Magnetic Polymer Composite Particles: Design and Magnetorheology

Abstract

:1. Introduction

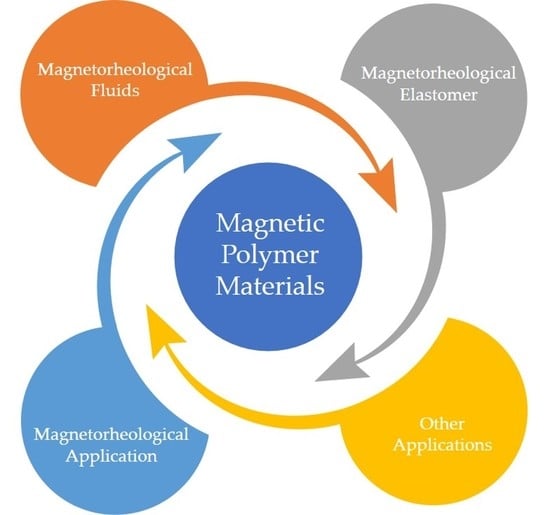

2. Magnetic Polymer Materials

2.1. Magnetic Iron-Based Polymer Composites

2.1.1. Iron Oxide

2.1.2. Carbonyl Iron

2.2. Other Magnetic Meltallic Polymer Composites

3. MR Characteristics

3.1. MR Fluids

| Rheological Model | Equation | Ref. |

|---|---|---|

| Bingham | [77] | |

| Herschel–Bulkley | [77] | |

| Casson | [77] | |

| Papanastasiou | [32] | |

| Cho–Choi–Jhon | [78] |

3.2. MR Elastomers

4. Applications of Magnetic Polymer Composite Particles

4.1. MR Applications

4.2. Other Applications

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lin, X.-M.; Samia, A.C.S. Synthesis, assembly and physical properties of magnetic nanoparticles. J. Magn. Magn. Mater. 2006, 305, 100–109. [Google Scholar]

- Lin, N.; Huang, J.; Dufresne, A. Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: A review. Nanoscale 2012, 4, 3274–3294. [Google Scholar]

- Sorokin, V.V.; Stepanov, G.V.; Shamonin, M.; Monkman, G.J.; Khokhlov, A.R.; Kramarenko, E.Y. Hysteresis of the viscoelastic properties and the normal force in magnetically and mechanically soft magnetoactive elastomers: Effects of filler composition, strain amplitude and magnetic field. Polymer 2015, 76, 191–202. [Google Scholar]

- Deng, L.; Jia, W.; Zheng, W.; Liu, H.; Jiang, D.; Li, Z.; Tian, Y.; Zhang, W.; Liu, J. Hierarchically magnetic Ni–Al binary layered double hydroxides: Towards tunable dual electro/magneto-stimuli performances. J. Ind. Eng. Chem. 2018, 58, 163–171. [Google Scholar]

- Gorodov, V.V.; Kostrov, S.A.; Kamyshinskii, R.A.; Kramarenko, E.Y.; Muzafarov, A.M. Modification of carbonyl iron particles by carboxyl-containing polydimethylsiloxanes. Russian Chem. Bull. 2018, 67, 1639–1647. [Google Scholar]

- Arief, I.; Mukhopadhyay, P.K. Yielding behavior and temperature-induced on-field oscillatory rheological studies in a novel MR suspension containing polymer-capped Fe3Ni alloy microspheres. J. Magn. Magn. Mater. 2017, 429, 236–240. [Google Scholar]

- Sun, C.; Lee, J.S.H.; Zhang, M. Magnetic nanoparticles in MR imaging and drug delivery. Adv. Drug Delivery Rev. 2008, 60, 1252–1265. [Google Scholar]

- Xie, Y.; Kocaefe, D.; Chen, C.; Kocaefe, Y. Review of Research on Template Methods in Preparation of Nanomaterials. J. Nanomater. 2016, 2016, 2302595. [Google Scholar]

- Adams, S.A.; Hauser, J.L.; Allen, A.C.; Lindquist, K.P.; Ramirez, A.P.; Oliver, S.; Zhang, J.Z. Fe3O4@SiO2 Nanoparticles Functionalized with Gold and Poly(vinylpyrrolidone) for Bio-Separation and Sensing Applications. ACS Appl. Nano Mater. 2018, 1, 1406–1412. [Google Scholar]

- Parveen, S.; Misra, R.; Sahoo, S.K. Nanoparticles: A boon to drug delivery, therapeutics, diagnostics and imaging. Nanomed. Nanotechnol. Biol. Med. 2012, 8, 147–166. [Google Scholar]

- Shubayev, V.I.; Pisanic, T.R.; Jin, S. Magnetic nanoparticles for theragnostics. Adv. Drug Delivery Rev. 2009, 61, 467–477. [Google Scholar]

- Cole, A.J.; Yang, V.C.; David, A.E. Cancer theranostics: The rise of targeted magnetic nanoparticles. Trends Biotechnol. 2011, 29, 323–332. [Google Scholar]

