Synthesis and Study of Fully Biodegradable Composites Based on Poly(butylene succinate) and Biochar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

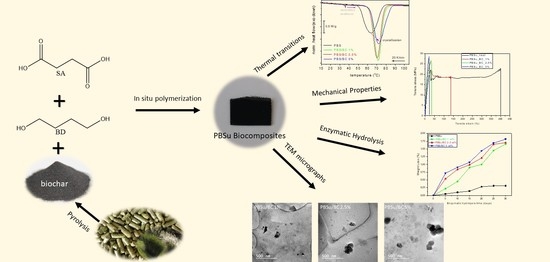

2.2. Synthesis of PBSu Biocomposites

2.3. Intrinsic Viscosity Measurement

2.4. Gel Permeation Chromatography–Size Exclusion Chromatography (GPC/SEC)

2.5. Nuclear Magnetic Resonance (NMR)

2.6. X-ray Diffraction Patterns (XRD)

2.7. Differential Scanning Calorimetry (DSC)

2.8. Polarized Light Microscope (PLM)

2.9. Light Flash Analysis (LFA)

2.10. Broadband Dielectric Spectroscopy (BDS)

2.11. Mechanical Properties

2.12. Scanning Electron Microscopy

2.13. Transmission Electron Microscopy (TEM)

2.14. Color Measurement

2.15. Enzymatic Hydrolysis

3. Results

3.1. BC Synthesis and Characterization

3.2. Synthesis and Characterization of In Situ Prepared PBSu/BC Biocomposites

3.3. Thermal Transitions

3.4. PLM Results

3.5. Thermal Diffusivity/Conductivity

3.6. Molecular Dynamics

3.7. Mechanical Properties

3.8. BC Dispersion Studied by Transmission Electron Microscopy (TEM)

3.9. Effect of Used BC Filler on PBSu Coloration

3.10. Enzymatic Hydrolysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiang, Y.; Jiang, L.; Zhou, Y.; Luo, Z.; Zhi, D.; Yang, J.; Lam, S.S. Microplastics and Environmental Pollutants: Key Interaction and Toxicology in Aquatic and Soil Environments. J. Hazard. Mater. 2022, 422, 126843. [Google Scholar] [CrossRef] [PubMed]

- Dimitriadi, A.; Papaefthimiou, C.; Genizegkini, E.; Sampsonidis, I.; Kalogiannis, S.; Feidantsis, K.; Bobori, D.C.; Kastrinaki, G.; Koumoundouros, G.; Lambropoulou, D.A.; et al. Adverse Effects Polystyrene Microplastics Exert on Zebrafish Heart—Molecular to Individual Level. J. Hazard. Mater. 2021, 416, 125969. [Google Scholar] [CrossRef] [PubMed]

- Kaloyianni, M.; Bobori, D.C.; Xanthopoulou, D.; Malioufa, G.; Sampsonidis, I.; Kalogiannis, S.; Feidantsis, K.; Kastrinaki, G.; Dimitriadi, A.; Koumoundouros, G.; et al. Toxicity and Functional Tissue Responses of Two Freshwater Fish after Exposure to Polystyrene Microplastics. Toxics 2021, 9, 289. [Google Scholar] [CrossRef] [PubMed]

- Bobori, D.C.; Dimitriadi, A.; Feidantsis, K.; Samiotaki, A.; Fafouti, D.; Sampsonidis, I.; Kalogiannis, S.; Kastrinaki, G.; Lambropoulou, D.A.; Kyzas, G.Z.; et al. Differentiation in the Expression of Toxic Effects of Polyethylene-Microplastics on Two Freshwater Fish Species: Size Matters. Sci. Total Environ. 2022, 830, 154603. [Google Scholar] [CrossRef] [PubMed]

- Ho, M.P.; Lau, K.T.; Wang, H.; Hui, D. Improvement on the Properties of Polylactic Acid (PLA) Using Bamboo Charcoal Particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent Advances in Nanocellulose-Based Different Biomaterials: Types, Properties, and Emerging Applications. J. Mater. Res. Technol. 2021, 14, 2601–2623. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, J.; Chen, G.Q. Polyhydroxyalkanoates, Challenges and Opportunities. Curr. Opin. Biotechnol. 2014, 30, 59–65. [Google Scholar] [CrossRef]

