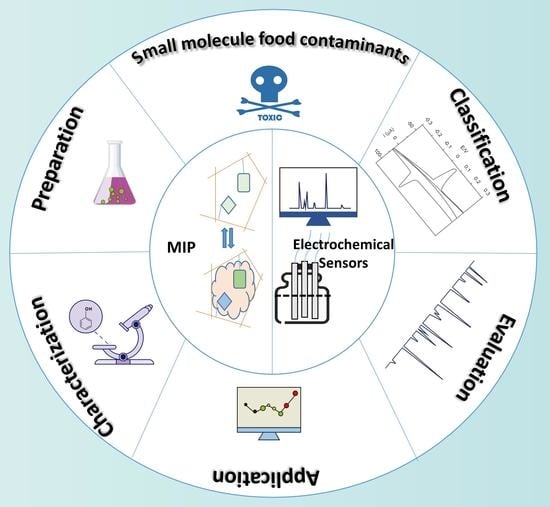

Application of Molecularly Imprinted Electrochemical Biomimetic Sensors for Detecting Small Molecule Food Contaminants

Abstract

:1. Introduction

2. Molecular Imprinting Technology

2.1. The Principle of MIPs

2.2. Preparation Methods

2.2.1. Bulk Polymerization

2.2.2. Suspension Polymerization

2.2.3. Emulsion Polymerization

2.2.4. Precipitation Polymerization

2.2.5. Surface Imprinting

2.3. MIP Characterization Methods and Performance Evaluation

2.3.1. MIP Characterization Methods

2.3.2. MIP Performance Evaluation

Adsorption Isotherm Model

Adsorption Kinetics

Adsorption Selectivity

Adsorption Performance

Chromatographic Evaluation

3. Electrochemical Sensors

3.1. Electric Current Sensors

3.2. Potentiometry Sensors

3.3. Capacitance/Impedance Sensors

3.4. Conductivity Sensors

4. Application of MIP Electrochemical Biomimetic Sensors for Detecting Small Molecule Chemical Food Contaminants

4.1. Antibiotic Residues

4.2. Pesticide Residues

4.3. Mycotoxins

4.4. Food Additives

4.5. Illegal Additives

4.6. Environmental Organic Pollutants

4.7. Heavy Metal Ions

5. Conclusions and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, F.; Shi, R.; Liu, R.; Tian, Y.; Yang, Z. Application of phage-display developed antibody and antigen substitutes in immunoassays for small molecule contaminants analysis: A mini-review. Food Chem. 2021, 339, 128084. [Google Scholar] [CrossRef] [PubMed]

- Binder, E.M.; Tan, L.M.; Chin, L.J.; Handl, J.; Richard, J. Worldwide occurrence of mycotoxins in commodities, feeds and feed ingredients. Anim. Feed Sci. Technol. 2007, 137, 265–282. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, Y.L.; Xiu, L.Y.; Qian, R.J.; Zhao, M.X.; Luo, P.J.; Ke, Y.B.; Li, G.M.; Jiang, W.X. Ultratrace Analysis of Neomycin Residues in Milk at Femtogram Levels by Flow-Through Immunoaffinity Chromatography Test. Food Anal. Methods 2021, 14, 2298–2307. [Google Scholar] [CrossRef]

- Vegh, R.; Soros, C.; Majercsik, N.; Sipos, L. Determination of Pesticides in Bee Pollen: Validation of a Multiresidue High-Performance Liquid Chromatography-Mass Spectrometry/Mass Spectrometry Method and Testing Pollen Samples of Selected Botanical Origin. J. Agric. Food Chem. 2022, 70, 1507–1515. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, S.V.; Holanda, M.H.B.; Cunha, H.O.; Oliveira, J.J.P.; Pontes, S.M.A.; Cruz, A.A.C.; Fechine, L.M.U.D.; Moura, T.A.; Paschoal, A.R.; Zambelli, R.A.; et al. Highly sensitive sensing of food additives based on fluorescent carbon quantum dots. J. Photoch. Photobio. A 2021, 411, 113198. [Google Scholar] [CrossRef]

- Chen, Z.J.; Wu, H.L.; Shen, Y.D.; Wang, H.; Zhang, Y.F.; Hammock, B.; Li, Z.F.; Luo, L.; Lei, H.T.; Xu, Z.L. Phosphate-triggered ratiometric fluoroimmunoassay based on nanobody-alkaline phosphatase fusion for sensitive detection of 1-naphthol for the exposure assessment of pesticide carbaryl. J. Hazard. Mater. 2022, 424, 127411. [Google Scholar] [CrossRef]

- Rasheed, T.; Bilal, M.; Nabeel, F.; Adeel, M.; Iqbal, H.M.N. Environmentally-related contaminants of high concern: Potential sources and analytical modalities for detection, quantification, and treatment. Environ. Int. 2019, 122, 52–66. [Google Scholar] [CrossRef]

- Cetinkaya, A.; Kaya, S.I.; Atici, E.B.; Corman, M.E.; Uzun, L.; Ozkan, S.A. A semi-covalent molecularly imprinted electrochemical sensor for rapid and selective detection of tiotropium bromide. Anal. Bioanal. Chem. 2022, 414, 8023–8033. [Google Scholar] [CrossRef]

- Bakhshpour, M.; Göktürk, I.; Gür, S.D.; Yılmaz, F.; Denizli, A. Sensor Applications for Detection in Agricultural Products, Foods, and Water. In Pesticides Bioremediation; Siddiqui, S., Meghvansi, M.K., Chaudhary, K.K., Eds.; Springer International Publishing: Cham, Germany, 2022; pp. 311–352. [Google Scholar]

- Venkatalaxmi, A.; Padmavathi, B.S.; Amaranath, T. A general solution of unsteady Stokes equations. FlDyR 2004, 35, 229–236. [Google Scholar] [CrossRef]

- Cheng, W.; Zhang, Q.; Wu, D.; Yang, Y.; Zhang, Y.; Tang, X. A facile electrochemical method for rapid determination of 3-chloropropane-1,2-diol in soy sauce based on nanoporous gold capped with molecularly imprinted polymer. Food Control 2022, 134, 108750. [Google Scholar] [CrossRef]

- Abu Shama, N.; Asir, S.; Ozsoz, M.; Gokturk, I.; Turkmen, D.; Yilmaz, F.; Denizli, A. Gold-Modified Molecularly Imprinted N-Methacryloyl-(l)-phenylalanine-containing Electrodes for Electrochemical Detection of Dopamine. Bioengineering 2022, 9, 87. [Google Scholar] [CrossRef] [PubMed]

