APTES-Modified Nanocellulose as the Formaldehyde Scavenger for UF Adhesive-Bonded Particleboard and Strawboard

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

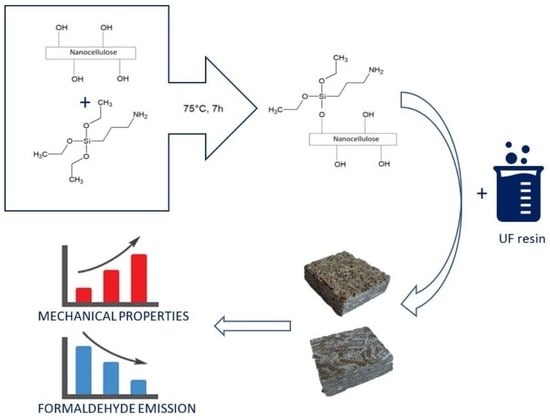

2.2. Nanocellulose Silanization

2.3. Characterization of Modified Nanocellulose

2.4. Adhesive Mixture Preparation

2.5. Investigations of Cured Adhesive Properties

2.6. Boards Manufacturing and Testing

2.7. Statistical Analysis

3. Results and Discussion

4. Conclusions

- The effectiveness of the applied method of nanocellulose silanization is confirmed on the basis of the coarse FTIR spectra indicating the presence of amino groups and increased nitrogen and silicon content.

- The functionalization of nanocellulose with APTES causes a slight decrease in its crystallinity.

- The addition of non-modified nanocellulose does not show the ability to absorb formaldehyde from an aqueous solution. In contrast, in the case of silanized nanocellulose, the formaldehyde-scavenging ability can be observed.

- The presence of APTES-modified nanocellulose in the cured UF adhesive can be observed in the FTIR spectra and increased silicon content.

- The introduction of non-modified NC does not influence the amount of formaldehyde contained in the cured UF adhesive; however, the silanization of nanoparticles prior to homogenization significantly decreased the content of formaldehyde due to the reactions with amino groups contained in the APTES molecule.

- The addition of nanocellulose does not affect the density and thickness swelling of the rape strawboards and particleboards.

- Nanocellulose addition to the UF adhesive causes an improvement in the bending strength, modulus of elasticity, and internal bond of strawboard and particleboard allowing for an extension in the range of their application.

- Functionalization of nanocellulose with APTES leads to a decrease in formaldehyde emission from boards, which is not observed in the case of non-modified nanocellulose.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Antov, P.; Savov, V.; Neykov, N. Reduction of Formaldehyde Emission from Engineered Wood Panels by Formaldehyde Scavengers—A Review. In Proceedings of the 13th International Scientific Conference Wood EMA 2020 and 31st International Scientific Conference ICWST, Vinkovci, Croatia, 28–30 September 2020. [Google Scholar]

- Hun, D.E.; Corsi, R.L.; Morandi, M.T.; Siegel, J.A. Formaldehyde in Residences: Long-term Indoor Concentrations and Influencing Factors. Indoor Air 2010, 20, 196–203. [Google Scholar] [CrossRef]

- Liu, M.; Wang, Y.; Wu, Y.; He, Z.; Wan, H. “Greener” Adhesives Composed of Urea-Formaldehyde Resin and Cottonseed Meal for Wood-Based Composites. J. Clean. Prod. 2018, 187, 361–371. [Google Scholar] [CrossRef]

- Ghani, A.; Ashaari, Z.; Bawon, P.; Lee, S.H. Reducing Formaldehyde Emission of Urea Formaldehyde-Bonded Particleboard by Addition of Amines as Formaldehyde Scavenger. Build. Environ. 2018, 142, 188–194. [Google Scholar] [CrossRef]

- Kishi, R.; Ketema, R.M.; Bamai, Y.A.; Araki, A.; Kawai, T.; Tsuboi, T.; Saito, I.; Yoshioka, E.; Saito, T. Indoor Environmental Pollutants and Their Association with Sick House Syndrome among Adults and Children in Elementary School. Build. Environ. 2018, 136, 293–301. [Google Scholar] [CrossRef]

- Dan, S.; Pant, M.; Kaur, T.; Pant, S. Toxic Effect of Formaldehyde: A Systematic Review. Int. Res. J. Mod. Eng. Technol. Sci. 2020, 2, 179–189. [Google Scholar]

