On the Mechanical, Thermal, and Rheological Properties of Polyethylene/Ultra-High Molecular Weight Polypropylene Blends

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of UHMWPP/PP Blends

2.3. Characterizations

3. Results and Discussions

3.1. Mechanical Properties

3.2. Thermal Properties

3.3. Rheological Properties

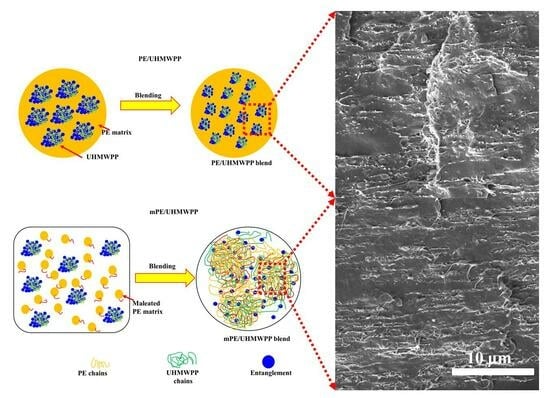

3.4. Morphology of Blends

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jaggi, H.S.; Satapathy, B.K.; Ray, A.R. Viscoelastic properties correlations to morphological and mechanical response of HDPE/UHMWPE blends. J. Polym. Res. 2014, 21, 482. [Google Scholar] [CrossRef]

- Wu, B.; Cai, Y.; Zhao, X.; Ye, L. Fabrication of well-miscible and highly enhanced polyethylene/ultrahigh molecular weight polyethylene blends by facile construction of interfacial intermolecular entanglement. Polym. Test. 2021, 93, 106973. [Google Scholar] [CrossRef]

- Wu, B.; Cai, Y.; Zhao, X.; Ye, L. Tailored bonded interfacial intermolecular entanglement of polyethylene/ultrahigh-molecular-weight polyethylene blends: Enhancing miscibility, reinforcement, and friction reduction. Ind. Eng. Chem. Res. 2021, 60, 5879–5889. [Google Scholar] [CrossRef]

- Koning, C.; Van Duin, M.; Pagnoulle, C.; Jerome, R. Strategies for compatibilization of polymer blends. Prog. Polym. Sci. 1998, 23, 707–757. [Google Scholar] [CrossRef]

- Ajji, A.; Utracki, L.A. Interphase and compatibilization of polymer blends. Polym. Eng. Sci. 1996, 36, 1574–1585. [Google Scholar] [CrossRef]

- Robeson, L. Historical Perspective of Advances in the Science and Technology of Polymer Blends. Polymers 2014, 6, 1251–1265. [Google Scholar] [CrossRef]

- Akkapeddi, M.K. Commercial Polymer Blends. In Polymer Blends Handbook; Utracki, L.A., Wilkie, C.A., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 1733–1883. ISBN 978-94-007-6064-6. [Google Scholar]

- Wang, J.; Zhang, X.; Jiang, L.; Qiao, J. Advances in toughened polymer materials by structured rubber particles. Prog. Polym. Sci. 2019, 98, 101160. [Google Scholar] [CrossRef]

- Vignesh, A.; Zhang, Q.; Ma, Y.; Liang, T.; Sun, W.-H. Attaining highly branched polyethylene elastomers by employing modified α-diiminonickel(II) catalysts: Probing the effects of enhancing fluorine atom on the ligand framework towards mechanical properties of polyethylene. Polymer 2020, 187, 122089. [Google Scholar] [CrossRef]

- Graziano, A.; Jaffer, S.; Sain, M. Review on modification strategies of polyethylene/polypropylene immiscible thermoplastic polymer blends for enhancing their mechanical behavior. J. Elastomers Plast. 2019, 51, 291–336. [Google Scholar] [CrossRef]

- Klimovica, K.; Pan, S.; Lin, T.-W.; Peng, X.; Ellison, C.J.; LaPointe, A.M.; Bates, F.S.; Coates, G.W. Compatibilization of i PP/HDPE Blends with PE-g-i PP Graft Copolymers. ACS Macro Lett. 2020, 9, 1161–1166. [Google Scholar] [CrossRef]

- Jiang, X.; Bin, Y.; Kikyotani, N.; Matsuo, M. Thermal, electrical and mechanical properties of ultra-high molecular weight polypropylene and carbon filler composites. Polym. J. 2006, 38, 419–431. [Google Scholar] [CrossRef]

- Kim, B.; Gavande, V.; Kim, G.; Lee, W.-K.; Kim, D.H. Rheological, Mechanical, and Thermal Properties of Ultrahigh Molecular Weight Polypropylene/Low Molecular Weight Polypropylene Blends. J. Macromol. Sci. Part B 2022, 61, 1202–1212. [Google Scholar]

- Kim, B.; Gavande, V.; Jeong, M.; Kim, Y.H.; Lee, W.-K. Properties of blends of ultra-high molecular weight polypropylene with various low molecular weight polypropylenes. Mol. Cryst. Liq. Cryst. 2023, 762, 63–70. [Google Scholar] [CrossRef]

