Biomedical Applications of Quaternized Chitosan

Abstract

:1. Introduction

2. Quaternized Chitosan Derivatives and Physicochemical Properties

2.1. N,N,N-Trimethyl Chitosan Chloride

2.2. N-[(2-Hydroxyl-3-Trimethyl Ammonium) Propyl] Chitosan

2.3. Pyridine Salt Grafted Quaternized Chitosan

2.4. Phosphonium Salt Grafted Quaternized Chitosan

2.5. Other Quaternized Chitosan Derivatives

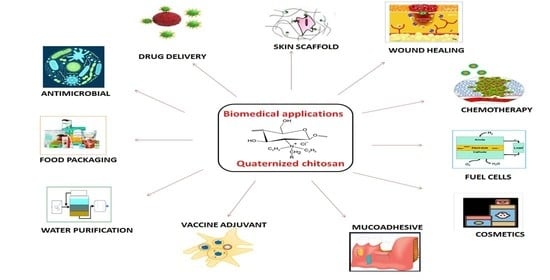

3. Biomedical Applications of Quaternized Chitosan Derivatives

3.1. Antimicrobial

3.2. Antiproliferative

3.3. Antibiofilm

3.4. Antifungal Activity

3.5. Mucoadhesiveness

3.6. Drug Carriers

3.6.1. Nanofibers

3.6.2. Hydrogel

3.6.3. Beads

3.6.4. Nanoparticles

3.6.5. Quaternized Chitosan Nanocomposites

3.6.6. Vaccine Adjuvants

4. Miscellaneous

4.1. Orthopedic Surgery

4.2. Dental Care and Cosmetics

5. Future Prospective

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mourya, V.K.; Inamdar, N.N. Chitosan-modifications and applications: Opportunities galore. React. Funct. Polym. 2008, 68, 1013–1051. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, A. The virtuous potential of chitosan oligosaccharide for promising biomedical applications. J. Mater. Res. 2020, 35, 1123–1134. [Google Scholar] [CrossRef]

- Islam, S.M.A.; Bhuvian, M.A.R.; Islam, M.N. Chitin and Chitosan: Structure, Properties and Applications in Biomedical Engineering. J. Polym. Environ. 2017, 25, 854–866. [Google Scholar] [CrossRef]

- Kahya, N. Water Soluble Chitosan Derivatives and their Biological Activities: A Review. Polym. Sci. 2019, 5, 1–16. [Google Scholar] [CrossRef]

- Kofuji, K.; Qian, C.; Nishimura, M.; Sugiyama, I.; Murata, Y.; Kawashima, S. Relationship between physicochemical characteristics and functional properties of chitosan. Eur. Polym. J. 2005, 41, 2784–2791. [Google Scholar] [CrossRef]

- Freier, T.; Koh, H.S.; Kazazian, K.; Shoichet, M.S. Controlling cell adhesion and degradation of chitosan films by N-acetylation. Biomaterials 2005, 26, 5872. [Google Scholar] [CrossRef]

- Yuan, Y.; Betsy, M.; Chesnutt, W.; Haggard, O.; Bumgardner Joel, D. Deacetylation of Chitosan: Material Characterization and in vitro Evaluation via Albumin Adsorption and Pre-Osteoblastic Cell Cultures. Materials 2011, 4, 1399–1416. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marques, C.; Som, C.; Schmutz, M.; Borges, O.; Borchard, G. How the Lack of Chitosan Characterization Precludes Implementation of the Safe-by-Design Concept. Front. Bioeng. Biotech. 2020, 8, 165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El Knidri, H.; Belaabed, R.; Addaou, A.; Laajeb, A.; Lahsini, A. Extraction, chemical modification and characterization of chitin and chitosan. Int. J. Biol. Macromol. 2018, 120 Pt A, 1181–1189. [Google Scholar] [CrossRef]

- Kumari, S.; Kumar, A.S.H.; Abanti, S.; Kumar, R.P. Physicochemical properties and characterization of chitosan synthesized from fish scales, crab and shrimp shells. Int. J. Biol. Macromol. 2017, 104 Pt B, 1697–1705. [Google Scholar] [CrossRef]

- Pillai, C.K.S.; Paul, W.; Sharma, C.P. Chitin and chitosan polymers: Chemistry, solubility and fiber formation. Prog. Polym. Sci. 2009, 34, 641–678. [Google Scholar] [CrossRef]

- Cai, J.; Dang, Q.; Liu, C.; Fan, B.; Yan, J.; Xu, Y.; Li, J. Preparation and characterization of N-benzoyl-O-acetyl-chitosan. Int. J. Biol. Macromol. 2015, 77, 52–58. [Google Scholar] [CrossRef] [PubMed]

- Ma, G.; Yang, D.; Zhou, Y.; Xiao, M.; Kennedy, J.F.; Nie, J. Preparation and characterization of water-soluble N-alkylated chitosan. Carbohydr. Polym. 2008, 74, 121–126. [Google Scholar] [CrossRef]

- Mohammadi, E.; Daraei, H.; Ghanbari, R.; Dehestani Athar, S.; Zandsalimi, Y.; Ziaee, A.; Maleki, A.; Yetilmezsoy, K. Synthesis of carboxylated chitosan modified with ferromagnetic nanoparticles for adsorptive removal of fluoride, nitrate, and phosphate anions from aqueous solutions. J. Mol. Liq. 2019, 273, 116–124. [Google Scholar] [CrossRef]

- Benediktsdóttir, B.E.; Baldursson, Ó.; Másson, M. Challenges in evaluation of chitosan and trimethylated chitosan (TMC) as mucosal permeation enhancers: From synthesis to in vitro application. J. Control. Release 2014, 173, 18–31. [Google Scholar] [CrossRef]

- Ramasamy, P.; Subhapradha, N.; Thinesh, T.; Selvin, J.; Selvan, K.M.; Shanmugam, V.; Shanmugam, A. Characterization of bioactive chitosan and sulfated chitosan from Doryteuthis singhalensis (Ortmann, 1891). Int. J. Biol. Macromol. 2017, 99, 682–691. [Google Scholar] [CrossRef]

- Cao, J.; You, J.; Zhang, L.; Zhou, J. Homogeneous synthesis and characterization of chitosan ethers prepared in aqueous alkali/urea solutions. Carbohydr. Polym. 2018, 185, 138–144. [Google Scholar] [CrossRef]

- Jia, Z.; Shen, D.; Xu, W. Synthesis and antibacterial activities of quaternary ammonium salt of chitosan. Carbohydr. Res. 2001, 333, 1–6. [Google Scholar] [CrossRef]

- Anraku, M.; Gebicki, J.M.; Iohara, D.; Tomida, H.; Uekama, K.; Maruyama, T.; Hirayama, F.; Otagiri, M. Antioxidant activities of chitosans and its derivatives in in vitro and in vivo studies. Carbohydr. Polym. 2018, 1, 141–149. [Google Scholar] [CrossRef]

- Kumirska, J.; Weinhold, M.X.; Thöming, J.; Stepnowski, P. Biomedical Activity of Chitin/Chitosan Based Materials—Influence of Physicochemical Properties Apart from Molecular Weight and Degree of N-Acetylation. Polymers 2011, 3, 1875–1901. [Google Scholar] [CrossRef]

- Aranaz, I.; Mengíbar, M.; Harris, R.; Miralles, B.; Acosta, N.; Calderon, L.; Sanchez, A.; Heras, A. Role of Physicochemical Properties of Chitin and Chitosan on their Functionality. Curr. Chem. Biol. 2014, 8, 27–42. [Google Scholar] [CrossRef]

- Chen, K.; Guo, B.; Luo, J. Quaternized carboxymethyl chitosan/organic montmorillonite nanocomposite as a novel cosmetic ingredient against skin aging. Carbohydr. Polym. 2017, 173, 100–106. [Google Scholar] [CrossRef]

- Jana, S.; Florczyk, S.; Leung, M.; Zhang, M. High-strength pristine porous chitosan scaffolds for tissue engineering. J. Mater. Chem. 2012, 22, 6291–6299. [Google Scholar] [CrossRef]

- Diabb Zavala, J.M.; Leija Gutiérrez, H.M.; Segura-Cárdenas, E.; Mamidi, N.; Morales-Avalos, R. Manufacture and mechanical properties of knee implants using SWCNTs/UHMWPE composites. J. Mech. Behav. Biomed. Mater. 2021, 120, 104554. [Google Scholar] [CrossRef] [PubMed]

- Mamidi, N.; Velasco Delgadillo, R.M.; Barrera, E.V. Covalently Functionalized Carbon Nano-Onions Integrated Gelatin Methacryloyl Nanocomposite Hydrogel Containing γ-Cyclodextrin as Drug Carrier for High-Performance pH-Triggered Drug Release. Pharmaceuticals 2021, 14, 291. [Google Scholar] [CrossRef]

