Design and Evaluation of Hybrid Composite Plates for Ballistic Protection: Experimental and Numerical Investigations

Abstract

:1. Introduction

2. Experimental Investigation

2.1. Geometrical Configuration and Sample Preparation

2.2. Ballistic Test

3. Numerical Investigation

3.1. Computational Grid

3.2. Material Modeling & Failure Criteria

- MAT_058 (MAT_LAMINATED_COMPOSITE_FABRIC) was used to model the composite woven fabric layers. The KFRP and CFRP were represented as shell elements in this FE model. This material’s failure criteria are based on Matzenmiller’s damage mechanics model, which can model the damages independently in the principal axis direction of any orthotropic material [30]. This makes it suitable for fabric composites. The elastic orthotropic material parameters for the longitudinal (x-direction), transverse (y-direction), and normal (z-direction) directions were defined to simulate the composite failure and predict the delamination accurately. Table 3 summarizes the defined material properties in MAT_058 [31,32].

- MAT_010 (MAT_ELASTIC_PLASTIC_HYDRO) was used to model the bullet used in real shooting tests, as this material model is suitable for hydrodynamic materials.

3.3. Interactions

- AUTOMATIC_SURFACE_TO_SURFACE_TIEBREAK was imposed to model the bonding between the composite layers (Kevlar and carbon fiber). In its formulation and during the loading, the damage of the material was a linear function of the distance between the two points which were initially in contact. When a critical opening was reached, the contact was being broken, and the bonded composite layers were converted into two separate surfaces with the regular surface-to-surface contact between them, see [23].

- AUTOMATIC_SURFACE_TO_SURFACE was defined between the bullet and the composite plate since this contact can deal with the deformations resulting from the bullet impact.

- ERODING_NODES_TO_SURFACE was used to simulate the erosion between the bullet and the composite layers in the body armor plates, as an erosion parameter is defined as a part of the material failure criteria in MAT_058 to delete any failed element from the simulation in order to save computational time, since the time-step is automatically adjusted, and to avoid random contact between failed elements.

- Between the composite layers, a tiebreak contact formulation was used. The tiebreak contact was used here as adhesive to bond the laminates. In its formulation and during the loading, the damage of the material was a linear function of the distance between the two points which were initially in contact. When the critical opening was reached, the contact was being broken, and the sub-laminates were converted into two different surfaces with the regular surface-to-surface contact between them, resulting in a strong displacement discontinuity.

3.4. Boundary Conditions

4. Results

4.1. Experimental Results

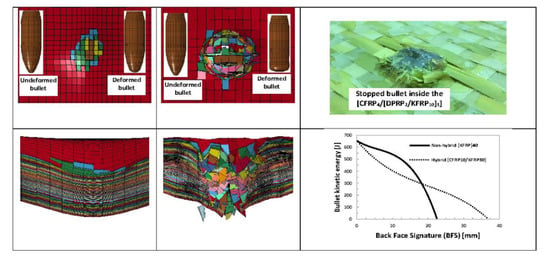

4.2. Numerical Results

5. Discussion

5.1. Macro-Energy Dissipation Mechanism of Armor Plates

5.1.1. Fabric Deformation & Destruction

5.1.2. Thermal Energy

5.1.3. Wave Propagation

5.2. Micro-Energy Dissipation Mechanism of Armor Plates

6. Conclusions

- The ballistic behaviors of flat and curved ballistic plates are identical.

- The material stacking sequence significantly affects the hybrid composite plates’ energy dissipation mechanism and, consequently, the energy absorption capability.

- Plates #5 and #6, the flat and curved [CFRP10/KFRP30], where the material sequence was ten layers of carbon fiber and 30 layers of Kevlar, displayed the highest energy absorption capability and passed the actual ballistic shooting test.

- Plates #3 and #4 with material sequence [CFRP4/KFRP6]4 had low energy dissipation mechanism and did not pass the ballistic shooting test.