- Bernardini, L.; Barbosa, E.; Charao, M.F.; Brucker, N. Formaldehyde Toxicity Reports from in Vitro and in Vivo Studies: A Review and Updated Data. Drug Chem. Toxicol. 2022, 45, 972–984. [Google Scholar] [CrossRef]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Sedliacik, J.; Savov, V.; Taghiyari, H.R.; Papadopoulos, A.N. Recent Progress in Ultra-Low Formaldehyde Emitting Adhesive Systems and Formaldehyde Scavengers in Wood-Based Panels: A Review. Wood Mater. Sci. Eng. 2022, 1–20. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Neykov, N. Sustainable Bio-Based Adhesives for Eco-Friendly Wood Composites. A Review. Wood Res. 2020, 65, 51–62. [Google Scholar] [CrossRef]

- Myers, G.E. Formaldehyde Emission from Particleboard and Plywood Paneling: Measurement, Mechanism, and Product Standards. For. Prod. J. 1983, 33, 27–37. [Google Scholar]

- Tohmura, S.; Inoue, A.; Sahari, S.H. Influence of the Melamine Content in Melamine-Urea-Formaldehyde Resins on Formaldehyde Emission and Cured Resin Structure. J. Wood Sci. 2001, 47, 451–457. [Google Scholar] [CrossRef]

- Park, B.-D.; Jeong, H.-W. Hydrolytic Stability and Crystallinity of Cured Urea–Formaldehyde Resin Adhesives with Different Formaldehyde/Urea Mole Ratios. Int. J. Adhes. Adhes. 2011, 31, 524–529. [Google Scholar] [CrossRef]

- Zaidon, A.; Hua, L.; Mohd, N. Effects of Ammonium Carbonate Post Treatment on Phenolic Resin Treated Sesenduk (Endospermum Diadenum) Wood. Sains Malays. 2015, 44, 987–994. [Google Scholar]

- Zimmermann, T.; Pöhler, E.; Geiger, T. Cellulose Fibrils for Polymer Reinforcement. Adv. Eng. Mater. 2004, 6, 754–761. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a Tiny Fiber with Huge Applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef]

- Sokołowska, A.; Olszyna, A.; Frąckowiak, I. Nanotechnologia w Inżynierii Materiałów Drzewnych. Inżynieria Mater. 2008, 29, 469–472. [Google Scholar]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Siuda, J. The Reduction of Adhesive Application in Plywood Manufacturing by Using Nanocellulose-reinforced Urea-formaldehyde Resin. J. Appl. Polym. Sci. 2021, 138, 49834. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Szentner, K. Properties of Plywood Produced with Urea-Formaldehyde Adhesive Modified with Nanocellulose and Microcellulose. Drv. Ind. 2020, 71, 61–67. [Google Scholar] [CrossRef] [Green Version]

- Ayrilmis, N.; Kwon, J.-H.; Lee, S.-H.; Han, T.-H.; Park, C.-W. Microfibrillated-Cellulose-Modified Urea-Formaldehyde Adhesives with Different F/U Molar Ratios for Wood-Based Composites. J. Adhes. Sci. Technol. 2016, 30, 2032–2043. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Lee, Y.-K.; Kwon, J.H.; Han, T.-H.; Kim, H.-J. Formaldehyde Emission and VOCs from LVLs Produced with Three Grades of Urea-Formaldehyde Resin Modified with Nanocellulose. Build. Environ. 2016, 97, 82–87. [Google Scholar] [CrossRef]

- Artner, M.A.; de Cademartori, P.H.G.; Avelino, F.; Lomonaco, D.; Magalhães, W.L.E. A Novel Design for Nanocellulose Reinforced Urea–Formaldehyde Resin: A Breakthrough in Amino Resin Synthesis and Biocomposite Manufacturing. Cellulose 2021, 28, 3435–3450. [Google Scholar] [CrossRef]

- Moslemi, A.; Behzad, T.; Pizzi, A. Addition of Cellulose Nanofibers Extracted from Rice Straw to Urea Formaldehyde Resin; Effect on the Adhesive Characteristics and Medium Density Fiberboard Properties. Int. J. Adhes. Adhes. 2020, 99, 102582. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, J.; Song, S.; Wu, G.; Pu, J. Modified Nanocrystalline Cellulose from Two Kinds of Modifiers Used for Improving Formaldehyde Emission and Bonding Strength of Urea-Formaldehyde Resin Adhesive. BioResources 2011, 6, 4430–4438. [Google Scholar]

