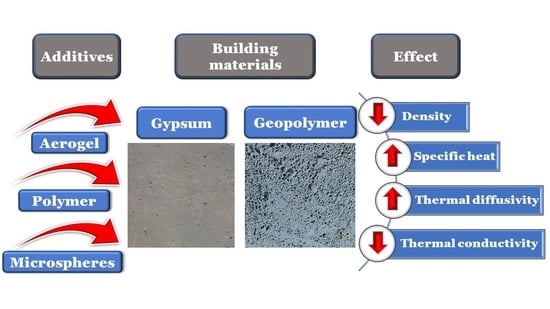

Comparison of the Thermal Properties of Geopolymer and Modified Gypsum

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

3.1. The Results of Density and Porosity

3.2. The Results of the Thermal Properties and Their Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pichniarczyk, P.; Niziurska, M.; Nosal, K. The Influence of Methylcellulose Viscosity on Properties of Gypsum Plaster Mortars. Mater. Ceram. 2012, 64, 558–562. (In Polish) [Google Scholar]

- Gruszczyński, M. Estimation of shrinkage strains of cement mortars and concrete with polymer addition. Cement Wapno. Beton 2007, 12/74, 139–144. [Google Scholar]

- Kamseu, E.; Bignozzi, M.C.; Melo, U.; Leonelli, C.; Sglavo, V.M. Design of inorganic polymer cements: Effects of matrix strengthening on microstructure. Constr. Build. Mater. 2013, 38, 1135–1145. [Google Scholar] [CrossRef]

- Kamseu, E.; Nait-Ali, B.; Bignozzi, M.; Leonelli, C.; Rossignol, S.; Smith, D. Bulk composition and microstructure dependence of effective thermal conductivity of porous inorganic polymer cements. J. Eur. Ceram. Soc. 2012, 32, 1593–1603. [Google Scholar] [CrossRef]

- Heim, D.; Mrowiec, A.; Pralat, K.; Mucha, M. Influence of Tylose MH1000 Content on Gypsum Thermal Conductivity. J. Mater. Civ. Eng. 2018, 30, 04018002. [Google Scholar] [CrossRef]

- Pichniarczyk, P.; Niziurska, M.; Nosal, K.; Wieczorek, M. Influence of methylcellulose on a microstructure of gypsum and cementitious mortars. Szkło Ceram. 2012, 63, 12–17. (In Polish) [Google Scholar]

- Najduchowska, M.; Pichniarczyk, P. Effect of hydrophobic agents on the properties of cement and gypsum mortars. Cement Wapno. Beton 2010, 15/77, 141–148. [Google Scholar]

- Ceske lupkove zavody. BAUCIS LK. Available online: www.cluz.cz/en/baucis-lk (accessed on 8 April 2021).

- Aluminium Powder. Available online: www.kovyachemie.cz/kontakty/ (accessed on 8 April 2021).

- Jaya, N.A.; Yun-Ming, L.; Cheng-Yong, H.; Abdullah, M.M.A.B.; Hussin, K. Correlation between pore structure, compressive strength and thermal conductivity of porous metakaolin geopolymer. Constr. Build. Mater. 2020, 247, 118641. [Google Scholar] [CrossRef]

- Khalil, A.; Tawfik, A.; Hegazy, A.; El-Shahat, M. Effect of some waste additives on the physical and mechanical properties of gypsum plaster composites. Constr. Build. Mater. 2014, 68, 580–586. [Google Scholar] [CrossRef]

- Tesárek, P.; Drchalova, J.; Kolísko, J.; Rovnaníková, P.; Černý, R. Flue gas desulfurization gypsum: Study of basic mechanical, hydric and thermal properties. Constr. Build. Mater. 2007, 21, 1500–1509. [Google Scholar] [CrossRef]

