Hybrid Bio-Inspired Structure Based on Nacre and Woodpecker Beak for Enhanced Mechanical Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design of Hybrid Bio-Inspired Structures

2.2. Sample Fabrication

2.3. Mechanical Testing

2.4. Finite Element Analysis

3. Results and Discussions

3.1. Experimental Tensile Test Response of Bio-Inspired Composites

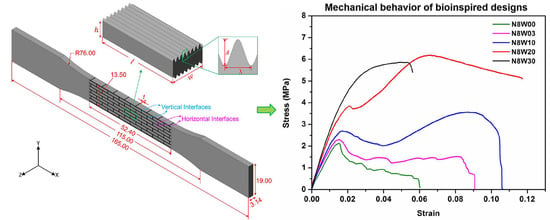

3.1.1. Influence of Tablet Waviness on Mechanical Behavior

3.1.2. Influence of Tablet Wave Number on Mechanical Behavior

3.2. Fracture Mechanisms and Morphologies

3.3. Simulation Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dunlop, J.W.C.; Fratzl, P. Biological composites. Annu. Rev. Mater. Res. 2010, 40, 1–24. [Google Scholar] [CrossRef]

- Studart, A.R. Biological and bioinspired composites with spatially tunable heterogeneous architectures. Adv. Funct. Mater. 2013, 23, 4423–4436. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chen, P.-Y.; Lin, A.Y.-M.; Seki, Y. Biological materials: Structure and mechanical properties. Prog. Mater. Sci. 2008, 53, 1–206. [Google Scholar] [CrossRef] [Green Version]

- Connections, M. Structural biological materials: Critical mechanics-materials connections. Science 2013, 339, 773–780. [Google Scholar]

- Lin, A.Y.M.; Meyers, M.; Vecchio, K.S. Mechanical properties and structure of Strombus gigas, Tridacna gigas, and Haliotis rufescens sea shells: A comparative study. Mater. Sci. Eng. C 2006, 26, 1380–1389. [Google Scholar] [CrossRef]

- Kotha, S.P.; Li, Y.; Guzelsu, N. Micromechanical model of nacre tested in tension. J. Mater. Sci. 2001, 36, 2001–2007. [Google Scholar] [CrossRef]

- Barthelat, F.; Tang, H.; Zavattieri, P.; Li, C.-M.; Espinosa, H. On the mechanics of mother-of-pearl: A key feature in the material hierarchical structure. J. Mech. Phys. Solids 2007, 55, 306–337. [Google Scholar] [CrossRef]

- Wang, R.Z.; Suo, Z.; Evans, A.G.; Yao, N.; Aksay, I.A. Deformation mechanisms in nacre. J. Mater. Res. 2001, 16, 2485–2493. [Google Scholar] [CrossRef]

- Barthelat, F.; Espinosa, H.D. An experimental investigation of deformation and fracture of nacre–mother of pearl. Exp. Mech. 2007, 47, 311–324. [Google Scholar] [CrossRef]

- Wegst, U.G.; Ashby, M.F. The mechanical efficiency of natural materials. Philos. Mag. 2004, 84, 2167–2186. [Google Scholar] [CrossRef]

- Wegst, U.G.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired structural materials. Nat. Mater. 2014, 14, 23–36. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Q.; Tang, Z. Layered nanocomposites inspired by the structure and mechanical properties of nacre. Chem. Soc. Rev. 2011, 41, 1111–1129. [Google Scholar] [CrossRef]

- Song, F.; Zhang, X.H.; Bai, Y.L. Microstructure and characteristics in the organic matrix layers of nacre. J. Mater. Res. 2002, 17, 1567–1570. [Google Scholar] [CrossRef] [Green Version]

- Katti, K.S.; Katti, D.; Pradhan, S.M.; Bhosle, A. Platelet interlocks are the key to toughness and strength in nacre. J. Mater. Res. 2005, 20, 1097–1100. [Google Scholar] [CrossRef]

- Ghimire, A.; Tsai, Y.-Y.; Chen, P.-Y.; Chang, S.-W. Tunable interface hardening: Designing tough bio-inspired composites through 3D printing, testing, and computational validation. Compos. Part B Eng. 2021, 215, 108754. [Google Scholar] [CrossRef]

- Askarinejad, S.; Choshali, H.A.; Flavin, C.; Rahbar, N. Effects of tablet waviness on the mechanical response of architected multilayered materials: Modeling and experiment. Compos. Struct. 2018, 195, 118–125. [Google Scholar] [CrossRef]

- Liu, F.; Li, T.; Jia, Z.; Wang, L. Combination of stiffness, strength, and toughness in 3D printed interlocking nacre-like composites. Extreme Mech. Lett. 2019, 35, 100621. [Google Scholar] [CrossRef]

- Espinosa, H.D.; Juster, A.L.; Latourte, F.J.; Loh, O.Y.; Grégoire, D.; Zavattieri, P. Tablet-level origin of toughening in abalone shells and translation to synthetic composite materials. Nat. Commun. 2011, 2, 173. [Google Scholar] [CrossRef]

- Mirzaeifar, R.; Dimas, L.S.; Qin, Z.; Buehler, M.J. Defect-tolerant bioinspired hierarchical composites: Simulation and Experiment. ACS Biomater. Sci. Eng. 2015, 1, 295–304. [Google Scholar] [CrossRef] [PubMed]

