Influence of Curvature Feature on Laser Heating during Tape Placement Process for Carbon Fiber Reinforced Polyether Ether Ketone Composite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Scattering Reflection Measurement

2.3. A Laser Irradiating Thermoplastic Composite Tape

3. Basic Principles

3.1. Laser Power Density Calculation

3.2. Analytical Model

3.3. Melt Pool Depth Approximation

4. Optical-Thermal Model for the Curved Specimen

5. Results and Discussion

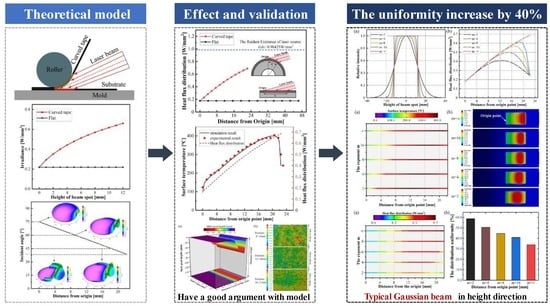

5.1. Effect of Curvature Feature on the Optical Behavior

5.2. Effect of Curvature Feature on the Power Density Distribution

5.3. Effect of Power Density Distribution on the Temperature Distribution and Surface Morphology

5.4. Influence of the Intensity Distribution of Laser Beam on the Heating Effect

6. Conclusions

- It was found that the curvature feature of the CF/PEEK composite indeed affected the optical behavior. The curvature feature made the incident angle range from 75° to 38.5°, and as the irradiated position was farther away from the origin, the crescent reflection pattern became gradually more apparent.

- Theoretical calculation results show that the curvature feature of the income tape makes the irradiance and absorptance change, causing the power density to increase as the distance from the origin increase. Hence the minimum energy density occurs at the origin position, the power density was only 18% of the radiant laser existence. The theoretical model was in good agreement with the optical simulation model. Accordingly, the difference in power density distribution between the income tape and the flat was great.

- The uneven distribution of power density caused a more significant change in the temperature distribution, melt pool depth, and surface morphology along the circumference. Experimental results indicated that the surface temperature variation was consistent with the power density distribution. Moreover, the melt pool depth appeared at 14 mm from the origin, and as the distance increased, the approximated melt pool depth increased to 56.5 μm. It also implied that a remarkable change in surface morphology occurred in the curved tape.

- The Super-Gaussian function was introduced into the theoretical model to describe the relationship between exponent and power density distribution. As the exponent m decreased, the irradiation uniformity improved, and the location of the highest power density became closer to the origin. When the typical Gaussian profile beam in the height direction of the beam is employed, the higher relative intensity compensates for the energy loss due to the lower irradiance and absorptance at the origin. Consequently, the resulting irradiation uniformity increased by up to 25%, significantly reducing the difference between the curved tape and the flat during the laser heating lay-up process.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Schledjewski, R. Thermoplastic tape placement process—In situ consolidation is reachable. Plast. Rubber Compos. 2009, 38, 379–386. [Google Scholar] [CrossRef]

- Khan, M.A.; Mitschang, P.; Schledjewski, R. Parametric study on processing parameters and resulting part quality through thermoplastic tape placement process. J. Compos. Mater. 2013, 47, 485–499. [Google Scholar] [CrossRef]

- Ranganathan, S.; Advani, S.G.; Lamontia, M.A. A Non-Isothermal Process Model for Consolidation and Void Reduction during In-Situ Tow Placement of Thermoplastic Composites. J. Compos. Mater. 1995, 29, 1040–1062. [Google Scholar] [CrossRef]

- Rosselli, F.; Santare, M.H.; Güçeri, S.I. Effects of processing on laser assisted thermoplastic tape consolidation. Compos. Part A Appl. Sci. Manuf. 1997, 28, 1023–1033. [Google Scholar] [CrossRef]

- Tierney, J.; Gillespie, J.W. Modeling of Heat Transfer and Void Dynamics for the Thermoplastic Composite Tow-Placement Process. J. Compos. Mater. 2003, 37, 1745–1768. [Google Scholar] [CrossRef]

- Martín, M.I.; Rodríguez-Lence, F.; Güemes, A.; Fernández-López, A.; Pérez-Maqueda, L.A.; Perejón, A. On the determination of thermal degradation effects and detection techniques for thermoplastic composites obtained by automatic lamination. Compos. Part A Appl. Sci. Manuf. 2018, 111, 23–32. [Google Scholar] [CrossRef]

- Pitchumani, R.; Ranganathan, S.; Don, R.C.; Gillespie, J.W.; Lamontia, M.A. Analysis of transport phenomena governing interfacial bonding and void dynamics during thermoplastic tow-placement. Int. J. Heat Mass Transf. 1996, 39, 1883–1897. [Google Scholar] [CrossRef]

- Sonmez, F.O.; Hahn, H.T. Modeling of Heat Transfer and Crystallization in Thermoplastic Composite Tape Placement Process. J. Thermoplast. Compos. Mater. 1997, 10, 198–240. [Google Scholar] [CrossRef]