- Demir, E.; Inam, O.; Inam, R. Determination of Ophthalmic Drug Proparacaine Using Multi-walled Carbon Nanotube Paste Electrode by Square Wave Stripping Voltammetry. Anal. Sci. 2018, 34, 771–776. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; Tang, Y.; Liu, Y.; Zhao, F.; Zeng, B. Kill two birds with one stone: Selective and fast removal and sensitive determination of oxytetracycline using surface molecularly imprinted polymer based on ionic liquid and ATRP polymerization. J. Hazard. Mater. 2022, 434, 128907. [Google Scholar] [CrossRef] [PubMed]

- Rahman, S.; Bozal-Palabiyik, B.; Unal, D.N.; Erkmen, C.; Siddiq, M.; Shah, A.; Uslu, B. Molecularly imprinted polymers (MIPs) combined with nanomaterials as electrochemical sensing applications for environmental pollutants. Trends Environ. Anal. Chem. 2022, 36, e00176. [Google Scholar] [CrossRef]

- Velusamy, V.; Arshak, K.; Korostynska, O.; Oliwa, K.; Adley, C. An overview of foodborne pathogen detection: In the perspective of biosensors. Biotechnol. Adv. 2010, 28, 232–254. [Google Scholar] [CrossRef]

- Qi, P.; Wang, J.; Wang, X.; Wang, Z.; Xu, H.; Di, S.; Wang, Q.; Wang, X. Sensitive and selective detection of the highly toxic pesticide carbofuran in vegetable samples by a molecularly imprinted electrochemical sensor with signal enhancement by AuNPs. RSC Adv. 2018, 8, 25334–25341. [Google Scholar] [CrossRef] [Green Version]

- Azizi, A.; Bottaro, C.S. A critical review of molecularly imprinted polymers for the analysis of organic pollutants in environmental water samples. J. Chromatogr. A 2020, 1614, 460603. [Google Scholar] [CrossRef]

- Medina Rangel, P.X.; Moroni, E.; Merlier, F.; Gheber, L.A.; Vago, R.; Tse Sum Bui, B.; Haupt, K. Chemical Antibody Mimics Inhibit Cadherin-Mediated Cell-Cell Adhesion: A Promising Strategy for Cancer Therapy. Angew. Chem. Int. Ed. Engl. 2020, 59, 2816–2822. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, X.X.; Cheng, N.; Luo, Y.B.; Lin, Y.H.; Xu, W.T.; Du, D. Recent advances in nanomaterials-based electrochemical (bio)sensors for pesticides detection. TrAC Trend Anal. Chem. 2020, 132, 116041. [Google Scholar] [CrossRef]

- Singh, A.K.; Lakshmi, G.B.V.S.; Fernandes, M.; Sarkar, T.; Gulati, P.; Singh, R.P.; Solanki, P.R. A simple detection platform based on molecularly imprinted polymer for AFB1 and FuB1 mycotoxins. Microchem. J. 2021, 171, 106730. [Google Scholar] [CrossRef]

- Rebelo, P.; Costa-Rama, E.; Seguro, I.; Pacheco, J.G.; Nouws, H.P.A.; Cordeiro, M.; Delerue-Matos, C. Molecularly imprinted polymer-based electrochemical sensors for environmental analysis. Biosens. Bioelectron. 2021, 172, 112719. [Google Scholar] [CrossRef] [PubMed]

- Carballido, L.; Karbowiak, T.; Cayot, P.; Gerometta, M.; Sok, N.; Bou-Maroun, E. Applications of molecularly imprinted polymers and perspectives for their use as food quality trackers. Chem-Us 2022, 8, 2330–2341. [Google Scholar] [CrossRef]

- Turiel, E.; Martín-Esteban, A. Molecularly imprinted polymers-based microextraction techniques. TrAC Trends Anal. Chem. 2019, 118, 574–586. [Google Scholar] [CrossRef]

- Dong, C.; Shi, H.; Han, Y.; Yang, Y.; Wang, R.; Men, J. Molecularly imprinted polymers by the surface imprinting technique. Eur. Polym. J. 2021, 145, 110231. [Google Scholar] [CrossRef]

- Ashley, J.; Shahbazi, M.A.; Kant, K.; Chidambara, V.A.; Wolff, A.; Bang, D.D.; Sun, Y. Molecularly imprinted polymers for sample preparation and biosensing in food analysis: Progress and perspectives. Biosens. Bioelectron. 2017, 91, 606–615. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; She, X.; Wang, L.; Fan, H.; Zhou, Q.; Huang, X.; Tang, J.Z. Preparation, Characterization and Application of a Molecularly Imprinted Polymer for Selective Recognition of Sulpiride. Materials 2017, 10, 475. [Google Scholar] [CrossRef] [Green Version]

- Poliwoda, A.; Mościpan, M.; Wieczorek, P.P. Application of Molecular Imprinted Polymers for Selective Solid Phase Extraction of Bisphenol A. Ecol. Chem. Eng. S 2016, 23, 651–664. [Google Scholar] [CrossRef] [Green Version]

- Zhao, W.; Sheng, N.; Zhu, R.; Wei, F.; Cai, Z.; Zhai, M.; Du, S.; Hu, Q. Preparation of dummy template imprinted polymers at surface of silica microparticles for the selective extraction of trace bisphenol A from water samples. J. Hazard. Mater. 2010, 179, 223–229. [Google Scholar] [CrossRef]

- Song, Z.H.; Li, J.H.; Lu, W.H.; Li, B.W.; Yang, G.Q.; Bi, Y.; Arabi, M.; Wang, X.Y.; Ma, J.P.; Chen, L.X. Molecularly imprinted polymers based materials and their applications in chromatographic and electrophoretic separations. TrAC Trend Anal. Chem. 2022, 146, 116504. [Google Scholar] [CrossRef]

- Demir, Ö.; Ulusoy, H.İ.; Özer, E.T.; Osman, B. Development of a new solid phase extraction method for sensitive determination of some carbamate pesticides in water using poly(EGDMA-MATrp) microbeads. Microchem. J. 2020, 158, 105317. [Google Scholar] [CrossRef]

- Zhou, X.; Lai, C.; Huang, D.; Zeng, G.; Chen, L.; Qin, L.; Xu, P.; Cheng, M.; Huang, C.; Zhang, C.; et al. Preparation of water-compatible molecularly imprinted thiol-functionalized activated titanium dioxide: Selective adsorption and efficient photodegradation of 2, 4-dinitrophenol in aqueous solution. J. Hazard. Mater. 2018, 346, 113–123. [Google Scholar] [CrossRef]

- Wang, Z.H.; Qiu, T.; Guo, L.H.; Ye, J.; He, L.F.; Li, X.Y. The synthesis of hydrophilic molecularly imprinted polymer microspheres and their application for selective removal of bisphenol A from water. React. Funct. Polym. 2017, 116, 69–76. [Google Scholar] [CrossRef]