- Sharma, R.; Sharma, A.; Chen, C. State of art on bioimaging by nanoparticles in hyperthermia and thermometry: Visualization of tissue protein targeting. Open Nanomed. J. 2011, 3, 10–23. [Google Scholar]

- Audonnet, V.; Malaquin, L.; Viovy, J.-L. Polymeric coatings on micro- and nanometric particles for bioapplications. Bioanal. Rev. 2011, 3, 41–66. [Google Scholar]

- Gijs, M.A.M.; Lacharme, F.; Lehmann, U. Microfluidic Applications of Magnetic Particles for Biological Analysis and Catalysis. Chem. Rev. 2010, 110, 1518–1563. [Google Scholar]

- Khan, A. Preparation and characterization of magnetic nanoparticles embedded in microgels. Mater. Lett. 2008, 62, 898–902. [Google Scholar]

- Li, G.-y.; Jiang, Y.-r.; Huang, K.-l.; Ding, P.; Chen, J. Preparation and properties of magnetic Fe3O4–chitosan nanoparticles. J. Alloys Compd. 2008, 466, 451–456. [Google Scholar]

- Raj, K.; Moskowitz, B.; Casciari, R. Advances in ferrofluid technology. J. Magn. Magn. Mater. 1995, 149, 174–180. [Google Scholar]

- Roger, J.; Pons, J.; Massart, R.; Halbreich, A.; Bacri, J. Some biomedical applications of ferrofluids. Eur. Phys. J. Appl. Phys. 1999, 5, 321–325. [Google Scholar]

- Ramos, J.; Klingenberg, D.J.; Hidalgo-Alvarez, R.; Vicente, J.d. Steady shear magnetorheology of inverse ferrofluids. J. Rheol. 2011, 55, 127–152. [Google Scholar]

- Esmaeilnezhad, E.; Choi, H.J.; Schaffie, M.; Gholizadeh, M.; Ranjbar, M.; Kwon, S.H. Rheological analysis of magnetite added carbonyl iron based magnetorheological fluid. J. Magn. Magn. Mater. 2017, 444, 161–167. [Google Scholar]

- Bae, D.H.; Choi, H.J.; Choi, K.; Nam, J.D.; Islam, M.S.; Kao, N. Microcrystalline cellulose added carbonyl iron suspension and its magnetorheology. Colloids Surf. A 2017, 514, 161–167. [Google Scholar]

- Chae, H.S.; Piao, S.H.; Maity, A.; Choi, H.J. Additive role of attapulgite nanoclay on carbonyl iron-based magnetorheological suspension. Colloid Polym. Sci. 2015, 293, 89–95. [Google Scholar]

- Piao, S.H.; Chae, H.S.; Choi, H.J. Carbonyl Iron Suspension With Core–Shell Structured Fe3O4@SiO2 Nanoparticle Additives and its Magnetorheological Property. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar]

- Kim, M.H.; Choi, K.; Nam, J.D.; Choi, H.J. Enhanced magnetorheological response of magnetic chromium dioxide nanoparticle added carbonyl iron suspension. Smart Mater. Struct. 2017, 26, 095006. [Google Scholar]

- Upadhyay, R.V.; Laherisheth, Z.; Shah, K. Rheological properties of soft magnetic flake shaped iron particle based magnetorheological fluid in dynamic mode. Smart Mater. Struct. 2014, 23, 015002. [Google Scholar]

- de Vicente, J.; González-Caballero, F.; Bossis, G.; Volkova, O. Normal force study in concentrated carbonyl iron magnetorheological suspensions. J. Rheol. 2002, 46, 1295–1303. [Google Scholar]

- Bombard, A.J.F.; Alcântara, M.R.; Knobel, M.; Volpe, P.L.O. Experimental study of mr suspensions of carbonyl iron powders with different particle sizes. Int. J. Mod. Phys. B 2005, 19, 1332–1338. [Google Scholar]

- Pu, H.; Jiang, F. Towards high sedimentation stability: Magnetorheological fluids based on CNT/Fe3O4 nanocomposites. Nanotechnology 2005, 16, 1486–1489. [Google Scholar]

- Seo, Y.P.; Han, S.; Choi, J.; Takahara, A.; Choi, H.J.; Seo, Y. Searching for a Stable High-Performance Magnetorheological Suspension. Adv. Mater. 2018, 30, 1704769. [Google Scholar]

- Han, S.; Choi, J.; Seo, Y.P.; Park, I.J.; Choi, H.J.; Seo, Y. High-Performance Magnetorheological Suspensions of Pickering-Emulsion-Polymerized Polystyrene/Fe3O4 Particles with Enhanced Stability. Langmuir 2018, 34, 2807–2814. [Google Scholar]

- Papanastasiou, T.C. Flows of Materials with Yield. J. Rheol. 1987, 31, 385–404. [Google Scholar]