- Britto, D.; Assis, O. Synthesis and mechanical properties of quaternary salts of chitosan-based films for food application. Int. J. Biol. Macromol. 2007, 41, 198–203. [Google Scholar] [CrossRef] [PubMed]

- Mamidi, N.; Velasco Delgadillo, R.M.; Gonzáles Ortiz, A.; Barrera, E.V. Carbon Nano-Onions Reinforced Multilayered Thin Film System for Stimuli-Responsive Drug Release. Pharmaceutics 2020, 12, 1208. [Google Scholar] [CrossRef]

- Mamidi, N.; Velasco Delgadillo, R.M.; Castrejon, J.V. Unconventional and facile production of a stimuli-responsive multifunctional system for simultaneous drug delivery and environmental remediation. Environ. Sci. Nano 2021, 8, 2081–2097. [Google Scholar] [CrossRef]

- Sajomsang, W.; Tantayanon, S.; Tangpasuthadol, V.; Daly, W.H. Quaternization of N-aryl chitosan derivatives: Synthesis, characterization and antibacterial activity. Carbohydr. Res. 2009, 344, 2502–2511. [Google Scholar] [CrossRef]

- Wu, D.; Zhu, L.; Li, Y.; Zhang, X.; Xu, S.; Yang, G.; Delair, T. Chitosan-based Colloidal Polyelectrolyte Complexes for Drug Delivery: A Review. Carbohydr. Polym. 2020, 238, 116–126. [Google Scholar] [CrossRef]

- Terayama, H.; Terayama, E. High molecular antibacterial substances derived from chitin. About the manufacture of Macramin. J. Antibiot. 1948, 2, 44–45. [Google Scholar]

- Polnok, A.; Borchard, G.; Verhoef, J.C.; Sarisuta, N.; Junginger, H.E. Influence of methylation process on the degree of quaternization of N-trimethyl chitosan chloride. Eur. J. Pharm. Biopharm. 2004, 57, 77–83. [Google Scholar] [CrossRef]

- Jintapattanakit, S.; Mao, T.; Kissel, V.B.J. Trimethyl chitosan and its applications in drug delivery. Eur. J. Pharm. Biopharm. 2008, 70, 563. [Google Scholar] [CrossRef]

- Snyman, D.J.H.; Hamman, J.S.; Kotze, J.E.; Rollings, A.F.K. The relationship between the absolute molecular weight and the degree of quaternisation of N-trimethyl chitosan chloride. Carbohydr. Polym 2002, 50, 145–150. [Google Scholar] [CrossRef]

- Snyman, D.; Hamman, J.H.; Kotze, A.F. Evaluation of the Mucoadhesive Properties of N-Trimethyl Chitosan Chloride. Drug Dev. Ind. Pharm. 2003, 29, 61–69. [Google Scholar] [CrossRef]

- International Conference on Chitin and Chitosan; Muzzarelli, R.; Jeuniaux, C.; Gooday, G.W. (Eds.) Plenum Press: Senigallia, Italy, 1986; pp. 303–306. [Google Scholar]

- Xu, T.; Xin, M.; Li, M.; Huang, H.; Zhou, S.; Liu, J. Synthesis, characterization and antibacterial activity of N,O-quaternary ammonium chitosan. Carbohydr. Res. 2011, 346, 2445–2450. [Google Scholar] [CrossRef]

- Seong, H.S.; Whang, H.S.; Ko, S.W. Synthesis of a Quaternary Ammonium Derivative of Chito-oligosaccharide as Antimicrobial Agent for Cellulosic Fibers. J. Appl. Polym. Sci. 2000, 76, 2009–2015. [Google Scholar] [CrossRef]

- Xiao, B.; Wan, Y.; Wang, X.; Zha, Q.; Liu, H.; Qiu, Z.; Zhang, S. Synthesis and characterization of N-(2-hydroxy)propyl-3-trimethyl ammonium chitosan chloride for potential application in gene delivery. Colloids Surf. B Biointerfaces 2012, 91, 168–174. [Google Scholar] [CrossRef]

- Wang, B.; Yang, X.; Qiao, C.; Li, Y.; Li, T.; Xu, C. Effects of chitosan quaternary ammonium salt on the physicochemical properties of sodium carboxymethyl cellulose-based films. Carbohydr. Polym. 2018, 184, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Shagdarova, B.; Lunkov, A.; Il’ina, A.; Varlamov, V. Investigation of the properties of N-[(2-hydroxy-3-trimethylammonium) propyl] chloride chitosan derivatives. Int. J. Biol. Macromol. 2019, 124, 994–1001. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Guo, Z.; Jiang, P. Synthesis, characterization, and antifungal activity of novel quaternary chitosan derivatives. Carbohydr. Res. 2010, 345, 1896–1900. [Google Scholar] [CrossRef] [Green Version]

- Tan, W.; Li, Q.; Dong, F.; Zhang, J.; Luan, F.; Wei, L.; Chen, Y.; Guo, Z. Novel cationic chitosan derivative bearing 1,2,3-triazolium and pyridinium: Synthesis, characterization, and antifungal property. Carbohydr. Polym. 2018, 182, 180–187. [Google Scholar] [CrossRef]

- Wei, L.; Li, Q.; Tan, W.; Dong, F.; Luan, F.; Guo, Z.; Saso, L.; Dux, L.; Wegrzyn, G.; Csont, T. Synthesis,characterization, and the antioxidant activity of double quaternized chitosan derivatives. Molecules 2017, 22, 501. [Google Scholar] [CrossRef] [Green Version]

- Jia, R.; Duan, Y.; Fang, Q.; Wang, X.; Huang, J. Pyridine-grafted chitosan derivative as an antifungal agent. Food Chem. 2016, 196, 381–387. [Google Scholar] [CrossRef]

- Wang, L.; Xu, X.; Guo, S.; Peng, Z.; Tang, T. Novel water soluble phosphonium chitosan derivatives: Synthesis, characterization and cytotoxicity studies. Int. J. Biol. Macromol. 2011, 48, 375–380. [Google Scholar] [CrossRef] [PubMed]

- Zeng, K.; Lin, F.X.; Xie, J.; Wang, M.Z.; Rong, J.L.; Zhao, Y.; You, Y.Z.; Asif, A.; Ge, X.W. Chitosan modified by g-ray-induced grafting of poly(tributyl-(4-vinylbenzyl)phosphonium) as a biosafe and high-efficiency gene carrier. New J. Chem. 2017, 41, 4182–4189. [Google Scholar] [CrossRef]

- Holappa, J.; Hjálmarsdóttir, M.; Másson, M.; Rúnarsson, Ö.; Asplund, T.; Soininen, P.; Nevalainen, T.; Järvinen, T. Antimicrobial activity of chitosan N-betainates. Carbohydr. Polym. 2006, 65, 114–118. [Google Scholar] [CrossRef]

- Rahimi, M.; Ahmadi, R.; Samadi Kafil, H.; Shafiei-Irannejad, V. A novel bioactive quaternized chitosan and its silver-containing nanocomposites as a potent antimicrobial wound dressing: Structural and biological properties. Mater. Sci. Eng. C 2019, 101, 360–369. [Google Scholar] [CrossRef] [PubMed]

- Zambito, Y.; Uccello-Barretta, G.; Zaino, C.; Balzano, F.; Di Colo, G. Novel transmucosal absorption enhancers obtained by aminoalkylation of chitosan. Eur. J. Pharm. Sci. 2006, 29, 460–469. [Google Scholar] [CrossRef]

- Zambito, Y.; Zaino, C.; Burchielli, S.; Carelli, V.; Serafini, M.F.; Di Colo, G. Novel quaternary ammonium chitosan derivatives for the promotion of intraocular drug absorption. J. Drug Deliv. Sci. Technol. 2007, 17, 19–24. [Google Scholar] [CrossRef]

- Freitas, E.D.; Moura, C.F., Jr.; Kerwald, J.; Beppu, M.M. An Overview of Current Knowledge on the Properties, Synthesis and Applications of Quaternary Chitosan Derivatives. Polymers 2020, 12, 2878. [Google Scholar] [CrossRef]

- Kulkarni, A.D.; Patel, H.M.; Surana, S.J.; Vanjari, Y.H.; Belgamwar, V.S.; Pardeshi, C.V. N,N,N-Trimethyl chitosan: An advanced polymer with myriad of opportunities in nanomedicine. Carbohydr. Polym. 2017, 157, 875–902. [Google Scholar] [CrossRef]