- Incorporating the untreated date palm natural fibers in the plate’s material sequence displayed good ballistic behavior, although it did not pass all three-trial ballistic tests. At the same time, the plate’s weight was more than the other tested plates. Hence, nanocomposites can be incorporated [37,38].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Institute for Economics & Peace. Global Terrorism Index 2018: Measuring the Impact of Terrorism; Institute for Economics & Peace: Sydney, Australia, 2018. [Google Scholar]

- Yuen, S.C.K.; Nurick, G. The use of tubular structures as cores for sandwich panels subjected to dynamic and blast loading: A current “state of the art”. In Blast Mitigation; Springer: Berlin/Heidelberg, Germany, 2014; pp. 229–248. [Google Scholar]

- Bhatnagar, A. Lightweight Ballistic Composites: Military and Law-Enforcement Applications; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Lakshmi, L.; Nandakumar, C. Investigations on the performance of metallic and composite body armors. Procedia Technol. 2016, 25, 170–177. [Google Scholar] [CrossRef] [Green Version]

- Brown, D. Us troops’ injuries in Iraq showed body armor’s value. The Washington Post, 4 May 2002. [Google Scholar]

- La Tourrette, T. The life-saving effectiveness of body armor for police officers. J. Occup. Environ. Hyg. 2010, 7, 557–562. [Google Scholar] [CrossRef] [PubMed]

- James, N. Body Armor for Law Enforcement Officers: In Brief; Congressional Research Service: Washington, DC, USA, 2016. [Google Scholar]

- Wen, Y.; Xu, C.; Wang, S.; Batra, R. Analysis of behind the armor ballistic trauma. J. Mech. Behav. Biomed. Mater. 2015, 45, 11–21. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.S.; Wetzel, E.D.; Wagner, N.J. The ballistic impact characteristics of kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. J. Mater. Sci. 2003, 38, 2825–2833. [Google Scholar] [CrossRef]

- Farjo, L.A.; Miclau, T. Ballistics, and mechanisms of tissue wounding. Injury 1997, 28, C12–C17. [Google Scholar] [CrossRef]

- Roberts, J.C.; Biermann, P.J.; O’Connor, J.V.; Ward, E.E.; Cain, R.P.; Carkhuff, B.G.; Merkle, A.C. Modeling nonpenetrating ballistic impact on a human torso. Johns Hopkins Apl Tech. Dig. 2005, 26, 84–92. [Google Scholar]

- Thomas, E.L. Opportunities in protection materials science and technology for future army applications. Adv. Ceram. Armor 2012, VIII, 145–148. [Google Scholar] [CrossRef]

- UK Ministry of Defence Standards. Proof of ordnance, munitions, armor, and explosives—Defstan 05-101(pt1)/1(2005). In PART 1: REQUIREMENTS; UK Ministry of Defence Standards: Glasgow, Scotland, 2005. [Google Scholar]

- Montgomery, J.S.; Chin, E.S. Protecting the future force-towards a new generation of metallic structural armor. Mil. Technol. 2008, 32, 110. [Google Scholar]

- Rice, K.; Riley, M.; Forster, A. Ballistic Resistance of Body Armor, Ballistic Resistance of Body Armor [Online]. Available online: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=33027 (accessed on 29 April 2021).

- Vargas-Gonzalez, L.R.; Gurganus, J.C. Hybridized composite architecture for mitigation of nonpenetrating ballistic trauma. Int. J. Impact Eng. 2015, 86, 295–306. [Google Scholar] [CrossRef]

- Liu, W.; Chen, Z.; Chen, Z.; Cheng, X.; Wang, Y.; Chen, X.; Liu, J.; Li, B.; Wang, S. Influence of different back laminate layers on ballistic performance of ceramic composite armor. Mater. Des. 2015, 87, 421–427. [Google Scholar] [CrossRef]

- Yuen, S.; Nurick, G. The energy-absorbing characteristics of tubular structures with geometric and material modifications: An overview. Appl. Mech. Rev. 2008, 61, 020802. [Google Scholar] [CrossRef]

- Xu, J.; Ma, Y.; Zhang, Q.; Sugahara, T.; Yang, Y.; Hamada, H. Crashworthiness of carbon fiber hybrid composite tubes molded by filament winding. Compos. Struct. 2016, 139, 130–140. [Google Scholar] [CrossRef]

