Influence of Gamma Irradiation and Water Aging on the Space Charge Characteristics of Epoxy Micro-Nano Composites

Abstract

:1. Introduction

2. Experimental Setup and Aging Procedure

2.1. Specimen Details

2.2. Aging Procedure

2.3. Space Charge Measurement

3. Results and Discussion

3.1. Impact of Gamma Irradiation on Space Charge Characteristics of Epoxy Micro-Nano Composites

3.2. Impact of Water Aging on Space Charge Characteristics of Epoxy Micro-Nanocomposites

3.3. Comparitive Study on the Impact of Gamma Irradiation and Water Aging of Space Charge Characteristics of Epoxy Micro-Nanocomposites

4. Conclusions and Future Scope

- Homo-charge formation due to charge injection phenomenon has been noticed in the space charge profile of both the unaged and aged epoxy micro-nano composite specimen.

- The threshold electric field (ET) tends to decrease and rate of space charge accumulation (b) increases with increase in gamma irradiation dose as well as increment in diffusion coefficient of water

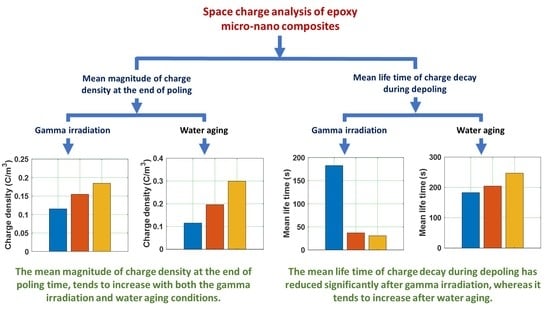

- Magnitude of accumulated space charge density is marginally increased in case of gamma irradiated samples than unaged sample, whereas a significant increment is noticed in water aged samples compared to unaged sample.

- The decay rate of the accumulated space charge is higher in gamma irradiated epoxy samples compared to unaged sample, whereas the space charge decay rate has reduced after water aging.

- Space charge profile of all the test samples during voltage polarity reversal reflected a portion of homo-charge accumulated before polarity reversal remained as hetero-charge just after polarity reversal.

- The electric field enhancement factor of aged samples tends to increase with increase in radiation dose as well as diffusion coefficient, indicating aged samples are subjected to higher field distortion

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tanaka, T.; Imai, T. Advanced Nanodielectrics; Jenny Stanford Publishing: Singapore, 2017; ISBN 9781315230740. [Google Scholar]

- Ellis, B. Chemistry and Technology of Epoxy Resins; Blackie Academic & Professional: Glasgow, UK, 1993; pp. 1–332. [Google Scholar]

- Bolon, D. Epoxy chemistry for electrical insulation. IEEE Electr. Insul. Mag. 1995, 11, 10–18. [Google Scholar] [CrossRef]

- Zhong, S.; Dang, Z.; Zhou, W.; Cai, H. Past and future on nanodielectrics. IET Nanodielectrics 2018, 1, 41–47. [Google Scholar] [CrossRef]

- Tanaka, T.; Imai, T. Advances in nanodielectric materials over the past 50 years. IEEE Electr. Insul. Mag. 2013, 29, 10–23. [Google Scholar] [CrossRef]

- Cao, Y.; Irwin, P.C.; Younsi, K. The future of nanodielectrics in the electrical power industry. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 797–807. [Google Scholar] [CrossRef]

- David, E.; Frechette, M. Polymer nanocomposites-major conclusions and achievements reached so far. IEEE Electr. Insul. Mag. 2013, 29, 29–36. [Google Scholar] [CrossRef]

- Atif, R.; Shyha, I.; Inam, F. Mechanical, Thermal, and Electrical Properties of Graphene-Epoxy Nanocomposites—A Review. Polymers 2016, 8, 281. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.M.; Jawaid, M. A Review on Potentiality of Nano Filler/Natural Fiber Filled Polymer Hybrid Composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Paul, S.; Sindhu, T.K. Effect of filler particle size on electric energy density of epoxy-aluminum nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2786–2794. [Google Scholar] [CrossRef]