- Dimulescu, I.A.; Nechifor, A.C.; Bǎrdacǎ, C.; Oprea, O.; Paşcu, D.; Totu, E.E.; Albu, P.C.; Nechifor, G.; Bungău, S.G. Accessible Silver-Iron Oxide Nanoparticles as a Nanomaterial for Supported Liquid Membranes. Nanomaterials 2021, 11, 1204. [Google Scholar] [CrossRef] [PubMed]

- Holappa, J.; Nevalainen, T.; Safin, R.; Soininen, P.; Asplund, T.; Luttikhedde, T.; Másson, M.; Järvinen, T. Novel water-soluble quaternary piperazine derivatives of chitosan: Synthesis and characterization. Macromol. Biosci. 2006, 6, 139–144. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, H.; Cao, C.; Zhang, J.; Li, F.; Huang, Q. Quaternized Chitosan-Capped Mesoporous Silica Nanoparticles as Nanocarriers for Controlled Pesticide Release. Nanomaterials 2016, 6, 126. [Google Scholar] [CrossRef] [Green Version]

- Cao, Z.; Liu, W.; Xiong, J.; Qu, N.; Li, H.; Yao, G. Synthesis and properties of N,N-dimethyl-O-quaternary ammonium chitosan. Adv. Mater. Res. 2011, 152, 1337–1341. [Google Scholar] [CrossRef]

- Cai, J.; Dang, Q.; Liu, C.; Wang, T.; Fan, B.; Yan, J.; Xu, Y. Preparation, characterization and antibacterial activity of O-acetyl-chitosan-N-2-hydroxypropyl trimethyl ammonium chloride. Int. J. Biol. Macromol. 2015, 80, 8–15. [Google Scholar] [CrossRef]

- Pedro, R.D.O.; Schmitt, C.C.; Neumann, M.G. Syntheses and characterization of amphiphilic quaternary ammonium chitosan derivatives. Carbohydr. Polym. 2016, 147, 97–103. [Google Scholar] [CrossRef]

- Zhang, A.; Ding, D.; Ren, J.; Zhu, X.; Yao, Y. Synthesis, characterization, and drug-release behavior of amphiphilic quaternary ammonium chitosan derivatives. J. Appl. Polym. Sci. 2014, 131, 1–9. [Google Scholar] [CrossRef]

- Badawy, M.E.; Rabea, E.I. Synthesis and antifungal property of N-(aryl) and quaternary N-(aryl) chitosan derivatives against Botrytis cinerea. Cellulose 2014, 21, 3121–3137. [Google Scholar] [CrossRef]

- Han, Y.; Lin, Q. Synthesis, characterization, and antibacterial activity of quaternized of N-aromatic chitosan derivatives. Appl. Mech. Mater. 2012, 138, 1202–1208. [Google Scholar] [CrossRef]

- Sang, W.; Tang, Z.; He, M.Y.; Hua, Y.P.; Xu, Q. Synthesis and preservative application of quaternized carboxymethyl chitosan containing guanidine groups. Int. J. Biol. Macromol. 2015, 75, 489–494. [Google Scholar] [CrossRef]

- Li, Z.; Yang, F.; Yang, R. Synthesis and characterization of chitosan derivatives with dual-antibacterial functional groups. Int. J. Biol. Macromol. 2015, 75, 378–387. [Google Scholar] [CrossRef] [PubMed]

- Alkahtane, A.A.; Ghanem, E.; Bungau, S.G.; Alarifi, S.; Ali, D.; Albasher, G.; Alkahtani, S.; Aleya, L.; Abdel-Daim, M.M. Carnosic acid alleviates chlorpyrifos-induced oxidative stress and inflammation in mice cerebral and ocular tissues. Environ. Sci. Pollut. Res. 2020, 27, 11663–11670. [Google Scholar] [CrossRef]

- Silva, D.S.; dos Santos, D.M.; Almeida, A.; Marchiori, L.; Campana-Filho, S.P.; Ribeiro, S.J.L.; Sarmento, B. N-(2-Hydroxy)-propyl-3-trimethylammonium, O-Mysristoyl Chitosan Enhances the Solubility and Intestinal Permeability of Anticancer Curcumin. Pharmaceutics 2018, 10, 245. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.H.; Liu, W.S.; Sun, J.F.; Hou, G.G.; Chen, Q.; Cong, W.; Zhao, F. Non-toxic O-quaternized chitosan materials with better water solubility and antimicrobial function. Int. J. Biolo. Macromol. 2016, 84, 418–427. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Zhang, Z.; Bao, X.; Xu, G.; Yao, P. Fatty acid and quaternary ammonium modified chitosan nanoparticles for insulin delivery. Colloids Surf. B 2018, 170, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Sahariah, P.; Gaware, V.S.; Lieder, R.; Jónsdóttir, S.; Hjálmarsdóttir, M.Á.; Sigurjonsson, O.E.; Másson, M. The Effect of Substituent, Degree of Acetylation and Positioning of the Cationic Charge on the Antibacterial Activity of Quaternary Chitosan Derivatives. Mar. Drugs 2014, 12, 4635–4658. [Google Scholar] [CrossRef]

- Jarmila, V.; Vavríková, E. Chitosan derivatives with antimicrobial, antitumour and antioxidant activities-a review. Curr. Pharm. Des. 2011, 17, 3596–3607. [Google Scholar]

- Sajomsang, W.; Gonil, P.; Saesoo, S. Synthesis and antibacterial activity of methylated N-(4-N,N-dimethylaminocinnamyl) chitosan chloride. Eur. Polym. J. 2009, 45, 2319–2328. [Google Scholar] [CrossRef]

- Avadi, M.R.; Sadeghi, A.M.M.; Tahzibi, A.; Bayati, K.; Pouladzadeh, M.; Zohuriaan-Mehr, M.J.; Rafiee-Tehrani, M. Diethylmethyl chitosan as an antimicrobial agent: Synthesis, characterization and antibacterial effects. Eur. Polym. J. 2004, 40, 1355–1361. [Google Scholar] [CrossRef]

- Sadeghi, A.M.; Dorkoosh, F.A.; Avadi, M.R.; Saadat, P.; Rafiee-Tehrani, M.; Junginger, H.E. Preparation, characterization and antibacterial activities of chitosan, N-trimethyl chitosan (TMC) and N-diethylmethyl chitosan (DEMC) nanoparticles loaded with insulin using both the ionotropic gelation and polyelectrolyte complexation methods. Int. J. Pharm. 2008, 355, 299–306. [Google Scholar] [CrossRef] [PubMed]

- Vallapa, N.; Wiarachai, O.; Thongchul, N.; Pan, J.; Tangpasuthadol, V.; Kiatkamjornwong, S.; Hoven, V.P. Enhancing antibacterial activity of chitosan surface by heterogeneous quaternization. Carbohydr. Polym. 2011, 83, 868–875. [Google Scholar] [CrossRef]

- Xu, T.; Xin, M.; Li, M.; Huang, H.; Zhou, S. Synthesis, characteristic and antibacterial activity of N,N,N-trimethyl chitosan and its carboxymethyl derivatives. Carbohydr. Polym. 2010, 81, 931–936. [Google Scholar] [CrossRef]

- Fu, X.; Shen, Y.; Jiang, X.; Huang, D.; Yan, Y. Chitosan derivatives with dual-antibacterial functional groups for antimicrobial finishing of cotton fabrics. Carbohydr. Polym. 2011, 85, 221–227. [Google Scholar] [CrossRef]

- Martins, A.F.; Facchi, S.P.; Follmann, H.D.; Pereira, A.G.; Rubira, A.F.; Muniz, E.C. Antimicrobial activity of chitosan derivatives containing N-quaternized moieties in its backbone: A review. Int. J. Mol. Sci. 2014, 15, 20800–20832. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Jiang, H.; Qiu, M.; Geng, X.; Yang, R.; Li, J.; Zhang, C. Antibacterial activity evaluation of quaternary chitin against Escherichia coli and Staphylococcus aureus. Int. J. Biol. Macromol. 2013, 52, 85–91. [Google Scholar] [CrossRef]

- Prado, H.J.; Matulewicz, M.C. Cationization of polysaccharides: A path to greener derivatives with many industrial applications. Eur. Polym. J. 2014, 52, 53–75. [Google Scholar] [CrossRef]

- Rieger, K.A.; Birch, N.P.; Schiffman, J.D. Designing electrospun nanofiber mats to promote wound healing—A review. J. Mater. Chem. B 2013, 1, 4531–4541. [Google Scholar] [CrossRef] [Green Version]

- Ignatova, M.G.; Manolova, N.E.; Toshkova, R.A.; Rashkov, I.B.; Gardeva, E.G.; Yossifova, L.S.; Alexandrov, M.T. Electrospun nanofibrous mats containing quaternized chitosan and polylactide with in vitro antitumor activity against HeLa cells. Biomacromolecules 2010, 11, 1633–1645. [Google Scholar] [CrossRef]

