The Variety of the Stress–strain Response of Silicone Foam after Aging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Main Materials and Equipment

2.2. Test Conditions and Procedures

3. Results and Discussion

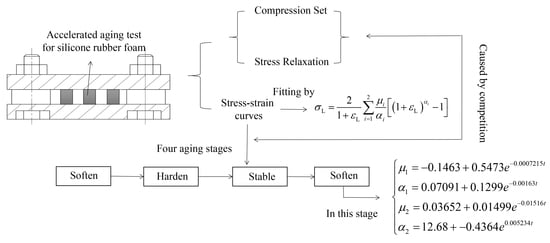

3.1. Variation of Compression Set, Stress–Relaxation, and Stress–strain Curve

3.2. Ogden Hyper-Foam Model

- where

3.3. Various of Model Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, P.C.; Yang, N.; Liu, D.; Qin, Z.M.; An, Y.; Chen, H.B. Coupling effects of gamma irradiation and absorbed moisture on silicone foam. Mater. Des. 2020, 195, 108998. [Google Scholar] [CrossRef]

- Lou, W.; Xie, C.; Guan, X. Coupled effects of temperature and compressive strain on aging of silicone rubber foam. Polym. Degrad. Stab. 2022, 195, 109810. [Google Scholar] [CrossRef]

- Kaneko, T.; Ito, S.; Minakawa, T.; Hirai, N.; Ohki, Y. Degradation mechanisms of silicone rubber under different aging conditions. Polym. Degrad. Stab. 2019, 168, 108936. [Google Scholar] [CrossRef]

- Celina, M.; Linde, E.; Brunson, D.; Quintana, A.; Giron, N. Overview of accelerated aging and polymer degradation kinetics for combined radiation-thermal environments. Polym. Degrad. Stab. 2019, 166, 353–378. [Google Scholar] [CrossRef]

- Liu, P.; Han, M.; Tang, B. Analysis on differences of accelerated degradation laws of different rubbers. Environ. Technol. 2019, 37, 44–48, 58. [Google Scholar]

- You, L.; Du, W.; Han, X.; Dong, X.; Deng, T. Buckling stress-strain simulation of neoprene hose inner rubber before and after hot oil aging. China Synth. Rubber Ind. 2020, 43, 18–22. [Google Scholar]

- Karekar, A.; Oßwald, K.; Reincke, K.; Langer, B.; Saalwächter, K. NMR Studies on the Phase-Resolved Evolution of Cross-Link Densities in Thermo-Oxidatively Aged Elastomer Blends. Macromolecules 2020, 53, 11166–11177. [Google Scholar] [CrossRef]

- Maxwell, R.S.; Cohenour, R.; Sung, W.; Solyom, D.; Patel, M. The effects of γ -radiation on the thermal, mechanical, and segmental dynamics of a silica filled, room temperature vulcanized polysiloxane rubber. Polym. Degrad. Stab. 2003, 80, 443–450. [Google Scholar] [CrossRef]

- Guo, X.; Luo, Y.; Chen, L.; Zhang, B.; Chen, Y.; Jia, D. Biomass antioxidant silica supported tea polyphenols with green and high-efficiency free radical capturing activity for rubber composites. Compos. Sci. Technol. 2022, 220, 109290. [Google Scholar] [CrossRef]

- Wan, S.; Li, T.; Chen, S.; Huang, X.; Cai, S.; He, X. Effect of multi-modified layered double hydroxide on aging resistance of nitrile-butadiene rubber. Compos. Sci. Technol. 2020, 195, 108193. [Google Scholar] [CrossRef]

- Patel, M.; Morrell, P.; Murphy, J. Continuous and intermittent stress relaxation studies on foamed polysiloxane rubber. Polym. Degrad. Stab. 2005, 87, 201–206. [Google Scholar] [CrossRef]

- Coons, J.E.; Mckay, M.D.; Hamada, M.S. A Bayesian analysis of the compression set and stress-strain behavior in a thermally aged silicone foam. Polym. Degrad. Stab. 2006, 91, 1824–1836. [Google Scholar] [CrossRef]

- Maiti, A.; Weisgraber, T.H.; Gee, R.H. Modeling the Mechanical and Aging Properties of Silicone Rubber and Foam—Stockpile-Historical & Additively Manufactured Materials; Lawrence Livermore National Lab. (LLNL): Livermore, CA, USA, 2014. [Google Scholar]

- Maiti, A.; Gee, R.; Weisgraber, T.; Chinn, S.; Maxwell, R. Constitutive modeling of radiation effects on the permanent set in a silicone elastomer. Polym. Degrad. Stab. 2008, 93, 2226–2229. [Google Scholar] [CrossRef]

- Wei, C.S.; Lu, A.; Sun, S.M.; Wei, X.W.; Zho, X.Y.; Sun, J. Establishment of Constitutive model of silicone rubber foams based on statistical theory of rubber elasticity. Chin. J. Polym. Sci. 2018, 36, 1077–1083. [Google Scholar] [CrossRef]

- Jia, D.; Yan, S.; Peng, Y.; Wei, L.; Wang, L.; Gao, Y.; Hao, Z.; Qiu, Y.; Wan, Q. Constitutive modeling of γ-irradiated silicone rubber foams under compression and shear loading. Polym. Degrad. Stab. 2021, 183, 109410. [Google Scholar] [CrossRef]