- Pleşa, I.; Noţingher, P.V.; Schlögl, S.; Sumereder, C.; Muhr, M. Properties of Polymer Composites Used in High-Voltage Applications. Polymers 2016, 8, 173. [Google Scholar] [CrossRef]

- Roy, M.; Nelson, J.; MacCrone, R.; Schadler, L.; Reed, C.; Keefe, R.; Zenger, W. Polymer nanocomposite dielectrics—The role of the interface. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 629–643. [Google Scholar] [CrossRef]

- Šupová, M.; Martynková, G.S.; Barabaszová, K. Effect of Nanofillers Dispersion in Polymer Matrices: A Review. Sci. Adv. Mater. 2011, 3, 1–25. [Google Scholar] [CrossRef]

- Sarathi, R.; Sahu, R.; Rajeshkumar, P. Understanding the thermal, mechanical and electrical properties of epoxy nanocomposites. Mater. Sci. Eng. A 2007, 445, 567–578. [Google Scholar] [CrossRef]

- Suriati, G.; Mariatti, M.; Azizan, A. Effects of filler shape and size on the properties of silver filled epoxy composite for electronic applications. J. Mater. Sci. Mater. Electron. 2011, 22, 56–63. [Google Scholar] [CrossRef]

- Guo, Y.; Du, B.X.; Liu, Y.; Tian, L. Tracking of epoxy/MgO nanocomposites under DC Stress. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 884–887. [Google Scholar]

- Sancaktar, E.; Bai, L. Electrically Conductive Epoxy Adhesives. Polymers 2011, 3, 427–466. [Google Scholar] [CrossRef] [Green Version]

- Qiang, D.; Wang, Y.; Chen, G.; Andritsch, T. Dielectric properties of epoxy silica and boron nitride nanocomposites and moisture/temperature influences. IET Nanodielectr. 2018, 1, 48–59. [Google Scholar] [CrossRef]

- Fothergill, J.C.; Nelson, J.K.; Fu, M. Dielectric properties of epoxy nanocomposites containing TiO2, Al2O3 and ZnO fillers. In Proceedings of the Annual Report—Conference on Electrical Insulation and Dielectric Phenomena, Boulder, CO, USA, 20 October 2004. [Google Scholar]

- Iyer, G.; Gorur, R.S.; Richert, R.; Krivda, A.; Schmidt, L.E. Dielectric properties of epoxy based nanocomposites for high voltage insulation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 659–666. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, H.; Peng, Z. Electrical properties of epoxy-based nanocomposites filled with graphene oxide. IEEE Electr. Insul. Mag. 2016, 31, 108–111. [Google Scholar]

- Wang, Z.; Zhou, W.; Dong, L.; Sui, X.; Cai, H.; Zuo, J.; Chen, Q. Dielectric spectroscopy characterization of relaxation process in Ni/epoxy composites. J. Alloys Compd. 2016, 682, 738–745. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Jung, D.; Jung, I.; Cifuentes, J.; Rhee, K.; Hui, D. Enhancement of mechanical properties of aluminium/epoxy composites with silane functionalization of aluminium powder. Compos. Part B Eng. 2012, 43, 1743–1748. [Google Scholar] [CrossRef]

- Imai, T.; Sawa, F.; Nakano, T.; Ozaki, T.; Shimizu, T.; Kozako, M.; Tanaka, T. Effects of nano- and micro-filler mixture on electrical insulation properties of epoxy based composites. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 319–326. [Google Scholar] [CrossRef]

- Goyanes, S.N.; König, P.G.; Marconi, J.D. Dynamic mechanical analysis of particulate-filled epoxy resin. J. Appl. Polym. Sci. 2003, 88, 883–892. [Google Scholar] [CrossRef]

