1. Introduction

The degradation of PES and PA polymers is being intensively studied, mainly due to growing concerns around the accumulation of plastics and microplastics in soils and oceans, to which textile waste also contributes. Polyamide 6 and polyamide 6.6 are commonly used in all textile products. Polyamide blends with elastane are the most popular fiber blend for swimwear today. Polyester fibers are used for the long lasting shape retention of swimsuits.

Polyamide 6 and polyamide 6.6 have excellent wear and abrasion resistance to chemicals and oil, and a good balance of mechanical properties. Polyamides tend to absorb moisture, which can affect their properties. Acids can lead to hydrolysis by nucleophilic substitution of the amino link, photolysis leads to scission (breaks in the polymer chains) of the amide linkage [

1]. Polyesters are formed by a condensation reaction very similar to the reaction used to produce polyamide. It is commonly used in various textile products. Thermoplastic polyesters have similar properties to PA 6 and PA 6.6, but have lower water absorption and a higher dimensional stability than polyamides. UV radiation absorbed by polyesters leads to scission. In the presence of water, hydrolysis occurs [

1]. The influence of UV radiation, water, temperature, humidity and chemical effects has been widely studied. Arhant et al. simulated modification in the physical-mechanical properties of PET polymers made by UV radiation and seawater by aging of PET in water at temperatures ranging from 80 to 110 °C up to 150 days. Embrittlement happens with scission when the polymer molar mass drops below 17 kg/mol during hydrolysis. The brittle state corresponds with a significant decrease in mechanical properties [

2]. Chaisupakitsin et al. observed the change in degradation of PET bottle polymers induced by UV radiation and the effect of degradation on drinking water, style and effervescence. After 8 months of sunlight exposure, the tensile strength decreased and the pH of the water changed from acidic to basic for all samples [

3]. A new mathematical model for the hydrolytic degradation of PET was proposed by Dubelley et al. The effects of humidity and temperature are included in the model. The model agrees with the data obtained from a literature study [

4].

Photodegradation of PET fibers under accelerated aging conditions was studied at the nanoscale using resonance-enhanced atomic force microscopy and infrared spectroscopy was investigated by Nguyen-Tri [

5]. PET fibers degrade in cementitious alkaline composites, but Rostami et al. concluded that in most applications, the properties of the composite are still improved by PET fibers [

6]. An experimental study on the hydrolysis of PA6 in water without oxygen is presented by Deshoulles et al.; 250 microns thick film samples were immersed in oxygen-free water for 2 years. Chain scission, an increase in crystallinity and a sharp increase in water content were observed. A new kinetic model considering water content increase is proposed. The model is used to predict the leakage of macromolecules from the polymer into the oceans [

7].

Reactive molecular simulations are used in an Arash study to predict the effect of water on thermal degradation of PA 6.6. The influence of water content on the activation energy and the pre-exponential factor of the cleavage reactions is investigated. A predictive tool to study the long-term thermal degradation of PA 6.6 is offered [

8]. Degradation of PA membranes by hydrogen halides and sulfuric acid was investigated by Jun et al. Characterization was carried out by SEM, FTIR and XPS. Sulfuric acid did not cause any changes in the membrane, but hydrogen halides changed the physicochemical properties of the membrane. The results can be used in recycling and industrial processes [

9].

Thermal oxidation of polyamide 6.6 between 140 °C and 200 °C is investigated in the study by Pliquet et al. The structural changes are monitored by infrared and UV spectroscopy and the microstructure was evaluated by DSC. Vickers µ-hardness was used to evaluate the physical-mechanical properties. Correlations were observed between the changes in chemical structure, change in microstructure and physical-mechanical properties [

10]. The degradation of PET and PA in swimsuits is less studied, but Apoloni Cianek simulated the degradation of PET, which is used to manufacture swimsuits in a swimming pool environment. Thermal analysis showed that the degradation occurs in the crystalline phase of the polymer. FTIR analysis showed that the reactions that take place during the degradation process involve the breaking of the polymer chains. Morphological analysis of SEM has shown a decrease in the average diameter of PET samples [

11]. In addition to PA and PET, the third polymer fiber used in swimsuits is polyurethane elastane fiber (Spandex), which is used for its stretchability. Marjo et al. studied swimsuits containing an elastane component made from polyetherurethane or polyesterurethane polymers. Hydrolysis was confirmed by thermal testing using ATR-FTIR spectroscopy. The oil on the material was the decomposition product of the polyester component of elastane [

12]. Elastane is sensitive to high temperatures. A study by Yin suggests separating PA and elastane in blended fabrics for recycling by heating the material, which damages the elastane but not the PA [

13]. All these studies confirm that ageing degrades PA, PES and elastane at the molecular level, but ageing also changes the properties of the textiles. The change in fabric properties further affects the comfort of the material, where the material must provide an optimum or minimum satisfactory level [

14], and the durability of the material.