- Yang, J.; Li, Y.; Wang, J.; Sun, X.; Cao, R.; Sun, H.; Huang, C.; Chen, J. Molecularly imprinted polymer microspheres prepared by Pickering emulsion polymerization for selective solid-phase extraction of eight bisphenols from human urine samples. Anal. Chim. Acta 2015, 872, 35–45. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.Y.; Ding, L.; Che, G.B.; Jiang, W.; Sang, L. Recent advances and trends of molecularly imprinted polymers for specific recognition in aqueous matrix: Preparation and application in sample pretreatment. TrAC Trend Anal. Chem. 2019, 114, 11–28. [Google Scholar] [CrossRef]

- Pardeshi, S.; Singh, S.K. Precipitation polymerization: A versatile tool for preparing molecularly imprinted polymer beads for chromatography applications. RSC Adv. 2016, 6, 23525–23536. [Google Scholar] [CrossRef]

- Zeng, H.; Yu, X.; Wan, J.; Cao, X. Rational design and synthesis of molecularly imprinted polymers (MIP) for purifying tylosin by seeded precipitation polymerization. Process Biochem. 2020, 94, 329–339. [Google Scholar] [CrossRef]

- Lai, J.P.; Yang, M.L.; Niessner, R.; Knopp, D. Molecularly imprinted microspheres and nanospheres for di(2-ethylhexyl)phthalate prepared by precipitation polymerization. Anal. Bioanal. Chem. 2007, 389, 405–412. [Google Scholar] [CrossRef] [PubMed]

- Eersels, K.; Lieberzeit, P.; Wagner, P. A review on synthetic receptors for bio-particle detection created by surface-imprinting techniques—From principles to applications. ACS Sens. 2016, 1, 1171–1187. [Google Scholar] [CrossRef]

- Chen, L.; Wang, X.; Lu, W.; Wu, X.; Li, J. Molecular imprinting: Perspectives and applications. Chem. Soc. Rev. 2016, 45, 2137–2211. [Google Scholar] [CrossRef] [PubMed]

- Arias, P.G.; Martinez-Perez-Cejuela, H.; Combes, A.; Pichon, V.; Pereira, E.; Herrero-Martinez, J.M.; Bravo, M. Selective solid-phase extraction of organophosphorus pesticides and their oxon-derivatives from water samples using molecularly imprinted polymer followed by high-performance liquid chromatography with UV detection. J. Chromatogr. A 2020, 1626, 461346. [Google Scholar] [CrossRef] [PubMed]

- Tian, L.; Guo, H.; Li, J.; Yan, L.; Zhu, E.; Liu, X.; Li, K. Fabrication of a near-infrared excitation surface molecular imprinting ratiometric fluorescent probe for sensitive and rapid detecting perfluorooctane sulfonate in complex matrix. J. Hazard. Mater. 2021, 413, 125353. [Google Scholar] [CrossRef] [PubMed]

- Surya, S.G.; Khatoon, S.; Ait Lahcen, A.; Nguyen, A.T.H.; Dzantiev, B.B.; Tarannum, N.; Salama, K.N. A chitosan gold nanoparticles molecularly imprinted polymer based ciprofloxacin sensor. RSC Adv. 2020, 10, 12823–12832. [Google Scholar] [CrossRef]

- Moein, M.M. Advancements of chiral molecularly imprinted polymers in separation and sensor fields: A review of the last decade. Talanta 2021, 224, 121794. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Zheng, X.; Chi, Y.; Wang, Y.; Sun, X.; Yue, Q.; Gao, B.; Xu, S. Molecularly imprinted carbon nanosheets supported TiO2: Strong selectivity and synergic adsorption-photocatalysis for antibiotics removal. J. Hazard. Mater. 2020, 383, 121211. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Wang, J.; Shah, T.; Liu, P.; Ahmad, M.; Zhang, Q.; Zhang, B. Development of surface imprinted heterogeneous nitrogen-doped magnetic carbon nanotubes as promising materials for protein separation and purification. Talanta 2021, 224, 121760. [Google Scholar] [CrossRef]

- Zhang, K.Y.; Wang, Y.F.; Wen, Q.Y.; Huang, Q.R.; Li, T.Q.; Zhang, Y.; Luo, D.L. Preparation and characterization of magnetic molecularly imprinted polymer for specific adsorption of wheat gliadin. J. Mol. Struct. 2022, 1265, 133227. [Google Scholar] [CrossRef]

- Feng, G.; Sun, J.; Wang, M.; Wang, M.; Li, Z.; Wang, S.; Zheng, L.; Wang, J.; She, Y.; Abd El-Aty, A.M. Preparation of molecularly imprinted polymer with class-specific recognition for determination of 29 sulfonylurea herbicides in agro-products. J. Chromatogr. A 2021, 1647, 462143. [Google Scholar] [CrossRef]

- Benedetti, B.; Di Carro, M.; Magi, E. Multivariate optimization of an extraction procedure based on magnetic molecular imprinted polymer for the determination of polycyclic aromatic hydrocarbons in sea water. Microchem. J. 2019, 145, 1199–1206. [Google Scholar] [CrossRef]

- Wang, M.; Liang, S.; Bai, L.; Qiao, F.; Yan, H. Green protocol for the preparation of hydrophilic molecularly imprinted resin in water for the efficient selective extraction and determination of plant hormones from bean sprouts. Anal. Chim. Acta 2019, 1064, 47–55. [Google Scholar] [CrossRef]

- Hu, W.; Xie, Y.; Lu, S.; Li, P.; Xie, T.; Zhang, Y.; Wang, Y. One-step synthesis of nitrogen-doped sludge carbon as a bifunctional material for the adsorption and catalytic oxidation of organic pollutants. Sci. Total Environ. 2019, 680, 51–60. [Google Scholar] [CrossRef]

- Zhu, G.; Cheng, G.; Lu, T.; Cao, Z.; Wang, L.; Li, Q.; Fan, J. An ionic liquid functionalized polymer for simultaneous removal of four phenolic pollutants in real environmental samples. J. Hazard. Mater. 2019, 373, 347–358. [Google Scholar] [CrossRef]

- Liang, W.; Lu, Y.; Li, N.; Li, H.; Zhu, F. Microwave-assisted synthesis of magnetic surface molecular imprinted polymer for adsorption and solid phase extraction of 4-nitrophenol in wastewater. Microchem. J. 2020, 159, 105316. [Google Scholar] [CrossRef]

- Wang, P.; Zhu, H.; Liu, J.; Ma, Y.; Yao, J.; Dai, X.; Pan, J. Double affinity integrated MIPs nanoparticles for specific separation of glycoproteins: A combination of synergistic multiple bindings and imprinting effect. Chem. Eng. J. 2019, 358, 143–152. [Google Scholar] [CrossRef]