- Aup-Ngoen, K.; Noipitak, M. Effect of Carbon-Rich Biochar on Mechanical Properties of PLA-Biochar Composites. Sustain. Chem. Pharm. 2020, 15, 100204. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Noroozi, R.; Sadeghianmaryan, A.; Jalalvand, M.; Hossain, M. Recent Advances in 3D-Printed Polylactide and Polycaprolactone-Based Biomaterials for Tissue Engineering Applications. Int. J. Biol. Macromol. 2022, 218, 930–968. [Google Scholar] [CrossRef]

- Mochane, M.J.; Magagula, S.I.; Sefadi, J.S.; Mokhena, T.C. A Review on Green Composites Based on Natural Fiber-Reinforced Polybutylene Succinate (PBS). Polymers 2021, 13, 1200. [Google Scholar] [CrossRef]

- Peñas, M.I.; Pérez-Camargo, R.A.; Hernández, R.; Müller, A.J. A Review on Current Strategies for the Modulation of Thermomechanical, Barrier, and Biodegradation Properties of Poly (Butylene Succinate) (PBS) and Its Random Copolymers. Polymers 2022, 14, 1025. [Google Scholar] [CrossRef] [PubMed]

- Klonos, P.A.; Papadopoulos, L.; Kasimatis, M.; Iatrou, H.; Kyritsis, A.; Bikiaris, D.N. Synthesis, Crystallization, Structure Memory Effects, and Molecular Dynamics of Biobased and Renewable Poly(n-Alkylene Succinate)s with n from 2 to 10. Macromolecules 2021, 54, 1106–1119. [Google Scholar] [CrossRef]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.N.; Lee, C.H. A Review on Properties and Application of Bio-based Poly(Butylene Succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef]

- Ezzeddine, I.; Ghorbel, N.; Ilsouk, M.; Arous, M.; Lahcini, M.; Bouharras, F.Z.; Raihane, M.; Kallel, A. Dielectric and Thermal Characteristics of Beidellite Nanoclay-Reinforced Poly(Butylene Succinate). Mater. Chem. Phys. 2021, 258, 123855. [Google Scholar] [CrossRef]

- Lule, Z.C.; Kim, J. Organic-Inorganic Hybrid Filler for Improved Thermal Conductivity and Anti-Dripping Performance of Polybutylene Succinate Composite. J. Clean. Prod. 2022, 340, 130781. [Google Scholar] [CrossRef]

- Das, C.; Tamrakar, S.; Kiziltas, A.; Xie, X. Incorporation of Biochar to Improve Mechanical, Thermal and Electrical Properties of Polymer Composites. Polymers 2021, 13, 2663. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, S. Preparation, Modification and Environmental Application of Biochar: A Review. J. Clean. Prod. 2019, 227, 1002–1022. [Google Scholar] [CrossRef]

- Qambrani, N.A.; Rahman, M.M.; Won, S.; Shim, S.; Ra, C. Biochar Properties and Eco-Friendly Applications for Climate Change Mitigation, Waste Management, and Wastewater Treatment: A Review. Renew. Sustain. Energy Rev. 2017, 79, 255–273. [Google Scholar] [CrossRef]

- Zouari, M.; Devallance, D.B.; Marrot, L. Effect of Biochar Addition on Mechanical Properties, Thermal Stability, and Water Resistance of Hemp-Polylactic Acid (PLA) Composites. Materials 2022, 15, 2271. [Google Scholar] [CrossRef]

- Bartoli, M.; Arrigo, R.; Malucelli, G.; Tagliaferro, A.; Duraccio, D. Recent Advances in Biochar Polymer Composites. Polymers 2022, 14, 2506. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Nanoindentation Assisted Analysis of Biochar Added Biocomposites. Compos. Part B Eng. 2016, 91, 219–227. [Google Scholar] [CrossRef]

- Haeldermans, T.; Samyn, P.; Cardinaels, R.; Vandamme, D.; Vanreppelen, K.; Cuypers, A.; Schreurs, S. Poly(Lactic Acid) Bio-Composites Containing Biochar Particles: Effects of Fillers and Plasticizer on Crystallization and Thermal Properties. Express Polym. Lett. 2021, 15, 343–360. [Google Scholar] [CrossRef]

- Cooper, C.J.; Abdelwahab, M.A.; Mohanty, A.K.; Misra, M. Hybrid Green Bionanocomposites of Bio-Based Poly(Butylene Succinate) Reinforced with Pyrolyzed Perennial Grass Microparticles and Graphene Nanoplatelets. ACS Omega 2019, 4, 20476–20485. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moore, A.L.; Shi, L. Emerging Challenges and Materials for Thermal Management of Electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Han, Z.; Fina, A. Thermal Conductivity of Carbon Nanotubes and Their Polymer Nanocomposites: A Review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef] [Green Version]