- Jun, C.S.; Kwon, S.H.; Choi, H.J.; Seo, Y. Polymeric Nanoparticle-Coated Pickering Emulsion-Synthesized Conducting Polyaniline Hybrid Particles and Their Electrorheological Study. ACS Appl. Mater. Interfaces 2017, 9, 44811–44819. [Google Scholar]

- Park, B.J.; Fang, F.F.; Choi, H.J. Magnetorheology: Materials and application. Soft Matter 2010, 6, 5246–5253. [Google Scholar]

- Lee, J.H.; Cho, M.S.; Choi, H.J.; Jhon, M.S. Effect of polymerization temperature on polyaniline based electrorheological suspensions. Colloid Polym. Sci. 1999, 277, 73–76. [Google Scholar]

- Prasad Rao, J.; Gruenberg, P.; Geckeler, K.E. Magnetic zero-valent metal polymer nanoparticles: Current trends, scope, and perspectives. Prog. Polym. Sci. 2015, 40, 138–147. [Google Scholar]

- Bloom, I.; Walker, L.K.; Basco, J.K.; Malkow, T.; Saturnio, A.; De Marco, G.; Tsotridis, G. A comparison of Fuel Cell Testing protocols – A case study: Protocols used by the U.S. Department of Energy, European Union, International Electrotechnical Commission/Fuel Cell Testing and Standardization Network, and Fuel Cell Technical Team. J. Power Sources 2013, 243, 451–457. [Google Scholar]

- Deng, Y.; Wang, L.; Yang, W.; Fu, S.; Elaı‘ssari, A. Preparation of magnetic polymeric particles via inverse microemulsion polymerization process. J. Magn. Magn. Mater. 2003, 257, 69–78. [Google Scholar]

- Mori, Y.; Kawaguchi, H. Impact of initiators in preparing magnetic polymer particles by miniemulsion polymerization. Colloids Surf. B 2007, 56, 246–254. [Google Scholar]

- Natour, S.; Levi-Zada, A.; Abu-Reziq, R. Magnetic Polyurea Nano-Capsules Synthesized via Interfacial Polymerization in Inverse Nano-Emulsion. Molecules 2019, 24. art. No. 2663. [Google Scholar]

- Lu, S.; Ramos, J.; Forcada, J. Self-Stabilized Magnetic Polymeric Composite Nanoparticles by Emulsifier-Free Miniemulsion Polymerization. Langmuir 2007, 23, 12893–12900. [Google Scholar]

- Kondo, A.; Kamura, H.; Higashitani, K. Development and application of thermo-sensitive magnetic immunomicrospheres for antibody purification. Appl. Microbiol. Biotechnol. 1994, 41, 99–105. [Google Scholar]

- Lu, S.; Qu, R.; Forcada, J. Preparation of magnetic polymeric composite nanoparticles by seeded emulsion polymerization. Mater. Lett. 2009, 63, 770–772. [Google Scholar]

- Choi, J.; Han, S.; Kim, H.; Sohn, E.-H.; Choi, H.J.; Seo, Y. Suspensions of Hollow Polydivinylbenzene Nanoparticles Decorated with Fe3O4 Nanoparticles as Magnetorheological Fluids for Microfluidics Applications. ACS Appl. Nano Mater. 2019, 2, 6939–6947. [Google Scholar]

- Agustin-Serrano, R.; Donado, F.; Rubio-Rosas, E. Magnetorheological fluid based on submicrometric silica-coated magnetite particles under an oscillatory magnetic field. J. Magn. Magn. Mater. 2013, 335, 149–158. [Google Scholar]

- Kim, M.W.; Bae, D.H.; Kwon, S.H.; Choi, H.J. Magnetite Embedded Mini-Emulsion Polymerized Polystyrene Particles and Their Magnetorheology. Macromol. Res. 2018, 26, 353–358. [Google Scholar]

- Chae, H.S.; Piao, S.H.; Han, W.J.; Choi, H.J. Core/Shell Polystyrene/Magnetite Hybrid Nanoparticles Fabricated by Pickering Emulsion Polymerization and Their Magnetorheological Response. Macromol. Chem. Phys. 2018, 219, 1700408. [Google Scholar]

- Gao, C.Y.; Piao, S.H.; Choi, H.J. Pickering emulsion polymerized magnetite-poly(methyl methacrylate) composite particles and their magnetorheology. Colloid Polym. Sci. 2017, 295, 959–966. [Google Scholar]

- Ahn, W.J.; Jung, H.S.; Choi, H.J. Pickering emulsion polymerized smart magnetic poly(methyl methacrylate)/Fe 2 O 3 composite particles and their stimulus-response. RSC Adv. 2015, 5, 23094–23100. [Google Scholar]

- Gao, C.Y.; Kim, M.W.; Bae, D.H.; Dong, Y.Z.; Piao, S.H.; Choi, H.J. Fe3O4 nanoparticle-embedded polystyrene composite particles fabricated via a Shirasu porous glass membrane technique and their magnetorheology. Polymer 2017, 125, 21–29. [Google Scholar]

