Synthesis, Characterization and Sorption Ability of Epoxy Resin-Based Sorbents with Amine Groups

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Polymeric Sorbents

2.3. Characteristics of Polymeric Sorbents

2.4. Adsorption Tests

3. Results and Discussion

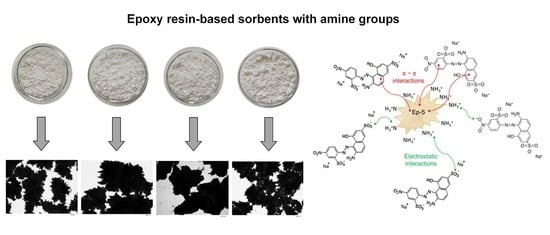

3.1. Visualization of Sorbents

3.2. ATR-FTIR Analysis

3.3. DSC Analysis

3.4. TGA Analysis

3.5. Adsorption Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Mohan, P. A Critical Review: The Modification, Properties, and Applications of Epoxy Resins. Polym. Plast. Technol. Eng. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Jin, F.-L.; Li, X.; Park, S.-J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Unnikrishnan, K.P.; Thachil, E.T. Toughening of epoxy resins. Des. Monomers Polym. 2006, 9, 129–152. [Google Scholar] [CrossRef] [Green Version]

- Paluvai, N.R.; Mohanty, S.; Nayak, S.K. Synthesis and Modifications of Epoxy Resins and Their Composites: A Review. Polym. Plast. Technol. Eng. 2014, 53, 1723–1758. [Google Scholar] [CrossRef]

- Pan, G.; Du, Z.; Zhang, C.; Li, C.; Yang, X.; Li, H. Synthesis, characterization, and properties of novel novolac epoxy resin containing naphthalene moiety. Polymer 2007, 48, 3686–3693. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Rosario, G.; Ureña, A. Comparative study on the adhesive properties of different epoxy resins. Int. J. Adhes. Adhes. 2006, 26, 125–132. [Google Scholar] [CrossRef]

- Yang, G.; Fu, S.-Y.; Yang, J.-P. Preparation and mechanical properties of modified epoxy resins with flexible diamines. Polymer 2007, 48, 302–310. [Google Scholar] [CrossRef]

- Yang, C.P.; Chen, W.T. Synthesis and properties of new polyimides derived from 1,5-bis(4-aminophenoxy)naphthalene and aromatic tetracarboxylic dianhydrides. J. Polym. Sci. A Polym. Chem. 1993, 31, 2799–2807. [Google Scholar] [CrossRef]

- Wang, C.S.; Lee, M.C. Synthesis, characterization, and properties of multifunctional naphthalene-containing epoxy resins cured with cyanate ester. J. Appl. Polym. Sci. 1999, 73, 1611–1622. [Google Scholar] [CrossRef]

- Wang, C.S.; Lee, M.C. Synthesis and modification of a naphthalene-containing trifunctional epoxy resin for electronic applications. J. Appl. Polym. Sci. 1998, 70, 1907–1921. [Google Scholar] [CrossRef]

- Xu, K.; Chen, M.C.; Zhang, K.; Hu, J.W. Synthesis and characterization of novel epoxy resin bearing naphthyl and limonene moieties, and its cured polymer. Polymer 2004, 45, 1133–1140. [Google Scholar] [CrossRef]

- Fila, K.; Gargol, M.; Goliszek, M.; Podkoscielna, B. Synthesis of epoxy resins derivatives of naphthalene-2,7-diol and their cross-linked products. J. Therm. Anal. Calorim. 2019, 138, 4349–4358. [Google Scholar] [CrossRef] [Green Version]

- Mustata, F.; Tudorachi, N.; Bicu, I. The kinetic study and thermal characterization of epoxy resins crosslinked with amino carboxylic acids. J. Anal. Appl. Pyrolysis 2015, 112, 180–191. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T.; Hassan, A. Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. J. Reinf. Plast. Compos. 2016, 35, 447–470. [Google Scholar] [CrossRef]

- Stoski, J.; Leite, N.F.; da Paixão, R.E.; Abate, G. Epoxy resin as a new alternative sorbent phase for stir bar sorptive extraction for the determination of triclosan and methyl-triclosan. J. Environ. Sci. Health A Tox. Hazard. Subst. Environ. Eng. 2017, 52, 1133–1140. [Google Scholar] [CrossRef] [PubMed]

- Chopabayeva, N.N.; Mukanov, K.N. Synthesis and application of nano-, meso- and macroporous sorbents based on lignin for detoxication of biological fluids. AIP Conf. Proc. 2014, 1599, 34. [Google Scholar]

- Ghosh, S.; Acharyya, M. Design of novolac resin-based network polymers for adsorptive removal of azo dye molecules. RSC Adv. 2016, 6, 28781–28786. [Google Scholar] [CrossRef]

- Hamdy, L.B.; Wakeham, R.J.; Taddei, M.; Barron, A.R.; Andreoli, E. Epoxy Cross-Linked Polyamine CO2 Sorbents Enhanced via Hydrophobic Functionalization. Chem. Mater. 2019, 31, 4673–4684. [Google Scholar] [CrossRef]

- Nguyen, A.M.; Dinh, N.P.; Cam, Q.M.; Sparrman, T.; Irgum, K. Preparation and characterization of sizable macroporous epoxy resin-based monolithic supports for flow-through systems. J. Sep. Sci. 2009, 32, 2608–2618. [Google Scholar] [CrossRef]