- Gutiérrez-González, S.; Gadea, J.; Rodríguez, A.; Blanco-Varela, M.; Calderón, V. Compatibility between gypsum and polyamide powder waste to produce lightweight plaster with enhanced thermal properties. Constr. Build. Mater. 2012, 34, 179–185. [Google Scholar] [CrossRef] [Green Version]

- Bulichen, D.; Plank, J. Water retention capacity and working mechanism of methyl hydroxypropyl cellulose (MHPC) in gypsum plaster—Which impact has sulfate? Cem. Concr. Res. 2013, 46, 66–72. [Google Scholar] [CrossRef]

- Kocemba, A. Water retention and setting in gypsum/polymers composites Zatrzymanie wody i zestalanie w kompozytach gips/polimer. Przemysł Chem. 2016, 1, 129–131. [Google Scholar] [CrossRef]

- Sikora, K.S.; Klemm, A.J. Effect of Superabsorbent Polymers on Workability and Hydration Process in Fly Ash Cementitious Composites. J. Mater. Civ. Eng. 2015, 27, 04014170. [Google Scholar] [CrossRef]

- Strzałkowski, J.; Garbalińska, H. Thermal and strength properties of lightweight concretes with the addition of aerogel particles. Adv. Cem. Res. 2016, 28, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Prałat, K.; Jaskulski, R.; Ciemnicka, J.; Makomaski, G. Analysis of the thermal properties and structure of gypsum modified with cellulose based polymer and aerogels. Arch. Civ. Eng. 2020, 66, 153–168. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Kubissa, W.; Pacewska, B.; Wilińska, I. Comparative Investigations of some Properties Related to Durability of Cement Concretes Containing Different Fly Ashes. Adv. Mater. Res. 2014, 1054, 154–161. [Google Scholar] [CrossRef]

- Woyciechowski, P.; Woliński, P.; Adamczewski, G. Prediction of Carbonation Progress in Concrete Containing Calcareous Fly Ash Co-Binder. Materials 2019, 12, 2665. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Yuan, J.; Wei, P.; Zhu, M. Effects of fly ash microspheres on sulfate erosion resistance and chlorion penetration resistance in concrete. J. Therm. Anal. Calorim. 2019, 139, 3395–3403. [Google Scholar] [CrossRef]

- Inozemtcev, A.S.; Sergeevich, A.; Korolev, E.V.; Smirnov, V.A. Nanoscale modifier as an adhesive for hollow microspheres to increase the strength of high-strength lightweight concrete. Struct. Concr. 2017, 18, 67–74. [Google Scholar] [CrossRef]

- Ciemnicka, J.; Jaskulski, R.; Kubissa, W.; Prałat, K. Influence of Selected Micro Additives Content nn Thermal Properties of Gypsum. Arch. Civ. Eng. Environ. 2019, 12, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Prałat, K.; Grabowski, M.; Ciemnicka, J. The Use of Micro Additives in Building Gypsum Materials. In Practical Aspects of Chemical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 10, pp. 336–345. [Google Scholar]

- Ghosh, A.; Subbarao, C. Microstructural Development in Fly Ash Modified with Lime and Gypsum. J. Mater. Civ. Eng. 2001, 13, 65–70. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Moghal, A.A.B. Role of Gypsum in the Strength Development of Fly Ashes with Lime. J. Mater. Civ. Eng. 2011, 23, 197–206. [Google Scholar] [CrossRef]

- Kusnerova, M.; Valicek, J.; Harnicarova, M.; Hryniewicz, T.; Rokosz, K.; Palková, Z.; Vaclavik, V.; Řepka, M.; Bendova, M. A Proposal for Simplifying the Method of Evaluation of Uncertainties in Measurement Results. Meas. Sci. Rev. 2013, 13, 1–6. [Google Scholar] [CrossRef]

- Prałat, K.; Kubissa, W.; Jaskulski, R.; Kubissa, W.; Pilarczyk, S. Wpływ wybranych mikrododatków na przewodnictwo cieplne oraz mikrostrukturę powierzchni modyfikowanych gipsów (Influence of selected micro-additives on thermal conductivity and microstructure of modified gypsum). Acta Sci. Pol. Archit. 2019, 18, 69–75. (In Polish) [Google Scholar]