- Park, D.E.; Chae, H.S.; Choi, H.J.; Maity, A. Magnetite–polypyrrole core–shell structured microspheres and their dual stimuli-response under electric and magnetic fields. J. Mater. Chem. C 2015, 3, 3150–3158. [Google Scholar]

- Dong, Y.Z.; Choi, H.J. Synthesis of Smart Poly(diphenylamine)/Magnetic Particle Composites and Their Electric/Magnetic Stimuli-Response. Macromol. Res. 2018, 26, 667–670. [Google Scholar]

- Kwon, S.H.; Sim, B.; Choi, H.J. Magnetorheological Characteristics of Nano-Sized Iron Oxide Coated Polyaniline Composites. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar]

- Lee, J.H.; Lu, Q.; Lee, J.Y.; Choi, H.J. Polymer-Magnetic Composite Particles of Fe3O4/Poly(o-anisidine) and Their Suspension Characteristics under Applied Magnetic Fields. Polymers 2019, 11, 219. [Google Scholar]

- Buendía, S.; Cabañas, G.; Álvarez-Lucio, G.; Montiel-Sánchez, H.; Navarro-Clemente, M.E.; Corea, M. Preparation of magnetic polymer particles with nanoparticles of Fe(0). J. Colloid Interface Sci. 2011, 354, 139–143. [Google Scholar]

- Fang, Z.; Qiu, X.; Huang, R.; Qiu, X.; Li, M. Removal of chromium in electroplating wastewater by nanoscale zero-valent metal with synergistic effect of reduction and immobilization. Desalination 2011, 280, 224–231. [Google Scholar]

- Mrlik, M.; Sedlacik, M.; Pavlinek, V.; Bazant, P.; Saha, P.; Peer, P.; Filip, P. Synthesis and magnetorheological characteristics of ribbon-like, polypyrrole-coated carbonyl iron suspensions under oscillatory shear. J. Appl. Polym. Sci. 2013, 128, 2977–2982. [Google Scholar]

- Mrlík, M.; Ilčíková, M.; Pavlínek, V.; Mosnáček, J.; Peer, P.; Filip, P. Improved thermooxidation and sedimentation stability of covalently-coated carbonyl iron particles with cholesteryl groups and their influence on magnetorheology. J. Colloid Interface Sci. 2013, 396, 146–151. [Google Scholar]

- Cvek, M.; Mrlík, M.; Mosnáček, J.; Babayan, V.; Kuceková, Z.; Humpolíček, P.; Pavlínek, V. The chemical stability and cytotoxicity of carbonyl iron particles grafted with poly(glycidyl methacrylate) and the magnetorheological activity of their suspensions. RSC Adv. 2015, 5, 72816–72824. [Google Scholar]

- Mrlik, M.; Pavlinek, V. Magnetorheological suspensions based on modified carbonyl iron particles with an extremely thin poly(n-butyl acrylate) layer and their enhanced stability properties. Smart Mater. Struct. 2016, 25, 085011. [Google Scholar]

- Cho, M.S.; Lim, S.T.; Jang, I.B.; Choi, H.J.; Jhon, M.S. Encapsulation of spherical iron-particle with PMMA and its magnetorheological particles. IEEE Trans. Magn. 2004, 40, 3036–3038. [Google Scholar]

- Park, I.H.; Kwon, S.H.; Choi, H.J.; Kim, N.H.; You, C.Y. Polyindole-Coated Soft-Magnetic Particles and their Viscoelastic Behaviors under Applied Magnetic Field. J. Magn. 2019, 24, 155–161. [Google Scholar]

- Lee, J.H.; Choi, H.J. Synthesis of core-shell formed carbonyl iron/polydiphenylamine particles and their rheological response under applied magnetic fields. Colloid Polym. Sci. 2018, 296, 1857–1865. [Google Scholar]

- Min, T.H.; Choi, H.J.; Kim, N.-H.; Park, K.; You, C.-Y. Effects of surface treatment on magnetic carbonyl iron/polyaniline microspheres and their magnetorheological study. Colloids Surf. A 2017, 531, 48–55. [Google Scholar]

- Kim, Y.H.; Ahn, W.J.; Choi, H.J.; Seo, Y. Fabrication and magnetic stimuli-response of polydopamine-coated core–shell structured carbonyl iron microspheres. Colloid Polym. Sci. 2016, 294, 329–337. [Google Scholar]

- Liu, Y.D.; Hong, C.H.; Choi, H.J. Polymeric colloidal magnetic composite microspheres and their magneto-responsive characteristics. Macromol. Res. 2012, 20, 1211–1218. [Google Scholar]

- Korth, B.D.; Keng, P.; Shim, I.; Bowles, S.E.; Tang, C.; Kowalewski, T.; Nebesny, K.W.; Pyun, J. Polymer-Coated Ferromagnetic Colloids from Well-Defined Macromolecular Surfactants and Assembly into Nanoparticle Chains. J. Am. Chem. Soc. 2006, 128, 6562–6563. [Google Scholar]