In a study by Salopek Čubrić et al. [

15], a significant decrease in all parameters de-scribing tensile properties of PET knitwear was observed after outdoor weathering, but structural parameters after weathering, such as horizontal and vertical density, remained similar. The heat resistance of polyester fabric also remained at almost the same level [

14]. In another study, the water vapor resistance of PA- and PET-coated fabrics decreased after outdoor weathering. The average reduction in water vapor resistance after summer weathering was 11.4% and after winter, weathering was 16.7% [

16]. The heat resistance of PES-coated PA and PET fabrics decreased by 13% and 25% after 3 months of summer and winter weathering, respectively, in a study by Potočić Matković et al. SEM analysis con-firmed deterioration of the PES layer unrelated to the PA and PET fabric substrate [

17]. The deterioration of the PA and PET substrate influenced the decrease in elongation properties, but mainly the decrease in breaking forces, especially after summer exposure [

18].

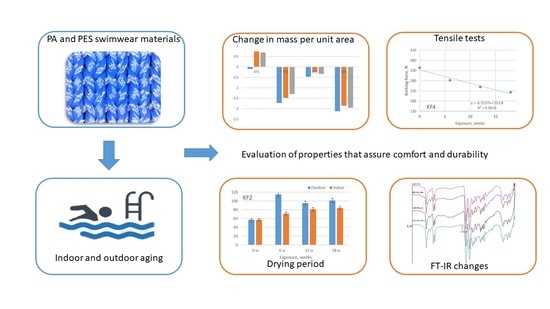

To the best of the authors’ knowledge, researchers have not previously addressed the development of protocols for aging materials in swimming pools that coincide with athlete training and continued use to provide an overview of material performance after specific aging. Therefore, this research aimed to: (i) develop specific aging protocols for swimwear; (ii) implement protocols in the material aging process; (iii) investigate the material properties that are important for durability and comfort in use; and (iv) analyze the effect of aging on material properties. In view of their purpose, the polymer materials were aged in swimming pool water (separately indoor and outdoor), washed in tap water and dried (separately indoor and outdoor). A comparative evaluation was carried out using various tests that are important in the evaluation of aged materials. The tests included microscopic analysis (visual observation—material appearance of non-aged and aged materials, de-termination of horizontal, vertical and overall loop density, measurement of maximum area of voids within loops), tensile tests (breaking force, breaking elongation), duration of fluid transport phases and total drying period of the material.

3. Results and Discussion

3.1. Results of the Microscopic Analysis

The representative microscopic images of the studied materials taken before aging (Wa) and after the simulated 18-week aging (both outdoor and indoor—Po-18w and Pi-18w) are shown in

Table 3. The images have been converted to grayscale to facilitate comparison. As can be seen, the structure of non-aged materials is very uniform, with no signs of deterioration of any kind. The structure of sample KF1 is slightly less visible as this material has been dyed a darker color, which has affected the visibility of the image to some extent, but even then the structure is fairly uniform. As can be seen further, there are noticeable changes in the appearance of the material after aging, i.e., there are changes in the surface of the material in terms of fibrillation. The fibrillation is present on the entire surface of aged materials. The longest protruding fiber has a length of 1.25 mm. Among the presented microscopic images, this phenomenon is best seen in the materials assigned as KF2 and KF3. Additional analysis of a large set of microscopic images taken on different segments of the aged materials revealed that the surface deterioration is more pronounced after outdoor aging, i.e., after additional exposure to direct sunlight. This result is in agreement with the results attributed to photodegradation by Nguyen-Tri [

5] and chemicals used for disinfecting by Cianek [

11], which also showed surface damage to PET fibers. The observed fibrillation on the material surface is expected to have a negative impact on the tactile comfort of the material and to facilitate the pilling. As shown in previous research, textile products, such as swimwear, appeal to the user’s sense and sense of touch [

24], which in this case is negatively affected by aging in KF2 and KF3 materials. At this point, there was no visually observed deterioration of the material structure that might indicate a significant change in other properties. There was no fading of the dyestuff on aged samples.