- Xie, M.; Liu, X.; Li, H. Influence of poly (ethylene glycol)-containing additives on extrusion of ultrahigh molecular weight polyethylene/polypropylene blend. J. Appl. Polym. Sci. 2006, 100, 1282–1288. [Google Scholar] [CrossRef]

- Qi, L.; Wu, L.; He, R.; Cheng, H.; Liu, B.; He, X. Synergistic toughening of polypropylene with ultra-high molecular weight polyethylene and elastomer-olefin block copolymers. RSC Adv. 2019, 9, 23994–24002. [Google Scholar] [CrossRef] [PubMed]

- Aumnate, C.; Rudolph, N.; Sarmadi, M. Recycling of Polypropylene/Polyethylene Blends: Effect of Chain Structure on the Crystallization Behaviors. Polymers 2019, 11, 1456. [Google Scholar] [CrossRef] [PubMed]

- Brant, P.; Brown, G.M.; Narvaez, A. Impact of order of catalytic ethylene and propylene polymerization on nanometer scale isotactic polypropylene-polyethylene blend morphology in nascent heterophasic granules revealed by low voltage scanning electron microscopy and scanning transmission ele. J. Appl. Polym. Sci. 2022, 139, 51938. [Google Scholar] [CrossRef]

- Deblieck, R.; Remerie, K.; Van den Fonteyne, W.; Boerakker, M. A morphology-based model to describe the low-temperature impact behaviour of rubber-toughened polypropylene. Polymers 2021, 13, 2218. [Google Scholar] [CrossRef]

- Graziano, A.; Titton Dias, O.A.; Sena Maia, B.; Li, J. Enhancing the mechanical, morphological, and rheological behavior of polyethylene/polypropylene blends with maleic anhydride-grafted polyethylene. Polym. Eng. Sci. 2021, 61, 2487–2495. [Google Scholar] [CrossRef]

- Le Corroller, P.; Favis, B.D. Effect of viscosity in ternary polymer blends displaying partial wetting phenomena. Polymer 2011, 52, 3827–3834. [Google Scholar] [CrossRef]

- Jordan, A.M.; Kim, K.; Soetrisno, D.; Hannah, J.; Bates, F.S.; Jaffer, S.A.; Lhost, O.; Macosko, C.W. Role of Crystallization on Polyolefin Interfaces: An Improved Outlook for Polyolefin Blends. Macromolecules 2018, 51, 2506–2516. [Google Scholar] [CrossRef]

- Jose, S.; Aprem, A.S.; Francis, B.; Chandy, M.C.; Werner, P.; Alstaedt, V.; Thomas, S. Phase morphology, crystallisation behaviour and mechanical properties of isotactic polypropylene/high density polyethylene blends. Eur. Polym. J. 2004, 40, 2105–2115. [Google Scholar] [CrossRef]

- Shen, L.; Gorbea, G.D.; Danielson, E.; Cui, S.; Ellison, C.J.; Bates, F.S. Threading-the-Needle: Compatibilization of HDPE/iPP blends with butadiene-derived polyolefin block copolymers. Proc. Natl. Acad. Sci. USA 2023, 120, e2301352120. [Google Scholar] [CrossRef]

- Kida, T.; Kimura, T.; Eno, A.; Janchai, K.; Yamaguchi, M.; Otsuki, Y.; Kimura, T.; Mizukawa, T.; Murakami, T.; Hato, K. Effect of ultra-high-molecular-weight molecular chains on the morphology, crystallization, and mechanical properties of polypropylene. Polymers 2021, 13, 4222. [Google Scholar] [CrossRef] [PubMed]

- Unger, T.; Klocke, L.; Herrington, K.; Miethlinger, J. Investigation of the rheological and mechanical behavior of Polypropylene/ultra-high molecular weight polyethylene compounds related to new online process control. Polym. Test. 2020, 86, 106442. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Li, X.; Chen, H.; Walton, K.; Wang, D. Correlation of miscibility and mechanical properties of polypropylene/olefin block copolymers: Effect of chain composition. J. Appl. Polym. Sci. 2012, 125, 666–675. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Jin, R. Synchronous toughening and reinforcing of polypropylene with ultrahigh-molecular-weight polyethylene via melt blending: Mechanical properties, morphology, and rheology. J. Appl. Polym. Sci. 2006, 100, 3498–3509. [Google Scholar] [CrossRef]

- Yu, C.-N.; Zhang, H.-C.; Su, S.-X.; Liang, Y. Dynamic rheological behavior, crystallization and friction performance of ultrahigh molecular weight polyethylene/polypropylene blends by multi-step melt processing strategy. J. Mater. Res. Technol. 2021, 15, 6747–6757. [Google Scholar] [CrossRef]

