Lead Free Multilayered Polymer Composites for Radiation Shielding

Abstract

:1. Introduction

2. Materials and Methods

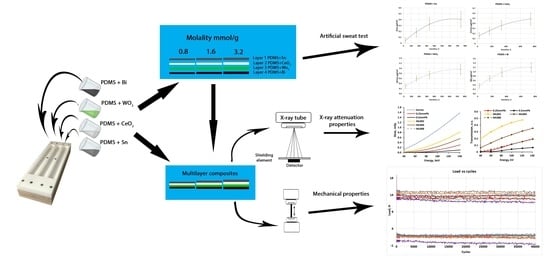

2.1. Fabrication of Experimental Samples

2.2. Material Characterization

2.3. Analysis of Experimental Samples

2.3.1. Evaluation of X-ray Attenuation Properties

2.3.2. Tensile Tests of Experimental Samples

2.3.3. Artificial Sweat Test

3. Results and Discussion

3.1. X-ray Attenuation Properties

3.2. Results of Tension Examinations

3.3. Results of Artificial Sweat Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Halankar, J.; Jhaveri, K.; Metser, U. A simple quality control tool for assessing integrity of lead equivalent aprons. Indian J. Radiol. Imaging 2017, 28, 167–176. [Google Scholar] [CrossRef]

- Jones, A.K.; Wagner, L. On the (f)utility of measuring the lead equivalence of protective garments. Med. Phys. 2013, 40, 113. [Google Scholar] [CrossRef]

- Mehnati, P.; Malekzadeh, R.; Sooteh, M.Y. Application of personal non-lead nano-composite shields for radiation protection in diagnostic radiology: A systematic review and meta-analysis. Nanomed. J. 2020, 7, 170–182. [Google Scholar]

- Dubey, K.A.; Chaudhari, C.V.; Suman, S.K.; Raje, N.; Mondal, R.K.; Grover, V.; Murali, S.; Bhardwaj, Y.K.; Varshney, L. Synthesis of flexible polymeric shielding materials for soft gamma rays: Physicomechanical and attenuation characteristics of radiation crosslinked polydimethylsiloxane/Bi2O3 composites. Polym. Compos. 2014, 37, 756–762. [Google Scholar] [CrossRef]

- AbuAlRoos, N.J.; Amin, N.A.B.; Zainon, R. Conventional and new lead-free radiation shielding materials for radiation protection in nuclear medicine: A review. Radiat. Phys. Chem. 2019, 165, 108439. [Google Scholar] [CrossRef]

- Kim, Y.; Park, S.; Seo, Y. Enhanced X-ray shielding ability of polymer-nonleaded instead of toxic lead metal composites by multilayer structuring. Ind. Eng. Chem. Res. 2015, 54, 5968–5973. [Google Scholar] [CrossRef]

- Dejangah, M.; Ghojavand, M.; Poursalehi, R.; Gholipour, P.R. X-ray attenuation and mechanical properties of tungsten-silicone rubber nanocomposites. Mater. Res. Express 2019, 6, 085045. [Google Scholar] [CrossRef]

- Kang, J.H.; Oh, S.H.; Oh, J.I.; Kim, S.H.; Choi, Y.S.; Hwang, E.H. Protection evaluation of non-lead radiation-shielding fabric: Preliminary exposure-dose study. Oral Radiol. 2018, 35, 1–6. [Google Scholar] [CrossRef]

- Toyen, D.; Rittirong, A.; Poltabtim, W.; Saenboonruang, K. Flexible lead-free, gamma shielding materials based on natural rubber/metal oxide composites. Iran. Polym. J. 2018, 27, 33–41. [Google Scholar] [CrossRef]

- Chai, H.; Tang, X.; Ni, M.; Chen, F.; Zhang, Y.; Chen, D.; Qiu, Y. Preparation and properties of novel, flexible, lead-free X-ray-shielding materials containing tungsten and bismuth(III) oxide. J Appl Polym Sci. 2016, 133, 43012–43019. [Google Scholar] [CrossRef]

- Nambiar, S.; Osei, E.K.; Yeow, J.T. Polymer nanocomposite based shielding against diagnostic X-rays. J. Appl. Polym. Sci. 2013, 127, 4939–4946. [Google Scholar] [CrossRef]

- Sonsilphong, A.; Wongkasem, N. Light-weight radiation protection by non-lead materials in X-ray regimes. In Proceedings of the 2014 International Conference on Electromagnetics in Advanced Applications (ICEAA), Palm Beach, Aruba, 3–8 August 2014; pp. 656–658. [Google Scholar] [CrossRef]