- Kamseu, E.; Ngouloure, Z.N.; Ali, B.N.; Zekeng, S.; Melo, U.; Rossignol, S.; Leonelli, C. Cumulative pore volume, pore size distribution and phases percolation in porous inorganic polymer composites: Relation microstructure and effective thermal conductivity. Energy Build. 2015, 88, 45–56. [Google Scholar] [CrossRef]

- Skvara, F.; Šulc, R.; Tišler, Z.; Skricik, P.; Šmilauer, V.; Zlámalová Cílová, Z. Preparation and properties of fly ash-based geo-polymer foams. Ceram. Silikáty 2014, 58, 188–197. [Google Scholar]

- He, R.; Dai, N.; Wang, Z. Thermal and Mechanical Properties of Geopolymers Exposed to High Temperature: A Literature Review. Adv. Civ. Eng. 2020, 2020, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Krakowiak, K.J.; Nannapaneni, R.G.; Moshiri, A.; Phatak, T.; Stefaniuk, D.; Sadowski, L.; Qomi, M.J.A. Engineering of high specific strength and low thermal conductivity cementitious composites with hollow glass microspheres for high-temperature high-pressure applications. Cem. Concr. Compos. 2020, 108, 103514. [Google Scholar] [CrossRef]

- Pogorzelski, J. Ostrożnie z niestacjonarnymi badaniami przewodności cieplnej! (Careful with non-stationary thermal conduc-tivity tests!). Prace Instytutu Techniki Budowlanej 2000, 29, 38–52. (In Polish) [Google Scholar]

- Jittabut, P. Effect of Nanosilica on Mechanical and Thermal Properties of Cement Composites for Thermal Energy Storage Materials. Energy Procedia 2015, 79, 10–17. [Google Scholar] [CrossRef] [Green Version]

- Vimmrová, A.; Keppert, M.; Svoboda, L.; Černý, R. Lightweight gypsum composites: Design strategies for multi-functionality. Cem. Concr. Compos. 2011, 33, 84–89. [Google Scholar] [CrossRef]

- Yu, Q.; Brouwers, H.J.H. Thermal properties and microstructure of gypsum board and its dehydration products: A theoretical and experimental investigation. Fire Mater. 2011, 36, 575–589. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rubio-De-Hita, P. Reuse of CD and DVD Wastes as Reinforcement in Gypsum Plaster Plates. Materials 2020, 13, 989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pavlík, Z.; Vejmelková, E.; Fiala, L.; Černý, R. Effect of Moisture on Thermal Conductivity of Lime-Based Composites. Int. J. Thermophys. 2009, 30, 1999–2014. [Google Scholar] [CrossRef]

- Šefflová, M.; Volf, M.; Pavlů, T. Thermal Properties of Concrete with Recycled Aggregate. Adv. Mater. Res. 2014, 1054, 227–233. [Google Scholar] [CrossRef]

- Vejmelková, E.; Koňáková, D.; Kulovaná, T.; Hubáček, A.; Cerny, R. Mechanical and Thermal Properties of Moderate-Strength Concrete with Ceramic Powder Used as Supplementary Cementitious Material. Adv. Mater. Res. 2014, 1054, 194–198. [Google Scholar] [CrossRef]

- Ben Mansour, M.; Soukaina, C.A.; Benhamou, B.; Ben Jabrallah, S. Thermal Characterization of a Tunisian Gypsum Plaster as Construction Material. Energy Procedia 2013, 42, 680–688. [Google Scholar] [CrossRef] [Green Version]

- Rahmanian, I.; Wang, Y. A combined experimental and numerical method for extracting temperature-dependent thermal conductivity of gypsum boards. Constr. Build. Mater. 2012, 26, 707–722. [Google Scholar] [CrossRef]