- Alkhatib, F.; Mahdi, E.; Dean, A. Development of composite double-hat energy absorber device subjected to traverser loads. Compos. Struct. 2020, 240, 112046. [Google Scholar] [CrossRef]

- Esnaola, A.; Ulacia, I.; Aretxabaleta, L.; Aurrekoetxea, J.; Gallego, I. Quasi-static crush energy absorption capability of e-glass/polyester and hybrid e-glass–basalt/polyester composite structures. Mater. Des. 2015, 76, 18–25. [Google Scholar] [CrossRef]

- Liu, Q.; Xing, H.; Ju, Y.; Ou, Z.; Li, Q. Quasi-static axial crushing and transverse bending of double hat shaped CFRP tubes. Compos. Struct. 2014, 117, 1–11. [Google Scholar] [CrossRef]

- Alkhatib, F.; Mahdi, E.; Dean, A. Crushing response of CFRP and kfrp composite corrugated tubes to quasi-static slipping axial loading: Experimental investigation and numerical simulation. Compos. Struct. 2020, 246, 112370. [Google Scholar] [CrossRef]

- Sastry, Y.S.; Budarapu, P.R.; Krishna, Y.; Devaraj, S. Studies on ballistic impact of the composite panels. Theor. Appl. Fract. Mech. 2014, 72, 2–12. [Google Scholar] [CrossRef]

- Samlal, S.; Santhanakrishnan, R.; Asritha, P.; Beegum, N.; Paulson, V. Projectile Impact Behavior on Various Kevlar Composites; AIP Publishing LLC: College Park, MA, USA, 2020; p. 030014. [Google Scholar]

- Meenakshi, S.; Srinivas, N.; Siddarth, Y.S.; Kamal, C.V.; Sudheendra, K.; Bhowmik, S.; Pitchan, M.K.; Epaarachchi, J.A. Numerical analysis of state of the art high-performance thermoplastic composite as lightweight bullet proof material. Mater. Res. Express 2019, 6, 095333. [Google Scholar]

- Rodríguez Millán, M.; Moreno, C.E.; Marco, M.; Santiuste, C.; Miguélez, H. Numerical analysis of the ballistic behaviour of kevlar® composite under impact of double-nosed stepped cylindrical projectiles. J. Reinf. Plast. Compos. 2016, 35, 124–137. [Google Scholar] [CrossRef] [Green Version]

- Dean, A.; Reinoso, J.; Jha, N.; Mahdi, E.; Rolfes, R. A phase-field approach for ductile fracture of short fiber-reinforced composites. Theor. Appl. Fract. Mech. 2020, 106, 102495. [Google Scholar] [CrossRef]

- Roberts, J.C.; Ward, E.E.; Merkle, A.C.; O’Connor, J.V. Assessing behind armor blunt trauma in accordance with the national institute of justice standard for personal body armor protection using finite element modeling. J. Trauma Acute Care Surg. 2007, 62, 1127–1133. [Google Scholar] [CrossRef]

- Matzenmiller, A.; Lubliner, J.; Taylor, R. A constitutive model for anisotropic damage in fiber-composites. Mech. Mater. 1995, 20, 125–152. [Google Scholar] [CrossRef]

- Lee, S.M. Handbook of Composite Reinforcements; John Wiley & Sons: London, UK, 1992. [Google Scholar]

- Lubin, G. Handbook of Composites; Springer Science & Business Media: Cambridge, UK, 2013. [Google Scholar]

- Kocer, H. Laminated and Hybrid Soft Body Armor for Ballistic Applications. Ph.D. Thesis, Auburn University, Auburn, Alabama, 2007. [Google Scholar]

- Shim, V.; Lim, C.; Foo, K. Dynamic mechanical properties of fabric armor. Int. J. Impact Eng. 2001, 25, 1–15. [Google Scholar] [CrossRef]

- Wilde, A.F.; Roylance, D.K.; Rogers, J.P.M. Photographic investigation of high-speed missile impact upon nylon fabric: Part i: Energy absorption and cone radial velocity in fabric. Text. Res. J. 1973, 43, 753–761. [Google Scholar] [CrossRef]