- Zhang, H.; She, Y.; Song, S.P.; Pu, J.W. Modified Nanocrystalline Cellulose Used for Improving Formaldehyde Emission and Bonding Strength of Urea Formaldehyde Resin Adhesive. In Key Engineering Materials; Trans Tech Publications, Ltd.: Bäch SZ, Switzerland, 2013; Volume 562, pp. 846–851. [Google Scholar]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Pinkl, S.; Gindl-Altmutter, W. Application of Surface Chemical Functionalized Cellulose Nanocrystals to Improve the Performance of UF Adhesives Used in Wood Based Composites-MDF Type. Carbohydr. Polym. 2019, 206, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Mirski, R.; Kawalerczyk, J.; Dziurka, D.; Siuda, J.; Wieruszewski, M. The Application of Oak Bark Powder as a Filler for Melamine-Urea-Formaldehyde Adhesive in Plywood Manufacturing. Forests 2020, 11, 1249. [Google Scholar] [CrossRef]

- Park, B.-D.; Causin, V. Crystallinity and Domain Size of Cured Urea–Formaldehyde Resin Adhesives with Different Formaldehyde/Urea Mole Ratios. Eur. Polym. J. 2013, 49, 532–537. [Google Scholar] [CrossRef]

- Neves, R.M.; Ornaghi Jr, H.L.; Zattera, A.J.; Amico, S.C. Recent Studies on Modified Cellulose/Nanocellulose Epoxy Composites: A Systematic Review. Carbohydr. Polym. 2021, 255, 117366. [Google Scholar] [CrossRef]

- Frank, B.P.; Durkin, D.P.; Caudill, E.R.; Zhu, L.; White, D.H.; Curry, M.L.; Pedersen, J.A.; Fairbrother, D.H. Impact of Silanization on the Structure, Dispersion Properties, and Biodegradability of Nanocellulose as a Nanocomposite Filler. ACS Appl. Nano Mater. 2018, 1, 7025–7038. [Google Scholar] [CrossRef]

- Huang, L.; Xia, P.; Liu, Y.; Fu, Y.; Jiang, Y.; Liu, S.; Wang, X. Production of Biodegradable Board Using Rape Straw and Analysis of Mechanical Properties. BioResources 2016, 11, 772–785. [Google Scholar] [CrossRef] [Green Version]

- Dziurka, D.; Mirski, R. Lightweight Boards from Wood and Rape Straw Particles. Doniesienia 2013, 56, 19–31. [Google Scholar]

- Baum, R.; Wajszczuk, K.; Pepliński, B.; Wawrzynowicz, J. Potential for Agricultural Biomass Production for Energy Purposes in Poland: A Review. Contemp. Econ. 2013, 7, 63–74. [Google Scholar] [CrossRef] [Green Version]

- Dukarska, D.; Czarnecki, R.; Dziurka, D.; Mirski, R. Construction Particleboards Made from Rapeseed Straw Glued with Hybrid PMDI/PF Resin. Eur. J. Wood Wood Prod. 2017, 75, 175–184. [Google Scholar] [CrossRef]

- Cosereanu, C.; Cerbu, C. Morphology, physical, and mechanical properties of particleboards made from rape straw and wood particles glued with urea-formaldehyde resin. BioResources 2019, 14, 2903–2918. [Google Scholar]

- Dusek, J.; Jerman, M.; Podlena, M.; Bohm, M.; Cerny, R. Sustainable composite material based on surface modified rape straw and environment-friendly adhesive. Constr. Build. Mater. 2021, 300, 124036. [Google Scholar] [CrossRef]

- Zou, R.; Xiong, H.; Tang, S. Natural weathering of rape straw flour (RSF)/HDPE and nano-SiO2/RSF/HDPE composites. Carbohydr. Polym. 2008, 73, 378–383. [Google Scholar] [CrossRef]

- Gajdačová, P.; Hýsek, Š.; Jarský, V. Utilisation of Winter Rapeseed in Wood-Based Materials as a Solution of Wood Shortage and Forest Protection. BioResources 2018, 13, 2546–2561. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Yu, T.; Feng, Z.; Sun, J.; Gu, X.; Li, H.; Fei, B.; Zhang, S. Preparation of 3-aminopropyltriethoxy Silane Modified Cellulose Microcrystalline and Their Applications as Flame Retardant and Reinforcing Agents in Epoxy Resin. Polym. Adv. Technol. 2020, 31, 1340–1348. [Google Scholar] [CrossRef]