- Thong, N.V.; Hung, T. Research on the parameters influencing the thermal conductivity of gypsum plasterboard under fire conditions. Cogent Eng. 2019, 6, 1569796. [Google Scholar] [CrossRef]

- Ashour, T.; Korjenic, A.; Korjenic, S.; Wu, W. Thermal conductivity of unfired earth bricks reinforced by agricultural wastes with cement and gypsum. Energy Build. 2015, 104, 139–146. [Google Scholar] [CrossRef]

- Maciej, J.; Shady, A. Thermal conductivity of gypsum with incorporated phase change material (PCM) for building applications. J. Power Technol. 2011, 91, 49–53. [Google Scholar]

- Le, V.S. Thermal conductivity of reinforced geopolymer foams. Ceram. Silik. 2019, 63, 365–373. [Google Scholar] [CrossRef]

- Rickard, W.D.; Vickers, L.; Van Riessen, A. Performance of fibre reinforced, low density metakaolin geopolymers under simulated fire conditions. Appl. Clay Sci. 2013, 73, 71–77. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, S.; Wang, Y.; Jiang, G.; Zhang, Y.; Chen, H.; Liang, M.; Long, G.; Chen, X. Effective thermal conductivity of porous media with roughened surfaces by fractal-monte carlo simulations. Fractals 2020, 28, 205002. [Google Scholar] [CrossRef]

- Kou, J.; Liu, Y.; Wu, F.; Fan, J.; Lu, H.; Xu, Y. Fractal analysis of effective thermal conductivity for three-phase (unsaturated) porous media. J. Appl. Phys. 2009, 106, 054905. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Ma, C.; Liu, Y.; Wang, D.; Liu, J. A model for the effective thermal conductivity of moist porous building materials based on fractal theory. Int. J. Heat Mass Transf. 2018, 125, 387–399. [Google Scholar] [CrossRef]

| Tested Sample | Geopolymer/Gypsum [g] | Activator/Water [g] | Additive [g] |

|---|---|---|---|

| Geopolymer + aluminum powder (GF) | 527 | 473 | 5.0 |

| Gypsum (G) | 572 | 428 | - |

| Gypsum + Polymer (GP) | 572 | 428 | 5.7 |

| Gypsum + Aerogel (GA) | 572 | 428 | 5.7 |

| Gypsum + Microspheres (GM) | 572 | 428 | 57.2 |

| Parameters | Tested Sample | ||||

|---|---|---|---|---|---|

| GF | G | GP | GA | GM | |

| Bulk density ρb1 [kg/m3] Calculated from Equation (1) | 281 | 991 | 941 | 923 | 922 |

| Bulk density ρb2 [kg/m3] Calculated from Equation (6) | 280 | 977 | 940 | 935 | 910 |

| Porosity p [%] | 85 | 44 | 48 | 49 | 49 |

| Statistical Parameters | Thermal Properties of the Geopolymer Sample (GF) | |||