- Kim, S.C.; Choi, J.R.; Jeon, B.K. Physical analysis of the shielding capacity for a lightweight apron designed for shielding low intensity scattering X-rays. Sci. Rep. 2016, 6, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Atxaga, R.O.G.; Marcos, J.; Jurado, M.; Carapelle, A.; Orava, R. Radiation shielding of composite space enclosures. Proc. Int. Astronaut. Congr. IAC 2012, 8, 6658–6667. [Google Scholar]

- Nambiar, S.; Yeow, J.T.W. Polymer-composite materials for radiation protection. ACS Appl. Mater. Interfaces 2012, 4, 5717–5726. [Google Scholar] [CrossRef]

- Labouriau, A.; Cady, C.; Gill, J.; Stull, J.; Ortiz-Acosta, D.; Henderson, K.; Hartung, V.; Quintana, A.; Celina, M. Gamma Irradiation and Oxidative Degradation of a Silica-Filled Silicone Elastomer. Polym. Degrad. Stab. 2015, 116, 62–74. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Liu, Q.; Ao, Y.; Wang, P.; Huang, W.; Chen, H. Gamma Irradiation-Induced Degradation of Silicone Encapsulation. Mater. Today Commun. 2022, 31, 103476. [Google Scholar] [CrossRef]

- Advances in Radiation Chemistry of Polymers. Available online: http://pc.ch.bme.hu/oktatas/konyvek/fizkem/Fizikai%20kemia_MSc_MuaSzal/2019%20osz_archiv/ea/Sugkh%20Ajanlott%20irodalom/TE_1420_web.pdf#page=29 (accessed on 30 March 2022).

- Consolidated Text: Council Directive 2013/59/Euratom of 5 December 2013 Laying Down Basic Safety Standards for Protection Against the Dangers Arising From Exposure to Ionising Radiation, and Repealing Directives 89/618/Euratom, 90/641/Euratom, 96/29/Euratom, 97/43/Euratom and 2003/122/Euratom. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02013L0059-20140117 (accessed on 30 March 2022).

- Li, Q.; Wei, Q.; Zheng, W.; Zheng, Y.; Okosi, N.; Wang, Z.; Su, M. Enhanced radiation shielding with conformal light-weight nanoparticle-polymer composite. ACS Appl. Mater. Interfaces 2018, 10, 35510–35515. [Google Scholar] [CrossRef]

- McCaffrey, J.P.; Mainegra-Hing, E.; Shen, H. Optimizing non-Pb radiation shielding materials using bilayers. Med. Phys. 2009, 36, 5586–5594. [Google Scholar] [CrossRef]

- Lim-aroon, P.; Wimolmala, E.; Sombatsompop, N.; Saenboonruang, K. Manufacturing process and properties of lead-free natural rubber sponge for use in X-ray and gamma ray shielding applications. IOP Conf. Ser. Mater. Sci. Eng. 2019, 526, 012015. [Google Scholar] [CrossRef]

- Kim, S.-C. Analysis of Shielding Performance of Radiation-Shielding Materials According to Particle Size and Clustering Effects. Appl. Sci. 2021, 11, 4010. [Google Scholar] [CrossRef]

- Adlienė, D.; Gilys, L.; Griškonis, E. Development and characterization of new tungsten and tantalum containing composites for radiation shielding in medicine. Nucl. Inst. Methods Phys. Res. B 2020, 467, 21–26. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.; Kim, Y.; Kim, E.; Seo, Y. Multilayer-Structured Non-leaded Metal/Polymer Composites for Enhanced X-ray Shielding. MRS Adv. 2018, 3, 1789–1797. [Google Scholar] [CrossRef]

- Kazemi, F.; Malekie, S. A Monte Carlo study on the shielding properties of a novel polyvinyl alcohol (PVA)/WO3 composite, against gamma rays, using the MCNPX code. J. Biomed. Phys. Eng. 2019, 9, 465. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.S.; Moon, J.H. Use of a genetic algorithm in the search for a near-optimal shielding design. Ann. Nucl. Energy 2010, 37, 120–129. [Google Scholar] [CrossRef]

- Cai, Y.; Hu, H.; Pan, Z.; Hu, G.; Zhang, T. A method to optimize the shield compact and lightweight combining the structure with components together by genetic algorithm and MCNP code. App. Rad. Isot. 2018, 139, 169–174. [Google Scholar] [CrossRef]

- Daneshvar, H.; Milan, K.G.; Sadr, A.; Sedighy, S.H.; Malekie, S.; Mosayebi, A. Multilayer radiation shield for satellite electronic components. Sci. Rep. 2021, 11, 20657. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Zhang, X.; Gao, Y.; Guo, S. High-efficiency, flexibility and lead-free X-ray shielding multilayered polymer composites: Layered structure design and shielding mechanism. Sci. Rep. 2021, 11, 4384. [Google Scholar] [CrossRef]

- Chohanhttps, J.S.; Boparaib, K.S.; Singhhttps, R.; Hashmie, M.S.J. Manufacturing techniques and applications of polymer matrix composites: A brief review. Adv. Mater. Process. Technol. 2020, 1–11. [Google Scholar] [CrossRef]