- Ndunda, E.N. Molecularly imprinted polymers—A closer look at the control polymer used in determining the imprinting effect: A mini review. J. Mol. Recognit. 2020, 33, e2855. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Zeng, H.; Wan, J.; Cao, X. Computational design of a molecularly imprinted polymer compatible with an aqueous environment for solid phase extraction of chenodeoxycholic acid. J. Chromatogr. A 2020, 1609, 460490. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Qin, L.; Cui, Y.; Liu, W.-f.; Liu, X.-g.; Yang, Y.-z. A hydrophilic surface molecularly imprinted polymer on a spherical porous carbon support for selective phenol removal from coking wastewater. New Carbon Mater. 2020, 35, 220–231. [Google Scholar] [CrossRef]

- Zouaoui, F.; Bourouina-Bacha, S.; Bourouina, M.; Jaffrezic-Renault, N.; Zine, N.; Errachid, A. Electrochemical sensors based on molecularly imprinted chitosan: A review. TrAC Trend Anal. Chem. 2020, 130, 115982. [Google Scholar] [CrossRef]

- Kriz, D.; Mosbach, K. Competitive Amperometric Morphine Sensor-Based on an Agarose Immobilized Molecularly Imprinted Polymer. Anal. Chim. Acta 1995, 300, 71–75. [Google Scholar] [CrossRef]

- Wang, W. Electrochemical sensor based on molecularly imprinted membranes at Au@CNTs nanocomposite-modified electrode for determination of prednisolone as a doping agent in sport. Int. J. Electrochem. Sci. 2022, 17, 220222. [Google Scholar] [CrossRef]

- Elfadil, D.; Lamaoui, A.; Della Pelle, F.; Amine, A.; Compagnone, D. Molecularly Imprinted Polymers Combined with Electrochemical Sensors for Food Contaminants Analysis. Molecules 2021, 26, 4607. [Google Scholar] [CrossRef]

- Richter, E.M.; Rocha, D.P.; Cardoso, R.M.; Keefe, E.M.; Foster, C.W.; Munoz, R.A.A.; Banks, C.E. Complete Additively Manufactured (3D-Printed) Electrochemical Sensing Platform. Anal. Chem. 2019, 91, 12844–12851. [Google Scholar] [CrossRef] [PubMed]

- Beluomini, M.A.; da Silva, J.L.; de Sa, A.C.; Buffon, E.; Pereira, T.C.; Stradiotto, N.R. Electrochemical sensors based on molecularly imprinted polymer on nanostructured carbon materials: A review. J. Electroanal. Chem. 2019, 840, 343–366. [Google Scholar] [CrossRef]

- Li, J.P.; Yin, W.L.; Tan, Y.J.; Pan, H.C. A sensitive electrochemical molecularly imprinted sensor based on catalytic amplification by silver nanoparticles for 3-indoleacetic acid determination. Sens. Actuators B 2014, 197, 109–115. [Google Scholar] [CrossRef]

- Thevenot, D.R.; Toth, K.; Durst, R.A.; Wilson, G.S. Electrochemical biosensors: Recommended definitions and classification. Biosens. Bioelectron. 2001, 16, 121–131. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, C.; Qi, L.; Liang, R.; Qin, W. Multifunctional Molecularly Imprinted Receptor-Based Polymeric Membrane Potentiometric Sensor for Sensitive Detection of Bisphenol A. Anal. Chem. 2022, 94, 7795–7803. [Google Scholar] [CrossRef]

- Iskierko, Z.; Checinska, A.; Sharma, P.S.; Golebiewska, K.; Noworyta, K.; Borowicz, P.; Fronc, K.; Bandi, V.; D’Souza, F.; Kutner, W. Molecularly imprinted polymer based extended-gate field-effect transistor chemosensors for phenylalanine enantioselective sensing. J. Mater. Chem. C 2017, 5, 969–977. [Google Scholar] [CrossRef] [Green Version]

- El-Akaad, S.; Mohamed, M.A.; Abdelwahab, N.S.; Abdelaleem, E.A.; De Saeger, S.; Beloglazova, N. Capacitive sensor based on molecularly imprinted polymers for detection of the insecticide imidacloprid in water. Sci. Rep. 2020, 10, 14479. [Google Scholar] [CrossRef]

- Pohanka, M.; Skládal, P. Electrochemical biosensors—Principles and applications. J. Appl. Biomed. 2008, 6, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Latif, U.; Ping, L.; Dickert, F.L. Conductometric Sensor for PAH Detection with Molecularly Imprinted Polymer as Recognition Layer. Sensors 2018, 18, 767. [Google Scholar] [CrossRef] [Green Version]

- Honeychurch, K.C.; Piano, M. Sensors for Environmental Monitoring and Food Safety. Biosensors 2022, 12, 366. [Google Scholar] [CrossRef]

- Tarannum, N.; Khatoon, S.; Dzantiev, B.B. Perspective and application of molecular imprinting approach for antibiotic detection in food and environmental samples: A critical review. Food Control 2020, 118, 107381. [Google Scholar] [CrossRef]

- de Faria, L.V.; Lisboa, T.P.; Campos, N.D.S.; Alves, G.F.; Matos, M.A.C.; Matos, R.C.; Munoz, R.A.A. Electrochemical methods for the determination of antibiotic residues in milk: A critical review. Anal. Chim. Acta 2021, 1173, 338569. [Google Scholar] [CrossRef] [PubMed]

- Kemper, N. Veterinary antibiotics in the aquatic and terrestrial environment. Ecol. Indic. 2008, 8, 1–13. [Google Scholar] [CrossRef]

- Long, F.; Zhang, Z.; Yang, Z.; Zeng, J.; Jiang, Y. Imprinted electrochemical sensor based on magnetic multi-walled carbon nanotube for sensitive determination of kanamycin. J. Electroanal. Chem. 2015, 755, 7–14. [Google Scholar] [CrossRef]

- Ayankojo, A.G.; Reut, J.; Ciocan, V.; Opik, A.; Syritski, V. Molecularly imprinted polymer-based sensor for electrochemical detection of erythromycin. Talanta 2020, 209, 120502. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Li, B.Q.; Song, Z.; Pan, S.H.; Zhang, Z.C.; Yao, H.; Zhu, S.Y.; Xu, G.B. A kanamycin sensor based on an electrosynthesized molecularly imprinted poly-o-phenylenediamine film on a single-walled carbon nanohorn modified glassy carbon electrode. Analyst 2017, 142, 218–223. [Google Scholar] [CrossRef]

- Wen, Y.; Liao, X.; Deng, C.; Liu, G.; Yan, Q.; Li, L.; Wang, X. Imprinted voltammetric streptomycin sensor based on a glassy carbon electrode modified with electropolymerized poly(pyrrole-3-carboxy acid) and electrochemically reduced graphene oxide. Microchim. Acta 2017, 184, 935–941. [Google Scholar] [CrossRef]