- Chiu, F.-C.; Lai, S.-M.; Ti, K.-T. Characterization and comparison of metallocene-catalyzed polyethylene/thermoplastic starch blends and nanocomposites. Polym. Test. 2009, 28, 243–250. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, Y.; Hu, H.; Li, J.; Zhou, W.; Zhao, X.; Peng, S. Effect of maleic anhydride grafted poly(lactic acid) on rheological behaviors and mechanical performance of poly(lactic acid)/poly(ethylene glycol) (PLA/PEG) blends. RSC Adv. 2022, 12, 31629–31638. [Google Scholar] [CrossRef]

- Li, Y.-M.; Wang, Y.; Bai, L.; Zhou, H.-L.-Z.; Yang, W.; Yang, M.-B. Dynamic rheological behavior of HDPE/UHMWPE blends. J. Macromol. Sci. Part B 2011, 50, 1249–1259. [Google Scholar] [CrossRef]

- Hammani, S.; Moulai-Mostefa, N.; Samyn, P.; Bechelany, M.; Dufresne, A.; Barhoum, A. Morphology, rheology and crystallization in relation to the viscosity ratio of polystyrene/polypropylene polymer blends. Materials 2020, 13, 926. [Google Scholar] [CrossRef] [PubMed]

- Souza, A.M.C.; Demarquette, N.R. Influence of coalescence and interfacial tension on the morphology of PP/HDPE compatibilized blends. Polymer 2002, 43, 3959–3967. [Google Scholar] [CrossRef]

- Banerjee, R.; Ray, S.S. Role of Rheology in Morphology Development and Advanced Processing of Thermoplastic Polymer Materials: A Review. ACS Omega 2023, 8, 27969–28001. [Google Scholar] [CrossRef] [PubMed]

| Sample Designation | PE (wt%) | mPE (wt%) | UHMWPP (wt%) |

|---|---|---|---|

| PE | 100 | - | 0 |

| P90U10 | 90 | - | 10 |

| P80U20 | 80 | - | 20 |

| P70U30 | 70 | - | 30 |

| P60U40 | 60 | - | 40 |

| P50U50 | 50 | - | 50 |

| mPE | - | 100 | 0 |

| mP90U10 | - | 90 | 10 |

| mP80U20 | - | 80 | 20 |

| mP70U30 | - | 70 | 30 |

| mP60U40 | - | 60 | 40 |

| mP50U50 | - | 50 | 50 |

| Sample | Ultimate Tensile Strength (MPa) | Elongation @ Break | Tm (°C) | Crystallinity (%) |

|---|---|---|---|---|

| PE | 30.75 ± 1.21 | 329.77 ± 16.82 | 135.3 | 76.28 |

| P90U10 | 13.12 ± 1.72 | 12.93± 1.55 | 131.6 | 72, - |

| P80U20 | 18.76 ± 1.26 | 18.49 ±1.22 | 133.1, 165 | 72.28, 24.73 |

| P70U30 | 22.41 ± 0.78 | 22.31 ± 0.80 | 133.6, 166.6 | 75.29, 25.50 |

| P60U40 | 25.97 ± 0.53 | 25.28 ± 0.60 | 137, 167 | 68.33, 27.49 |

| P50U50 | 30.24 ± 1.33 | 27.65 ± 1.3 | 136, 167.6 | 62.28, 24 |

| mPE | 25.10 ± 1.53 | 273.33 ± 27.76 | 135.5 | 67.80 |

| mP90U10 | 24.64 ± 0.93 | 7.48 ± 1.11 | 134.3, 165.8 | 65.38, 18.21 |

| mP80U20 | 27.60 ± 0.74 | 6.70 ± 0.35 | 131, 164.3 | 63.93, 27.68 |

| mP70U30 | 32.07 ± 0.75 | 7.54 ± 0.46 | 131.3, 164.6 | 62.10, 28.36 |

| mP60U40 | 29.10 ± 0.73 | 8.31 ± 0.96 | 131.4, 165.3 | 63.12, 35.25 |

| mP50U50 | 28.83 ± 0.85 | 10.79 ± 0.40 | 133.8, 168.6 | 56.70, 28.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavande, V.; Jeong, M.; Lee, W.-K. On the Mechanical, Thermal, and Rheological Properties of Polyethylene/Ultra-High Molecular Weight Polypropylene Blends. Polymers 2023, 15, 4236. https://doi.org/10.3390/polym15214236

Gavande V, Jeong M, Lee W-K. On the Mechanical, Thermal, and Rheological Properties of Polyethylene/Ultra-High Molecular Weight Polypropylene Blends. Polymers. 2023; 15(21):4236. https://doi.org/10.3390/polym15214236

Chicago/Turabian StyleGavande, Vishal, Mingi Jeong, and Won-Ki Lee. 2023. "On the Mechanical, Thermal, and Rheological Properties of Polyethylene/Ultra-High Molecular Weight Polypropylene Blends" Polymers 15, no. 21: 4236. https://doi.org/10.3390/polym15214236