- Tierney, J.J.; Gillespie, J.W., Jr. Crystallization kinetics behavior of PEEK based composites exposed to high heating and cooling rates. Compos. Part A Appl. Sci. Manuf. 2004, 35, 547–558. [Google Scholar] [CrossRef]

- Sonmez, F.O.; Akbulut, M. Process optimization of tape placement for thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2013–2023. [Google Scholar] [CrossRef]

- Dedieu, C.; Barasinski, A.; Chinesta, F.; Dupillier, J.-M. On the prediction of residual stresses in automated tape placement. Int. J. Mater. 2017, 10, 633–640. [Google Scholar] [CrossRef]

- Dedieu, C.; Barasinski, A.; Chinesta, F.; Dupillier, J.-M. About the origins of residual stresses in in situ consolidated thermoplastic composite rings. Int. J. Mater. 2017, 10, 779–792. [Google Scholar] [CrossRef]

- Fathi-Hafshejani, P.; Soltani-Tehrani, A.; Shamsaei, N.; Mahjouri-Samani, M. Laser incidence angle influence on energy density variations, surface roughness, and porosity of additively manufactured parts. Addit. Manuf. 2022, 50, 102572. [Google Scholar] [CrossRef]

- Ayoola, W.A.; Suder, W.J.; Williams, S.W. Effect of beam shape and spatial energy distribution on weld bead geometry in conduction welding. Opt. Laser Technol. 2019, 117, 280–287. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P.; Matuszyk, T.I.; Cardew-Hall, M.J. Thermal modelling of the laser-assisted thermoplastic tape placement process. J. Thermoplast. Compos. Mater. 2015, 28, 1445–1462. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P. A combined optical-thermal model for near-infrared laser heating of thermoplastic composites in an automated tape placement process. Compos. Part A Appl. Sci. Manuf. 2015, 75, 104–115. [Google Scholar] [CrossRef]

- Grove, S.M. Thermal modelling of tape laying with continuous carbon fibre-reinforced thermoplastic. Composites 1988, 19, 367–375. [Google Scholar] [CrossRef]

- Maurer, D.; Mitschang, P. Laser-powered tape placement process–simulation and optimization. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 129–137. [Google Scholar]

- Schaefer, P.M.; Gierszewski, D.; Kollmannsberger, A.; Zaremba, S.; Drechsler, K. Analysis and improved process response prediction of laser- assisted automated tape placement with PA-6/carbon tapes using Design of Experiments and numerical simulations. Compos. Part A Appl. Sci. Manuf. 2017, 96, 137–146. [Google Scholar] [CrossRef]

- Sonmez, F.O.; Hahn, H.T. Analysis of the On-Line Consolidation Process in Thermoplastic Composite Tape Placement. J. Thermoplast. Compos. Mater. 1997, 10, 543–572. [Google Scholar] [CrossRef]

- Tumkor, S.; Turkmen, N.; Chassapis, C.; Manoochehri, S. Modeling of heat transfer in thermoplastic composite tape lay-up manufacturing. Int. Commun. Heat Mass Transf. 2001, 28, 49–58. [Google Scholar] [CrossRef]

- Grouve, W. Weld Strength of Laser-Assisted Tape-Placed Thermoplastic Composites. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2012. [Google Scholar]

- Stokes-Griffin, C.M.; Compston, P. Optical characterisation and modelling for oblique near-infrared laser heating of carbon fibre reinforced thermoplastic composites. Opt. Lasers Eng. 2015, 72, 1–11. [Google Scholar] [CrossRef]

- Reichardt, J.; Baran, I.; Akkerman, R. New analytical and numerical optical model for the laser assisted tape winding process. Compos. Part A Appl. Sci. Manuf. 2018, 107, 647–656. [Google Scholar] [CrossRef]

- Zaami, A.; Baran, I.; Bor, T.; Akkerman, R. Optical characterization of fiber-reinforced thermoplastic tapes for laser-based composite manufacturing. Compos. Part A Appl. Sci. Manuf. 2021, 146, 106402. [Google Scholar] [CrossRef]

- Schlick, C. An Inexpensive BRDF Model for Physically-based Rendering. Comput. Graph. Forum 1994, 13, 233–246. [Google Scholar] [CrossRef]

- Nicodemus, F.E. Directional Reflectance and Emissivity of an Opaque Surface. Appl. Opt. 1965, 4, 767–775. [Google Scholar] [CrossRef]

- Zaami, A.; Baran, I.; Bor, T.C.; Akkerman, R. New process optimization framework for laser assisted tape winding of composite pressure vessels: Controlling the unsteady bonding temperature. Mater. Des. 2020, 196, 109130. [Google Scholar] [CrossRef]