- Neves, R.M.; Ornaghi Jr, H.L.; Zattera, A.J.; Amico, S.C. The Influence of Silane Surface Modification on Microcrystalline Cellulose Characteristics. Carbohydr. Polym. 2020, 230, 115595. [Google Scholar] [CrossRef]

- Siuda, J.; Mazela, B.; Perdoch, W.; Zborowska, M. Efficiency of cellulose silanization–the influence of seasoning conditions. In Proceedings of the 14th Northern European Network for Wood Science and Engineering (WSE), Tallin, Estonia, 2–3 October 2018. [Google Scholar]

- Nelson, M.L.; O’Connor, R.T. Relation of Certain Infrared Bands to Cellulose Crystallinity and Crystal Lattice Type. Part II. A New Infrared Ratio for Estimation of Crystallinity in Celluloses I and II. J. Appl. Polym. Sci. 1964, 8, 1325–1341. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliačik, J.; Kačík, F.; Noshchenko, G.; Kleinová, A. Lignocellulosic Waste Fibers and Their Application as a Component of Urea-Formaldehyde Adhesive Composition in the Manufacture of Plywood. Eur. J. Wood Wood Prod. 2019, 77, 495–508. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliačik, J.; Noshchenko, G.; Kačík, F.; Bekhta, N. Characteristics of Beech Bark and Its Effect on Properties of UF Adhesive and on Bonding Strength and Formaldehyde Emission of Plywood Panels. Eur. J. Wood Wood Prod. 2021, 79, 423–433. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Siuda, J.; Dziurka, D.; Mirski, R.; Woźniak, M.; Stuper-Szablewska, K. The soy flour as an extender for uf and muf adhesives in birch plywood production. Wood Res. 2021, 66, 1015–1031. [Google Scholar] [CrossRef]

- Veigel, S.; Rathke, J.; Weigl, M.; Gindl-Altmutter, W. Particle Board and Oriented Strand Board Prepared with Nanocellulose-Reinforced Adhesive. J. Nanomater. 2012, 2012, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Dukarska, D.; Kawalerczyk, J.; Włodarczyk, J. Properties of the water-resistant plywood glued with pf resin with the addition of tannin filler and nanoclay. Wood Res. 2022, 67, 241–253. [Google Scholar] [CrossRef]

- EN 120; Wood-Based Panels-Determination of Formaldehyde Release-Extraction Method (Called Perforator Method). CEN, European Committee for Standardization: Brusseles, Belgium, 2011.

- Dziurka, D.; Mirski, R. Properties of Liquid and Polycondensed UF Resin Modified with PMDI. Drv. Ind. 2014, 65, 115–119. [Google Scholar] [CrossRef]

- EN 310; Wood-Based Panels-Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization:: Brussels, Belgium, 1999.

- EN 319; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 323; Wood-Based Panels-Determination of Density. European Committee for Standardization: Brussels, Belgium, 2001.

- EN 317; Particleboards and Fibreboards–Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1998.

- ISO 12460-3; Wood-Based Panels—Determination of Formaldehyde Release—Part 3: Gas Analysis Method. International Organization for Standardization: Geneva, Switzerland, 2020.

- Haqani, M.; Roghani-Mamaqani, H.; Salami-Kalajahi, M. Synthesis of Dual-Sensitive Nanocrystalline Cellulose-Grafted Block Copolymers of N-Isopropylacrylamide and Acrylic Acid by Reversible Addition-Fragmentation Chain Transfer Polymerization. Cellulose 2017, 24, 2241–2254. [Google Scholar] [CrossRef]

- Panahian, P.; Salami-Kalajahi, M.; Hosseini, M.S. Synthesis of Dual Thermoresponsive and PH-Sensitive Hollow Nanospheres by Atom Transfer Radical Polymerization. J. Polym. Res. 2014, 21, 455. [Google Scholar] [CrossRef]

- Mazlita, Y.; Lee, H.V.; Hamid, S.B.A. Preparation of Cellulose Nanocrystals Bio-Polymer from Agro-Industrial Wastes: Separation and Characterization. Polym. Polym. Compos. 2016, 24, 719–728. [Google Scholar] [CrossRef]