- Liu, B.; Tang, D.; Zhang, B.; Que, X.; Yang, H.; Chen, G. Au(III)-promoted magnetic molecularly imprinted polymer nanospheres for electrochemical determination of streptomycin residues in food. Biosens. Bioelectron. 2013, 41, 551–556. [Google Scholar] [CrossRef]

- Yang, G.; Zhao, F. Electrochemical sensor for chloramphenicol based on novel multiwalled carbon nanotubes@molecularly imprinted polymer. Biosens. Bioelectron. 2015, 64, 416–422. [Google Scholar] [CrossRef]

- Jamieson, O.; Soares, T.C.C.; de Faria, B.A.; Hudson, A.; Mecozzi, F.; Rowley-Neale, S.J.; Banks, C.E.; Gruber, J.; Novakovic, K.; Peeters, M.; et al. Screen Printed Electrode Based Detection Systems for the Antibiotic Amoxicillin in Aqueous Samples Utilising Molecularly Imprinted Polymers as Synthetic Receptors. Chemosensors 2019, 8, 5. [Google Scholar] [CrossRef]

- Shi, X.; Ren, X.; Jing, N.; Zhang, J. Electrochemical Determination of Ampicillin Based on an Electropolymerized Poly(o-Phenylenediamine)/Gold Nanoparticle/Single-Walled Carbon Nanotube Modified Glassy Carbon Electrode. Anal. Lett. 2020, 53, 2854–2867. [Google Scholar] [CrossRef]

- Jafari, S.; Dehghani, M.; Nasirizadeh, N.; Baghersad, M.H.; Azimzadeh, M. Label-free electrochemical detection of Cloxacillin antibiotic in milk samples based on molecularly imprinted polymer and graphene oxide-gold nanocomposite. Measurement 2019, 145, 22–29. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, R.; Chen, Y.; Wang, G. Electrochemical determination of enrofloxacin based on molecularly imprinted polymer via one-step electro-copolymerization of pyrrole and o -phenylenediamine. J. Electroanal. Chem. 2017, 806, 130–135. [Google Scholar] [CrossRef]

- Ye, C.; Chen, X.; Zhang, D.; Xu, J.; Xi, H.; Wu, T.; Deng, D.; Xiong, C.; Zhang, J.; Huang, G. Study on the properties and reaction mechanism of polypyrrole@norfloxacin molecularly imprinted electrochemical sensor based on three-dimensional CoFe-MOFs/AuNPs. Electrochim. Acta 2021, 379, 138174. [Google Scholar] [CrossRef]

- Rebelo, P.; Pacheco, J.G.; Cordeiro, M.N.D.S.; Melo, A.; Delerue-Matos, C. Azithromycin electrochemical detection using a molecularly imprinted polymer prepared on a disposable screen-printed electrode. Anal. Methods 2020, 12, 1486–1494. [Google Scholar] [CrossRef]

- Rad, A.O.; Azadbakht, A. An aptamer embedded in a molecularly imprinted polymer for impedimetric determination of tetracycline. Microchim. Acta 2019, 186, 56. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Shi, Z.; Chang, Y.; Wang, X.; Yu, L.; Guo, C.; Zhang, J.; Bai, B.; Sun, D.; Fan, S. Surface molecularly imprinted magnetic MOFs: A novel platform coupled with magneto electrode for high throughput electrochemical sensing analysis of oxytetracycline in foods. Food Chem. 2021, 363, 130337. [Google Scholar] [CrossRef]

- Reynoso, E.C.; Torres, E.; Bettazzi, F.; Palchetti, I. Trends and Perspectives in Immunosensors for Determination of Currently-Used Pesticides: The Case of Glyphosate, Organophosphates, and Neonicotinoids. Biosensors 2019, 9, 20. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Kim, K.H.; Deep, A. Recent advancements in sensing techniques based on functional materials for organophosphate pesticides. Biosens. Bioelectron. 2015, 70, 469–481. [Google Scholar] [CrossRef]

- Motaharian, A.; Motaharian, F.; Abnous, K.; Hosseini, M.R.; Hassanzadeh-Khayyat, M. Molecularly imprinted polymer nanoparticles-based electrochemical sensor for determination of diazinon pesticide in well water and apple fruit samples. Anal. Bioanal. Chem. 2016, 408, 6769–6779. [Google Scholar] [CrossRef]

- Toro, M.J.U.; Marestoni, L.D.; Sotomayor, M.D.P.T. A new biomimetic sensor based on molecularly imprinted polymers for highly sensitive and selective determination of hexazinone herbicide. Sens. Actuators B 2015, 208, 299–306. [Google Scholar] [CrossRef]

- Gholivand, M.B.; Karimian, N.; Malekzadeh, G. Computational design and synthesis of a high selective molecularly imprinted polymer for voltammetric sensing of propazine in food samples. Talanta 2012, 89, 513–520. [Google Scholar] [CrossRef] [PubMed]

- Aghoutane, Y.; Diouf, A.; Osterlund, L.; Bouchikhi, B.; El Bari, N. Development of a molecularly imprinted polymer electrochemical sensor and its application for sensitive detection and determination of malathion in olive fruits and oils. Bioelectrochemistry 2020, 132, 107404. [Google Scholar] [CrossRef] [PubMed]

- Ghorbani, A. Detection of Chloridazon in Aqueous Matrices Using a Nano- Sized Chloridazon-Imprinted Polymer-Based Voltammetric Sensor. Int. J. Electrochem. Sci. 2020, 15, 2913–2922. [Google Scholar] [CrossRef]

- Wong, A.; Foguel, M.V.; Khan, S.; Oliveira, F.M.d.; Tarley, C.R.T.; Sotomayor, M.D.P.T. Development of an Electrochemical Sensor Modified with Mwcnt-Cooh and Mip for Detection of Diuron. Electrochim. Acta 2015, 182, 122–130. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Liu, J.; Zhang, Y.; Gu, M.; Wang, D.; Dang, Y.Y.; Ye, B.C.; Li, Y. A robust electrochemical sensing platform using carbon paste electrode modified with molecularly imprinted microsphere and its application on methyl parathion detection. Biosens. Bioelectron. 2018, 106, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Amatatongchai, M.; Sroysee, W.; Sodkrathok, P.; Kesangam, N.; Chairam, S.; Jarujamrus, P. Novel three-Dimensional molecularly imprinted polymer-coated carbon nanotubes (3D-CNTs@MIP) for selective detection of profenofos in food. Anal. Chim. Acta 2019, 1076, 64–72. [Google Scholar] [CrossRef]