- Chatterjee, J.; Bettge, M.; Haik, Y.; Jen Chen, C. Synthesis and characterization of polymer encapsulated Cu–Ni magnetic nanoparticles for hyperthermia applications. J. Magn. Magn. Mater. 2005, 293, 303–309. [Google Scholar]

- Kim, J.N.; Dong, Y.Z.; Choi, H.J. Pickering Emulsion Polymerized Polyaniline/Zinc-ferrite Composite Particles and Their Dual Electrorheological and Magnetorheological Responses. ACS Omega 2020, 5, 7675–7682. [Google Scholar]

- Seo, Y.P.; Choi, H.J.; Lee, J.R.; Seo, Y. Modeling and analysis of an electrorheological flow behavior containing semiconducting graphene oxide/polyaniline composite particles. Colloids Surf. A 2014, 457, 363–367. [Google Scholar]

- Rosenfeld, N.C.; Wereley, N.M. Volume-constrained optimization of magnetorheological and electrorheological valves and dampers. Smart Mater. Struct. 2004, 13, 1303–1313. [Google Scholar]

- Choi, H.J.; Zhang, W.L.; Kim, S.; Seo, Y. Core-Shell Structured Electro- and Magneto-Responsive Materials: Fabrication and Characteristics. Materials 2014, 7, 7460–7471. [Google Scholar]

- Ghaffari, A.; Hashemabadi, S.H.; Ashtiani, M. A review on the simulation and modeling of magnetorheological fluids. J. Intell. Mater. Syst. Struct. 2014, 26, 881–904. [Google Scholar]

- Kim, Y.J.; Liu, Y.D.; Seo, Y.; Choi, H.J. Pickering-Emulsion-Polymerized Polystyrene/Fe2O3 Composite Particles and Their Magnetoresponsive Characteristics. Langmuir 2013, 29, 4959–4965. [Google Scholar]

- Ke, D.D.; Turcotte, G. Viscosity of Biomaterials. Chem. Eng. Commun. 1980, 6, 273–282. [Google Scholar]

- Cho, M.S.; Choi, H.J.; Jhon, M.S. Shear stress analysis of a semiconducting polymer based electrorheological fluid system. Polymer 2005, 46, 11484–11488. [Google Scholar]

- Choi, H.J.; Cho, M.S.; Kim, J.W.; Kim, C.A.; Jhon, M.S. A yield stress scaling function for electrorheological fluids. Appl. Phys. Lett. 2001, 78, 3806–3808. [Google Scholar]

- Seo, Y.P.; Choi, H.J.; Seo, Y. A simplified model for analyzing the flow behavior of electrorheological fluids containing silica nanoparticle-decorated polyaniline nanofibers. Soft Matter 2012, 8, 4659–4663. [Google Scholar]

- Seo, Y. A new yield stress scaling function for electrorheological fluids. J. Non-Newtonian Fluid Mech. 2011, 166, 241–243. [Google Scholar]

- Schwarzl, F. Numerical calculation of stress relaxation modulus from dynamic data for linear viscoelastic materials. Rheol. Acta 1975, 14, 581–590. [Google Scholar]

- Park, B.J.; Kim, T.H.; Choi, H.J.; Lee, J.H. Emulsion polymerized polystyrene/montmorillonite nanocomposite and its viscoelastic characteristics. J. Macromol. Sci., Part B: Phys. 2007, 46, 341–354. [Google Scholar]

- Chertovich, A.V.; Stepanov, G.V.; Kramarenko, E.Y.; Khokhlov, A.R. New Composite Elastomers with Giant Magnetic Response. Macromol. Mater. Eng. 2010, 295, 336–341. [Google Scholar]

- Kwon, S.H.; Lee, J.H.; Choi, H.J. Magnetic Particle Filled Elastomeric Hybrid Composites and Their Magnetorheological Response. Materials 2018, 11, 1040. [Google Scholar]

- Denver, H.; Heiman, T.; Martin, E.; Gupta, A.; Borca-Tasciuc, D.-A. Fabrication of polydimethylsiloxane composites with nickel nanoparticle and nanowire fillers and study of their mechanical and magnetic properties. J. Appl. Phys. 2009, 106, 064909. [Google Scholar]

- Antonel, P.S.; Jorge, G.; Perez, O.E.; Butera, A.; Leyva, A.G.; Negri, R.M. Magnetic and elastic properties of CoFe2O4- polydimethylsiloxane magnetically oriented elastomer nanocomposites. J. Appl. Phys. 2011, 110, 043920. [Google Scholar]

- Mordina, B.; Tiwari, R.K.; Setua, D.K.; Sharma, A. Magnetorheology of Polydimethylsiloxane Elastomer/FeCo3 Nanocomposite. J. Phys. Chem. C 2014, 118, 25684–25703. [Google Scholar]

- Li, Y.; Li, J.; Li, W.; Du, H. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23, 123001. [Google Scholar]