- Wulandari, W.T.; Rochliadi, A.; Arcana, I.M. Nanocellulose Prepared by Acid Hydrolysis of Isolated Cellulose from Sugarcane Bagasse. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 10th Joint Conference on Chemistry, Solo, Indonesia, 8–9 September 2015; IOP Publishing: Bristol, UK, 2016; Volume 107, p. 012045. [Google Scholar]

- Kargarzadeh, H.; Ahmad, I.; Abdullah, I.; Dufresne, A.; Zainudin, S.Y.; Sheltami, R.M. Effects of Hydrolysis Conditions on the Morphology, Crystallinity, and Thermal Stability of Cellulose Nanocrystals Extracted from Kenaf Bast Fibers. Cellulose 2012, 19, 855–866. [Google Scholar] [CrossRef]

- Yang, J. Manufacturing of Nanocrystalline Cellulose. Master’s Thesis, Aalto University, Espoo, Finland, 2017. [Google Scholar]

- Gao, Q.; Zhu, Q.; Guo, Y.; Yang, C.Q. Formation of Highly Hydrophobic Surfaces on Cotton and Polyester Fabrics Using Silica Sol Nanoparticles and Nonfluorinated Alkylsilane. Ind. Eng. Chem. Res. 2009, 48, 9797–9803. [Google Scholar] [CrossRef]

- Tang, Y.; Yang, S.; Zhang, N.; Zhang, J. Preparation and Characterization of Nanocrystalline Cellulose via Low-Intensity Ultrasonic-Assisted Sulfuric Acid Hydrolysis. Cellulose 2014, 21, 335–346. [Google Scholar] [CrossRef]

- Selulosa-Polivinilklorida, S.R.N.; Sheltami, R.M.; Kargarzadeh, H.; Abdullah, I. Effects of Silane Surface Treatment of Cellulose Nanocrystals on the Tensile Properties of Cellulose-Polyvinyl Chloride Nanocomposite. Sains Malays 2015, 44, 801–810. [Google Scholar]

- Jin, K.; Tang, Y.; Zhu, X.; Zhou, Y. Polylactic Acid Based Biocomposite Films Reinforced with Silanized Nanocrystalline Cellulose. Int. J. Biol. Macromol. 2020, 162, 1109–1117. [Google Scholar] [CrossRef] [PubMed]

- Woźniak, M.; Ratajczak, I. A Reaction of [3-(2-Aminoethylamino)Propyl] Trimethoxysilane with Wood and Cellulose–Chemical Analyses. Ann. Wars. Univ. Life Sci.-SGGW 2020, 109, 43–47. [Google Scholar] [CrossRef]

- Neves, R.M.; Ornaghi Jr, H.L.; Duchemin, B.; Zattera, A.J.; Amico, S.C. In-Depth Study of the Microcrystalline Cellulose Amino-Functionalization Efficiency. Cellulose 2021. [Google Scholar] [CrossRef]

- Xu, L.; Liang, H.-W.; Yang, Y.; Yu, S.-H. Stability and Reactivity: Positive and Negative Aspects for Nanoparticle Processing. Chem. Rev. 2018, 118, 3209–3250. [Google Scholar] [CrossRef]

- del Cerro, D.R.; Koso, T.V.; Kakko, T.; King, A.W.; Kilpeainen, I. Crystallinity reduction and enhancement in the chemical reactivity of cellulose by non-dissolving pre-treatment with tetrabutylphosphonium acetate. Cellulose 2020, 27, 5545–5562. [Google Scholar] [CrossRef] [Green Version]

- Majdoub, M.; Essamlali, Y.; Amadine, O.; Ganetri, I.; Hafnaoui, A.; Khouloud, M.; Zahouily, M. Octadecylamine as chemical modifier for tuned hydrophobicity of surface modified cellulose: Toward organophilic cellulose nanocrystals. Cellulose 2021, 28, 7717–7734. [Google Scholar] [CrossRef]

- Beaumont, M.; Bacher, M.; Opietnik, M.; Gindl-Altmutter, W.; Potthast, A.; Rosenau, T. A general aqueous silanization protocol to introduce vinyl, mercapto or azido functionalities onto cellulose fibers and nanocelluloses. Molecules 2018, 23, 1427. [Google Scholar] [CrossRef]

- Candan, Z.; Akbulut, T. Nano-Engineered Plywood Panels: Performance Properties. Compos. Part B Eng. 2014, 64, 155–161. [Google Scholar] [CrossRef]