- Goodman, M.; Naiman, D.Q.; Lakind, J.S. Systematic review of the literature on triclosan and health outcomes in humans. Crit. Rev. Toxicol. 2018, 48, 1–51. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakamura, T.; Kashimura, N.; Noji, T.; Suzuki, O.; Ambo, Y.; Nakamura, F.; Kishida, A. Triclosan-coated sutures reduce the incidence of wound infections and the costs after colorectal surgery: A randomized controlled trial. Surgery 2013, 153, 576–583. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Yang, S.B.; Wang, Y.G.; Zhang, S.H.; Yu, Z.F.; Tang, T.T. Bacterial inhibition potential of quaternised chitosan-coated VICRYL absorbable suture: An in vitro and in vivo study. J. Orthop. Translat. 2016, 8, 49–61. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Ao, H.; Wang, Y.; Lin, W.; Yang, S.; Zhang, S.; Yu, Z.; Tang, T. Cytocompatibility with osteogenic cells and enhanced in vivo anti-infection potential of quaternized chitosan-loaded titania nanotubes. Bone Res. 2016, 4, 16027. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, M.; Yang, Y. Quaternized chitosan promotes the antiproliferative effect of vemurafenib in melanoma cells by increasing cell permeability. Onco Targets Ther. 2018, 11, 8293–8299. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wongwanakul, R.; Jianmongkol, S.; Gonil, P.; Sajomsang, W.; Maniratanachote, R.; Aueviriyavit, S. Biocompatibility study of quaternized chitosan on the proliferation and differentiation of Caco-2 cells as an in vitro model of the intestinal barrier. J. Bioact. Compat. Polym. 2017, 32, 92–107. [Google Scholar] [CrossRef]

- Penesyan, A.; Gillings, M.; Paulsen, I.T. Antibiotic discovery: Combatting bacterial resistance in cells and in biofilm communities. Molecules 2015, 20, 5286–5298. [Google Scholar] [CrossRef] [Green Version]

- Tan, H.; Ma, R.; Lin, C.; Liu, Z.; Tang, T. Quaternized Chitosan as an Antimicrobial Agent: Antimicrobial Activity, Mechanism of Action and Biomedical Applications in Orthopedics. Int. J. Mol. Sci. 2013, 14, 1854–1869. [Google Scholar] [CrossRef]

- Arciola, C.R.; Campoccia, D.; Montanaro, L. Implant infections: Adhesion, biofilm formation and immune evasion. Nat. Rev. Microbiol. 2018, 16, 397–409. [Google Scholar] [CrossRef]

- Patel, R. Biofilm and antimicrobial resistance. Clin. Orthop. Relat. Res. 2005, 437, 41–47. [Google Scholar] [CrossRef]

- Zaha, D.C.; Bungau, S.; Uivarosan, D.; Tit, D.M.; Maghiar, T.A.; Maghiar, O.; Pantis, C.; Fratila, O.; Rus, M.; Vesa, C.M. Antibiotic Consumption and Microbiological Epidemiology in Surgery Departments: Results from a Single Study Center. Antibiotics 2020, 9, 81. [Google Scholar] [CrossRef] [Green Version]

- Piras, A.M.; Zambito, Y.; Burgalassi, S.; Monti, D.; Tampucci, S.; Terreni, E.; Fabiano, A.; Balzano, F.; Uccello-Barretta, G.; Chetoni, P. A water-soluble, mucoadhesive quaternary ammonium chitosan-methyl-_-cyclodextrin conjugate forming inclusion complexes with dexamethasone. J. Mater. Sci. Mater. Med. 2018, 29, 42. [Google Scholar] [CrossRef]

- Piras, A.M.; Esin, S.; Benedetti, A.; Maisetta, G.; Fabiano, A.; Zambito, Y.; Batoni, G. Antibacterial, Antibiofilm, and Antiadhesive Properties of Different Quaternized Chitosan Derivatives. Int. J. Mol. Sci. 2019, 20, 6297. [Google Scholar] [CrossRef] [Green Version]

- Li, M.Q.; Chen, X.G.; Liu, J.M.; Zhang, W.F.; Tang, X.X. Molecular weight-dependent antifungal activity and action mode of chitosan against Fulvia fulva (Cooke) Ciffrri. J. Appl. Polym. Sci. 2011, 119, 3127–3135. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Xing, R.G.; Liu, S.; Zhong, Z.M.; Ji, X.; Wang, L.; Li, P.C. The influence of the cationic of quaternized chitosan on antifungal activity. Int. J. Food Microbiol. 2007, 118, 214–217. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.Y.; Xing, R.E.; Liu, S.; Zhong, Z.M.; Ji, X.; Wang, L.; Li, P.C. The influence of molecular weight of quaternized chitosan on antifungal activity. Carbohydr. Polym. 2008, 71, 694–697. [Google Scholar] [CrossRef]

- Chethan, P.D.; Vishalakshi, B.; Sathish, L.; Ananda, K.; Poojary, B. Preparation of substituted quaternized arylfuran chitosan derivatives and their antimicrobial activity. Int. J. Biol. Macromol. 2013, 59, 158–164. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira Pedro, R.; Takaki, M.; Gorayeb, T.C.; Del Bianchi, V.L.; Thomeo, J.C.; Tiera, M.J.; de Oliveira Tiera, V.A. Synthesis, characterization and antifungal activity of quaternary derivatives of chitosan on Aspergillus flavus. Microbiol. Res. 2013, 168, 50–55. [Google Scholar] [CrossRef]

- Il’Ina, A.V.; Shagdarova, B.T.; Lun’Kov, A.P.; Kulikov, S.N.; Varlamov, V.P. In vitro antifungal activity of metal complexes of a quaternized chitosan derivative with copper ions. Microbiology 2017, 86, 590–595. [Google Scholar] [CrossRef]

- De Souza, R.H.F.V.; Takaki, M.; Pedro, R.D.O.; Gabriel, J.D.S.; Tiera, M.J.; Tiera, V.A.D.O.; De Souza, R.V. Hydrophobic effect of amphiphilic derivatives of chitosan on the antifungal activity against Aspergillus flavus and Aspergillus parasiticus. Molecules 2013, 18, 4437–4450. [Google Scholar] [CrossRef] [PubMed]

- Nechifor, A.C.; Pîrțac, A.; Albu, P.C.; Grosu, A.R.; Dumitru, F.; Dimulescu, I.A.; Oprea, O.; Pașcu, D.; Nechifor, G.; Bungău, S.G. Recuperative Amino Acids Separation through Cellulose Derivative Membranes with Microporous Polypropylene Fiber Matrix. Membranes 2021, 11, 429. [Google Scholar] [CrossRef]

- Yostawonkul, J.; Surassmo, S.; Iempridee, T.; Pimtong, W.; Suktham, K.; Sajomsang, W.; Gonil, P.; Ruktanonchai, U.R. Surface modification of nanostructure lipid carrier (NLC) by oleoyl-quaternized-chitosan as a mucoadhesive nanocarrier. Colloids Surf. B Biointerfaces 2017, 149, 301–311. [Google Scholar] [CrossRef]

- Naik, J.B.; Pardeshi, S.; Patil, R.P.; Patil, P.B.; Mujumdar, A. Mucoadhesive Micro-/Nano Carriers in Ophthalmic Drug Delivery: An Overview. BioNano Sci. 2020, 10, 564–582. [Google Scholar] [CrossRef]

- Konovalova, M.; Shagdarova, B.; Zubareva, A.; Generalov, A.; Grechikhina, M.; Svirshchevskaya, E. Development of mucoadhesive chitosan-based drug delivery system. Prog. Chem. Appl. Chitin Deriv. 2018, 203, 108–113. [Google Scholar] [CrossRef]

- Bai, B.; Mi, X.; Xiang, X.; Heiden, P.A.; Heldt, C.L. Non-enveloped virus reduction with quaternized chitosan nanofibers containing graphene. Carbohydr Res. 2013, 18, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Dos Santosa, D.M.; Leiteb, I.S.; de Lacerda Bukzema, A.; de Oliveira Santosa, R.P.; Frollinia, E.; Inadab, N.M.; Campana-Filho, S.P. Nanostructured electrospun nonwovens of poly(ε-caprolactone)/quaternized chitosan for potential biomedical applications. Carbohydr. Polym. 2018, 186, 110–121. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Show, P.L.; Ng, I.S.; Lin, G.Y.; Chiu, C.Y.; Chang, Y.K. Antibacterial activity of quaternized chitosan modified nanofiber membrane. Int. J. Biol. Macromol. 2019, 126, 569–577. [Google Scholar] [CrossRef] [PubMed]