Polymeric materials produced with knitting technology have the most unstable structure compared to materials produced with other technologies. The data on fabric density and its changes due to exposure to various influences are quite valuable in knitted fabrics. They give some insight into the structural transformation that can affect other material properties. The changes in material densities (expressed as percentages) compared to the densities of non-aged materials are shown in

Table 4. The values shown include the average density of loops in the horizontal and vertical directions, as well as the overall loop density. To illustrate the changes in material densities (in the horizontal and vertical direction and in both directions), the results are presented for each material and after the longest exposure time. Reduced knit density, in either direction, compromises comfort or material aesthetics. It can be assumed that it is more associated with a loss of elastic properties in PET than in PA blends.

Another material parameter determined by microscopic analysis was the maximum area of voids within the material structural elements. Despite the fact that this analysis is usually performed using only magnifying glass, microscopic analysis was used for this research because it provides more reliable and precise data with high reading accuracy. The results in

Table 5 show that the effect of aging factors on the materials causes a significant increase in the maximum area of voids on the polyamide materials. Namely, the maximum area of voids for polyamide materials increases from 0.003/0.005 mm

2 (non-aged specimen) to 0.007 mm

2. There is an obvious change in the ideal shape of the basic unit of the structure, which may affect the change in other properties of the material. It is important to note that no such significant change was observed in polyester materials (the maximum area of voids is 0.001 and 0.002 mm

2 before aging, and 0.001–0.003 mm

2 after aging). Since the values of maximum void area after outdoor and indoor exposure are similar, it is not possible to draw a conclusion with certainty about the influence of individual aging on the observed changes.

3.2. Results of the Test of Mass per Unit Area

In the previous study [

6], related to the exposure of polyester material in alkaline media, the positive effect on the reduction of mass per unit area was reported. In contrast to this study, the results presented in

Figure 4 indicate a specific behavior of porous knitted structures, especially after outdoor exposure. Namely, for all the studied materials, the mass per unit area increases in the first phase of exposure to outdoor conditions (i.e., after 6 weeks of exposure),

Figure 4. This fact should be explained by a rapid and significant change in the fabric structure, leading to a shrinkage of the material, which consequently affects the increase in mass per unit area. With further exposure of the materials, the mass per unit area decreases, indicating that the material structure changes and the material relaxes (i.e., shrinkage decreases). For materials aged indoors, different material behavior is observed in terms of changes in mass per unit area. In particular, the mass of materials with elastane (materials KF2, KF3 and KF4) decreases after exposure. As can be seen, this decrease is not proportional to the duration of exposure. In contrast, the mass per unit area of the polyester material without elastane content increases due to the exposure, which leads to the conclusion that the material without elastane content shrinks more than the material with elastane content. It is to be assumed that fabric KF1, with longer exposure to indoor aging, would follow the behavior of other fabrics.

3.3. Results of Tensile Testing

The instability of the knitted structure allows the knitted material to fit the body better and is therefore preferable for use in sportswear. The average stresses acting in different types of knitted material for sportswear are rather low. The peculiarity of swimwear for athletes (especially professional athletes) is that such materials fit very tightly to the body to allow faster body movements in the water. At this point, the stresses acting on such a material are much higher than the stresses acting on materials for other purposes. Since the aging process affects the changes in tensile properties, the data on the breaking force are essential to describe issues related to the durability of the material. A significant decrease in the physical-mechanical properties of PET fibers has been previously reported after exposure to UV radiation [

3], UV radiation and seawater [

2], and on PET and PA fibers after outdoor exposure [

14,

17]. The results of the tensile tests, which focus on the measured values of the breaking force, are shown in

Figure 5 and

Figure 6.

As can be seen from the figures, the values of the measured breaking forces of the non-aged materials are in the range of 187–417 N, being higher for the polyamide materials. After the longest exposure period (18 weeks in this case), the values are much lower and are in the range of 132–265 N. A positive correlation is observed between the exposure duration (as independent variable) and the breaking force (as dependent variable) for both aging in outdoor and indoor environments. The corresponding linear regression coefficients (R2) show a strong correlation between the observed variables for all materials aged outdoors (R2 ranges from 0.84–0.98). A slightly stronger correlation is present for the polyamide materials (materials KF3 and KF4). The decrease in breaking force due to aging is up to 40% (for material KF4), which indicates that the durability of this material is significantly reduced and its further use for athletes cannot be recommended. The reason for such a result is the fact that the structure of the material, as well as the strength of polyamide and polyester yarns, is strongly negatively affected by immersion in swimming pool water and exposure to sunlight. Compared to the results of aging under indoor conditions, the trend previously observed is the same, but the decrease in breaking force is less pronounced. In this type of aging, the values of breaking force after the longest period of exposure are in the range of 148–391 N. This observation can be explained by the absence of the additional influence of sunlight. The values of R2 are in the range of 0.74–0.96, indicating a moderate to strong positive correlation between breaking force and exposure time.