- Cheeseman, B.A.; Bogetti, T.A. Ballistic impact into fabric and compliant composite laminates. Compos. Struct. 2003, 61, 161–173. [Google Scholar] [CrossRef]

- Keshtegar, B.; Bagheri, M.; Meng, D.; Kolahchi, R.; Trung, N.-T. Fuzzy reliability analysis of nanocomposite ZnO beams using the hybrid analytical-intelligent method. Eng. Comput. 2020, 106, 102495. [Google Scholar] [CrossRef]

- Taherifar, R.; Zareei, S.A.; Bidgoli, M.R.; Kolahchi, R. Application of differential quadrature and Newmark methods for dynamic response in pad concrete foundation covered by piezoelectric layer. J. Comput. Appl. Math. 2021, 382, 113075. [Google Scholar] [CrossRef]

- Kumar, P.A.V.; Dean, A.; Reinoso, J.; Lenarda, P.; Paggi, M. Phase-field modeling of fracture in functionally graded materials: Γ-convergence and mechanical insight on the effect of grading. Thin-Walled Struct. 2021, 159, 107234. [Google Scholar]

- Dean, A.; Kumar, P.A.V.; Reinoso, J.; Gerendt, C.; Paggi, M.; Mahdi, E.; Rolfes, R. A multi phase-field fracture model for long fiber-reinforced composites based on the puck theory of failure. Compos. Struct. 2020, 251, 112446. [Google Scholar] [CrossRef]

- Mahdi, E.; Dean, A. The Effect of Filler Content on the Tensile Behavior of Polypropylene/Cotton Fiber and poly(vinyl chloride)/Cotton Fiber Composites. Materials 2020, 13, 753. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Plate | Layers Configuration | Thickness [mm] | Weight [g] | |

|---|---|---|---|---|

| #1 | Flat non-hybrid [KFRP]40 | [(KFRP)40] | 10.1 ± 0.3 | 743.0 ± 18.7 |

| #2 | Curved non-hybrid [KFRP]40 | [(KFRP)40] | 9.9 ± 0.1 | 730.3 ± 4.5 |

| #3 | Flat hybrid [CFRP4/KFRP6]4 | [(CFRP)4/(KFRP)6/(CFRP)4/(KFRP)6/(CFRP)4/(KFRP)6/(CFRP)4/(KFRP)6] | 13.1 ± 0.3 | 842.0 ± 18.7 |

| #4 | Curved hybrid [CFRP4/KFRP6]4 | [(CFRP)4/(KFRP)6/(CFRP)4/(KFRP)6/(CFRP)4/(KFRP)6/(CFRP)4/(KFRP)6] | 12.6 ± 0.1 | 794.0 ± 5.3 |

| #5 | Flat hybrid [CFRP10/KFRP30] | [(CFRP)10/(KFRP)30] | 11.1 ± 0.3 | 915.0 ± 8.0 |

| #6 | Curved hybrid [CFRP10/KFRP30] | [(CFRP)10/(KFRP)30] | 11.1 ± 0.1 | 902.3 ± 8.1 |

| #7 | Flat [CFRP4/[DPRP2/KFRP10]3] | [(CFRP)4/(DPRP)2/(KFRP)10/(DPRP)2/(KFRP)10/(DPRP)2/(KFRP)10] | 16.3 ± 0.2 | 1509.0 ± 14.6 |