- Cvek, M.; Mrlík, M.; Ilčíková, M.; Mosnáček, J.; Münster, L.; Pavlínek, V. Synthesis of Silicone Elastomers Containing Silyl-Based Polymer-Grafted Carbonyl Iron Particles: An Efficient Way To Improve Magnetorheological, Damping, and Sensing Performances. Macromolecules 2017, 50, 2189–2200. [Google Scholar]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Composites Part B 2008, 39, 933–961. [Google Scholar]

- Fuchs, A.; Sutrisno, J.; Gordaninejad, F.; Caglar, M.B.; Yanming, L. Surface polymerization of iron particles for magnetorheological elastomers. J. Appl. Polym. Sci. 2010, 117, 934–942. [Google Scholar]

- Mehnert, M.; Hossain, M.; Steinmann, P. Towards a thermo-magneto-mechanical framework for magneto-rheological elastomers. Int. J. Solids Struct. 2017, 128, 117–132. [Google Scholar]

- Parlak, Z.; Engin, T. Time-dependent CFD and quasi-static analysis of magnetorheological fluid dampers with experimental validation. Int. J. Mech. Sci. 2012, 64, 22–31. [Google Scholar]

- Yang, T.-H.; Koo, J.-H.; Kim, S.-Y.; Kyung, K.-U.; Kwon, D.-S. Application of magnetorheological fluids for a miniature haptic button: Experimental evaluation. J. Intell. Mater. Syst. Struct. 2012, 23, 1025–1031. [Google Scholar]

- Chen, J.Z.; Liao, W.H. Design, testing and control of a magnetorheological actuator for assistive knee braces. Smart Mater. Struct. 2010, 19, 035029. [Google Scholar]

- Lee, C.-H.; Jang, M.-G. Virtual Surface Characteristics of a Tactile Display Using Magneto-Rheological Fluids. Sensors 2011, 11, 2845–2856. [Google Scholar]

- Patil, S.R.; Powar, K.P.; Sawant, S.M. Thermal analysis of magnetorheological brake for automotive application. Appl. Therm. Eng. 2016, 98, 238–245. [Google Scholar]

- Neelakantan, V.A.; Washington, G.N. Modeling and reduction of centrifuging in magnetorheological (MR) transmission clutches for automotive applications. J. Intell. Mater. Syst. Struct. 2005, 16, 703–711. [Google Scholar]

- Choi, S.; Song, H.; Lee, H.; Lim, S.; Kim, J.; Choi, H.J. Vibration control of a passenger vehicle featuring magnetorheological engine mounts. Int. J. Veh. Des. 2003, 33, 2–16. [Google Scholar]

- Lee, J.-W.; Hong, K.-P.; Kwon, S.H.; Choi, H.J.; Cho, M.-W. Suspension Rheology and Magnetorheological Finishing Characteristics of Biopolymer-Coated Carbonyliron Particles. Ind. Eng. Chem. Res. 2017, 56, 2416–2424. [Google Scholar]

- Oh, J.S.; Kim, J.K.; Lee, S.R.; Choi, S.B.; Song, B.K. Design of tactile device for medical application using magnetorheological fluid. J. Phys.: Conf. Ser. 2013, 412, 012047. [Google Scholar]

- Ginder, J.; Schlotter, W.; Nichols, M. Magnetorheological Elastomers in Tunable Vibration Absorbers; SPIE: Bellingham, WA, USA, 2001; Volume 4331. [Google Scholar]

- Yang, Z.; Qin, C.; Rao, Z.; Ta, N.; Gong, X. Design and analyses of axial semi-active dynamic vibration absorbers based on magnetorheological elastomers. J. Intell. Mater. Syst. Struct. 2014, 25, 2199–2207. [Google Scholar]

- Mikhailov, V.P.; Bazinenkov, A.M. Active vibration isolation platform on base of magnetorheological elastomers. J. Magn. Magn. Mater. 2017, 431, 266–268. [Google Scholar]

- Sun, S.; Yang, J.; Du, H.; Zhang, S.; Yan, T.; Nakano, M.; Li, W. Development of magnetorheological elastomers–based tuned mass damper for building protection from seismic events. J. Intell. Mater. Syst. Struct. 2018, 29, 1777–1789. [Google Scholar]

- Dyniewicz, B.; Bajkowski, J.M.; Bajer, C.I. Semi-active control of a sandwich beam partially filled with magnetorheological elastomer. Mech. Syst. Signal Proc. 2015, 60–61, 695–705. [Google Scholar]

- Szmidt, T.; Pisarski, D.; Konowrocki, R.; Awietjan, S.; Boczkowska, A. Adaptive Damping of a Double-Beam Structure Based on Magnetorheological Elastomer. Shock Vib. 2019, 2019, 8526179. [Google Scholar]

- Ge, L.; Gong, X.; Wang, Y.; Xuan, S. The conductive three dimensional topological structure enhanced magnetorheological elastomer towards a strain sensor. Compos. Sci. Technol. 2016, 135, 92–99. [Google Scholar]