- Mi, X.; Vijayaragavan, K.S.; Heldt, C. Virus adsorption of water-stable quaternized chitosan nanofibers. Carbohydr. Res. 2014, 387C, 24–29. [Google Scholar] [CrossRef] [PubMed]

- Mi, X.; Heldt, C.L. Adsorption of a non-enveloped mammalian virus to functionalized nanofibers. Colloids Surf. B Biointerfaces 2014, 121, 319–324. [Google Scholar] [CrossRef]

- Ignatova, M.; Yossifova, L.; Gardeva, E.; Manolova, N.; Toshkova, R.; Rashkov, I.; Alexandrov, M. Antiproliferative activity of nanofibers containing quaternized chitosan and/or doxorubicin against MCF-7 human breast carcinoma cell line by apoptosis. J. Bioact. Compat. Polym. 2011, 26, 539–551. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, H.; Liu, X.; Mao, J.; Gu, S.; Xu, W. Potential of quaternization-functionalized chitosan fiber for wound dressing. Int. J. Biol. Macromol. 2013, 52, 327–332. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, L.; Wang, Y.; Mei, L.; Fan, R.; He, M.; Wang, C.; Tong, A.; Chen, H.; Guo, G. Stereocomplexed electrospun nanofibers containing poly (lactic acid) modified quaternized chitosan for wound healing. Carbohydr. Polym. 2020, 247, 116754. [Google Scholar] [CrossRef]

- Liu, G.; Tsen, W.C.; Jang, S.C.; Hu, F.; Zhong, F.; Zhang, B.; Wang, J.; Liu, H.; Wang, G.; Wen, S.; et al. Composite membranes from quaternized chitosan reinforced with surface-functionalized PVDF electrospun nanofibers for alkaline direct methanol fuel cells. J. Membr. Sci. 2020, 611, 118242. [Google Scholar] [CrossRef]

- Xiao, X.; Zhu, Y.; Liao, J.; Wang, T.; Sun, W.; Tong, Z. High-efficient and synergetic antibacterial nanocomposite hydrogel with quaternized chitosan/Ag nanoparticles prepared by one-pot UV photochemical synthesis. Biopolymers 2020, 111, e23354. [Google Scholar] [CrossRef] [PubMed]

- You, J.; Xie, S.; Cao, J.; Ge, H.; Xu, M.; Zhang, L.; Zhou, J. Quaternized Chitosan/Poly(acrylic acid) Polyelectrolyte Complex Hydrogels with Tough, Self-Recovery, and Tunable Mechanical Properties. Macromolecules 2016, 49, 1049–1059. [Google Scholar] [CrossRef]

- Mamidi, N.; Delgadillo, R.M.V. Design, fabrication and drug release potential of dual stimuli-responsive composite hydrogel nanoparticle interfaces. Colloid Surf. B 2021, 204, 111819. [Google Scholar] [CrossRef] [PubMed]

- Xue, H.; Hu, L.; Xiong, Y.; Zhu, X.; Wei, C.; Cao, F.; Zhou, W.; Sun, Y.; Endo, Y.; Liu, M.; et al. Quaternized chitosan-Matrigel-polyacrylamide hydrogels as wound dressing for wound repair and regeneration. Carbohydr. Polym. 2019, 226, 115302. [Google Scholar] [CrossRef]

- Wei, S.; Liu, X.; Zhou, J.; Zhang, J.; Dong, A.; Huang, P.; Wang, W.; Deng, L. Dual-crosslinked nanocomposite hydrogels based on quaternized chitosan and clindamycin-loaded hyperbranched nanoparticles for potential antibacterial applications. Int. J. Biol. Macromol. 2020, 155, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Bian, S.; Li, Z.; Zhang, Z.; Liu, Y.; Zhai, X.; Pan, H.; Zhao, X. Catechol modified quaternized chitosan enhanced wet adhesive and antibacterial properties of injectable thermo-sensitive hydrogel for wound healing. Carbohydr. Polym. 2020, 249, 116826. [Google Scholar] [CrossRef]

- Fathi, P.; Omidi, M.-Y.; Mozafari, M.; Zamanian, A. Synthesis and characterization of timolol maleate-loaded quaternized chitosan-based thermosensitive hydrogel: A transparent topical ocular delivery system for the treatment of glaucoma. Int. J. Biol. Macromol. 2020, 159, 117–128. [Google Scholar]

- Ren, Y.; Zhao, X.; Liang, X.P.; Ma, X.; Guo, B. Injectable hydrogel based on quaternized chitosan, gelatin and dopamine as localized drug delivery system to treat Parkinson’s disease. Int. J. Biol. Macromol. 2017, 105, 1079–1087. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-Q.; Liu, Y.; Wang, Y.-X.; Wu, Y.-J.; Jia, P.-Y.; Shan, J.-J.; Wu, J.; Ma, G.-H.; Su, Z.-G. The potential adjuvanticity of quaternized chitosan hydrogel based microparticles for porcine reproductive and respiratory syndrome virus inactivated vaccine. Int. Immunopharm. 2016, 39, 84–91. [Google Scholar] [CrossRef]

- Riham, R.; Mohamed Mahmoud, H.; Abu Elella, M.; Sabaa, W. Synthesis, characterization and applications of N-quaternized chitosan/poly(vinyl alcohol) hydrogels. Int. J. Biol. Macromol. 2015, 80, 149–161. [Google Scholar]

- Tan, Y.; Wu, H.; Xie, T.; Chen, L.; Hu, S.; Tian, H.; Wang, Y.; Wang, J. Characterization and antibacterial effect of quaternized chitosan anchored cellulose beads. Int. J. Biol. Macromol. 2020, 155, 1325–1332. [Google Scholar] [CrossRef]

- Sowmya, A.; Meenakshi, S. An efficient and regenerable quaternary amine modified chitosan beads for the removal of nitrate and phosphate anions. J. Environ. Chem. Eng. 2013, 1, 906–915. [Google Scholar] [CrossRef]

- Eskandarloo, H.; Godec, M.; Arshadi, M.; Padilla-Zakour, O.I.; Abbaspourrad, A. Multi-porous quaternized chitosan/polystyrene microbeads for scalable, efficient heparin recovery. Chem. Eng. J. 2018, 348, 399–408. [Google Scholar] [CrossRef]

- Quinlan, P.; Nathan, G.; Kam, T. Removal of 2-naphthoxyacetic acid from aqueous solution using quaternized chitosan beads. Can. J. Chem. Eng. 2016, 95. [Google Scholar] [CrossRef]

- Li, Q.; Wang, W.; Hu, G.; Cui, X.; Sun, D.; Jin, Z.; Zhao, K. Evaluation of Chitosan Derivatives Modified Mesoporous Silica Nanoparticles as Delivery Carrier. Molecules 2021, 26, 2490. [Google Scholar] [CrossRef]

- Abdel-Aziz, M.M.; Elella, M.H.A.; Mohamed, R.R. Green synthesis of quaternized chitosan/silver nanocomposites for targeting mycobacterium tuberculosis and lung carcinoma cells (A-549). Int. J. Biol. Macromol. 2020, 142, 244–253. [Google Scholar] [CrossRef]

- Luo, J.; Han, G.; Xie, M.; Cai, Z.; Wang, X. Quaternized chitosan/montmorillonite nanocomposite resin and its adsorption behavior. Iran. Polym. J. 2015, 24, 531–539. [Google Scholar] [CrossRef]

- Jang, S.-C.; Chuang, F.-S.; Tsen, W.-C.; Kuo, T.-W. Quaternized chitosan/functionalized carbon nanotubes composite anion exchange membranes. J. Appl. Polym. Sci. 2019, 136, 47778. [Google Scholar] [CrossRef]

- Chunli, G.; Shujun, Z.; Wen-Chin, T.; Fuqiang, H.; Fei, Z.; Bingqing, Z.; Hai, L. Hierarchical layered double hydroxide coated carbon nanotube modified quaternized chitosan/polyvinyl alcohol for alkaline direct methanol fuel cells. J Power Sources 2019, 441, 227176. [Google Scholar]

- Dhiman, P.; Bhatia, M. Ketoconazole loaded quaternized chitosan nanoparticles-PVA film: Preparation and evaluation. Polym. Bull. 2021. [Google Scholar] [CrossRef]

- Ji, Q.X.; Zhao, Q.S.; Deng, J.; Lü, R. A novel injectable chlorhexidine thermosensitive hydrogel for periodontal application: Preparation, antibacterial activity and toxicity evaluation. J. Mater. Sci. Mater. Med. 2010, 21, 2435–2442. [Google Scholar] [CrossRef]

