1. Introduction

Basalt fibre is a bio-derived mineral fibre from volcanic rocks and has several advantages, such as good chemical resistance and mechanical properties [

1,

2,

3,

4,

5,

6]. Basalt fibre has similar tensile properties as glass fibres and has a higher maximum service temperature than glass and carbon fibres, as shown in

Table 1. This enables basalt fibre composites to be a viable and sustainable alternative to glass fibre composites for structural applications. Moreover, it has a higher maximum service temperature and good chemical resistance, which makes it suitable for applications in harsh environments, such as composite pipes for the oil and gas industries or chemical storage tanks [

1].

Basalt fibre has been studied by several scientists to explore the fibre used as reinforcement for polymer composites [

2,

3,

7,

8,

9,

10,

11]. With good mechanical properties in combination with high temperature and alkaline resistance, basalt fibre is a good candidate for composites with thermoset matrices such as epoxy and polyester. Arshad et al. [

7] reported epoxy hybrid composites having a high resistance to changes in temperature and significant enhanced mechanical performance. Basalt fibre reinforced epoxy composites also demonstrated higher resistance to aging in alkaline medium and heat than those of glass fibre epoxy composites based on E-glass and S-glass fibres, while the mechanical properties of the basalt fibre composites are closer to those that of S-glass composites and greater than those of E-glass composites. These properties are connected to the high adhesion between the basalt fibres and epoxy [

8].

With increasing demand for lightweight, sustainable materials for metal-replacement in various industries, the global thermoplastic composite market has been projected to reach USD 16.3 billion by 2023 [

12]. Thermoplastic composites can be recycled and welded, allowing composites to be part of a circular economy and also offer the possibility of forming large composite structures in a shorter timeframe [

13,

14,

15]. However, the research for thermoplastic composites is less established than that for thermoset composites due to issues such as fibre-matrix compatibility, high processing temperatures, and processing difficulty [

13,

14,

15,

16]. Regarding basalt fibre reinforced thermoplastics BFRTP), most of studies have been focused on short basalt fibre composites with thermoplastic matrices including polypropylene (PP), polypropylene/poly(butylene terephthalate) and poly(vinylidene fluoride)/poly(methyl methacrylate) blends for manufacturing with injection moulding process [

2,

3,

4,

16,

17,

18]. The mechanical properties of the short-fibre composites were limited by the loading of the fibres, in which the fibre loading was recommended at lower than 20% wt. There are also limited fundamental studies to understand the potential of basalt fibre thermoplastic composites by looking into the performance of unidirectional continuous fibre composites for better design for application of the composites.

Other aspects include fibre-matrix compatibility and adhesion. The sizing of commercial continuous basalt fibre was developed for epoxy applications, limiting its mechanical performance. Attempts have been made to improve the fibre-matrix adhesion through the use of different compatibilisers or sizing agents [

18,

19]. Russo et al. [

19] showed that the use of polypropylene-graft-maleic anhydride improved the flexural and impact performance of continuous BF-PP composites. However, the highest flexural strength value achieved was 81.1 MPa, which was significantly lower than the expected strength values of continuous glass fibre thermoplastic composites. This could be due to lower fibre volume fraction or composite quality issues, which were not investigated in the study. Therefore, there is a need to understand the processing of the continuous basalt fibre thermoplastic composites in order to achieve a good quality composite with the consistent and good mechanical performance required for structural applications.

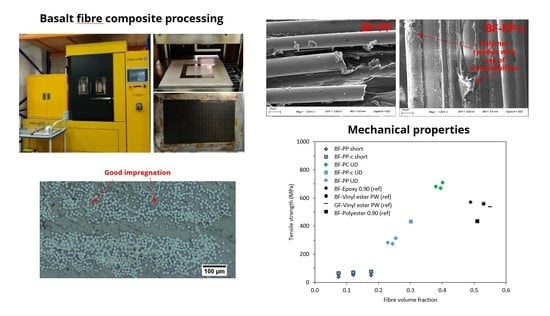

In the present study, a processing study was conducted for the continuous basalt fibre thermoplastic composites to resolve fibre spreading issues and improve matrix impregnation. Basalt fibre is typically sized for epoxy polymers; therefore, polypropylene-graft-maleic anhydride was used as a compatibiliser to improve the fibre-matrix adhesion for basalt fibre-polypropylene (BF-PP) composites. Tensile properties, degree of impregnation, and fibre volume fraction were characterised. Additionally, the effect of compatibiliser on the tensile and impact properties of short BF-PP composites was also studied. Analytical models were used to predict the Young’s modulus values for the short and continuous fibre composites, and the predictions will be compared to the experimental results.

5. Conclusions

Basalt continuous fibre composites with Polypropylene (PP) and Polycarbonate (PC) matrices were fabricated using a compression moulding process and process optimisation was conducted to resolve the fibre spreading issues and improve fibre-matrix impregnation. Drying is critical for BF-PC composites and the modified procedure with a higher pre-consolidation temperature enabled good matrix impregnation into the basalt fibres with minimal fibre movements. For BF-PP composites, a compatibiliser was required to improve fibre-matrix compatibility and improve the tensile strength. Moreover, it was found that the tensile and impact properties for BF-PP short-fibre composites did not increase beyond a fibre loading of 30 wt% if no compatibiliser was used, but the values continued to increase at 40 wt% with the use of compatibiliser. When benchmarked against BF and glass fibre (GF) thermoset composites, a lower fibre volume fraction was obtained for the BFRTP, but the BF-PC composites could achieve comparable mechanical properties. Analytical modelling of the Young’s moduli of the BF-PP short-fibre composites was predicted with the Halpin-Tsai model as compared to the Halpin-Tsai (random) model, indicating induced fibre orientation along the testing direction during processing for short BF-PP composites. The experimental Young’s modulus values reached at least 69% and 81% of the theoretical values for BF-PP and BF-PC composites, respectively, which indicated that BF-PC composites had better stress transfer than BF-PP composites. This study lays the foundation for the processing and basic mechanical properties of basalt fibre thermoplastic composites with PC and PP as the polymer matrix and contributes to the working knowledge of BFRTP for potential future applications in various sectors such as construction, aerospace, and marine.