- Tsekmes, I.A.; Morshuis, P.H.F.; Smit, J.J.; Kochetov, R. Enhancing the thermal and electrical performance of epoxy microcomposites with the addition of nanofillers. IEEE Electr. Insul. Mag. 2015, 31, 32–42. [Google Scholar] [CrossRef]

- Mishra, P.; Gautam, R.; Vinu, R.; Sarathi, R. Understanding the water droplet initiated discharges on gamma irradiated silicone rubber insulation. Polym. Eng. Sci. 2019, 59, 182–191. [Google Scholar] [CrossRef] [Green Version]

- Babu, M.S.; Sarathi, R.; Vasa, N.J.; Imai, T. Investigation on space charge and charge trap characteristics of gamma-irradiated epoxy micro–nano composites. High Volt. 2020, 5, 191–201. [Google Scholar] [CrossRef]

- Babu, M.S.; Velmurugan, R.; Sarathi, R.; Imai, T. Influence of water ageing on variation in space charge and thermo-mechanical properties of epoxy micro-nano composites. IET Sci. Meas. Technol. 2021, 15, 44–60. [Google Scholar] [CrossRef]

- Desai, B.M.A.; Mishra, P.; Vasa, N.J.; Sarathi, R.; Imai, T. Understanding the performance of corona aged epoxy nano micro composites. Micro Nano Lett. 2018, 13, 1280–1285. [Google Scholar] [CrossRef]

- Liang, M.; Wong, K. Improving the Long-term Performance of Composite Insulators Use Nanocomposite: A Review. Energy Procedia 2017, 110, 168–173. [Google Scholar] [CrossRef]

- Das, S.; Gupta, N. Charge trapping and transport phenomenon in aged and unaged epoxy resin and polyethylene. Int. Trans. Electr. Energy Syst. 2014, 25, 948–957. [Google Scholar] [CrossRef]

- Preetha, P.; Thomas, M.J.; Ranjan, R. Electrothermal ageing of epoxy nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 2081–2089. [Google Scholar] [CrossRef]

- Ning, X.; Xiang, Z.; Peng, Z.; Zhang, S.; Chen, S. Effect of UV ageing on space charge characteristics of epoxy resin and its nanocomposites. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 784–787. [Google Scholar]

- Laghari, J.; Hammoud, A. A Brief Survey of Radiation Effects on Polymer Dielectrics. IEEE Trans. Nucl. Sci. 1990, 37, 1076–1083. [Google Scholar] [CrossRef]

- Chen, G.; Zhong, L.; Xie, H.; Banford, H.; Davies, A. The influence of oxidation on space charge formation in gamma-irradiated low-density polyethylene. Radiat. Phys. Chem. 2003, 66, 247–255. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Banford, H.M.; Davies, A.E. The influence of gamma radiation on space charge formation in low-density polyeth-ylene. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena—CEIDP ’96, Millbrae, CA, USA, 23 October 1996; pp. 821–824. [Google Scholar]

- Nogueira, P.; Torres, A.; Abad, M.J.; Cano, J.; Barral, L. Effect of water sorption on the structure and mechanical properties of an epoxy resin system. J. Appl. Polym. Sci. 2001, 80, 71–80. [Google Scholar] [CrossRef]

- Zou, C.; Fothergill, J.C.; Rowe, S.W. The effect of water absorption on the dielectric properties of epoxy nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 106–117. [Google Scholar] [CrossRef]

- Wang, L.; Wang, K.; Chen, L.; He, C.; Zhang, Y. Hydrothermal effects on the thermomechanical properties of high performance epoxy/clay nanocomposites. Polym. Eng. Sci. 2005, 46, 215–221. [Google Scholar] [CrossRef]

- Pitarresi, G.; Toscano, A.; Alessi, S. Fracture toughness of synthesised high-performance epoxies subject to accelerated water aging. Polym. Test. 2018, 68, 248–260. [Google Scholar] [CrossRef]

