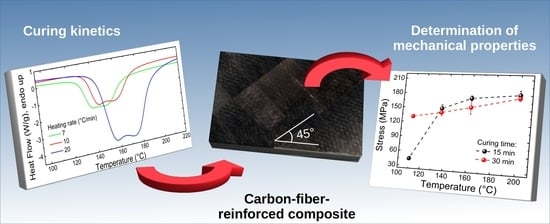

Influence of Epoxy Resin Curing Kinetics on the Mechanical Properties of Carbon Fiber Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Laminates

2.3. Differential Scanning Calorimetry

2.4. Tensile Tests

3. Results and Discussion

3.1. Non-Isothermal Characterization by DSC: Kinetic Parameters

3.2. Residual Conversion Degree

3.3. Influence of the Curing Temperature on the Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wan, Y.; Takahashi, J. Tensile and compressive properties of chopped carbon fiber tapes reinforced thermoplastics with different fiber lengths and molding pressures. Compos. Part A Appl. Sci. Manuf. 2016, 87, 271–281. [Google Scholar] [CrossRef]

- Taketa, I.; Okabe, T.; Kitano, A. Strength improvement in unidirectional arrayed chopped strands with interlaminar toughening. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1174–1178. [Google Scholar] [CrossRef]

- Raimondo, M.; De Nicola, F.; Volponi, R.; Binder, W.; Michael, P.; Russo, S.; Guadagno, L. Self-repairing CFRPs targeted towards structural aerospace applications. Int. J. Struct. Integr. 2016, 7, 656–670. [Google Scholar] [CrossRef]

- Tang, S.; Hu, C. Design, Preparation and Properties of Carbon Fiber Reinforced Ultra-High Temperature Ceramic Composites for Aerospace Applications: A Review. J. Mater. Sci. Technol. 2017, 33, 117–130. [Google Scholar] [CrossRef]

- Sharma, V.K. Influence of amine functionalized multi-walled carbonnanotubes on the mechanical properties of carbonfiber/epoxy composites. Mater. Today Proc. 2021, 37, 2978–2981. [Google Scholar] [CrossRef]

- Vasile, B.S.; Birca, A.C.; Surdu, V.A.; Neacsu, I.A.; Nicoară, A.I. Ceramic composite materials obtained by electron-beam physical vapor deposition used as thermal barriers in the aerospace industry. Nanomaterials 2020, 10, 370. [Google Scholar] [CrossRef] [Green Version]

- Rouway, M.; Boulahia, Z.; Chakhchaoui, N.; Cherkaoui, O.; Omari, L.; Fraija, F. Graphene and Carbone nanotubes reinforced ceramic nanocomposite TiO2-MgO: Experimental and numerical study. Mater. Today Proc. 2020, 30, 809–815. [Google Scholar] [CrossRef]

- Mahajan, Y.R.; Johnson, R. (Eds.) Handbook of Advanced Ceramics and Composites; Springer International Publishing: Cham, Switzerland, 2020; Volume 15, ISBN 978-3-319-73255-8. [Google Scholar]

- Gokhale, A.A.; Prasad, N.E.; Basu, B. (Eds.) Light Weighting for Defense, Aerospace, and Transportation; Indian Institute of Metals Series; Springer: Singapore, 2019; ISBN 978-981-15-1262-9. [Google Scholar]

- Katz-Demyanetz, A.; Popov, V.V.; Kovalevsky, A.; Safranchik, D.; Koptyug, A. Powder-bed additive manufacturing for aerospace application: Techniques, metallic and metal/ceramic composite materials and trends. Manuf. Rev. 2019, 6, 5. [Google Scholar] [CrossRef] [Green Version]

- Feraboli, P.; Peitso, E.; Deleo, F.; Cleveland, T.; Graves, M.; Stickler, P. Characterization of Discontinuous Carbon Fiber/Epoxy Systems for Aerospace Applications: Part I. In Proceedings of the 22nd Annual Technical Conference, American Institute of Aeronautics and Astronautics, Seattle, WA, USA, 17–19 September 2007. [Google Scholar]

- Feraboli, P.; Peitso, E.; Deleo, F.; Cleveland, T.; Stickler, P.B. Characterization of Prepreg-Based Discontinuous Carbon Fiber/Epoxy Systems. J. Reinf. Plast. Compos. 2009, 28, 1191–1214. [Google Scholar] [CrossRef]

- Li, C.; Xian, G.; Li, H. Effect of postcuring immersed in water under hydraulic pressure on fatigue performance of large-diameter pultruded carbon/glass hybrid rod. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1148–1160. [Google Scholar] [CrossRef]