- Candan, Z.; Akbulut, T. Developing Environmentally Friendly Wood Composite Panels by Nanotechnology. BioResources 2013, 8, 3590–3598. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhu, X. Measurement of Formaldehyde and VOCs Emissions from Wood-Based Panels with Nanomaterial-Added Melamine-Impregnated Paper. Constr. Build. Mater. 2014, 66, 132–137. [Google Scholar] [CrossRef]

- Nomura, A.; Jones, C.W. Enhanced Formaldehyde-vapor Adsorption Capacity of Polymeric Amine-incorporated Aminosilicas. Chem.–A Eur. J. 2014, 20, 6381–6390. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhu, Y.; Yu, Y.; Song, J. Improve Performance of Soy Flour-Based Adhesive with a Lignin-Based Resin. Polymers 2017, 9, 261. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Su, J.-F.; Huang, Z.; Yuan, X.-Y.; Wang, X.-Y.; Li, M. Structure and Properties of Carboxymethyl Cellulose/Soy Protein Isolate Blend Edible Films Crosslinked by Maillard Reactions. Carbohydr. Polym. 2010, 79, 145–153. [Google Scholar] [CrossRef]

- Ghahri, S.; Mohebby, B.; Pizzi, A.; Mirshokraie, A.; Mansouri, H.R. Improving Water Resistance of Soy-Based Adhesive by Vegetable Tannin. J. Polym. Environ. 2018, 26, 1881–1890. [Google Scholar] [CrossRef]

- Gwon, J.G.; Lee, S.Y.; Doh, G.H.; Kim, J.H. Characterization of Chemically Modified Wood Fibers Using FTIR Spectroscopy for Biocomposites. J. Appl. Polym. Sci. 2010, 116, 3212–3219. [Google Scholar] [CrossRef]

- Singh, S.; Dhakar, G.L.; Kapgate, B.P.; Maji, P.K.; Verma, C.; Chhajed, M.; Rajkumar, K.; Das, C. Synthesis and Chemical Modification of Crystalline Nanocellulose to Reinforce Natural Rubber Composites. Polym. Adv. Technol. 2020, 31, 3059–3069. [Google Scholar] [CrossRef]

- Indarti, E.; Rohaizu, R.; Wanrosli, W.D. Silylation of TEMPO Oxidized Nanocellulose from Oil Palm Empty Fruit Bunch by 3-Aminopropyltriethoxysilane. Int. J. Biol. Macromol. 2019, 135, 106–112. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, X.; Liu, H.; Liu, K.; Du, H.; Kumar, A.; Sharma, G.; Si, C. Recent Advances in Hydrophobic Modification of Nanocellulose. Curr. Org. Chem. 2021, 25, 417–436. [Google Scholar]

- Huang, P.; Wu, M.; Kuga, S.; Wang, D.; Wu, D.; Huang, Y. One-step Dispersion of Cellulose Nanofibers by Mechanochemical Esterification in an Organic Solvent. ChemSusChem 2012, 5, 2319–2322. [Google Scholar] [CrossRef]

- Geng, S.; Wei, J.; Aitomäki, Y.; Noël, M.; Oksman, K. Well-Dispersed Cellulose Nanocrystals in Hydrophobic Polymers by in Situ Polymerization for Synthesizing Highly Reinforced Bio-Nanocomposites. Nanoscale 2018, 10, 11797–11807. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Germiniani, L.G.; da Silva, L.C.; Plivelic, T.S.; Gonçalves, M.C. Poly (ε-Caprolactone)/Cellulose Nanocrystal Nanocomposite Mechanical Reinforcement and Morphology: The Role of Nanocrystal Pre-Dispersion. J. Mater. Sci. 2019, 54, 414–426. [Google Scholar] [CrossRef]

- Vatansever, E.; Arslan, D.; Nofar, M. Polylactide Cellulose-Based Nanocomposites. Int. J. Biol. Macromol. 2019, 137, 912–938. [Google Scholar] [CrossRef] [PubMed]

- Boran, S.; Usta, M.; Gümüşkaya, E. Decreasing Formaldehyde Emission from Medium Density Fiberboard Panels Produced by Adding Different Amine Compounds to Urea Formaldehyde Resin. Int. J. Adhes. Adhes. 2011, 31, 674–678. [Google Scholar] [CrossRef]