- Chen, G.; Hao, M.; Xu, Z.; Vaughan, A.; Cao, J.; Wang, H. Review of high voltage direct current cables. CSEE J. Power Energy Syst. 2015, 1, 9–21. [Google Scholar] [CrossRef]

- Montanari, G.; Morshuis, P. Space charge phenomenology in polymeric insulating materials. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 754–767. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Yin, Y. Research progress on space charge measurement and space charge characteristics of nanodielectrics. IET Nanodielectr. 2018, 1, 114–121. [Google Scholar] [CrossRef]

- Zhang, Y.; Christen, T.; Meng, X.; Chen, J.; Rocks, J. Research progress on space charge characteristics in polymeric insulation. J. Adv. Dielectr. 2016, 6, 1630001. [Google Scholar] [CrossRef] [Green Version]

- Noah, P.M.; Zavattoni, L.; Agnel, S.; Notingher, P.; Laurentie, J.; Guille, O.; Vinson, P.; Girodet, A. Measurement of space charge distribution in alumina-filled epoxy resin for application in HVDC GIS. In Proceedings of the 2017 IEEE Conference on Electrical Insulation and Dielectric Phenomenon (CEIDP), Fort Worth, TX, USA, 22–25 October 2017; pp. 613–616. [Google Scholar]

- Wang, S.; Luo, S.; Tu, Y.; Wang, C.; Qin, S. Effect of polarity reversal on space charge properties of CB/LDPE composite under DC field. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1349–1354. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Wu, K.; Peng, Z.R.; Cheng, Y.H.; Tu, D.M. Effect of voltage reversal on space charge and transient field in LDPE films under temperature gradient. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 140–149. [Google Scholar] [CrossRef]

- Chen, G.; Davies, A.; Banford, H. Influence of radiation environments on space charge formation in γ-irradiated LDPE. IEEE Trans. Dielectr. Electr. Insul. 1999, 6, 882–886. [Google Scholar] [CrossRef]

- Montanari, G.; Palmieri, F. The effect of humidity on space charge accumulation in XLPE. In Proceedings of the 2003 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Albuquerque, NM, USA, 19–22 October 2003; pp. 205–208. [Google Scholar]

- Lewis, T.J. Interfaces: Nanometric dielectrics. J. Phys. D Appl. Phys. 2005, 38, 202–212. [Google Scholar] [CrossRef]

- Tanaka, T.; Kozako, M.; Fuse, N.; Ohki, Y. Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 669–681. [Google Scholar] [CrossRef]

- Ahmed, N.; Srinivas, N. Review of space charge measurements in dielectrics. IEEE Trans. Dielectr. Electr. Insul. 1997, 4, 644–656. [Google Scholar] [CrossRef]

- Huner, U. Effect of Water Absorption on the Mechanical Properties of Flax Fiber Reinforced Epoxy Composites. Adv. Sci. Technol. Res. J. 2015, 9, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Chong, Y.L.; Fu, M. Calibration of the pulsed electroacoustic technique in the presence of trapped charge. Meas. Sci. Technol. 2006, 17, 1974–1980. [Google Scholar] [CrossRef] [Green Version]

- Dissado, L.; Laurent, C.; Montanari, G.; Morshuis, P. Demonstrating a threshold for trapped space charge accumulation in solid dielectrics under dc field. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 612–620. [Google Scholar] [CrossRef]

- Alijagic-Jonuz, B. Dielectric Properties and Space Charge Dynamics of Polymeric High Voltage DC Insulating Materials. Ph.D. Thesis, Faculty of Electrical Engineering, Mathematics and Computer Science, Delft, The Netherlands, 17 December 2007. [Google Scholar]

- Montanari, G.; Fabiani, D. Evaluation of dc insulation performance based on space-charge measurements and accelerated life tests. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 322–328. [Google Scholar] [CrossRef]