|---|---|---|---|---|

| λ [W/(m·K)] | Cv [MJ/(m3·K)] | Cp [J/(kg·K)] | a [mm2/s] | |

| Quartile, Q1 | 0.1140 | 0.4691 | 1675 | 0.2411 |

| Median, M | 0.1141 | 0.4716 | 1684 | 0.2418 |

| Quartile, Q3 | 0.1141 | 0.4730 | 1689 | 0.2432 |

| Interquartile range, IQR = (Q3 − Q1) | 0.0001 | 0.0039 | 14 | 0.0021 |

| Higher outlier, HO = Q3 + 1.5·IQR | 0.1143 | 0.4789 | 1710 | 0.2464 |

| Lower outlier, LO = Q1 − 1.5·IQR | 0.1139 | 0.4633 | 1654 | 0.2380 |

| Average value, | 0.1141 | 0.4711 | 1683 | 0.2421 |

| Standard deviation, s | 0.0002 | 0.0023 | 8 | 0.0013 |

| Coefficient of variation, CV [%] | 0.14 | 0.49 | 0.49 | 0.53 |

| Upper critical value, UCV | 0.1142 | 0.4735 | 1691 | 0.2434 |

| Lower critical value, LCV | 0.1139 | 0.4688 | 1674 | 0.2408 |

| Statistical Parameters | Thermal Properties of the Gypsum Sample (G) | |||

| λ [W/(m·K)] | Cv [MJ/(m3·K)] | Cp [J/(kg·K)] | a [mm2/s] | |

| Quartile, Q1 | 0.2887 | 1.5036 | 1539 | 0.1905 |

| Median, M | 0.2919 | 1.5206 | 1556 | 0.1919 |

| Quartile, Q3 | 0.2942 | 1.5269 | 1563 | 0.1936 |

| Interquartile range, IQR = (Q3 − Q1) | 0.0055 | 0.0233 | 24 | 0.0031 |

| Higher outlier, HO = Q3 + 1.5·IQR | 0.3024 | 1.5620 | 1599 | 0.1984 |

| Lower outlier, LO = Q1 − 1.5·IQR | 0.2805 | 1.4686 | 1503 | 0.1858 |

| Average value, | 0.2917 | 1.5170 | 1553 | 0.1923 |

| Standard deviation, s | 0.0045 | 0.0205 | 21 | 0.0018 |

| Coefficient of variation, CV [%] | 1.55 | 1.35 | 1.35 | 0.92 |

| Upper critical value, UCV | 0.2940 | 1.5281 | 1563 | 0.1932 |

| Lower critical value, LCV | 0.2895 | 1.5059 | 1542 | 0.1914 |

| Statistical Parameters | Thermal Properties of the Gypsum Sample Modified with Polymer (GP) | |||

| λ [W/(m·K)] | Cv [MJ/(m3·K)] | Cp [J/(kg·K)] | a [mm2/s] | |

| Quartile, Q1 | 0.2478 | 1.4755 | 1568 | 0.1697 |

| Median, M | 0.2563 | 1.4963 | 1590 | 0.1716 |

| Quartile, Q3 | 0.2595 | 1.5096 | 1604 | 0.1729 |

| Interquartile range, IQR = (Q3 − Q1) | 0.0117 | 0.0341 | 36 | 0.0032 |

| Higher outlier, HO = Q3 + 1.5·IQR | 0.2770 | 1.5607 | 1659 | 0.1776 |

| Lower outlier, LO = Q1 − 1.5·IQR | 0.2303 | 1.4244 | 1514 | 0.1649 |

| Average value, | 0.2556 | 1.5011 | 1583 | 0.1716 |

| Standard deviation, s | 0.0069 | 0.0142 | 33 | 0.0023 |

| Coefficient of variation, CV [%] | 2.70 | 0.95 | 2.11 | 1.36 |

| Upper critical value, UCV | 0.2590 | 1.5088 | 1603 | 0.1728 |

| Lower critical value, LCV | 0.2522 | 1.4933 | 1587 | 0.1704 |

| Statistical Parameters | Thermal Properties of the Gypsum Sample Modified with Aerogel (GA) | |||

| λ [W/(m·K)] | Cv [MJ/(m3·K)] | Cp [J/(kg·K)] | a [mm2/s] | |

| Quartile, Q1 | 0.2930 | 1.2775 | 1390 | 0.1996 |

| Median, M | 0.2959 | 1.4270 | 1553 | 0.2044 |

| Quartile, Q3 | 0.2998 | 1.4925 | 1624 | 0.2184 |

| Interquartile range, IQR = (Q3 − Q1) | 0.0068 | 0.2150 | 234 | 0.0188 |

| Higher outlier, HO = Q3 + 1.5·IQR | 0.3101 | 1.8150 | 1975 | 0.2466 |

| Lower outlier, LO = Q1 − 1.5·IQR | 0.2828 | 0.9549 | 1039 | 0.1714 |

| Average value, | 0.2954 | 1.3994 | 1523 | 0.2074 |

| Standard deviation, s | 0.0072 | 0.1241 | 135 | 0.0095 |

| Coefficient of variation, CV [%] | 2.44 | 8.87 | 8.87 | 4.57 |

| Upper critical value, UCV | 0.2989 | 1.4662 | 1595 | 0.2123 |

| Lower critical value, LCV | 0.2918 | 1.3326 | 1450 | 0.2026 |

| Statistical Parameters | Thermal Properties of the Gypsum Sample Modified with Microspheres (GM) | |||