- Henry, J.; Pimenta, S. Bio-inspired non-self-similar hierarchical microstructures for damage tolerance. Compos. Sci. Technol. 2020, 201, 108374. [Google Scholar] [CrossRef]

- Gu, G.X.; Libonati, F.; Wettermark, S.D.; Buehler, M.J. Printing nature: Unraveling the role of nacre’s mineral bridges. J. Mech. Behav. Biomed. Mater. 2017, 76, 135–144. [Google Scholar] [CrossRef] [PubMed]

- Ubaid, J.; Wardle, B.L.; Kumar, S. Bioinspired compliance grading motif of mortar in nacreous materials. ACS Appl. Mater. Interfaces 2020, 12, 33256–33266. [Google Scholar] [CrossRef] [PubMed]

- McKittrick, J.; Chen, P.-Y.; Bodde, S.G.; Yang, W.; Novitskaya, E.; Meyers, M. The structure, functions, and mechanical properties of keratin. JOM 2012, 64, 449–468. [Google Scholar] [CrossRef]

- Liu, Y.; Qiu, X.; Zhang, X.; Yu, T.X. Response of woodpecker’s head during pecking process simulated by material point method. PLoS ONE 2015, 10, e0122677. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, L.; Cheung, J.T.-M.; Pu, F.; Li, D.; Zhang, M.; Fan, Y. Why do woodpeckers resist head impact injury: A biomechanical investigation. PLoS ONE 2011, 6, e26490. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, N.; Horstemeyer, M.; Rhee, H.; Nabors, B.; Liao, J.; Williams, L.N. Hierarchical multiscale structure–property relationships of the red-bellied woodpecker (Melanerpes carolinus) beak. J. R. Soc. Interface 2014, 11, 20140274. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seki, Y.; Kad, B.; Benson, D.; Meyers, M.A. The toucan beak: Structure and mechanical response. Mater. Sci. Eng. C 2006, 26, 1412–1420. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G.; Xiang, X. Energy absorption of a bio-inspired honeycomb sandwich panel. J. Mater. Sci. 2019, 54, 6286–6300. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Zhang, P.; To, A.C. Transversely isotropic hyperelastic-viscoplastic model for glassy polymers with application to additive manufactured photopolymers. Int. J. Plast. 2016, 80, 56–74. [Google Scholar] [CrossRef]

- Libonati, F.; Gu, G.X.; Qin, Z.; Vergani, L.; Buehler, M.J. Bone-inspired materials by design: Toughness amplification observed using 3D printing and testing. Adv. Eng. Mater. 2016, 18, 1354–1363. [Google Scholar] [CrossRef] [Green Version]

- Su, F.Y.; Sabet, F.A.; Tang, K.; Garner, S.; Pang, S.; Tolley, M.T.; Jasiuk, I.; McKittrick, J. Scale and size effects on the mechanical properties of bioinspired 3D printed two-phase composites. J. Mater. Res. Technol. 2020, 9, 14944–14960. [Google Scholar] [CrossRef]

| Design | λ (mm) | A (mm) | h (mm) | l (mm) | t (mm) | w (mm) | fv (%) |

|---|---|---|---|---|---|---|---|

| N8W00 | 0.3927 | 0 | 1.5 | 7.5 | 0.3 | 3.1415 | 78.994 |

| N8W03 | 0.3927 | 0.1178 | 1.5 | 7.5 | 0.3 | 3.1415 | 78.993 |

| N8W10 | 0.3927 | 0.3927 | 1.5 | 7.5 | 0.3 | 3.1415 | 78.992 |

| N8W20 | 0.3927 | 0.7854 | 1.5 | 7.5 | 0.3 | 3.1415 | 79.001 |

| N8W30 | 0.3927 | 1.1781 | 1.5 | 7.5 | 0.3 | 3.1415 | 79.876 |

| N6W20 | 0.5236 | 1.0472 | 1.5 | 7.5 | 0.3 | 3.1415 | 79.635 |

| N7W20 | 0.4488 | 0.8976 | 1.5 | 7.5 | 0.3 | 3.1415 | 79.373 |

| N9W20 | 0.3491 | 0.6981 | 1.5 | 7.5 | 0.3 | 3.1415 | 79.071 |

| N10W20 | 0.3141 | 0.6283 | 1.5 | 7.5 | 0.3 | 3.1415 | 78.990 |

| Material | E (MPa) | σb (MPa) | v |

|---|---|---|---|

| VeroWhite | 1927 | 35 | 0.3 |

| TangoPlus | 3.5 | 1.2 | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Z.; Wang, B.; Xiao, H.; Duan, Y. Hybrid Bio-Inspired Structure Based on Nacre and Woodpecker Beak for Enhanced Mechanical Performance. Polymers 2021, 13, 3681. https://doi.org/10.3390/polym13213681

Ding Z, Wang B, Xiao H, Duan Y. Hybrid Bio-Inspired Structure Based on Nacre and Woodpecker Beak for Enhanced Mechanical Performance. Polymers. 2021; 13(21):3681. https://doi.org/10.3390/polym13213681

Chicago/Turabian StyleDing, Zhongqiu, Ben Wang, Hong Xiao, and Yugang Duan. 2021. "Hybrid Bio-Inspired Structure Based on Nacre and Woodpecker Beak for Enhanced Mechanical Performance" Polymers 13, no. 21: 3681. https://doi.org/10.3390/polym13213681