- Zaami, A.; Baran, I.; Bor, T.C.; Akkerman, R. 3D Numerical Modeling of Laser Assisted Tape Winding Process of Composite Pressure Vessels and Pipes—Effect of Winding Angle, Mandrel Curvature and Tape Width. Materials 2020, 13, 2449. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Schäkel, M.; Baran, I.; Janssen, H.; van Drongelen, M.; Akkerman, R. A new global kinematic-optical-thermal process model for laser-assisted tape winding with an application to helical-wound pressure vessel. Mater. Des. 2020, 193, 108854. [Google Scholar] [CrossRef]

- Boley, C.D.; Rubenchik, A.M. Modeling of laser interactions with composite materials. Appl. Opt. 2013, 52, 3329. [Google Scholar] [CrossRef]

- Filip, J.; Vávra, R.; Maile, F.J. Optical analysis of coatings including diffractive pigments using a high-resolution gonioreflectometer. J. Coat. Technol. Res. 2019, 16, 555–572. [Google Scholar] [CrossRef]

- Le Louët, V.; Rousseau, B.; Le Corre, S.; Boyard, N.; Tardif, X.; Delmas, J.; Delaunay, D. Directional spectral reflectivity measurements of a carbon fibre reinforced composite up to 450 °C. Int. J. Heat Mass Transf. 2017, 112, 882–890. [Google Scholar] [CrossRef]

- Baho, O.; Ausias, G.; Grohens, Y.; Férec, J. Simulation of laser heating distribution for a thermoplastic composite: Effects of AFP head parameters. Int. J. Adv. Manuf. Technol. 2020, 110, 2105–2117. [Google Scholar] [CrossRef]

- Baho, O.; Ausias, G.; Grohens, Y.; Barile, M.; Lecce, L.; Férec, J. Automated fibre placement process for a new hybrid material: A numerical tool for predicting an efficient heating law. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106360. [Google Scholar] [CrossRef]

- Agarwal, V.; Guçeri, S.I.; Mccullough, R.L.; Schultz, J.M. Thermal Characterization of the Laser-Assisted Consolidation Process. J. Thermoplast. Compos. Mater. 1992, 5, 115–135. [Google Scholar] [CrossRef]

- Weiler, T. Thermal Skin Effect in Laser-Assisted Tape Placement of Thermoplastic Composites [Thermischer Skineffekt Beim Laserunterstützten Tapelegen von Thermoplastischen Faserverbundkunststoffen]; 1. Auflage; Apprimus Verlag: Aachen, Germany, 2019; ISBN 978-3-86359-739-9. [Google Scholar]

- Weiler, T.; Emonts, M.; Wollenburg, L.; Janssen, H. Transient thermal analysis of laser-assisted thermoplastic tape placement at high process speeds by use of analytical solutions. J. Thermoplast. Compos. Mater. 2018, 31, 311–338. [Google Scholar] [CrossRef]

- Çelik, O.; Choudhary, A.; Peeters, D.; Teuwen, J.; Dransfeld, C. Deconsolidation of thermoplastic prepreg tapes during rapid laser heating. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106575. [Google Scholar] [CrossRef]

- Song, X.; Li, B.; Guo, Z.; Wang, S.; Cai, D.; Wen, J. Influences of pump beam distribution on thermal lensing spherical aberration in an LD end-pumped Nd:YAG laser. Opt. Commun. 2009, 282, 4779–4783. [Google Scholar] [CrossRef]

| Parameters | Melting Temperature Tmelting [°C] | Density ρ [kg/m3] | Specific Heat Capacity Cp [J/kg/K] | Thermal Conductivity | |

|---|---|---|---|---|---|

| kxx [W/m/K] | kyy(kzz) [W/m/K] | ||||

| Value | 343 | 1540 | 1100 | 4.92 | 0.61 |

| Parameters | Symbol | Value |

|---|---|---|

| Laser power | Pl | 150 W |

| Laser spot width | w0 | 14 mm |

| Laser spot height | h0 | 12 mm |

| Laser beam inclination angle | αr | 0.26 rad |

| Tape radius | Rr | 35 mm |

| Tape width | wt | 12.7 mm |

| Roller width | wr | 20 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Li, Y.; Huan, D.; Wang, W.; Li, Y.; Li, L. Influence of Curvature Feature on Laser Heating during Tape Placement Process for Carbon Fiber Reinforced Polyether Ether Ketone Composite. Polymers 2023, 15, 289. https://doi.org/10.3390/polym15020289

Liu H, Li Y, Huan D, Wang W, Li Y, Li L. Influence of Curvature Feature on Laser Heating during Tape Placement Process for Carbon Fiber Reinforced Polyether Ether Ketone Composite. Polymers. 2023; 15(2):289. https://doi.org/10.3390/polym15020289

Chicago/Turabian StyleLiu, Hongquan, Yong Li, Dajun Huan, Wuqiang Wang, Yanrui Li, and Lisha Li. 2023. "Influence of Curvature Feature on Laser Heating during Tape Placement Process for Carbon Fiber Reinforced Polyether Ether Ketone Composite" Polymers 15, no. 2: 289. https://doi.org/10.3390/polym15020289