- Mupunga, I.; Lebelo, S.L.; Mngqawa, P.; Rheeder, J.P.; Katerere, D.R. Natural occurrence of aflatoxins in peanuts and peanut butter from Bulawayo, Zimbabwe. J. Food Prot. 2014, 77, 1814–1818. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Ryu, D. Worldwide Occurrence of Mycotoxins in Cereals and Cereal-Derived Food Products: Public Health Perspectives of Their Co-occurrence. J. Agric. Food Chem. 2017, 65, 7034–7051. [Google Scholar] [CrossRef]

- Luo, S.; Du, H.; Kebede, H.; Liu, Y.; Xing, F. Contamination status of major mycotoxins in agricultural product and food stuff in Europe. Food Control 2021, 127, 108120. [Google Scholar] [CrossRef]

- Radi, A.E.; Eissa, A.; Wahdan, T. Molecularly Imprinted Impedimetric Sensor for Determination of Mycotoxin Zearalenone. Electroanalysis 2020, 32, 1788–1794. [Google Scholar] [CrossRef]

- Pacheco, J.G.; Castro, M.; Machado, S.; Barroso, M.F.; Nouws, H.P.A.; Delerue-Matos, C. Molecularly imprinted electrochemical sensor for ochratoxin A detection in food samples. Sens. Actuators B 2015, 215, 107–112. [Google Scholar] [CrossRef]

- Li, W.; Diao, K.; Qiu, D.; Zeng, Y.; Tang, K.; Zhu, Y.; Sheng, Y.; Wen, Y.; Li, M. A highly-sensitive and selective antibody-like sensor based on molecularly imprinted poly(L-arginine) on COOH-MWCNTs for electrochemical recognition and detection of deoxynivalenol. Food Chem. 2021, 350, 129229. [Google Scholar] [CrossRef] [PubMed]

- Hatamluyi, B.; Rezayi, M.; Beheshti, H.R.; Boroushaki, M.T. Ultra-sensitive molecularly imprinted electrochemical sensor for patulin detection based on a novel assembling strategy using Au@Cu-MOF/N-GQDs. Sens. Actuators B 2020, 318, 128219. [Google Scholar] [CrossRef]

- Ishidate, M., Jr.; Sofuni, T.; Yoshikawa, K.; Hayashi, M.; Nohmi, T.; Sawada, M.; Matsuoka, A. Primary mutagenicity screening of food additives currently used in Japan. Food Chem. Toxicol. 1984, 22, 623–636. [Google Scholar] [CrossRef]

- Carocho, M.; Morales, P.; Ferreira, I.C.F.R. Natural food additives: Quo vadis? Trends Food Sci. Technol. 2015, 45, 284–295. [Google Scholar] [CrossRef] [Green Version]

- Qin, C.; Guo, W.; Liu, Y.; Liu, Z.; Qiu, J.; Peng, J. A Novel Electrochemical Sensor Based on Graphene Oxide Decorated with Silver Nanoparticles–Molecular Imprinted Polymers for Determination of Sunset Yellow in Soft Drinks. Food Anal. Methods 2017, 10, 2293–2301. [Google Scholar] [CrossRef]

- Yue, X.; Luo, X.; Zhou, Z.; Bai, Y. Selective electrochemical determination of tertiary butylhydroquinone in edible oils based on an in-situ assembly molecularly imprinted polymer sensor. Food Chem. 2019, 289, 84–94. [Google Scholar] [CrossRef]

- Li, L.; Zheng, H.; Guo, L.; Qu, L.; Yu, L. A sensitive and selective molecularly imprinted electrochemical sensor based on Pd-Cu bimetallic alloy functionalized graphene for detection of amaranth in soft drink. Talanta 2019, 197, 68–76. [Google Scholar] [CrossRef]

- Xiao, D.; Jiang, Y.; Bi, Y. Molecularly imprinted polymers for the detection of illegal drugs and additives: A review. Microchim. Acta 2018, 185, 247. [Google Scholar] [CrossRef]

- Fu, C.; Liu, C.; Li, Y.; Guo, Y.; Luo, F.; Wang, P.; Guo, L.; Qiu, B.; Lin, Z. Homogeneous Electrochemical Biosensor for Melamine Based on DNA Triplex Structure and Exonuclease III-Assisted Recycling Amplification. Anal. Chem. 2016, 88, 10176–10182. [Google Scholar] [CrossRef] [PubMed]

- Giroto, A.S.; Garcia, R.H.S.; Colnago, L.A.; Klamczynski, A.; Glenn, G.M.; Ribeiro, C. Role of urea and melamine as synergic co-plasticizers for starch composites for fertilizer application. Int. J. Biol. Macromol. 2020, 144, 143–150. [Google Scholar] [CrossRef] [PubMed]

- Rovina, K.; Siddiquee, S. Electrochemical sensor based rapid determination of melamine using ionic liquid/zinc oxide nanoparticles/chitosan/gold electrode. Food Control 2016, 59, 801–808. [Google Scholar] [CrossRef]

- Yu, C.; Li, L.; Ding, Y.; Liu, H.; Cui, H.; Zhang, F.; Lin, J.; Duan, Y. A sensitive molecularly imprinted electrochemical aptasensor for highly specific determination of melamine. Food Chem. 2021, 363, 130202. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.Y.; Ha, W.; Shi, Y.P. Sensitive colorimetric detection of melamine in processed raw milk using asymmetrically PEGylated gold nanoparticles. Talanta 2019, 194, 475–484. [Google Scholar] [CrossRef]

- Rao, H.; Chen, M.; Ge, H.; Lu, Z.; Liu, X.; Zou, P.; Wang, X.; He, H.; Zeng, X.; Wang, Y. A novel electrochemical sensor based on Au@PANI composites film modified glassy carbon electrode binding molecular imprinting technique for the determination of melamine. Biosens. Bioelectron. 2017, 87, 1029–1035. [Google Scholar] [CrossRef]

- Zhang, B.; Fan, X.; Zhao, D. Computer-Aided Design of Molecularly Imprinted Polymers for Simultaneous Detection of Clenbuterol and Its Metabolites. Polymers 2018, 11, 17. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Tian, L.; Zhang, X.; Sun, Z.; Shan, X.; Wu, Q.; Chen, R.; Lu, J. A novel molecularly imprinted polymer electrochemiluminescence sensor based on Fe2O3@Ru(bpy)32+ for determination of clenbuterol. Sens. Actuators B 2022, 350, 130822. [Google Scholar] [CrossRef]

- Sinkkonen, S.; Paasivirta, J. Degradation half-life times of PCDDs, PCDFs and PCBs for environmental fate modeling. Chemosphere 2000, 40, 943–949. [Google Scholar] [CrossRef]