- Kawasetsu, T.; Horii, T.; Ishihara, H.; Asada, M. Mexican-hat-like response in a flexible tactile sensor using a magnetorheological elastomer. Sensors 2018, 18, 587. [Google Scholar]

- Lee, D.; Lee, M.; Jung, N.; Yun, M.; Lee, J.; Thundat, T.; Jeon, S. Modulus-tunable magnetorheological elastomer microcantilevers. Smart Mater. Struct. 2014, 23, 055017. [Google Scholar]

- Xu, Z.; Wang, Q.; Zhu, K.; Jiang, S.; Wu, H.; Yi, L. Preparation and characterization of magnetorheological elastic polishing composites. J. Intell. Mater. Syst. Struct. 2019, 30, 1481–1492. [Google Scholar]

- Fahrni, F.; Prins, M.W.J.; van Ijzendoorn, L.J. Micro-fluidic actuation using magnetic artificial cilia. Lab Chip 2009, 9, 3413–3421. [Google Scholar]

- Zhao, X.; Kim, J.; Cezar, C.A.; Huebsch, N.; Lee, K.; Bouhadir, K.; Mooney, D.J. Active scaffolds for on-demand drug and cell delivery. Proc. Natl. Acad. Sci. USA 2011, 108, 67. [Google Scholar]

- Gu, H.; Lee, S.W.; Carnicelli, J.; Zhang, T.; Ren, D. Magnetically driven active topography for long-term biofilm control. Nat. Commun. 2020, 11, 2211. [Google Scholar]

- Jones, C.D.; Lyon, L.A. Synthesis and Characterization of Multiresponsive Core−Shell Microgels. Macromolecules 2000, 33, 8301–8306. [Google Scholar]

- Mohammed, L.; Gomaa, H.G.; Ragab, D.; Zhu, J. Magnetic nanoparticles for environmental and biomedical applications: A review. Particuology 2017, 30, 1–14. [Google Scholar]

- Scott, T.B.; Popescu, I.C.; Crane, R.A.; Noubactep, C. Nano-scale metallic iron for the treatment of solutions containing multiple inorganic contaminants. J. Hazard. Mater. 2011, 186, 280–287. [Google Scholar]

- Zhang, W.-X. Nanoscale Iron Particles for Environmental Remediation: An Overview. J. Nanopart. Res. 2003, 5, 323–332. [Google Scholar]

- Ul-Islam, M.; Ullah, M.W.; Khan, S.; Manan, S.; Khattak, W.A.; Ahmad, W.; Shah, N.; Park, J.K. Current advancements of magnetic nanoparticles in adsorption and degradation of organic pollutants. Environ. Sci. Pollut. Res. 2017, 24, 12713–12722. [Google Scholar]

- Fauconnier, N.; Pons, J.N.; Roger, J.; Bee, A. Thiolation of maghemite nanoparticles by dimercaptosuccinic acid. J. Colloid Interface Sci. 1997, 194, 427–433. [Google Scholar]

- Rajh, T.; Chen, L.X.; Lukas, K.; Liu, T.; Thurnauer, M.C.; Tiede, D.M. Surface restructuring of nanoparticles: An efficient route for ligand-metal oxide crosstalk. J. Phys. Chem. B. 2002, 106, 10543–10552. [Google Scholar]

- Xu, C.; Xu, K.; Gu, H.; Zheng, R.; Liu, H.; Zhang, X.; Guo, Z.; Xu, B. Dopamine as a robust anchor to immobilize functional molecules on the iron oxide shell of magnetic nanoparticles. J. Am. Chem. Soc. 2004, 126, 9938–9939. [Google Scholar]

- Kim, M.; Chen, Y.; Liu, Y.; Peng, X. Super-stable, high-quality Fe3O4 dendron-nanocrystals dispersible in both organic and aqueous solutions. Adv. Mater. 2005, 1975, 1429–1432. [Google Scholar]

- Wang, Y.; Teng, X.; Wang, J.-S.; Yang, H. Solvent-free atom transfer radical polymerization in the synthesis of Fe2O3@polystyrene core-shell nanoparticles. Nano Lett. 2003, 3, 789–793. [Google Scholar]

- Marutani, E.; Yamamoto, S.; Ninjbadgar, T.; Tsujii, Y.; Fukuda, T.; Takano, M. Surface initiated atom transfer radical polymerization of methyl methacrylate on magnetite nanoparticles. Polymer 2004, 45, 2231–2235. [Google Scholar]

- Ninjbadgar, T.; Yamamoto, S.; Fukuda, T. Synthesis and magnetic properties of the γ-Fe2O3/poly(methyl methacrylate)-core/shell nanoparticles. Solid State Sci. 2004, 6, 879–885. [Google Scholar]

- Gelbrich, T.; Feyen, M.; Schmidt, A.M. Magnetic thermoresponsive core-shell nanoparticles. Macromolecules 2006, 39, 3469–3472. [Google Scholar]

- Matsuno, R.; Yamamoto, K.; Otsuka, H.; Takahara, A. Polystyrene-grafted magnetite nanoparticles prepared through surface-initiated nitroxyl-mediated radical polymerization. Chem. Mater. 2003, 15, 3–5. [Google Scholar]