- Resetco, C.; Frank, D.; Dikić, T.; Claessens, S.; Verbrugge, T.; Du Prez, F.E. Thiolactone-Based Polymers for Formaldehyde Scavenging Coatings. Eur. Polym. J. 2016, 82, 166–174. [Google Scholar] [CrossRef]

- Mirski, R.; Derkowski, A.; Kawalerczyk, J.; Dziurka, D.; Walkiewicz, J. The Possibility of Using Pine Bark Particles in the Chipboard Manufacturing Process. Materials 2022, 15, 5731. [Google Scholar] [CrossRef]

- Baharoğlu, M.; Nemli, G.; Sarı, B.; Birtürk, T.; Bardak, S. Effects of Anatomical and Chemical Properties of Wood on the Quality of Particleboard. Compos. Part B Eng. 2013, 52, 282–285. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, X.; Pizzi, A.; Delmotte, L. Wheat straw particleboard bonding improvements by enzyme pretreatment. Holz Als Roh-Und Werkst. 2003, 61, 49–54. [Google Scholar] [CrossRef]

- EN 312; Particleboards. Specifications. European Committee for Standardization: Brussels, Belgium, 2010.

- Vineeth, S.K.; Gadhave, R.V.; Gadekar, P.T. Nanocellulose Applications in Wood Adhesives. Open J. Polym. Chem. 2019, 9, 63–75. [Google Scholar] [CrossRef]

- Mondal, S. Review on nanocellulose polymer nanocomposites. Polym.-Plast. Technol. Eng. 2018, 57, 1377–1391. [Google Scholar] [CrossRef]

- Ng, H.-M.; Sin, L.T.; Bee, S.-T.; Tee, T.-T.; Rahmat, A.R. Review of nanocellulose polymer composite characteristics and challenges. Polym.-Plast. Technol. Eng. 2017, 56, 687–731. [Google Scholar] [CrossRef]

- Dukarska, D. The Effect of an Addition of Nano-SiO2 to Urea Resin on the Properties of Boards Manufactured from Rape Straw. Ann. Wars. Univ. Life Sci.-SGGW. For. Wood Technol. 2013, 82, 242–245. [Google Scholar]

- Beech, J.C. The Thickness Swelling of Wood Particleboard. Holzforschung 1975, 29, 11–18. [Google Scholar] [CrossRef]

- Park, B.-D.; Jeong, H.-W. Effects of Acid Hydrolysis on Microstructure of Cured Urea-formaldehyde Resins Using Atomic Force Microscopy. J. Appl. Polym. Sci. 2011, 122, 3255–3262. [Google Scholar] [CrossRef]

| Type of Wood-Based Panel | Cellulose Modification | Effect on Formaldehyde | Additional Effects | References |

|---|---|---|---|---|

| Plywood | - | No clear effect | Improved bonding quality and mechanical properties Reduced adhesive consumption | [17,18] |

| Laminated veneer lumber (LVL) | - | No clear effect | Reduced VOC emission Improved bonding quality | [19,20] |

| Particleboard | - | Decreased emission | Improved mechanical properties Reduced water uptake | [21] |

| Fiberboard | - | Decreased emission | Improved mechanical properties | [22] |

| Plywood | Silanization | Decreased emission | Improved bonding quality | [23] |

| Plywood | Silanization | Decreased emission | Improved bonding quality | [24] |

| Fiberboard | Silanization | Decreased emission | Improved mechanical properties | [24] |

| Fiberboard | Silanization | Decreased emission | Improved mechanical properties Reduced water uptake | [25] |

| Variant Label | UF Resin (g) | Suspension (g) | Nanocellulose Modification * | H2O (g) | Hardener (g) | |