- Chuang, C.C.; Tsai, M.H.; Yen, H.J.; Shyu, H.F.; Cheng, K.M.; Chen, X.A.; Chen, C.C.; Young, J.J.; Kau, J.H. A fucoidan-quaternary chitosan nanoparticle adjuvant for anthrax vaccine as an alternative to CpG oligodeoxynucleotides. Carbohydr. Polym. 2020, 229, 115403. [Google Scholar] [CrossRef]

- Zhao, K.; Li, S.; Li, W.; Yu, L.; Duan, X.; Han, J.; Wang, X.; Jin, Z. Quaternized chitosan nanoparticles loaded with the combined attenuated live vaccine against Newcastle disease and infectious bronchitis elicit immune response in chicken after intranasal administration. Drug Deliv. 2017, 24, 1574–1586. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Cheng, D.; Lu, S.; Huang, F.; Li, G. Preparation of quaternary ammonium salt of chitosan nanoparticles and their textile properties on Antheraea pernyi silk modification. Textile Res. J. 2014, 84, 2115–2124. [Google Scholar] [CrossRef]

- Wen, Y.; Zhang, X.Y.; Sheng, L.; Lian, X.J. Preparation and In Vitro Release Study of Quaternized Chitosan Nanoparticles. Adv. Mater. Res. 2014, 1053, 466–472. [Google Scholar] [CrossRef]

- Abueva, S.D.; Kim, C.; Lee, B.; Nath, B.T. Chitosan-hyaluronic acid polyelectrolyte complex scaffold crosslinked with genipin for immobilization and controlled release of BMP-2. Carbohydr. Polym. 2015, 115, 160–169. [Google Scholar]

- Omer, A.M.; Ziora, Z.M.; Tamer, T.M.; Khalifa, R.E.; Hassan, M.A.; Mohy-Eldin, M.S.; Blaskovich, M.A.T. Formulation of Quaternized Aminated Chitosan Nanoparticles for Efficient Encapsulation and Slow Release of Curcumin. Molecules 2021, 26, 449. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Hao, S.; Sun, B.; Zhao, D.; Yan, X.; Jin, Z.; Zhao, K. Quaternized Chitosan Nanoparticles in Vaccine Applications. Curr. Med. Chem. 2020, 27, 4932–4944. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Chu, C.H. Dual stimuli responsive glycidyl methacrylate chitosan-quaternary ammonium hybrid hydrogel and its bovine serum albumin release. J. Appl. Polym. Sci. 2013, 130, 3736–3745. [Google Scholar] [CrossRef]

- Li, X.; Xing, R.; Xu, C.; Liu, S.; Qin, Y.; Li, K.; Yu, H.; Li, P. Immunostimulatory effect of chitosan and quaternary chitosan: A review of potential vaccine adjuvants. Carbohydr. Polym. 2021, 264, 118050. [Google Scholar] [CrossRef] [PubMed]

- Verheul, R.J.; Amidi, M.; van der Wal, S.; van Riet, E.; Jiskoot, W.; Hennink, W.E. Synthesis, characterization and in vitro biological properties of O-methyl free N,N,N-trimethylated chitosan. Biomaterials 2008, 29, 3642–3649. [Google Scholar] [CrossRef] [PubMed]

- Malik, A.; Gupta, M.; Gupta, V.; Gogoi, H.; Bhatnagar, R. Novel application of trimethyl chitosan as an adjuvant in vaccine delivery. Int. J. Nanomed. 2018, 13, 7959–7970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kammona, O.; Kiparissides, C. Recent advances in nanocarrier-based mucosal delivery of biomolecules. J. Control. Release 2012, 161, 781–794. [Google Scholar] [CrossRef]

- Zhao, K.; Zhang, Y.; Zhang, X.; Li, W.; Shi, C.; Guo, C.; Dai, C.; Chen, Q.; Jin, Z.; Zhao, Y.; et al. Preparation and efficacy of Newcastle disease virus DNA vaccine encapsulated in chitosan nanoparticles. Int. J. Nanomed. 2014, 9, 389–402. [Google Scholar] [CrossRef] [Green Version]

- Tao, W.; Zheng, H.Q.; Fu, T.; He, Z.J.; Hong, Y. N-(2-hydroxy) propyl-3-trimethylammonium chitosan chloride: An immune-enhancing adjuvant for hepatitis E virus recombinant polypeptide vaccine in mice. Hum. Vaccines Immunother. 2017, 13, 1818–1822. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heyman, B. Regulation of antibody responses via antibodies, complement, and Fc receptors. Annu. Rev. Immunol. 2000, 18, 709–737. [Google Scholar] [CrossRef]

- Almalik, A.; Alradwan, I.; Majrashi, M.A.; Alsaffar, B.A.; Algarni, A.T.; Alsuabeyl, M.S.; Alrabiah, H.; Tirelli, N.; Alhasan, A.H. Cellular responses of hyaluronic acid-coated chitosan nanoparticles. Toxicol. Res. 2018, 7, 942–950. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Wu, S.; Hou, L.; Wei, W.; Zhou, M.; Su, Z.; Wu, J.; Chen, W.; Ma, G. Novel thermal-sensitive hydrogel enhances both humoral and cell-mediated immune responses by intranasal vaccine delivery. Eur. J. 2012, 81, 486–497. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Fan, Q.Z.; Liu, Y.; Yue, H.; Ma, X.W.; Wu, J.; Ma, G.H.; Su, Z.G. Improving adjuvanticity of quaternized chitosan-based microgels for H5N1 split vaccine by tailoring the particle properties to achieve antigen dose sparing effect. Int. J. Pharm. 2016, 515, 84–93. [Google Scholar] [CrossRef] [PubMed]

- Brokstad, K.A.; Eriksson, J.C.; Cox, R.J.; Tynning, T.; Olofsson, J.; Jonsson, R.; Davidsson, A. Parenteral vaccination against influenza does not induce a local antigen-specific immune response in the nasal mucosa. J. Infect. Dis. 2002, 185, 878–884. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neutra, M.R.; Kozlowski, P.A. Mucosal vaccines: The promise and the challenge. Nat. Rev. Immunol. 2006, 6, 148–158. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Huang, S.; Lu, L.; Song, X.; Li, P.; Wang, F. Curdlan sulfate-O-linked quaternized chitosan nanoparticles: Potential adjuvants to improve the immunogenicity of exogenous antigens via intranasal vaccination. Int. J. Nanomed. 2018, 13, 2377–2394. [Google Scholar] [CrossRef] [Green Version]

- Nevagi, R.J.; Khalil, Z.G.; Hussein, W.M.; Powell, J.; Batzloff, M.R.; Capon, R.J.; Good, M.F.; Skwarczynski, M.; Toth, I. Polyglutamic acid-trimethyl chitosan-based intranasal peptide nano-vaccine induces potent immune responses against group A streptococcus. Acta Biomater. 2018, 80, 278–287. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tan, H.L.; Peng, Z.X.; Li, Q.T.; Xu, X.F.; Guo, S.R.; Tang, T.T. The use of quaternised chitosan-loaded PMMA to inhibit biofilm for-mation and downregulate the virulence-associated gene expression of antibiotic-resistant staphylococcus. Biomaterials 2012, 33, 365–377. [Google Scholar] [CrossRef]

- Tan, H.L.; Guo, S.R.; Yang, S.B.; XU, X.F.; Tang, T.T. Physical characterization and osteogenic activity of the quaternized chitosan-loaded PMMA bone cement. Acta Biomater. 2012, 8, 2166–2174. [Google Scholar] [CrossRef]

- Tan, H.L.; Ao, H.Y.; Ma, R.; Lin, W.T.; Tang, T.T. In vivo effect of quaternized chitosan-loaded polymethylmethacrylate bone cement on methicillin-resistant Staphylococcus epidermidis infection of the tibial metaphysis in a rabbit model. Antimicrob. Agents Chem. 2014, 58, 6016–6023. [Google Scholar] [CrossRef] [Green Version]

- Peng, Z.X.; Wang, L.; Du, L.; Guo, S.R.; Wang, X.Q.; Tang, T.T. Adjustment of the antibacterial activity and biocompatibility of hydroxypropyltrimethyl ammonium chloride chitosan by varying the degree of substitution of quaternary ammonium. Carbohydr. Polym. 2010, 81, 275–283. [Google Scholar] [CrossRef]

- Sun, L.; Du, Y.; Fan, L.; Chen, X.; Yang, J. Preparation, characterization and antimicrobial activity of quaternized carboxymethyl chitosan and application as pulp-cap. Polymer 2006, 47, 1796–1804. [Google Scholar] [CrossRef]