- She, D.; Dong, J.; Zhang, J.; Liu, L.; Sun, Q.; Geng, Z.; Peng, P. Development of Black and Biodegradable Biochar/Gutta Percha Composite Films with High Stretchability and Barrier Properties. Compos. Sci. Technol. 2019, 175, 1–5. [Google Scholar] [CrossRef]

- Mohanty, A.; Vivekanandhan, S.; Anstey, A.; Misra, M. Sustainable Composites from Renewable Biochar and Engineering Plastic. In Proceedings of the ICCM International Conferences on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Funck, A.; Kaminsky, W. Polypropylene Carbon Nanotube Composites by in Situ Polymerization. Compos. Sci. Technol. 2007, 67, 906–915. [Google Scholar] [CrossRef]

- Parker, W.J.; Jenkins, R.J.; Butler, C.P.; Abbott, G.L. Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity. J. Appl. Phys. 1961, 32, 1679–1684. [Google Scholar] [CrossRef]

- Cowan, R.D. Pulse Method of Measuring Thermal Diffusivity at High Temperatures. J. Appl. Phys. 1963, 34, 926–927. [Google Scholar] [CrossRef]

- Herrmann, G. Dynamics of Composite Materials, 1st ed.; Schönhals, A., Szymoniak, P., Eds.; Springer: Cham, Switzerland, 2022; Volume 5, ISBN 9783030897222. [Google Scholar]

- Savvidis, G.; Karanikas, V.; Zarkogianni, M.; Eleftheriadis, I.; Nikolaidis, N.; Tsatsaroni, E. Screen-Printing of Cotton with Natural Pigments: Evaluation of Color and Fastness Properties of the Prints. J. Nat. Fibers 2017, 14, 326–334. [Google Scholar] [CrossRef]

- Han, J.; Shi, J.; Xie, Z.; Xu, J.; Guo, B. Synthesis, Properties of Biodegradable Poly(Butylene Succinate-Co-Butylene 2-Methylsuccinate) and Application for Sustainable Release. Materials 2019, 12, 1507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahn, B.D.; Kim, S.H.; Kim, Y.H.; Yang, J.S. Synthesis and Characterization of the Biodegradable Copolymers from Succinic Acid and Adipic Acid with 1,4-Butanediol. J. Appl. Polym. Sci. 2001, 82, 2808–2826. [Google Scholar] [CrossRef]

- Platnieks, O.; Gaidukovs, S.; Neibolts, N.; Barkane, A.; Gaidukova, G.; Thakur, V.K. Poly(Butylene Succinate) and Graphene Nanoplatelet–Based Sustainable Functional Nanocomposite Materials: Structure-Properties Relationship. Mater. Today Chem. 2020, 18, 100351. [Google Scholar] [CrossRef]

- Grigoriadou, I.; Nianias, N.; Hoppe, A.; Terzopoulou, Z.; Bikiaris, D.; Will, J.; Hum, J.; Roether, J.A.; Detsch, R.; Boccaccini, A.R. Evaluation of Silica-Nanotubes and Strontium Hydroxyapatite Nanorods as Appropriate Nanoadditives for Poly(Butylene Succinate) Biodegradable Polyester for Biomedical Applications. Compos. Part B Eng. 2014, 60, 49–59. [Google Scholar] [CrossRef]

- Arandia, I.; Mugica, A.; Zubitur, M.; Arbe, A.; Liu, G.; Wang, D.; Mincheva, R.; Dubois, P.; Müller, A.J. How Composition Determines the Properties of Isodimorphic Poly(Butylene Succinate- Ran -Butylene Azelate) Random Biobased Copolymers: From Single to Double Crystalline Random Copolymers. Macromolecules 2015, 48, 43–57. [Google Scholar] [CrossRef] [Green Version]

- Papageorgiou, D.G.; Zhuravlev, E.; Papageorgiou, G.Z.; Bikiaris, D.; Chrissafis, K.; Schick, C. Kinetics of Nucleation and Crystallization in Poly(Butylene Succinate) Nanocomposites. Polymer 2014, 55, 6725–6734. [Google Scholar] [CrossRef]

- Hegde, M.; Samulski, E.T.; Rubinstein, M.; Dingemans, T.J. The Role of Crystallinity in SWCNT-Polyetherimide Nanocomposites. Compos. Sci. Technol. 2015, 110, 176–187. [Google Scholar] [CrossRef]