| Part | No. of Elements | No. of Nodes | Element Type |

|---|---|---|---|

| Composite layer | 3600 × 40 | 3721 × 40 | Shell |

| Bullet | 34,503 | 36,564 | Solid |

| Mechanical Property | Woven CFRP | Woven KFRP |

|---|---|---|

| Mass density, ρ | 1.6 × 10−6 kg/mm3 | 1.44 × 10−6 kg/mm3 |

| Young’s Modulus, Exx = Eyy | 175 GPa | 18.5 GPa |

| Young’s Modulus, Ezz | 8.8 GPa | 6 GPa |

| Shear modulus, Gxy | 5.5 GPa | 1 GPa |

| Shear modulus, Gyz = Gzx | 2.5 GPa | 5.43 GPa |

| Major Poisson’s ratio, νxy | 0.3 | 0.25 |

| Minor Poisson’s ratio, νzx = νzy | 0.02545 | 0.33 |

| Longitudinal compressive strength | 850 MPa | 190 MPa |

| Longitudinal tensile strength | 1000 MPa | 480 MPa |

| Transverse compressive strength | 850 MPa | 190 MPa |

| Transverse tensile strength | 1000 MPa | 480 MPa |

| In-plane Shear strength | 670 MPa | 50 MPa |

| Longitudinal compressive strain | 0.8% | 0.6% |

| Longitudinal tensile strain | 0.85% | 1.6% |

| Transverse compressive strain | 0.8% | 0.6% |

| Transverse tensile strain | 0.85% | 1.6% |

| In-plane shear strain | 1.8% | 1% |

| Plate | Sample No. | BFS in mm | |||

|---|---|---|---|---|---|

| Shoot 1 | Shoot 2 | Shoot 3 | |||

| #1 | Flat non-hybrid [KFRP]40 | 1 | 20.0 | 24.3 | 22.5 |

| 2 | 26.9 | 21.5 | 26.5 | ||

| 3 | 23.5 | 22.3 | 33.5 | ||

| #2 | Curved non-hybrid [KFRP]40 | 1 | 27.2 | 22.5 | 29.8 |

| 2 | 21.0 | 24.8 | 32.7 | ||

| 3 | 26.8 | 31.1 | 35.0 | ||

| #3 | Flat hybrid [CFRP4/KFRP6]4 | 1 | N/A * | 36.1 | 42 |

| 2 | N/A * | N/A * | 35.3 | ||

| 3 | N/A * | 41.9 | 37.0 | ||

| #4 | Curved hybrid [CFRP4/KFRP6]4 | 1 | 39.0 | N/A * | 40.2 |

| 2 | N/A * | N/A * | 43.2 | ||

| 3 | N/A * | N/A * | 39.8 | ||

| #5 | Flat hybrid [CFRP10/KFRP30] | 1 | 26.2 | 26 | 32.0 |

| 2 | 21.3 | 22.5 | 23.4 | ||

| 3 | 23.0 | 27.9 | 24.5 | ||

| #6 | Curved hybrid [CFRP10/KFRP30] | 1 | 33.3 | 29.2 | 31.5 |

| 2 | 24.2 | 26.7 | 21.0 | ||

| 3 | 25.1 | 22.2 | 25.9 | ||

| #7 | Flat [CFRP4/[DPRP2/KFRP10]3] | 1 | 38.2 | 40.5 | N/A * |

| 2 | 41.0 | N/A * | N/A * | ||

| 3 | N/A * | N/A * | N/A * | ||

| Non-Hybrid [KFRP40] Armor Plate (Plate #1) | Hybrid [CFRP10/KFRP30] Armor Plate (Plate #5) | |||

|---|---|---|---|---|

Top view |  |  | ||

Front view |  BFS: 22.5 mm (Experimental BFS: 20.0 mm) |  BFS: 36.8 mm (Experimental BFS: 26.2 mm) | ||

Bullet deformation after an impact |  |  |  |  |

| Undeformed bullet | Deformed bullet | Undeformed bullet | Deformed bullet | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkhatib, F.; Mahdi, E.; Dean, A. Design and Evaluation of Hybrid Composite Plates for Ballistic Protection: Experimental and Numerical Investigations. Polymers 2021, 13, 1450. https://doi.org/10.3390/polym13091450

Alkhatib F, Mahdi E, Dean A. Design and Evaluation of Hybrid Composite Plates for Ballistic Protection: Experimental and Numerical Investigations. Polymers. 2021; 13(9):1450. https://doi.org/10.3390/polym13091450

Chicago/Turabian StyleAlkhatib, Farah, Elsadig Mahdi, and Aamir Dean. 2021. "Design and Evaluation of Hybrid Composite Plates for Ballistic Protection: Experimental and Numerical Investigations" Polymers 13, no. 9: 1450. https://doi.org/10.3390/polym13091450