- Hajalilou, A.; Mazlan, S.A.; Shilan, S.T.; Abouzari-Lotf, E. Enhanced magnetorheology of soft magnetic carbonyl iron suspension with binary mixture of Ni-Zn ferrite and Fe3O4 nanoparticle additive. Colloid Polym. Sci. 2017, 295, 1499–1510. [Google Scholar]

- Kwon, S.H.; An, J.S.; Choi, S.Y.; Chung, K.H.; Choi, H.J. Poly(glycidyl methacrylate) Coated Soft-Magnetic Carbonyl Iron/Silicone Rubber Composite Elastomer and Its Magnetorheology. Macromol. Res. 2019, 27, 448–453. [Google Scholar]

- Ruiz-López, J.A.; Fernández-Toledano, J.C.; Hidalgo-Alvarez, R.; de Vicente, J. Testing the mean magnetization approximation, dimensionless and scaling numbers in magnetorheology. Soft Matter 2016, 12, 1468–1476. [Google Scholar]

- Fu, Y.; Yao, J.; Zhao, H.; Zhao, G.; Wan, Z.; Qiu, Y. Fabrication and magnetorheology of bidisperse magnetic microspheres coated with gelatin and multi-walled carbon nanotubes. Smart Mater. Struct. 2018, 27, 125001. [Google Scholar]

- Morillas, J.R.; Yang, J.; de Vicente, J. Double-gap plate–plate magnetorheology. J. Rheol. 2018, 62, 1485–1494. [Google Scholar]

- Elsaady, W.; Oyadiji, S.O.; Nasser, A. A review on multi-physics numerical modelling in different applications of magnetorheological fluids. J. Intell. Mater. Syst. Struct. 2020, 31, 1855–1897. [Google Scholar]

| Magnetic Particles | Polymer | Method | Density [g/cm3] | Ms Value [emu/g] | Ref. |

|---|---|---|---|---|---|

| Fe3O4 | Polydivinylbenzene | Distillation-precipitation polymerization | 1.83 | 41 | [44] |

| Fe3O4 | Poly(diphenylamine) | Coprecipitation | 2.44 | 77.1 | [52] |

| Fe3O4 | Poly(o-anisidine) | Chemical oxidation polymerization | 2.52 | 36 | [54] |

| Fe3O4 | Polystyrene | Mini-emulsion polymerization | 2.8 | 27 | [46] |

| Fe3O4 | Polystyrene | Pickering emulsion polymerization | 1.69 | 59 | [47] |

| Fe3O4 | Polystyrene | Shirasu porous glass membrane technique | 2.29 | 31.7 | [48] |

| Fe2O3 | Poly(methyl methacrylate) | Pickering emulsion polymerization | 1.68 | 20.05 | [50] |

| Fe3O4 | Polyaniline | Micelle-assisted self-assembly method | N.D. | 39.4 | [53] |

| CI | Polypyrrole | In situ polymerization | N.D. | ≈120 | [57] |

| CI | Cholesteryl groups | Surface modification | N.D. | ≈180 | [58] |

| CI | Poly(glycidyl methacrylate) | Atom transfer radical polymerization | N.D. | 215 | [59] |

| CI | Poly(n-butyl acrylate) | Atom transfer radical polymerization | N.D. | 227 | [60] |

| CI | Polyindole | Chemical oxidation polymerization | 7.3 | 180 | [62] |

| CI | Poly(diphenylamine) | Oxidative dispersion polymerization | 7.42 | 191 | [63] |

| CI | Polyaniline | Chemical oxidation polymerization | 4.21 | 136 | [64] |

| CI | Polydopamine | In situ self-oxidative polymerization | 6.17 | 135 | [65] |

| CI | Poly(methyl methacrylate) | In situ dispersion polymerization | 4.5 | 151 | [61] |

| Metallic cobalt | Polystyrene | Nitroxide-mediated polymerization | N.D. | 38 | [67] |

| Copper nickel alloy | Polyethylene glycol | Oil/water emulsion | N.D. | 45 | [68] |

| ZnFe2O4 | Polyaniline | Pickering emulsion polymerization | 5.4 | 73.7 | [69] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Q.; Choi, K.; Nam, J.-D.; Choi, H.J. Magnetic Polymer Composite Particles: Design and Magnetorheology. Polymers 2021, 13, 512. https://doi.org/10.3390/polym13040512

Lu Q, Choi K, Nam J-D, Choi HJ. Magnetic Polymer Composite Particles: Design and Magnetorheology. Polymers. 2021; 13(4):512. https://doi.org/10.3390/polym13040512

Chicago/Turabian StyleLu, Qi, Kisuk Choi, Jae-Do Nam, and Hyoung Jin Choi. 2021. "Magnetic Polymer Composite Particles: Design and Magnetorheology" Polymers 13, no. 4: 512. https://doi.org/10.3390/polym13040512