 14, 298. [Google Scholar] [CrossRef]

- Santos, J.D.; Fernández, A.; Ripoll, L.; Blanco, N. Experimental Characterization and Analysis of the In-Plane Elastic Properties and Interlaminar Fracture Toughness of a 3D-Printed Continuous Carbon Fiber-Reinforced Composite. Polymers 2022, 14, 506. [Google Scholar] [CrossRef]

- Thor, M.; Sause, M.G.R.; Hinterhölzl, R.M. Mechanisms of Origin and Classification of Out-of-Plane Fiber Waviness in Composite Materials—A Review. J. Compos. Sci. 2020, 4, 130. [Google Scholar] [CrossRef]

- Tang, H.; Sun, Q.; Li, Z.; Su, X.; Yan, W. Longitudinal Compression Failure of 3D Printed Continuous Carbon Fiber Reinforced Composites: An Experimental and Computational Study. Compos. Part A 2021, 146, 106416. [Google Scholar] [CrossRef]

| Property | Onyx™ | Kevlar® |

|---|---|---|

| Tensile Modulus [GPa] | 2.4 | 21 |

| Tensile Strain at Break [%] | 25 | 2.7 |

| Flexural Strength [MPa] | 71 | 240 |

| Flexural Modulus [GPa] | 3 | 26 |

| Density [g/cm3] | 1.2 | 1.2 |

| Testing Method | ASTM Standard | Fiber Orientation | Infill Geometry | Fiber Volume (vol%) | Fiber Reinforcement Rings |

|---|---|---|---|---|---|

| Tension | D3039 | Concentric | Rectangular | 18.77% | 2 |

| Bending | D790 | Concentric | Rectangular | 17.25% | 4 |

| Sample | Max Stress (MPa) | ||

|---|---|---|---|

| KFT1 | 33.93 | 0.004 | 9.17 |

| KFT2 | 37.75 | 0.0041 | 10.47 |

| KFT3 | 36.43 | 0.0045 | 9.22 |

| KFT4 | 38.25 | 0.0043 | 9.84 |

| KFT5 | 32.42 | 0.0039 | 9.14 |

| Mean | 35.756 | 0.00416 | 9.57 |

| Research | CFRC | |

|---|---|---|

| This research | Onyx™–Kevlar® | |

| Heitkamp et al. [44] | Nylon–Kevlar® | |

| Mohammadizadeh et al. [39] | Nylon–Kevlar® | |

| Cofaru et al. [60] | Onyx™–Kevlar® | |

| Ojha et al. [63] | Onyx™–Kevlar® | |

| Ansari [61] | Onyx™–Kevlar® |

| Sample | ||||

|---|---|---|---|---|

| KFB1 | 212.64 | 7.88 | 52.51 | 4.12 |

| KFB2 | 219.93 | 7.84 | 52.31 | 4.10 |

| KFB3 | 224.62 | 7.90 | 52.72 | 4.13 |

| KFB4 | 213.85 | 7.46 | 50.99 | 3.99 |

| KFB5 | 217.30 | 7.70 | 53.71 | 4.19 |

| Mean | 217.67 | 7.75 | 52.45 | 4.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno-Núñez, B.A.; Abarca-Vidal, C.G.; Treviño-Quintanilla, C.D.; Sánchez-Santana, U.; Cuan-Urquizo, E.; Uribe-Lam, E. Experimental Analysis of Fiber Reinforcement Rings’ Effect on Tensile and Flexural Properties of Onyx™–Kevlar® Composites Manufactured by Continuous Fiber Reinforcement. Polymers 2023, 15, 1252. https://doi.org/10.3390/polym15051252

Moreno-Núñez BA, Abarca-Vidal CG, Treviño-Quintanilla CD, Sánchez-Santana U, Cuan-Urquizo E, Uribe-Lam E. Experimental Analysis of Fiber Reinforcement Rings’ Effect on Tensile and Flexural Properties of Onyx™–Kevlar® Composites Manufactured by Continuous Fiber Reinforcement. Polymers. 2023; 15(5):1252. https://doi.org/10.3390/polym15051252

Chicago/Turabian StyleMoreno-Núñez, Benjamín Alberto, César Gustavo Abarca-Vidal, Cecilia D. Treviño-Quintanilla, Ulises Sánchez-Santana, Enrique Cuan-Urquizo, and Esmeralda Uribe-Lam. 2023. "Experimental Analysis of Fiber Reinforcement Rings’ Effect on Tensile and Flexural Properties of Onyx™–Kevlar® Composites Manufactured by Continuous Fiber Reinforcement" Polymers 15, no. 5: 1252. https://doi.org/10.3390/polym15051252