- Kadama, J.; Chen, H.; Zhou, T.; Kushioka, J.; Okada, R.; Tsukazaki, H.; Tateiwa, D.; Nakagawa, S.; Ukon, Y.; Bal, Z.; et al. Antibacterial efficacy of quaternized chitosan coating on 3D printed titanium cage in rat intervertebral disc space. Spine J. 2021, 21, 1529–9430. [Google Scholar]

- Verlee, A.; Mincke, S.; Stevens, C.V. Recent developments in antibacterial and antifungal chitosan and its derivatives. Carbohydr. Polym. 2017, 164, 268–283. [Google Scholar] [CrossRef]

- Tavaria, F.K.; Costa, E.M.; Pintado, M.M.; Pina-Vaz, I.; Carvalho, M.F.; Pintado, M.M. A quitosana como biomaterial odontológico: Estado da arte. Rev. Bras. Eng. Bioméd. 2013, 29, 110–120. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Du, J.; Peng, Z. Correlation between Enterococcus faecalis and persistent intraradicular infection compared with primary intraradicular infection: A systematic review. J. Endod. 2015, 41, 1207–1213. [Google Scholar] [CrossRef]

- Patel, E.; Pradeep, P.; Kumar, P.; Choonara, Y.E.; Pillay, V. Oroactive dental biomaterials and their use in endodontic therapy. J. Biomed. Mater. Res. B Appl. Biomater. 2020, 108, 201–212. [Google Scholar] [CrossRef]

- Troiano, G.; Perrone, D.; Dioguardi, M.; Buonavoglia, A.; Ardito, F.; Lo Muzio, L. In vitro evaluation of the cytotoxic activity of three epoxy resin-based endodontic sealers. Dent. Mater. J. 2018, 37, 374–378. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, N.; Ji, Y.; Zhu, Y.; Wu, X.; Mei, L.; Zhang, H.; Deng, J.; Wang, S. Antibacterial effect of chitosan and its derivative on Enterococcus faecalis associated with endodontic infection. Exp. Ther. Med. 2020, 19, 3805–3813. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, H.L.; Wang, R.S.; Hsu, Y.C.; Chuang, C.C.; Chan, H.R.; Chiu, H.C.; Wang, Y.B.; Chen, K.Y.; Fu, E. Antifungal effect of tissue conditioners containing poly(acryloyloxyethyltrimethyl ammonium chloride)-grafted chitosan on Candida albicans growth in vitro. J. Dent. Sci. 2018, 13, 160–166. [Google Scholar] [CrossRef] [PubMed]

- Gonil, P.; Sajomsang, W.; Ruktanonchai, U.R.; Pimpha, N.; Sramala, I.; Nuchuchua, O.; Saesoo, S.; Chaleawlertumpon, S.; Puttipipatkhachorn, S. Novel quaternized chitosan containing β-cyclodextrin moiety: Synthesis, characterization and antimicrobial activity. Carbohydr. Polym. 2011, 83, 905–913. [Google Scholar] [CrossRef]

- Ji, Q.X.; de Zhong, Y.; Lü, R.; Zhang, W.Q.; Deng, J.; Chen, X.G. In vitro evaluation of the biomedical properties of chitosan and quaternized chitosan for dental applications. Carbohydr. Res. 2009, 344, 1297–1302. [Google Scholar] [CrossRef] [PubMed]

- Ji, Q.X.; Deng, J.; Yu, X.B.; Xu, Q.C.; Xu, X.Y. An in vitro evaluation of the antibacterial activity of chitosan-based thermosensitive hydrogel against periodontal pathogens. Shanghai Kou Qiang Yi Xue 2009, 18, 397–400. [Google Scholar] [PubMed]

- Sakulwech, S.; Lourith, N.; Ruktanonchai, U.; Kanlayavattanakul, M. Preparation and characterization of nanoparticles from quaternized cyclodextrin-grafted chitosan associated with hyaluronic acid for cosmetics. Asian J. Pharm. Sci. 2018, 13, 498–504. [Google Scholar] [CrossRef] [PubMed]

- Khalaji, S.; Golshan Ebrahimi, N.; Hosseinkhani, H. Enhancement of biocompatibility of PVA/HTCC blend polymer with collagen for skin care application. Int. J. Polym. Mater. Polym. Biomater. 2021, 70, 459–468. [Google Scholar] [CrossRef]

| Parameters | Responses |

|---|---|

| Degree of quaternization (<65%) | Increased cytotoxicity |

| Increased mucoadhesiveness | |

| Decreased anticoagulation effect | |

| Degree of quaternization (≥20%) | Increased antimicrobial action in pH = 7.2 |

| No effect on antimicrobial action in acidic pH | |

| Degree of substitution (<1%) | Increased antioxidant property |

| Degree of substitution (<25%) | Increased antithrombin action and acid-binding capacity |

| Degree of substitution (>1%) | Decreased moisture absorption and retention ability |

| High concentration | Increased particle size, aggregation, zeta potential, cytotoxicity |

| Decreased knockdown efficiency and poor transfection efficacy |

| Quaternized Chitosan Derivatives | Biomedical Applications | References |

|---|---|---|

| N,N,N-trimethyl-O-(2-hydroxy-3-trimethylammonium propyl) chitosan (TMHTMAPC) | Antimicrobial against S. aureus and E. coli in both acidic and alkaline pH. | [37,54] |

| Water soluble N-piperazine chitosan | Pharmaceutical application | [55] |

| Water soluble N-betainate chitosan | Antibacterial for S. aureus and E. coli Effect of antibacterial efficacy decreased with increase in amino group substitution. | [48,56] |

| N,N-dimethyl-O-quaternary ammonium chitosan | Cosmeceuticals (moisturizer), antibacterial | [57] |

| O-acetyl-chitosan-N-2-hydroxypropyl trimethyl ammonium chloride | Antibacterial (S. aureus and E. coli), Food preservative | [58] |

| Amphiphilic 5-(bromo pentyl) trimethyl ammonium conjugated with dodecyl aldehyde chitosan (BPTADDACH) | Efficient drug carrier for hydrophobic candidates | [59] |

| Diethylaminoethyl-2-N-carboxymethyl-6-O Chitosan (DEAE–CMC) containing vitamin B12 microspheres | Blood compatible drug delivery system | [60] |

| N,N,N-(diethyl aryl) chitosan chloride | Antifungal/fungicide for crop threatening Botrytis cinerea. | [61] |

| Quaternized N-(aryl) chitosan | Modified antimicrobial action against E. coli, P. aeruginosa, S. aureus and A. niger due to presence of phenol hydroxyl group | [62] |

| Quaternized carboxymethyl chitosan containing guanidine groups (QGCMC) | Food preservative (enhanced shelf life of strawberries), strong bactericidal action in all ranges of pH (acidic, alkaline and neutral) | [63] |

| O-quaternary ammonium N-acyl thiourea chitosan (OQCATUCS) | Synergistic antimicrobial action for S. aureus, E. coli, A. niger, P. aeruginosa and B. subtilis | [64] |

| N,O-[N,N-diethylaminomethyl (diethyl dimethylene ammonium) n] methyl chitosan | Intraocular drug delivery (Enhanced permeability of dexamethasone) | [51,65] |

| Diethylaminoethyl-2-N-carboxymethyl-6-O Chitosan (DEAE–CMC) containing vitamin B12 microspheres | Blood compatible drug delivery system | [60,66] |

| Components | Purpose | Research Outcomes | References |

|---|---|---|---|

| HTCC and PVA | Retention of non-enveloped virus on the highly charged HTCC/PVA nanofibers. | Nano-scaled HTCC/PVA nanofibers (100–200 nm) were developed, having the potential to adsorb mammalian virus porcine parvovirus (95%). The developed system followed Freundlich isotherm and showed fast adsorption kinetics (pseudo first order), which suggested the formation of efficient filter material for the purification of water | [110] |

| Doxorubicin, poly (L-lactide-coD, L-lactide) and QCh | Doxorubicin embedded poly (L-lactide-coD, L-lactide) mats were modified with QCh to enhance anti-proliferative activity. | Developed mats were evaluated against human breast carcinoma cell lines (MCF-7) and exhibited reduced cell viability and amplified antiproliferative activity. Fluorescent microscopy revealed that the presence of QCh induced apoptosis, which was the primary mechanism of MCF-7 cell death. | [111] |

| 2,3-Epoxy-propyl trimethyl ammonium chloride | QCh fibres were designed using 2,3-epoxypropyl trimethyl. Ammonium chloride following ring open reaction to modify antibacterial and liquid absorption capacity. | Outcomes revealed excellent water retention capacity, modified swelling index and mechanical strength compared to bare chitosan. Superior antibacterial efficacy against S. aureus and lower cytotoxicity suggested its vital role in fabricating wound dressing materials. | [112] |