- Kurczewska, J.; Schroeder, G. Epoxy resin modified with amine as an effective complexing agent of metal cations. Cent. Eur. J. Chem. 2013, 11, 1723–1728. [Google Scholar] [CrossRef]

- Kambarova, E.A.; Gavrilenko, M.A.; Bektenov, N.A. Zeolites modified with polyethylene polyamine and epoxy resin to extract lead ions from wastewater. Bull. Tomsk Polytech. Univ. Geo Assets Eng. 2021, 332, 7–13. [Google Scholar]

- Podkoscielna, B.; Gawdzik, B. Influence of diluent compositions on the porous structure of methacrylate derivatives of aromatic diols and divinylbenzene. Appl. Surf. Sci. 2010, 256, 2462–2467. [Google Scholar] [CrossRef]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef] [Green Version]

- Freundlich, H.M.F. Over the adsorption in solution. J. Phys. Chem. 1906, 57, 385–470. [Google Scholar]

- Sobiesiak, M.; Podkoscielna, B.; Sevastyanova, O. Thermal degradation behavior of lignin-modified porous styrene-divinylbenzene and styrene-bisphenol A glycerolate diacrylate copolymer microspheres. J. Anal. Appl. Pyrolysis. 2017, 123, 364–375. [Google Scholar] [CrossRef]

- Namasivayam, C.; Yamuna, R.; Arasi, D.J.S.E. Removal of acid violet from wastewater by adsorption on waste red mud. Environ. Geol. 2001, 41, 269–273. [Google Scholar]

- Wawrzkiewicz, M.; Kotowska, U.; Sokół, A. Purification of textile effluents containing C.I. Acid Violet 1: Adsorptive removal versus hydrogen peroxide and peracetic acid based advanced oxidation. Processes 2021, 9, 1911. [Google Scholar] [CrossRef]

- Wawrzkiewicz, M.; Podkoscielna, B.; Podkoscielny, P. Application of functionalized DVB-co-GMA polymeric microspheres in the enhanced sorption process of hazardous dyes from dyeing baths. Molecules 2020, 25, 5247. [Google Scholar] [CrossRef]

| Sample | Ethylene Glycol (mL) | Epidian 5 (g) | TETA (g)/(wt %) | Toluene (mL) | Surfactant (g) | N (%) |

|---|---|---|---|---|---|---|

| Ep5-TETA1 | 150 | 15 | 1.0/(6.67) | 10 | - | 2.774 |

| Ep5-TETA1.5 | 1.5/(10.00) | - | 3.523 | |||

| Ep5-TETA2 | 2.0/(13.33) | - | 4.396 | |||

| Ep5-TETA1.5+S | 1.5/(10.00) | 1.5 | 4.327 |

| Samples | Tg (°C) | Tonset (°C) | Tmax (°C) | Toffset (°C) |

|---|---|---|---|---|

| Ep5-TETA1 | 3.2 | 320 | 358 | 393 |

| Ep5-TETA1.5 | −0.5 | 322 | 356 | 375 |

| Ep5-TETA2 | −3.1 | 294 | 348 | 384 |

| Ep5-TETA1.5+S | −5.5 | 267 | 349 | 382 |

| Samples | T1% (°C) | T5% (°C) | T50% (°C) | RM (%) |

|---|---|---|---|---|

| Ep5-TETA1 | 105 | 271 | 395 | 10.0 |

| Ep5-TETA1.5 | 118 | 305 | 384 | 6.0 |

| Ep5-TETA2 | 119 | 309 | 385 | 7.5 |

| Ep5-TETA1.5+S | 151 | 270 | 373 | 3.4 |

| Parameters | Ep5-TETA1 | Ep5-TETA1.5 | Ep5-TETA2 | Ep5-TETA1.5+S |

|---|---|---|---|---|

| Langmuir | ||||

| Q0 (mg/g) | 3.44 | 4.06 | 8.83 | 3.61 |

| kL (L/mg) | 0.012 | 0.015 | 0.018 | 0.015 |

| R2 | 0.989 | 0.963 | 0.996 | 0.993 |

| Freundlich | ||||

| kF (mg1−1/n·L1/n/g) | 0.104 | 0.475 | 0.621 | 0.353 |

| 1/n | 0.579 | 0.337 | 0.430 | 0.378 |

| R2 | 0.886 | 0.937 | 0.980 | 0.973 |

| Dubinin-Radushkevich | ||||

| kDR (mol2/J2) | 3.69 × 10−5 | 1.61 × 10−5 | 1.89 × 10−5 | 1.70 × 10−5 |

| qm (mg/g) | 2.23 | 2.73 | 5.70 | 2.49 |

| R2 | 0.854 | 0.759 | 0.651 | 0.696 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Podkościelna, B.; Wawrzkiewicz, M.; Klapiszewski, Ł. Synthesis, Characterization and Sorption Ability of Epoxy Resin-Based Sorbents with Amine Groups. Polymers 2021, 13, 4139. https://doi.org/10.3390/polym13234139

Podkościelna B, Wawrzkiewicz M, Klapiszewski Ł. Synthesis, Characterization and Sorption Ability of Epoxy Resin-Based Sorbents with Amine Groups. Polymers. 2021; 13(23):4139. https://doi.org/10.3390/polym13234139

Chicago/Turabian StylePodkościelna, Beata, Monika Wawrzkiewicz, and Łukasz Klapiszewski. 2021. "Synthesis, Characterization and Sorption Ability of Epoxy Resin-Based Sorbents with Amine Groups" Polymers 13, no. 23: 4139. https://doi.org/10.3390/polym13234139