- Sazali1, M.A.; Rashid, N.K.A.; Hamzah, K. A review on multilayer radiation shielding. IOP Conf. Ser. Mater. Sci. Eng. 2019, 555, 012008. [Google Scholar] [CrossRef]

- Li, D.; Jia, D.; Yang, Z.; Zhou, Y. Principles, Design, Structure and Properties of Ceramics for Microwave Absorption or Transmission at High-Temperatures. Int. Mater. Rev. 2022, 67, 266–297. [Google Scholar] [CrossRef]

- Nation Institute of Standarts and Technology, Physical Meas. Laboratory, XCOM. Available online: https://physics.nist.gov/PhysRefData/Xcom/html/xcom1.html (accessed on 30 March 2022).

- Chalmers, G.J. Structural shielding design for medical imaging X-ray facilities (NCRP Report No 147). Phys. Med. Biol. 2005, 50, 4243–4244. [Google Scholar] [CrossRef]

- Radiation Protection in Radiology—Large Facilities Safety Procedures for the Installation, Use and Control of X-ray Equipment in Large Medical Radiological Facilities Safety Code 35. Available online: https://publications.gc.ca/collections/collection_2009/sc-hc/H128-1-08-545E.pdf (accessed on 30 March 2022).

- Miller, D.L.; Vañó, E.; Bartal, G.; Balter, S.; Dixon, R.; Padovani, R.; Schueler, B.; Cardella, J.F.; de Baère, T. Occupational radiation protection in interventional radiology (CIRSE GUIDELINES). Cardiovasc. Intervent. Radiol. 2010, 33, 230–239. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Metal Molality, mmol/g | Number of Metal Moles | Monolayer Weight, g | |||

|---|---|---|---|---|---|

| Layer 1 PDMS + Sn | Layer 2 PDMS + CeO2 | Layer 3 PDMS + WO3 | Layer 4 PDMS + WO3 | ||

| 0.8 | 0.002 | 2.5 + 0.236 | 2.5 + 0.344 | 2.5 + 0.464 | 2.5 + 0.418 |

| 1.6 | 0.004 | 2.5 + 0.473 | 2.5 + 0.688 | 2.5 + 0.927 | 2.5 + 0.836 |

| 3.2 | 0.008 | 2.5 + 0.945 | 2.5 + 1.377 | 2.5 + 1.855 | 2.5 + 1.672 |

| Molality, mmol/g | Thickness, mm | ||||

|---|---|---|---|---|---|

| Layer 1 PDMS + Sn | Layer 2 PDMS + CeO2 | Layer 3 PDMS + WO3 | Layer 4 PDMS + Bi | Multilayer | |

| 0.8 | 0.695 | 0.912 | 0.730 | 0.731 | 3.949 |

| 1.6 | 0.888 | 1.033 | 0.801 | 0.873 | 4.031 |

| 3.2 | 0.919 | 1.072 | 0.847 | 1.006 | 4.161 |

| Polymer Composite | Molality, mmol/g | Density, g/cm3 | Area Density, g/cm2 |

|---|---|---|---|

| PDMS + Sn | 0.8 | 1.082 | 0.114 |

| 1.6 | 1.158 | 0.124 | |

| 3.2 | 1.312 | 0.144 | |

| PDMS + CeO2 | 0.8 | 1.115 | 0.118 |

| 1.6 | 1.228 | 0.133 | |

| 3.2 | 1.440 | 0.162 | |

| PDMS + WO3 | 0.8 | 1.154 | 0.123 |

| 1.6 | 1.304 | 0.143 | |

| 3.2 | 1.577 | 0.181 | |

| PDMS + Bi | 0.8 | 1.148 | 0.122 |

| 1.6 | 1.292 | 0.139 | |

| 3.2 | 1.562 | 0.174 | |

| Multilayer | 0.8 | 1.125 | - |

| 1.6 | 1.246 | - | |

| 3.2 | 1.474 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gilys, L.; Griškonis, E.; Griškevičius, P.; Adlienė, D. Lead Free Multilayered Polymer Composites for Radiation Shielding. Polymers 2022, 14, 1696. https://doi.org/10.3390/polym14091696

Gilys L, Griškonis E, Griškevičius P, Adlienė D. Lead Free Multilayered Polymer Composites for Radiation Shielding. Polymers. 2022; 14(9):1696. https://doi.org/10.3390/polym14091696

Chicago/Turabian StyleGilys, Laurynas, Egidijus Griškonis, Paulius Griškevičius, and Diana Adlienė. 2022. "Lead Free Multilayered Polymer Composites for Radiation Shielding" Polymers 14, no. 9: 1696. https://doi.org/10.3390/polym14091696