- Tessema, A.; Zhao, D.; Moll, J.; Xu, S.; Yang, R.; Li, C.; Kumar, S.K.; Kidane, A. Effect of Filler Loading, Geometry, Dispersion and Temperature on Thermal Conductivity of Polymer Nanocomposites. Polym. Test. 2017, 57, 101–106. [Google Scholar] [CrossRef] [Green Version]

- Pudełko, A.; Postawa, P.; Stachowiak, T.; Malińska, K.; Dróżdż, D. Waste Derived Biochar as an Alternative Filler in Biocomposites—Mechanical, Thermal and Morphological Properties of Biochar Added Biocomposites. J. Clean. Prod. 2021, 278, 123850. [Google Scholar] [CrossRef]

- Soccio, M.; Nogales, A.; Lotti, N.; Munari, A.; Ezquerra, T.A. The β Relaxation as a Probe to Follow Real-Time Polymer Crystallization in Model Aliphatic Polyesters. Polymer 2007, 48, 4742–4750. [Google Scholar] [CrossRef]

- Klonos, P.A.; Papadopoulos, L.; Papageorgiou, G.Z.; Kyritsis, A.; Pissis, P.; Bikiaris, D.N. Interfacial Interactions, Crystallization, and Molecular Dynamics of Renewable Poly(Propylene Furanoate) in Situ Filled with Initial and Surface Functionalized Carbon Nanotubes and Graphene Oxide. J. Phys. Chem. C 2020, 124, 10220–10234. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The Effect of Bio-Carbon Addition on the Electrical, Mechanical, and Thermal Properties of Polyvinyl Alcohol/Biochar Composites. J. Compos. Mater. 2016, 50, 1161–1168. [Google Scholar] [CrossRef]

- Qian, S.; Sheng, K.; Yao, W.; Yu, H. Poly(Lactic Acid) Biocomposites Reinforced with Ultrafine Bamboo-Char: Morphology, Mechanical, Thermal, and Water Absorption Properties. J. Appl. Polym. Sci. 2016, 133, 43425. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly (Lactic Acid)—Biochar Biocomposites: Effect of Processing and Filler Content on Rheological. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [Green Version]

- Sundarakannan, R.; Arumugaprabu, V.; Manikandan, V.; Vigneshwaran, S. Mechanical Property Analysis of Biochar Derived from Cashew Nut Shell Waste Reinforced Polymer Matrix. Mater. Res. Express 2019, 6, 125349. [Google Scholar] [CrossRef]

- Botta, L.; Teresi, R.; Titone, V.; Salvaggio, G.; La Mantia, F.P.; Lopresti, F. Use of Biochar as Filler for Biocomposite Blown Films: Structure-Processing-Properties Relationships. Polymers 2021, 13, 3953. [Google Scholar] [CrossRef]

- Terzopoulou, Z.N.; Papageorgiou, G.Z.; Papadopoulou, E.; Athanassiadou, E.; Reinders, M.; Bikiaris, D.N. Development and Study of Fully Biodegradable Composite Materials Based on Poly(Butylene Succinate) and Hemp Fibers or Hemp Shives. Polym. Compos. 2016, 37, 407–421. [Google Scholar] [CrossRef]

- Vidal, J.L.; Yavitt, B.M.; Wheeler, M.D.; Kolwich, J.L.; Donovan, L.N.; Sit, C.S.; Hatzikiriakos, S.G.; Jalsa, N.K.; MacQuarrie, S.L.; Kerton, F.M. Biochar as a Sustainable and Renewable Additive for the Production of Poly(ε-Caprolactone) Composites. Sustain. Chem. Pharm. 2022, 25, 100586. [Google Scholar] [CrossRef]

- Bikiaris, D.N. Nanocomposites of Aliphatic Polyesters: An Overview of the Effect of Different Nanofillers on Enzymatic Hydrolysis and Biodegradation of Polyesters. Polym. Degrad. Stab. 2013, 98, 1908–1928. [Google Scholar] [CrossRef]

- Kong, X.; Qi, H.; Curtis, J.M. Synthesis and Characterization of High-Molecular Weight Aliphatic Polyesters from Monomers Derived from Renewable Resources. J. Appl. Polym. Sci. 2014, 131, 40579. [Google Scholar] [CrossRef]