- Li, J.; Mai, Z.; Xie, J.; Lu, Z. Durability of components of FRP-concrete bonded reinforcement systems exposed to chloride environments. Compos. Struct. 2022, 279, 114697. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Sharma, A.; Pandey, A.; Shukla, D.K.; Pandey, K.N. Effect of Self-Healing Dicyclopentadiene Microcapsules on Fracture Toughness of Epoxy. Mater. Today Proc. 2018, 5, 21256–21262. [Google Scholar] [CrossRef]

- Feraboli, P.; Gasco, F.; Wade, B.; Maier, S.; Kwan, R.; Salmon, W.; Masini, A.; Deoto, L.; Reggiani, M. Lamborghini “forged composite®” technology for the suspension arms of the sesto elemento. In Proceedings of the American Society for Composites: 26th Technical Conference, Montreal, QC, Canada, 26–28 September 2011; pp. 1–13. [Google Scholar]

- Wulfsberg, J.; Herrmann, A.; Ziegmann, G.; Lonsdorfer, G.; Stöß, N.; Fette, M. Combination of Carbon Fibre Sheet Moulding Compound and Prepreg Compression Moulding in Aerospace Industry. Procedia Eng. 2014, 81, 1601–1607. [Google Scholar] [CrossRef] [Green Version]

- González González, M.; Cabanelas, J.C.; Baselga, J. Applications of FTIR on epoxy resins-identification, monitoring the curing process, phase separation and water uptake. In Infrared Spectroscopy-Materials Science, Engineering and Technology; Theophanides, T., Ed.; IntechOpen: London, UK, 2012; Volume Voume 2, pp. 261–284. [Google Scholar]

- Parameswaranpillai, J.; Pulikkalparambil, H.; Rangappa, S.M.; Siengchin, S. (Eds.) Epoxy Composites: Fabrication, Characterization and Applications; Wiley: New York, NY, USA, 2021; ISBN 9783527824083. [Google Scholar]

- Patel, A.; Maiorana, A.; Yue, L.; Gross, R.A.; Manas-Zloczower, I. Curing Kinetics of Biobased Epoxies for Tailored Applications. Macromolecules 2016, 49, 5315–5324. [Google Scholar] [CrossRef]

- Groshart, C.P.; Okkerman, P.C.; Pijnenburg, A.M.C.M. Chemical Study on Bisphenol A; Rijkswaterstaat, RIKZ: Den Haag, The Netherlands, 2001. [Google Scholar]

- Mohan, P. A Critical Review: The Modification, Properties, and Applications of Epoxy Resins. Polym. Plast. Technol. Eng. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Bajpai, A.; Davidson, J.R.; Robert, C. Studies on the Modification of Commercial Bisphenol-A-Based Epoxy Resin Using Different Multifunctional Epoxy Systems. Appl. Mech. 2021, 2, 419–430. [Google Scholar] [CrossRef]

- Nikolic, G.; Zlatkovic, S.; Cakic, M.; Cakic, S.; Lacnjevac, C.; Rajic, Z. Fast Fourier Transform IR Characterization of Epoxy GY Systems Crosslinked with Aliphatic and Cycloaliphatic EH Polyamine Adducts. Sensors 2010, 10, 684–696. [Google Scholar] [CrossRef]

- Wu, F.; Zhou, X.; Yu, X. Reaction mechanism, cure behavior and properties of a multifunctional epoxy resin, TGDDM, with latent curing agent dicyandiamide. RSC Adv. 2018, 8, 8248–8258. [Google Scholar] [CrossRef] [Green Version]

- Mphahlele, K.; Ray, S.S.; Kolesnikov, A. Cure kinetics, morphology development, and rheology of a high-performance carbon-fiber-reinforced epoxy composite. Compos. Part B Eng. 2019, 176, 107300. [Google Scholar] [CrossRef]

- Ramírez-Herrera, C.A.; Cruz-Cruz, I.; Jiménez-Cedeño, I.H.; Martínez-Romero, O.; Elías-Zúñiga, A. Influence of the Epoxy Resin Process Parameters on the Mechanical Properties of Produced Bidirectional [±45°] Carbon/Epoxy Woven Composites. Polymers 2021, 13, 1273. [Google Scholar] [CrossRef] [PubMed]

- Macan, J.; Brnardić, I.; Ivanković, M.; Mencer, H.J. DSC study of cure kinetics of DGEBA-based epoxy resin with poly(oxypropylene) diamine. J. Therm. Anal. Calorim. 2005, 81, 369–373. [Google Scholar] [CrossRef]

