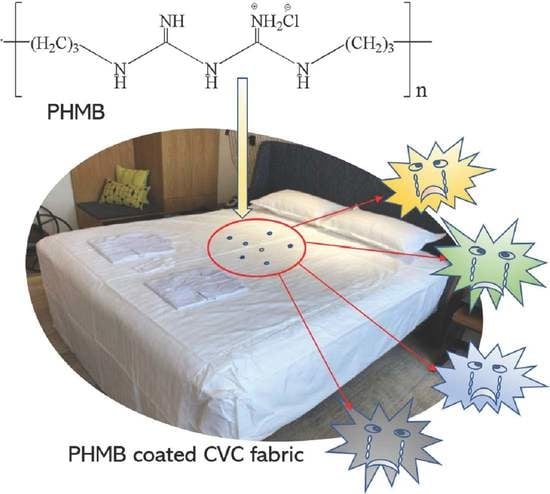

Development of Antiviral CVC (Chief Value Cotton) Fabric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Treatment

2.2. Qualitative Determination of PHMB

2.3. Antiviral Activity Measurement

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- IHME COVID-19 Forecasting Team. Modeling COVID-19 scenarios for the United States. Nat. Med. 2021, 27, 94–105. [Google Scholar] [CrossRef]

- WHO Coronavirus (COVID-19) Dashboard. Available online: https://covid19.who.int/ (accessed on 9 April 2021).

- Wang, W.Y.; Chiou, J.C.; Yip, J.; Yung, K.F.; Kan, C.W. Development of Durable Antibacterial Textile Fabrics for Potential Application in Healthcare Environment. Coatings 2020, 10, 520. [Google Scholar] [CrossRef]

- Rong, L.; Liu, H.; Wang, B.; Mao, Z.; Xu, H.; Zhang, L.; Zhong, Y.; Feng, X.; Sui, X. Durable antibacterial and hydrophobic cotton fabrics utilizing enamine bonds. Carbohydr. Polym. 2019, 211, 173–180. [Google Scholar] [CrossRef]

- Yousefi, M.; Dadashpour, M.; Hejazi, M.; Hasanzadeh, M.; Behnam, B.; de la Guardia, M.; Shadjou, N.; Mokhtarzadeh, A. Anti-bacterial activity of graphene oxide as a new weapon nanomaterial to combat multidrug-resistance bacteria. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 74, 568–581. [Google Scholar] [CrossRef]

- Granados, A.; Pleixats, R.; Vallribera, A. Recent Advances on Antimicrobial and Anti-Inflammatory Cotton Fabrics Containing Nanostructures. Molecules 2021, 26, 3008. [Google Scholar] [CrossRef]

- Edgar, K.J.; Zhang, H. Antibacterial modification of Lyocell fiber: A review. Carbohydr. Polym. 2020, 250, 116932. [Google Scholar] [CrossRef]

- Bar, G.; Biswas, D.; Pati, S.; Chaudhary, K.; Bar, M. Antiviral finishing on textiles—An Overview. Text. Leather Rev. 2021, 4, 5–22. [Google Scholar] [CrossRef]

- Iyigundogdu, Z.U.; Demir, O.; Asutay, A.B.; Sahin, F. Developing Novel Antimicrobial and Antiviral Textile Products. Appl. Biochem. Biotechnol. 2017, 181, 1155–1166. [Google Scholar] [CrossRef]

- Simoncic, B.; Tomsic, B. Structures of Novel Antimicrobial Agents for Textiles—A Review. Text. Res. J. 2010, 80, 1721–1737. [Google Scholar] [CrossRef]

- Chindera, K.; Mahato, M.; Sharma, A.K.; Horsley, H.; Kloc-Muniak, K.; Kamaruzzaman, N.F.; Kumar, S.; McFarlane, A.; Stach, J.; Bentin, T.; et al. The antimicrobial polymer PHMB enters cells and selectively condenses bacterial chromosomes. Sci. Rep. 2016, 6, 23121. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, C.; Xie, Y.; Yang, Y.; Zheng, Y.; Meng, H.; He, W.; Qiao, K. Highly transparent, highly flexible composite membrane with multiple antimicrobial effects used for promoting wound healing. Carbohydr. Polym. 2019, 222, 114985. [Google Scholar] [CrossRef]

- De Paula, G.F.; Netto, G.I.; Mattoso, L.H.C. Physical and Chemical Characterization of Poly(hexamethylene biguanide) Hydrochloride. Polymers 2011, 3, 928–941. [Google Scholar] [CrossRef]