|---|---|---|---|---|---|---|

| H2O | Nanocellulose | |||||

| REF | 100 | 0 | 0 | - | 13.5 | 2 |

| 1%NC-S | 100 | 9 | 1 | S | 0 | 2 |

| 2%NC-S | 100 | 18 | 2 | S | 0 | 2 |

| 1%NC-N | 100 | 9 | 1 | N | 0 | 2 |

| 2%NC-N | 100 | 18 | 2 | N | 0 | 2 |

| Variant | TCI (A1370/A2900) | LOI (A1430/898) |

|---|---|---|

| NC | 1.13 | 1.57 |

| NC-S | 1.04 | 1.55 |

| Variant | Elemental Composition | |

|---|---|---|

| N (%) | Si (mg/kg) | |

| NC | 0.00 | 0.00 |

| NC-S | 3.24 ± 0.059 | 459.13 ± 1.16 |

| Silicon Content (%) | ||||

|---|---|---|---|---|

| REF | 1%NC-S | 2%NC-S | 1%NC-N | 2%NC-N |

| 0.00 a | 0.98 ± 0.02 b | 1.99 ± 0.03 c | 0.00 a | 0.00 a |

| Variant of Board | Density (kg/m3) | Bending Strength (N/mm2) | Modulus of Elasticity (N/mm2) | Internal Bond (N/mm2) | Thickness Swelling (%) | HCHO Emission (mg/m2 h) | |

|---|---|---|---|---|---|---|---|

| 2 h | 24 h | ||||||

| PB-REF | 602 ± 12 a | 12.4 ± 1.1 b | 1582 ± 21 a | 0.27 ± 0.03 b | 23.1 ± 2.1 a | 27.3 ± 2.1 a | 4.9 ± 0.2 b |

| PB-1%NC-S | 598 ± 17 a | 14.8 ± 1.3 c | 1731 ± 12 b | 0.38 ± 0.08 c | 23.3 ± 2.4 a | 28.2 ± 1.8 a | 3.3 ± 0.3 a |

| PB-2%NC-S | 601 ± 11 a | 14.5 ± 1.7 c | 1743 ± 18 b | 0.39 ± 0.04 c | 23.4 ± 2.1 a | 27.8 ± 1.4 a | 3.1 ± 0.2 a |

| PB-1%NC-N | 599 ± 19 a | 13.9 ± 1.4 c | 1738 ± 16 b | 0.37 ± 0.05 c | 22.7 ± 1.8 a | 27.2 ± 2.3 a | 4.7 ± 0.3 b |

| PB-2%NC-N | 603 ± 11 a | 14.1 ± 0.9 c | 1741 ± 12 b | 0.39 ± 0.04 c | 23.5 ± 1.7 a | 26.9 ± 2.1 a | 4.8 ± 0.4 b |

| RB-REF | 609 ± 12 a | 10.1 ± 1.3 a | 1576 ± 22 a | 0.17 ± 0.03 a | 28.3 ± 2.1 b | 31.4 ± 3.1 b | 4.8 ± 0.2 b |

| RB-1%NC-S | 596 ± 10 a | 12.9 ± 1.4 b | 1581 ± 25 a | 0.29 ± 0.04 b | 27.8 ± 1.6 b | 32.1 ± 2.3 b | 3.2 ± 0.3 a |

| RB-2%NC-S | 594 ± 11 a | 13.1 ± 0.7 b | 1579 ± 16 a | 0.31 ± 0.03 b | 28.3 ± 1.9 b | 31.8 ± 1.9 b | 3.1 ± 0.2 a |

| RB-1%NC-N | 604 ± 17 a | 12.5 ± 0.9 b | 1568 ± 18 a | 0.29 ± 0.03 b | 27.9 ± 2.2 b | 32.5 ± 2.9 b | 4.6 ± 0.4 b |

| RB-2%NC-N | 601 ± 14 a | 12.4 ± 1.3 b | 1563 ± 24 a | 0.31 ± 0.02 b | 28.2 ± 2.3 b | 31.5 ± 1.8 b | 4.8 ± 0.3 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawalerczyk, J.; Walkiewicz, J.; Dziurka, D.; Mirski, R.; Brózdowski, J. APTES-Modified Nanocellulose as the Formaldehyde Scavenger for UF Adhesive-Bonded Particleboard and Strawboard. Polymers 2022, 14, 5037. https://doi.org/10.3390/polym14225037

Kawalerczyk J, Walkiewicz J, Dziurka D, Mirski R, Brózdowski J. APTES-Modified Nanocellulose as the Formaldehyde Scavenger for UF Adhesive-Bonded Particleboard and Strawboard. Polymers. 2022; 14(22):5037. https://doi.org/10.3390/polym14225037

Chicago/Turabian StyleKawalerczyk, Jakub, Joanna Walkiewicz, Dorota Dziurka, Radosław Mirski, and Jakub Brózdowski. 2022. "APTES-Modified Nanocellulose as the Formaldehyde Scavenger for UF Adhesive-Bonded Particleboard and Strawboard" Polymers 14, no. 22: 5037. https://doi.org/10.3390/polym14225037