- Zhou, T.-C.; Chen, G.; Liao, R.-J.; Xu, Z. Charge trapping and detrapping in polymeric materials: Trapping parameters. J. Appl. Phys. 2011, 110, 043724. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Fu, M. The Influence of Gamma Irradiation on Space Charge in LDPE. In Proceedings of the 2006 IEEE 8th International Conference on Properties and applications of Dielectric Materials, Bali, Indonesia, 26–30 June 2006; pp. 131–134. [Google Scholar]

- Liu, P.; Ning, X.; Peng, Z.; Xiang, Z.; Feng, H.; Zhang, H. Effect of temperature on space charge characteristics in epoxy resin. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 65–71. [Google Scholar] [CrossRef]

- Fabiani, D.; Montanari, G.C.; Testa, L. Effect of aspect ratio and water contamination on the electric properties of nanostructured insulating materials. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 221–230. [Google Scholar] [CrossRef]

- Saha, D.; Anisimov, A.G.; Groves, R.M.; Tsekmes, I.A.; Morshuis, P.H.F.; Kochetov, R. Epoxy-hBN nanocomposites: A study on space charge behavior and effects upon material. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1718–1725. [Google Scholar] [CrossRef]

- Montanari, G. Relation between space charge and polymeric insulation ageing: Cause and effect. IEE Proc. Sci. Meas. Technol. 2003, 150, 53–57. [Google Scholar] [CrossRef]

- Fu, M.; Dissado, L.A.; Chen, G.; Fothergill, J.C. Space charge formation and its modified electric field under applied voltage reversal and temperature gradient in XLPE cable. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 851–860. [Google Scholar] [CrossRef] [Green Version]

| Specimen | ET (kV/mm−1) | b (µCV−1 m−2) |

|---|---|---|

| Unaged | 8.08 | 0.876 |

| 4 kGy | 7.88 | 0.952 |

| 8 kGy | 7.83 | 1.038 |

| Specimen | n1 | a | n2 | b |

|---|---|---|---|---|

| Unaged | 0.0502 | 0.00548 | 0.0649 | 2.26 × 10−5 |

| 4 kGy | 0.1190 | 0.02708 | 0.0356 | 2.37 × 10−4 |

| 8 kGy | 0.1288 | 0.03261 | 0.0557 | 2.25 × 10−4 |

| Specimen | ET (kV/mm−1) | b (µCV−1 m−2) |

|---|---|---|

| Unaged | 8.03 | 0.875 |

| Aged at RT | 6.26 | 0.891 |

| Aged at 90 °C | 5.94 | 1.008 |

| Specimen | n1 | a | n2 | b |

|---|---|---|---|---|

| Unaged | 0.0502 | 0.00548 | 0.0649 | 2.26 × 10−5 |

| Aged at RT | 0.0908 | 0.00489 | 0.1053 | 11.23 × 10−5 |

| Aged at 90 °C | 0.1524 | 0.00405 | 0.1465 | 12.21 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sukesh Babu, M.; Sarathi, R.; Imai, T.; Tanaka, T. Influence of Gamma Irradiation and Water Aging on the Space Charge Characteristics of Epoxy Micro-Nano Composites. Polymers 2021, 13, 964. https://doi.org/10.3390/polym13060964

Sukesh Babu M, Sarathi R, Imai T, Tanaka T. Influence of Gamma Irradiation and Water Aging on the Space Charge Characteristics of Epoxy Micro-Nano Composites. Polymers. 2021; 13(6):964. https://doi.org/10.3390/polym13060964

Chicago/Turabian StyleSukesh Babu, Myneni, Ramanujam Sarathi, Takahiro Imai, and Toshikatsu Tanaka. 2021. "Influence of Gamma Irradiation and Water Aging on the Space Charge Characteristics of Epoxy Micro-Nano Composites" Polymers 13, no. 6: 964. https://doi.org/10.3390/polym13060964