- Lakho, D.A.; Yao, D.; Cho, K.; Ishaq, M.; Wang, Y. Study of the Curing Kinetics toward Development of Fast-Curing Epoxy Resins. Polym. Plast. Technol. Eng. 2017, 56, 161–170. [Google Scholar] [CrossRef]

- Merad, L.; Cochez, M.; Margueron, S.; Jauchem, F.; Ferriol, M.; Benyoucef, B.; Bourson, P. In-situ monitoring of the curing of epoxy resins by Raman spectroscopy. Polym. Test. 2009, 28, 42–45. [Google Scholar] [CrossRef] [Green Version]

- Hardis, R.; Jessop, J.L.P.; Peters, F.E.; Kessler, M.R. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos. Part A Appl. Sci. Manuf. 2013, 49, 100–108. [Google Scholar] [CrossRef] [Green Version]

- Rogers, M.G. The structure of epoxy resins using NMR and GPC techniques. J. Appl. Polym. Sci. 1972, 16, 1953–1958. [Google Scholar] [CrossRef]

- Sojka, S.A.; Moniz, W.B. The curing of an epoxy resin as followed by carbon-13 NMR spectroscopy. J. Appl. Polym. Sci. 1976, 20, 1977–1982. [Google Scholar] [CrossRef]

- Russo, C.; Fernández-Francos, X.; De la Flor, S. Rheological and Mechanical Characterization of Dual-Curing Thiol-Acrylate-Epoxy Thermosets for Advanced Applications. Polymers 2019, 11, 997. [Google Scholar] [CrossRef] [Green Version]

- Drakonakis, V.M.; Seferis, J.C.; Doumanidis, C.C. Curing Pressure Influence of Out-of-Autoclave Processing on Structural Composites for Commercial Aviation. Adv. Mater. Sci. Eng. 2013, 2013, 356824. [Google Scholar] [CrossRef] [Green Version]

- ASTM E2890-12(2018); Standard Test Method for Kinetic Parameters for Thermally Unstable Materials by Differential Scanning Calorimetry Using the Kissinger Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- ASTM E698-18; Standard Test Method for Kinetic Parameters for Thermally Unstable Materials Using Differential Scanning Calorimetry and the Flynn/Wall/Ozawa Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- Borchardt, H.J.; Daniels, F. The Application of Differential Thermal Analysis to the Study of Reaction Kinetics. J. Am. Chem. Soc. 1957, 79, 41–46. [Google Scholar] [CrossRef]

- Friedman, H.L. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J. Polym. Sci. Part C Polym. Symp. 2007, 6, 183–195. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [CrossRef]

- Thanki, J.D.; Parsania, P.H. Dynamic DSC curing kinetics and thermogravimetric study of epoxy resin of 9,9′-bis(4-hydroxyphenyl)anthrone-10. J. Therm. Anal. Calorim. 2017, 130, 2145–2156. [Google Scholar] [CrossRef]

- Jubsilp, C.; Takeichi, T.; Rimdusit, S. Polymerization kinetics. In Handbook of Benzoxazine Resins; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 9780444537904. [Google Scholar]

- Martin, J.L. Kinetic analysis of two DSC peaks in the curing of an unsaturated polyester resin catalyzed with methylethylketone peroxide and cobalt octoate. Polym. Eng. Sci. 2007, 47, 62–70. [Google Scholar] [CrossRef]

- Wan, J.; Gan, B.; Li, C.; Molina-Aldareguia, J.; Kalali, E.N.; Wang, X.; Wang, D.-Y. A sustainable, eugenol-derived epoxy resin with high biobased content, modulus, hardness and low flammability: Synthesis, curing kinetics and structure–property relationship. Chem. Eng. J. 2016, 284, 1080–1093. [Google Scholar] [CrossRef] [Green Version]

- Sbirrazzuoli, N.; Mititelu-Mija, A.; Vincent, L.; Alzina, C. Isoconversional kinetic analysis of stoichiometric and off-stoichiometric epoxy-amine cures. Thermochim. Acta 2006, 447, 167–177. [Google Scholar] [CrossRef]

- Vertuccio, L.; Russo, S.; Raimondo, M.; Lafdi, K.; Guadagno, L. Influence of carbon nanofillers on the curing kinetics of epoxy-amine resin. RSC Adv. 2015, 5, 90437–90450. [Google Scholar] [CrossRef]