| Poly (lactic acid), QCh | Stereo complex crystallite (SC) membrane containing poly (lactic acid) QCh were employed to design disinfectant wound dressing material. | The enhanced thermal and mechanical properties of developed SC membrane owing to restricted mobility of lactide chains. They have better wound healing capacity (100% in 15 days). This biomass-based membrane was multifunctional as it has antioxidant, antibacterial and wound healing efficacy. | [113] |

| Silica coated poly (vinylidene) fluoride and QCh | High-performance anion exchange silica-coated (vinylidene) fluoride along with QCh nanofibrous membrane were designed. | The surface of silica-coated poly (vinylidene) fluoride was grafted with quaternized chitosan to pursue dual action, i.e., ion exchange and strong reinforcement substrate. QCh-impregnated nanofibers showed superb mechanical strength (11.9Mpa). Adorned positive charges created channel-like ion transport channels that could efficiently serve as anion exchange membrane. | [114] |

| Objective | Components | Research Highlights | References |

|---|---|---|---|

| Multifunctional QCh-based polyacrylamide hydrogel was developed that contained hemostatic and skin adhesive properties | QCh, Matrigel-polyacrylamide | The developed hybrid hydrogel had a three-dimensional microporous integrity and exhibited high mechanical strength and good adhesiveness with low toxicity. The outcomes from the histology study demonstrated improvement in wound healing, collagen deposition, and stimulation of skin adnexal regeneration. The developed QCh-based antibacterial hydrogel demonstrated promising potential for designing wound dressing materials. | [118] |

| Dual crosslinked QCh-clindamycin loaded hydrogel was prepared to manage methicillin-resistant S. aureus (MRSA) bacteria | QCh, clindamycin | The developed nanocomposite-embedded hydrogel withstood sufficient mechanical and injectable efficiencies. The system responded on variable pH that enabled maximum interaction with MRSA bacteria (90% killed) in acidic conditions and overcame the antibiotic resistance challenge. | [119] |

| A novel wound dressing-based injectable hydrogel was designed employing QCh and PLEL (PLEL-nBG-QCS-C) hydrogel to promote angiogenesis. | QCh and PLEL [Poly (D, L-lactide)-poly (ethylene glycol)-poly (D,L-lactide)] and bioactive glass | PLEL hydrogels preloaded with bioactive glass (CaO-SiO2-P2O5) could efficiently seal the broken skin and increase the cure rate of wounds. Additionally, they were thermosensitive, tissue adhesive, and antibacterial. | [120] |

| QCh-based timolol maleate thermosensitive hydrogel was prepared for improved ophthalmic disorders. | Timolol maleate, Sodium hydrogen carbonate, QCh | The developed transparent thermosensitive hydrogel presented desirable porosity, swelling index, and biodegradability. The addition of sodium hydrogen carbonate enabled enhanced thermosensitivity to the system. In vitro drug release revealed the initial burst release in early hours followed by controlled release of timolol maleate for a week. This supported the potential use of the developed hydrogel for glaucoma management. | [121] |

| Dopamine-gelatin-crosslinked QCh injectable hydrogel was prepared to localize delivery for the combat of Parkinson and associated inflammation as well. | Dopamine, QCh, Metronidazole, gelatin | The formulated injectable hydrogel exhibited sufficient rheological parameters. The cytocompatibility of hydrogel revealed the cell viability and proliferation of L929 fibroblast cells. In vitro study exposed localized release of both dopamine and metronidazole. | [122] |

| QCh-based pH-sensitive veterinary hydrogel vaccine for improved cellular and humoral responses. | QCh, MontanideTM ISA206 and glycerophosphate | The developed hydrogel was biocompatible, safe, and had efficiencies to adsorb inactivated porcine reproductive and respiratory syndrome virus. Moreover, the system ruled out the downsides of mineral oil side effects and encouraged immunogenicity. | [123] |

| Development of NQC-loaded thermostable and multifunctional hydrogel | N-quaternized chitosan (NQC), poly vinyl alcohol, glutaraldehyde | Different hydrogels on varying concentration of NQC and PVA were designed to modify metal ion uptake, swelling capacity, compatibility, and antibacterial efficacy. | [124] |

| Objective | Components | Research Highlights | References |

|---|---|---|---|

| Ketoconazole was entrapped in QCh NPs for superior antifungal activity | Ketoconazole, QCh, sodium triphosphate | Nanoscaled KCZ-QCSNPs displayed superb entrapment efficiency (~90%). Performed tube dilution method revealed preeminent antimicrobial activity. | [134] |

| QCh derivative ‘HTCC’ NPs were embedded in various fabric materials to evaluate antimicrobial efficacy. | HTCC, cotton fabric, polyester, polyacrylic acid | The developed HTCC nanoparticles embedded in cotton fabric exhibited superior antimicrobial action against Fusarium oxysporum and Bacillus subtilis compared to polyester and mixture of cotton. | [135] |

| Anthrax vaccine adjuvant containing Fucoidan-HTCC nanoparticles were developed to improve rapid induction of immunity | Sulphated polysaccharide (Fucoidan, FUC) and HTCC | An active complexation between opposite-charged FUC and HTCC was conducted through varying their mass ratio. MTT assay on L929 or JAWS dendritic cells evaluated low cytotoxicity, improved cellular internalization and high cell viability. Combination of FUC-HTCCNPs and anthrax vaccine adsorbed (AVA) significantly improved magnitude of cellular/humoral immunity and mice survival rate compared to administration of AVA alone. | [136] |

| Nanoparticles containing N-2-HTCC and N,O-CMC encapsulated vaccine antigens (IBV/H120) were developed for significant increments in lymphocytes, interleukins, and interferon in chicken | N-2-HTCC, N,O-carboxy methyl chitosan (CMC), infectious bronchitis virus (IBV)/H120 and Newcastle disease virus (NDV) | The developed nanoparticles, i.e., N-2-HTCC-CMC/NDV/IBV, predicted great stability and low cytotoxicity on storing at 37 °C for 3 weeks. In vivo assay on chicken revealed sustained release of both NDV and IBV with enhanced release of IgG and IgA that facilitated the proliferation of immune modifiers in chicken body. The developed QCh-based NPs showed the potential to combat respiratory diseases in chicken. | [137] |

| Ecofriendly QCh derivative HTCC nanoparticles were designed to increase the durability and microbial resistance of Antheraea pernyi silk fabric. | HTCC and 1,2,3,4 butane tetracarboxylic acid, sodium hypophosphite | The conventional dip-and-dry-cure method was applied to evaluate silk fabric durability (A. pernyi). Wrinkle resistance, microbial resistance (against S. aureus and E. coli) and shrinkage resistance were observed even after washing A. pernyi silk fabric more than 50 times. | [138] |

| 5-flurouracil (5-FU) embedded HTCC NPs developed for improved entrapment efficiency and in vitro release | 5-FU, HTCC, sodium tripoly-phosphate (TPP) | 5-FU/HTCC NPs were prepared through ionic gelation method via electrostatic interaction between positive-charged HTCC and negative-charged TPP. Encapsulated 5-FU exhibited controlled release profile in pH 7.4 buffer. | [139] |

| QCh-Based System | Biomedical Application | References |

|---|---|---|

| Conjugates of chitosan and HTCC | Antibacterial activity against oral pathogen | [172] |

| Thermosensitive CS-HTCC/GP-Chlorhexidine hydrogel | Local drug delivery for periodontal treatment | [135] |

| CS-HTCC/GP thermosensitive hydrogel | Antibacterial efficient activator for periodontal pathogens such as Porphyromonas gingivalis, Actinobacillus actinomycetemcomitans and Prevotella intermedia. | [173] |

| Conjugate of Quaternized carboxymethyl chitosan (QCMC) and calcium hydroxide | QCMC strongly induced reparative dentine formation and showed a better ability in dentin inducing compared with calcium hydroxide. | [162] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pathak, K.; Misra, S.K.; Sehgal, A.; Singh, S.; Bungau, S.; Najda, A.; Gruszecki, R.; Behl, T. Biomedical Applications of Quaternized Chitosan. Polymers 2021, 13, 2514. https://doi.org/10.3390/polym13152514

Pathak K, Misra SK, Sehgal A, Singh S, Bungau S, Najda A, Gruszecki R, Behl T. Biomedical Applications of Quaternized Chitosan. Polymers. 2021; 13(15):2514. https://doi.org/10.3390/polym13152514

Chicago/Turabian StylePathak, Kamla, Shashi Kiran Misra, Aayush Sehgal, Sukhbir Singh, Simona Bungau, Agnieszka Najda, Robert Gruszecki, and Tapan Behl. 2021. "Biomedical Applications of Quaternized Chitosan" Polymers 13, no. 15: 2514. https://doi.org/10.3390/polym13152514