- Weber, R.; Bell, L.; Watson, A.; Petrlik, J.; Paun, M.C.; Vijgen, J. Assessment of pops contaminated sites and the need for stringent soil standards for food safety for the protection of human health. Environ. Pollut. 2019, 249, 703–715. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, Y.; Yang, R.; Li, J.; Qu, L. A highly sensitive and selective electrochemical sensor based on polydopamine functionalized graphene and molecularly imprinted polymer for the 2,4-dichlorophenol recognition and detection. Talanta 2019, 195, 691–698. [Google Scholar] [CrossRef]

- Zheng, X.; Li, H.; Xia, F.; Tian, D.; Hua, X.; Qiao, X.; Zhou, C. An Electrochemical Sensor for Ultrasensitive Determination the Polychlorinated Biphenyls. Electrochim. Acta 2016, 194, 413–421. [Google Scholar] [CrossRef]

- McLaughlin, M.J.; Hamon, R.E.; McLaren, R.G.; Speir, T.W.; Rogers, S.L. Review: A bioavailability-based rationale for controlling metal and metalloid contamination of agricultural land in Australia and New Zealand. Aust. J. Soil Res. 2000, 38, 1037–1086. [Google Scholar] [CrossRef]

- Dahaghin, Z.; Kilmartin, P.A.; Mousavi, H.Z. Novel ion imprinted polymer electrochemical sensor for the selective detection of lead(II). Food Chem. 2020, 303, 125374. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, T.; Hamidi, N.; Ganjali, M.R.; Rafiei, F. Determination of subnanomolar levels of mercury (II) by using a graphite paste electrode modified with MWCNTs and Hg(II)-imprinted polymer nanoparticles. Microchim. Acta 2017, 185, 16. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Chang, Q.; Zhao, J.; Ye, B.C. Novel electrochemical sensing platform based on ion imprinted polymer with nanoporous gold for ultrasensitive and selective determination of As(3). Microchim. Acta 2020, 187, 571. [Google Scholar] [CrossRef]

- Samandari, L.; Bahrami, A.; Shamsipur, M.; Farzin, L.; Hashemi, B. Electrochemical preconcentration of ultra-trace Cd2+ from environmental and biological samples prior to its determination using carbon paste electrode impregnated with ion imprinted polymer nanoparticles. Int. J. Environ. Anal. Chem. 2019, 99, 172–186. [Google Scholar] [CrossRef]

- Alizadeh, T.; Mirzaee, S.; Rafiei, F. All-solid-state Cr(III)-selective potentiometric sensor based on Cr(III)-imprinted polymer nanomaterial/MWCNTs/carbon nanocomposite electrode. Int. J. Environ. Anal. Chem. 2017, 97, 1283–1297. [Google Scholar] [CrossRef]

| Preparation Methods | Advantages | Disadvantages | Ref. |

|---|---|---|---|

| Bulk polymerization | Simple, rapid, cheap, robust, resistant to harsh environments, and does not require a sophisticated or expensive analytical instrument. | Irregular morphology, low yield, template leakage, binding sites deeply buried, destroyed binding sites. | [26,27,28,29,30] |

| Suspension polymerization | Regular particles. | Poor recognition, polydisperse size, and polarity solvent interfere with the imprinting process. | [30,31,32] |

| Emulsion polymerization | High specific surface area, regular shape, size, good dispersity, narrow particle distribution, water-soluble. | Low binding capacity. | [33,34,35] |

| Precipitation polymerization | No stabilizers, simple, good yields, less time, small and uniform size, and suitable im-print of different compounds. | High dilution conditions, careful adjustment of the synthetic parameters, and a large porogen volume. | [36,37,38] |

| Surface imprinting | Uniform and controllable particle size, good selectivity and stability, high adsorption capacity, fast mass transfer and binding kinetics, and good reproducibility. | Limited surface areas. | [25,39,40] |

| Class | Electrochemical Techniques | Functional Monomer | Target | Polymerization Method | Transducer (Modified) | Sample | LOD (mol/L) | Linear Range (mol/L) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Aminoglycosides | CV | o-phenylenediamine | Kanamycin | Electropoly-merization | GCE-SWCNH-COOH | Water | 1.0 × 10−5 | 1.0-5.0 × 10−5 | [77] |

| CV and DPV | MAA | Kanamycin | Surface imprinting | GCE-CNT (Fe3O4) | Chicken/liver, pig/liver, milk | 2.3 × 10−11 | 1.0 × 10−10–1.0 × 10−6 | [75] | |

| DPV | Pyrrole-3-carboxylic acid | Streptomycin | Electropolymerization | GCE (PPy3C/ERGO) | Porcine kidney, honey | 0.5 × 10−9 | 0.2–8.0 × 10−8, 0.08–1.0 × 10−6 | [78] | |

| SWV | o-phenylenediamine | Streptomycin | One-pot method | ITO | Milk, honey | 1.72 × 10−10 | 8.6 × 10−8–3.44 × 10−5 | [79] | |

| Amphenicols | DPV | C16VimCl | Chloramphenicol | Surface imprinting | GCE (P-r-GO, CKM-3) | Milk, honey | 1.0 × 10−10 | 5.0 × 10−9–5.0 × 10−7, 5.0 × 10−7–4.0 × 10−6 | [80] |

| β-lactams | CV | Acrylamide | Amoxicillin | Bulk polymerization | SPE | Water | 1.89 ± 1.03 × 10−9; 0.54 ± 0.1 × 10−9 | 0.01–5 × 10−7 | [81] |

| CV | o-phenylenediamine | Ampicillin | Electropolymerization | GCE (Au NPs/SWCNTs) | Milk | 1.0 × 10−9 | 5.0 × 10−8–1.0 × 10−5 | [82] | |

| DPV | MAA | Cloxacillin | Bulk polymerization | SPCE (GO-Au NPs) | Milk | 3.6 × 10−8 | 1.1–7.5 × 10−7 | [83] | |

| Fluoroquinolones | CV | MAA | Ciprofloxacin | Bulk polymerization | GCE (Ch-AuNP) | Water, milk, pharmaceuticals | 2.1 × 10−7 | 0.01–1 × 10−4 | [43] |

| CV and SWV | Pyrrole and o-phenylenediamine | Enrofloxacin | Electropolymerization | PGE | Pharmaceuticals | 6.57 × 10−13 | 1.0 × 10−4–1.0 × 10−10 | [84] | |

| CV | Pyrrole | Norfloxacin | Electropolymerization | GCE (CoFe-MOFs/Au NPs) | Milk | 1.31 × 10−13 | 0.05–1.0 × 10−10, 0.1–1.0 × 10−9, 1.0–6.0 × 10−9 | [85] | |

| Macrolides | DPV | 4-ABA | Azithromycin | Electropolymerization | SPCE | Water | 8.0 × 10−8 | 0.05–1.0 × 10−5 | [86] |