| λ [W/(m·K)] | Cv [MJ/(m3·K)] | Cp [J/(kg·K)] | a [mm2/s] | |

| Quartile, Q1 | 0.2728 | 1.4403 | 1562 | 0.1855 |

| Median, M | 0.2768 | 1.4549 | 1578 | 0.1896 |

| Quartile, Q3 | 0.2830 | 1.4858 | 1611 | 0.1959 |

| Interquartile range, IQR = (Q3 − Q1) | 0.0102 | 0.0455 | 49 | 0.0104 |

| Higher outlier, HO = Q3 + 1.5·IQR | 0.2983 | 1.5540 | 1685 | 0.2116 |

| Lower outlier, LO = Q1 − 1.5·IQR | 0.2575 | 1.3721 | 1488 | 0.1698 |

| Average value, | 0.2797 | 1.4678 | 1592 | 0.1930 |

| Standard deviation, s | 0.0088 | 0.0310 | 34 | 0.0087 |

| Coefficient of variation, CV [%] | 3.15 | 2.11 | 2.11 | 4.53 |

| Upper critical value, UCV | 0.2840 | 1.4845 | 1608 | 0.1974 |

| Lower critical value, LCV | 0.2753 | 1.4511 | 1576 | 0.1885 |

| Tested Sample | Designated Confidence Intervals |

|---|---|

| GF | P (0.1139 ≤ λ ≤ 0.1142) = 0.95 |

| P (1674 ≤ Cp ≤ 1691) = 0.95 | |

| P (0.2408 ≤ a ≤ 0.2434) = 0.95 | |

| G | P (0.2895 ≤ λ ≤ 0.2940) = 0.95 |

| P (1542 ≤ Cp ≤ 1563) = 0.95 | |

| P (0.1914 ≤ a ≤ 0.1932) = 0.95 | |

| GP | P (0.2522 ≤ λ ≤ 0.2590) = 0.95 |

| P (1587 ≤ Cp ≤ 1603) = 0.95 | |

| P (0.1704 ≤ a ≤ 0.1728) = 0.95 | |

| GA | P (0.2918 ≤ λ ≤ 0.2989) = 0.95 |

| P (1450 ≤ Cp ≤ 1595) = 0.95 | |

| P (0.2026 ≤ a ≤ 0.2126) = 0.95 | |

| GM | P (0.2753 ≤ λ ≤ 0.2840) = 0.95 |

| P (1576 ≤ Cp ≤ 1608) = 0.95 | |

| P (0.1885 ≤ a ≤ 0.194) = 0.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prałat, K.; Ciemnicka, J.; Koper, A.; Buczkowska, K.E.; Łoś, P. Comparison of the Thermal Properties of Geopolymer and Modified Gypsum. Polymers 2021, 13, 1220. https://doi.org/10.3390/polym13081220

Prałat K, Ciemnicka J, Koper A, Buczkowska KE, Łoś P. Comparison of the Thermal Properties of Geopolymer and Modified Gypsum. Polymers. 2021; 13(8):1220. https://doi.org/10.3390/polym13081220

Chicago/Turabian StylePrałat, Karol, Justyna Ciemnicka, Artur Koper, Katarzyna Ewa Buczkowska, and Piotr Łoś. 2021. "Comparison of the Thermal Properties of Geopolymer and Modified Gypsum" Polymers 13, no. 8: 1220. https://doi.org/10.3390/polym13081220