- Batista, E.M.C.C.; Shultz, J.; Matos, T.T.S.; Fornari, M.R.; Ferreira, T.M.; Szpoganicz, B.; De Freitas, R.A.; Mangrich, A.S. Effect of Surface and Porosity of Biochar on Water Holding Capacity Aiming Indirectly at Preservation of the Amazon Biome. Sci. Rep. 2018, 8, 10677. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sample | [η] (dL/g) | Μn (g/mol) | PDI |

|---|---|---|---|

| PBSu | 0.89 | 70,350 | 1.67 |

| PBSu/BC 1 wt% | 0.77 | 67,080 | 1.59 |

| PBSu/BC 2.5 wt% | 0.85 | 61,980 | 1.75 |

| PBSu/BC 5 wt% | 0.76 | 63,730 | 1.60 |

| DSC | |||||||

|---|---|---|---|---|---|---|---|

| Sample | Tc (°C) | ΔHc,n (J/gPBSu) | CFc (wt) & | Tg (°C) | Δcp (J/gsample∙K) | Tcc (°C) | Tm (°C) |

| PBSu | 64 | 64 | 30.47% | −35 | 0.24 | 95 | 115 |

| PBSu/BC 1 wt% | 72 | 69 | 32.86% | −35 | 0.24 | 97 | 115 |

| PBSu/BC 2.5 wt% | 70 | 70 | 33.33% | −34 | 0.23 | 98 | 115 |

| PBSu/BC 5 wt% | 72 | 73 | 34.76% | −34 | 0.23 | 98 | 114 |

| LFA ⁑ | |||

|---|---|---|---|

| Sample | Ρ (g/cm3) | α (mm2/s) | λ (W/m∙K) |

| PBSu | 1.41 | 0.08 | 0.12 |

| PBSu/BC 1 wt% | 1.24 | 0.11 | 0.13 |

| PBSu/BC 2.5 wt% | 1.21 | 0.14 | 0.17 |

| PBSu/BC 5 wt% | 1.13 | 0.20 | 0.22 |

| Sample | Tensile Strength at Yield (MPa) | Tensile Strength at Break (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) | Impact Strength (J/m2) |

|---|---|---|---|---|---|

| PBSu | 22.4 ± 0.4 | 22.2 ± 0.5 | 440 ± 35 | 103 ± 8.9 | 1.29 ± 0.08 |

| PBSu/BC 1 wt% | 25.7 ± 0.7 | 21.2 ± 1.2 | 131 ± 15 | 135 ± 4.5 | 1.53 ± 0.11 |

| PBSu/BC 2.5 wt% | 26.7 ± 1.3 | 26.5 ± 1.5 | 22 ± 7 | 144 ± 12 | 1.74 ± 0.15 |

| PBSu/BC 5 wt% | - | 29.0 ± 1.5 | 20 ± 4 | 150 ± 11 | 1.41 ± 0.12 |

| Samples | L | a | b | c | h | K/S |

|---|---|---|---|---|---|---|

| PBSu | 88.57 | −1 | 3.13 | 3.03 | 11.15 | 0.11 |

| PBSu/BC 1 wt% | 29.71 | 0.05 | 0.41 | 0.15 | 96.93 | 9.89 |

| PBSu/BC 2.5 wt% | 17.39 | −0.1 | −0.66 | 0.68 | 286.95 | 22.82 |

| PBSu/BC 5 wt% | 15.58 | 0.14 | −0.5 | 0.59 | 252.32 | 26.18 |

| Sample | Contact Angle (Degree) |

|---|---|

| PBSu | 72.67 ± 1.87 |

| PBSu/BC 1 wt% | 70.87 ± 1.11 |

| PBSu/BC 2.5 wt% | 71.83 ± 1.54 |

| PBSu/BC 5 wt% | 69.45 ± 1.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papadopoulou, K.; Klonos, P.A.; Kyritsis, A.; Mašek, O.; Wurzer, C.; Tsachouridis, K.; Anastasiou, A.D.; Bikiaris, D.N. Synthesis and Study of Fully Biodegradable Composites Based on Poly(butylene succinate) and Biochar. Polymers 2023, 15, 1049. https://doi.org/10.3390/polym15041049

Papadopoulou K, Klonos PA, Kyritsis A, Mašek O, Wurzer C, Tsachouridis K, Anastasiou AD, Bikiaris DN. Synthesis and Study of Fully Biodegradable Composites Based on Poly(butylene succinate) and Biochar. Polymers. 2023; 15(4):1049. https://doi.org/10.3390/polym15041049

Chicago/Turabian StylePapadopoulou, Katerina, Panagiotis A. Klonos, Apostolos Kyritsis, Ondřej Mašek, Christian Wurzer, Konstantinos Tsachouridis, Antonios D. Anastasiou, and Dimitrios N. Bikiaris. 2023. "Synthesis and Study of Fully Biodegradable Composites Based on Poly(butylene succinate) and Biochar" Polymers 15, no. 4: 1049. https://doi.org/10.3390/polym15041049