| CV | m-phenylenediamine | Erythromycin | Electropolymerization | SPE | Water | 1.0 × 10−10 | 0.2–1.6 × 10−8 | [76] | |

| Tetracyclines | CV | Dopamine and oligonucleotides | Tetracycline | Electropolymerization | GCE (Au NPs) | Milk | 1.44 × 10−13 | 5.0 × 10−9–1.0 × 10−7, 1.0 × 10−9–1.0 × 10−6 | [87] |

| DPV | 3-Aminopropyltriethoxysiloxane | Oxytetracycline | Surface imprinting polymerization | Magneto electrode | Milk | __ | 2.17 × 10−9–2.17 × 10−4 | [88] |

| Electrochemical Techniques | Functional Monomer | Target | Polymerization Method | Transducer (Modified) | Sample | LOD (mol/L) | Linear Range (mol/L) | Ref. |

|---|---|---|---|---|---|---|---|---|

| CV and SWV | methylpropenoic acid | diazinon | Suspension polymerization | CPE | Well water, apple fruit | 7.9 × 10−10 | 2.5 × 10−9–1.0 × 10−7, 1.0 × 10−7–2.0 × 10−6 | [91] |

| DPV | 2-vinylpyridine | hexazinone | Noncovalent approach | CPE | Water | 2.6 × 10−12 | 1.9 × 10−11–1.1 × 10−10 | [92] |

| DPV | acrylamide | propazine | Precipitation polymerization | CPE | Onion, tomato, lettuce | 1.0 × 10−9 | 0.01–1.0 × 10−6, 0.1–5.5 × 10−5 | [93] |

| CV and DPV | acrylamide | malathion | Deposition polymerization | SPE (Au NPs) | Olive oils, fruits | 1.8 × 10−11 | 3.0 × 10−13–3 × 10−9 | [94] |

| CV and DPV | Aminobenzoic acid | carbofuran | Electropolymerization | GCE (Au NPs) | Vegetable | 2.4 × 10−8 | 5.0 × 10−8–4.0 × 10−4 | [17] |

| DPV | methacrylic acid, vinyl benzene | chloridazon | Precipitation polymerization | CPE (MWCNT) | Water | 6.2 × 10−8 | 5.7 × 10−7–4.0 × 10−4 | [95] |

| SWV | MAA | diuron | Bulk polymerization | CPE (MWCNT-COOH) | Water | 9.0 × 10−9 | 5.2 × 10−8–1.25 × 10−6 | [96] |

| CV | MAA | methyl parathion | Precipitation polymerization | CPE | Soil, vegetable | 3.4 × 10−13 | 1.0 × 10−12–8.0 × 10−9 | [97] |

| CV | MAA | paraoxon | Surface imprinting polymerization | GCE (3D-CNTs) | Vegetable | 2 × 10−9 | 1.010−8–2 × 10−4 | [98] |

| Electrochemical Techniques | Functional Monomer | Target | Polymerization Method | Transducer (Modified) | Sample | LOD (mol/L) | Linear Range (mol/L) | Ref. |

|---|---|---|---|---|---|---|---|---|

| DPV | Aniline | AFB1, FuB1 | Chemical oxidative polymerization | A–ITO, F–ITO | Corn | 1.0 × 10−12 (AFB1), 4.6 × 10−13 (FuB1) | 3.2 × 10−12–1.6 × 10−9 (AFB1), 1.4 × 10−12–7.0 × 10−10 (FuB1) | [21] |

| CV | o–phenylenediamine | Zearalenone | Electropolymerization | SPGE | Corn flakes | 6.3 × 10−10 | 7.85 × 10−9–6.28 × 10−7 | [102] |

| DPV | pyrrole | ochratoxin A | Electropolymerization | GCE (MWCNTs) | Spiked beer, wine | 4.1 × 10−9 | 0.05–1.0 × 10−6 | [103] |

| CV | L–arginine | deoxynivalenol | Electropolymerization | GCE (COOH–MWCNTs) | Wheat flour | 7.0 × 10−8 | 1.0 × 10−7–7.0 × 10−5 | [104] |

| DPV | aniline | patulin | Electropolymerization | GCE (Au@Cu–MOF/N–GQDs) | Apple juice | 4.6 × 10−12 | 6.5 × 10−12–4.6 × 10−7 | [105] |

| Electrochemical Techniques | Functional Monomer | Target | Polymerization Method | Electrode (Modified) | Sample | LOD (mol/L) | Linear Range (mol/L) | Ref. |

|---|---|---|---|---|---|---|---|---|

| CV | 4–vinyl pyridine | Pb2+ | Suspension polymerization | GCE | Water, fruit juice | 2.4 × 10−10 | 4.8 × 10−10–3.5 × 10−7 | [125] |

| SWV | Itaconic acid | Hg2+ | Precipitation polymerization | CPE | Water | 2.9 × 10−11 | 1.0 × 10−10–2.0 × 10−8 | [126] |

| CV | o–phenylenediamine | AS3+ | Electropolymerization | GE (IIP–NPG) | Water | 7.1 × 10−12 | 2.0 × 10−11–9.0 × 10−9 | [127] |

| DPV | MAA | Cd2+ | Bulk polymerization | CPE (IIP) | Spiked water, rice, blood | 1.99 × 10−9 | 4.0 × 10−9–5.0 × 10−7 | [128] |

| ISEs | Itaconic acid | Cr3+ | Thermal polymerization | CPE (IIP–MWCNTs) | Sea, river water, soil | 5.9 × 10−7 | 1.0 × 10−6–1.0 × 10−1 | [129] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, Y.; Duan, J.; Wang, M.; Cao, J.; She, Y.; Cao, Z.; Li, G.; Jin, F.; Wang, J.; Abd El-Aty, A.M. Application of Molecularly Imprinted Electrochemical Biomimetic Sensors for Detecting Small Molecule Food Contaminants. Polymers 2023, 15, 187. https://doi.org/10.3390/polym15010187

Shao Y, Duan J, Wang M, Cao J, She Y, Cao Z, Li G, Jin F, Wang J, Abd El-Aty AM. Application of Molecularly Imprinted Electrochemical Biomimetic Sensors for Detecting Small Molecule Food Contaminants. Polymers. 2023; 15(1):187. https://doi.org/10.3390/polym15010187

Chicago/Turabian StyleShao, Yunling, Jiaqi Duan, Miao Wang, Jing Cao, Yongxin She, Zhen Cao, Guangyue Li, Fen Jin, Jing Wang, and A. M. Abd El-Aty. 2023. "Application of Molecularly Imprinted Electrochemical Biomimetic Sensors for Detecting Small Molecule Food Contaminants" Polymers 15, no. 1: 187. https://doi.org/10.3390/polym15010187