- Yuan, G.; Cranston, R. Recent Advances in Antimicrobial Treatments of Textiles. Text. Res. J. 2008, 78, 60–72. [Google Scholar] [CrossRef]

- Gargoubi, S.; Tolouei, R.; Chevallier, P.; Levesque, L.; Ladhari, N.; Boudokhane, C.; Mantovani, D. Enhancing the functionality of cotton fabric by physical and chemical pre-treatments: A comparative study. Carbohydr. Polym. 2016, 147, 28–36. [Google Scholar] [CrossRef] [PubMed]

- Blackburn, R.S.; Harvey, A.; Kettle, L.L.; Payne, J.D.; Russell, S.J. Sorption of poly (hexamethylenebiguanide) on cellulose: Mechanism of binding and molecular recognition. Langmuir 2006, 22, 5636–5644. [Google Scholar] [CrossRef]

- Wågberg, L.; Ödberg, L.; Lindström, T.; Aksberg, R. Kinetics of adsorption and ion-exchange reactions during adsorption of cationic polyelectrolytes onto cellulosic fibers. Colloid Surf. 1988, 31, 119–124. [Google Scholar] [CrossRef]

- Maryann, E.; Aksberg, R.; Ödberg, L.; Berg, J.C. Adsorption and reconformation of a series of cationic polyacrylamides on charged surfaces. Colloid Surf. 1991, 53, 183–191. [Google Scholar]

- Cao, Y.; Gu, J.; Wang, S.; Zhang, Z.; Yu, H.; Li, J.; Chen, S. Guanidine-functionalized cotton fabrics for achieving permanent antibacterial activity without compromising their physicochemical properties and cytocompatibility. Cellulose 2020, 27, 6027–6036. [Google Scholar] [CrossRef]

- Chen-Yu, J.H.; Eberhardt, D.M.; Kincade, D.H. Antibacterial and laundering properties of AMS and PHMB as finishing agents on fabric for health care workers’ uniforms. Cloth. Text. Res. J. 2007, 25, 258–272. [Google Scholar] [CrossRef]

- Lau, J.Y.N.; Chan, D.S.B.; Chiou, J.; Kan, C.W.; Lam, K.H.; Lam, W.H.; Yung, K.F. Durable Antimicrobial Treatment of Textile for Use in Healthcare Environment; Avalon Polymills (HK) Ltd.: Hong Kong, China, 2019. [Google Scholar]

- Pinto, F.; Maillard, J.Y.; Denyer, S.P.; McGeechan, P. Polyhexamethylene biguanide exposure leads to viral aggregation. J. Appl. Microbiol. 2010, 108, 1880–1888. [Google Scholar] [CrossRef]

- Pinto, F. Mechanisms of Action of Polyhexamethylene Biguanide-Based Biocides Against Non-Enveloped Virus; Cardiff University: Cardiff, UK, 2010. [Google Scholar]

- Chin, A.W.; Chu, J.T.; Perera, M.R.; Hui, K.P.; Yen, H.L.; Chan, M.C.; Peiris, M.; Poon, L.L. Stability of SARS-CoV-2 in different environmental conditions. Lancet 2020, 1, e10. [Google Scholar] [CrossRef]

| Sample | Logarithm Average of Infectivity Titer (PFU/Vial) | Antiviral Activity | Percentage (%) | |

|---|---|---|---|---|

| Control | Immediately after inoculation | 5.29 | N/A | N/A |

| After contacting for 2 h | 4.78 | 0.51 | 69.37 | |

| PHMB treated fabric | After contacting for 2 h | 4.07 | 1.22 | 94.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.-Y.; Yim, S.-L.; Wong, C.-H.; Kan, C.-W. Development of Antiviral CVC (Chief Value Cotton) Fabric. Polymers 2021, 13, 2601. https://doi.org/10.3390/polym13162601

Wang W-Y, Yim S-L, Wong C-H, Kan C-W. Development of Antiviral CVC (Chief Value Cotton) Fabric. Polymers. 2021; 13(16):2601. https://doi.org/10.3390/polym13162601

Chicago/Turabian StyleWang, Wen-Yi, Sui-Lung Yim, Chun-Ho Wong, and Chi-Wai Kan. 2021. "Development of Antiviral CVC (Chief Value Cotton) Fabric" Polymers 13, no. 16: 2601. https://doi.org/10.3390/polym13162601