- Fang, H.; Li, J.; Chen, H.; Liu, B.; Huang, W.; Liu, Y.; Wang, T. Radiation induced degradation of silica reinforced silicone foam: Experiments and modeling. Mech. Mater. 2017, 105, 148–156. [Google Scholar] [CrossRef]

- Maiti, A.; Small, W.; Kroonblawd, M.P.; Lewicki, J.P.; Goldman, N.; Wilson, T.S.; Saab, A.P. Constitutive model of radiation aging effects in filled silicone elastomers under strain. J. Phys. Chem. B 2021, 125, 10047–10057. [Google Scholar] [CrossRef]

- Lou, W.; Xie, C.; Guan, X. Thermal-aging constitutive model for a silicone rubber foam under compression. Polym. Degrad. Stab. 2022, 198, 109873. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Q.; Liu, R.; Chen, M.; Zhang, C.; Li, X.; Li, W.; Wang, H. Compressive stress-hydrothermal aging behavior and constitutive model of shield tunnel EPDM rubber material. Constr. Build. Mater. 2022, 320, 126298. [Google Scholar] [CrossRef]

- Maiti, A.; Small, W.; Lewicki, J.P.; Chinn, S.; Wilson, T.; Saab, A.P. Age-aware constitutive materials model for a 3D printed polymeric foam. Sci. Rep. 2019, 9, 15923. [Google Scholar] [CrossRef]

- Moon, B.; Lee, J.; Park, S.; Seok, C.-S. Study on the aging behavior of natural rubber/butadiene rubber (NR/BR) blends using a parallel spring model. Polymers 2018, 10, 658. [Google Scholar] [CrossRef] [PubMed]

- Bahrololoumi, A.; Shaafaey, M.; Ayoub, G.; Dargazany, R. Thermal aging coupled with cyclic fatigue in cross-linked polymers: Constitutive modeling & FE implementation. Int. J. Solids Struct. 2022, 252, 111800. [Google Scholar]

- Zhang, L.; Fu, J.; Pang, M.; Li, H.; Wang, X. The influence of thermal-oxidative aging on crosslink structure and mechanical properties of special fluoroelastomer. Elastomer 2010, 4, 6. [Google Scholar]

- Fan, Z.; Chen, C.; Hu, W.; Wang, Q. Effects of microstructure on the lager compression behavior of rubber foams. Mech. Strength 2015, 37, 6. [Google Scholar]

- Hill, R. Aspects of invariance in solid mechanics. Adv. Appl. Mech. 1979, 18, 1–75. [Google Scholar]

- Storakers, B. On material representation and constitutive branching in finite compressible elasticity. J. Mech. Phys. Solids 1986, 34, 125–145. [Google Scholar] [CrossRef]

- Ogden, R.W. Non-Linear Elastic Deformations; Courier Corporation: Chelmsford, MA, USA, 1997. [Google Scholar]

- Yan, S.; Jia, D.; Yu, Y.; Wang, L.; Qiu, Y.; Wan, Q. Influence of γ-irradiation on mechanical behaviors of poly methyl-vinyl silicone rubber foams at different temperatures. Mech. Mater. 2020, 151, 103639. [Google Scholar] [CrossRef]

- Jin, F.; Xiao, S.; He, Q.; Jia, D.; Fang, Y. Characterization of the uncertainty of superelastic compression and stress relaxation of silicon foam. Chin. J. Appl. Mech. 2018, 35, 1200–1206, 1414. [Google Scholar]

| Aging Time/h | |||||

|---|---|---|---|---|---|

| 0 | 0.4684 | 0.2349 | 0.05117 | 10.76 | 0.5196 |

| 8 | 0.4387 | 0.2193 | 0.01676 | 14.13 | 0.4555 |

| 16 | 0.4272 | 0.2137 | 0.03456 | 12.8 | 0.4618 |

| 24 | 0.3806 | 0.1904 | 0.04111 | 12.27 | 0.4217 |

| 36 | 0.3797 | 0.19 | 0.04296 | 12.24 | 0.4227 |

| 48 | 0.3809 | 0.1906 | 0.04335 | 12.13 | 0.4243 |

| 72 | 0.3791 | 0.1896 | 0.04202 | 12.02 | 0.4211 |

| 96 | 0.3615 | 0.1809 | 0.03921 | 11.98 | 0.4007 |

| 144 | 0.3492 | 0.1747 | 0.03844 | 11.75 | 0.3876 |

| 192 | 0.3281 | 0.1642 | 0.03724 | 11.49 | 0.3653 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, Z.; Zhu, M.; Liang, T.; Wu, F.; Xu, Z.; Yang, Y.; Liu, Y. The Variety of the Stress–strain Response of Silicone Foam after Aging. Polymers 2022, 14, 3606. https://doi.org/10.3390/polym14173606

Shao Z, Zhu M, Liang T, Wu F, Xu Z, Yang Y, Liu Y. The Variety of the Stress–strain Response of Silicone Foam after Aging. Polymers. 2022; 14(17):3606. https://doi.org/10.3390/polym14173606

Chicago/Turabian StyleShao, Zhaoqun, Min Zhu, Tianxi Liang, Fei Wu, Zijian Xu, Yang Yang, and Yilong Liu. 2022. "The Variety of the Stress–strain Response of Silicone Foam after Aging" Polymers 14, no. 17: 3606. https://doi.org/10.3390/polym14173606