- Kravchenko, O.G.; Kravchenko, S.G.; Pipes, R.B. Chemical and thermal shrinkage in thermosetting prepreg. Compos. Part A Appl. Sci. Manuf. 2016, 80, 72–81. [Google Scholar] [CrossRef]

- Kravchenko, O.G.; Kravchenko, S.G.; Pipes, R.B. Cure history dependence of residual deformation in a thermosetting laminate. Compos. Part A Appl. Sci. Manuf. 2017, 99, 186–197. [Google Scholar] [CrossRef]

| Heating Rate (°C/min) | TPeak1 (K) | TPeak2 (K) | ΔHPeak1 (J/g) | ΔHPeak2 (J/g) | ΔHExp (J/g) | Relative Weight to the Total Reaction | ||

|---|---|---|---|---|---|---|---|---|

| Reaction 1 | Reaction 2 | |||||||

| 1 | 384 | 391 | 30.43 | 98.74 | 126.06 | 0.98 | 0.24 | 0.76 |

| 4 | 402 | 412 | 46.32 | 264.92 | 304.29 | 0.99 | 0.15 | 0.87 |

| 7 | 411 | 423 | 69.34 | 373.55 | 435.45 | 0.98 | 0.16 | 0.86 |

| 10 | 417 | 431 | 67.73 | 316.39 | 385.84 | 1 | 0.18 | 0.82 |

| 20 | 428 | 445 | 106.50 | 348.78 | 449.27 | 0.99 | 0.24 | 0.78 |

| Reaction (Ea, kJ/mol) | β (°C/min) | m | n | Z (s−1) | R2 |

|---|---|---|---|---|---|

| 1 (88.63) | 1 | 0.65 | 0.89 | 7.40 × 109 | 0.9995 |

| 4 | 0.65 | 0.90 | 7.41 × 109 | 0.9993 | |

| 7 | 0.63 | 0.91 | 6.58 × 109 | 0.9994 | |

| 10 | 0.62 | 0.92 | 6.06 × 109 | 0.9995 | |

| 20 | 0.58 | 0.95 | 4.63 × 109 | 0.9992 | |

| 2 (76.22) | 1 | 0.60 | 0.96 | 5.96 × 107 | 0.9997 |

| 4 | 0.48 | 1.03 | 4.23 × 107 | 0.9984 | |

| 7 | 0.47 | 1.08 | 3.58 × 107 | 0.9992 | |

| 10 | 0.45 | 1.08 | 3.18 × 107 | 0.9989 | |

| 20 | 0.45 | 1.09 | 2.93 × 107 | 0.9991 |

| Curing Time (min) | Curing Temperature (°C) | TPeak (°C) | Enthalpy (J/g) | Conversion Degree (Residual) |

|---|---|---|---|---|

| 0 | Uncured | - | 445.40 | 1.000 |

| 15 | 110 | 147 | 397.46 | 0.892 |

| 135 | 172 | 62.08 | 0.139 | |

| 160 | 232 | 14.32 | 0.032 | |

| 30 | 110 | 151 | 207.13 | 0.465 |

| 135 | 172 | 19.18 | 0.043 | |

| 160 | 189 | 2.98 | 0.007 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cruz-Cruz, I.; Ramírez-Herrera, C.A.; Martínez-Romero, O.; Castillo-Márquez, S.A.; Jiménez-Cedeño, I.H.; Olvera-Trejo, D.; Elías-Zúñiga, A. Influence of Epoxy Resin Curing Kinetics on the Mechanical Properties of Carbon Fiber Composites. Polymers 2022, 14, 1100. https://doi.org/10.3390/polym14061100

Cruz-Cruz I, Ramírez-Herrera CA, Martínez-Romero O, Castillo-Márquez SA, Jiménez-Cedeño IH, Olvera-Trejo D, Elías-Zúñiga A. Influence of Epoxy Resin Curing Kinetics on the Mechanical Properties of Carbon Fiber Composites. Polymers. 2022; 14(6):1100. https://doi.org/10.3390/polym14061100

Chicago/Turabian StyleCruz-Cruz, Isidro, Claudia A. Ramírez-Herrera, Oscar Martínez-Romero, Santos Armando Castillo-Márquez, Isaac H. Jiménez-Cedeño, Daniel Olvera-Trejo, and Alex Elías-Zúñiga. 2022. "Influence of Epoxy Resin Curing Kinetics on the Mechanical Properties of Carbon Fiber Composites" Polymers 14, no. 6: 1100. https://doi.org/10.3390/polym14061100