Materials made using knitting technology are known to have improved comfort properties, especially when elastane yarns are also used for plating. The previously published researches showed that the content of elastane in the material structure has a significant influence on the elastic properties (primary elastic recovery) of the materials [

25,

26]. The results of the measured breaking elongation of the investigated materials confirmed this evidence. More precisely, the breaking elongation of non-aged polyester material without elastane component is only 182 N, while the breaking elongation of the polyester material with the addition of 15% of elastane component increases by 52% (

Figure 7). The effect of smaller differences in elastane content (in this case 20% and 22%, respectively, as defined in

Table 1) has no effect on the changes in breaking elongation that can be considered significant. The experiment presented in this study provided insight into the changes of breaking forces due to aging. Unlike the breaking force, the breaking elongation does not decrease with the same trend over the exposure time. The graphs presented in

Figure 7 show a decrease of breaking elongation with increasing exposure duration. The coefficients describing this relationship range from 0.55 to 0.87, mostly indicating a medium correlation. The graphs shown in

Figure 8 indicate that there is no uniform change in breaking elongation when the materials are aged indoors. This primarily relates to polyester materials where the relationship between the observed variables (breaking elongation and exposure duration) is very weak (R

2 is 0.0012 and 0.0167 respectively). These results led to the conclusion that the chemicals and pool water do not affect the changes in the breaking elongation of the materials in the same way that exposure to sunlight does. When the measured values of breaking elongation are placed directly in the context of the measured mass per unit area (through correlation coefficients shown in

Table 6), it can be seen that the change in breaking elongation strongly follows the changes in mass per unit area (the correlation coefficient is 0.867). In terms of comfort assurance, the results showed that outdoor aging of materials should have a stronger negative effect than aging indoor.

The F/E curves for material KF1 measured under outdoor and indoor conditions are shown in

Figure 9. To illustrate the behavior of the material in the elastic, elastoplastic, and plastic regions, F/E curves are further extracted for each material and compared for non-aged materials and materials that have been subjected to aging (6w, 12w, and 18w). For illustration, the F/E curves for material KF1 are shown in

Figure 9 (for both outdoor and indoor measurement conditions). As can be seen from

Figure 9a, the first region, i.e., the elastic region, is linear and corresponds to an estimated elongation of 58% (point P1). This region is very important for the functionality and durability of materials and is therefore used in the process of material design. The second region starts at elongation of 58% (point P1) and ends at 90% (point P2). This is an elastoplastic region, which is considered to be a boundary region between the elastic and plastic. The stretching of the materials of material KF1 with the tensile tester was carried out up to the breaking point, which in this case corresponds to the force of 302 N and the elongation of 182% (point P3).

The F/E curves of each material and each condition are further used to define the points associated with the regions and to define the fragments of elongation of the materials (expressed as percentages),

Figure 10 and

Figure 11.

From

Figure 10, it can be seen that the material KF3 has the lowest fragment of elastic region for all exposure duration (12% for non-aged; 15% for 6 weeks of exposure; 16% for 12 weeks; 16% for 18 weeks). On the contrary, material KF2 has the highest fragment of elastic region (32%; 35%; 35%; 33%, respectively). It is also observed that PA materials (KF3 and KF4) have lower fragments of the elastic region than PES materials (KF1 and KF2). It must be emphasized that for all materials the fragment of the elastic region increases with the aging of the material. For all the materials studied, it should be noted that the elastoplastic region is between 14% and 31%, while the plastic region is between 35% and 65%. Material KF3 has the higher plastic region range (62–65%).

Looking at

Figure 11, where the material is aged indoors, again the KF3 material has the lowest fragment of the elastic region (12% for non-aged; 24% at 6 weeks exposure; 33% at 12 weeks; 25% at 18 weeks). However, the KF1 material has the lowest fragment of elastic region in indoor aging (32–39%). No regularities are observed in the change of fragment of the elastic region changes due to aging time. For all the materials studied, it should be noted that the elastoplastic region is between 9% and 29%, while the plastic region is between 39% and 68%.

Comparing the relationship between outdoor and indoor aging, no significant differences are observed between the regions for materials KF1 and KF4. For the KF2 material, deviations can be seen at 12 and 18 weeks of exposure, while for the KF3 material this difference already exists at 6 weeks of aging exposure.

3.4. Results of Total Drying Period and Fluid Transport Phases

The determination of drying period of swimwear materials is extremely important for achieving comfort during the phases when the athlete is not in the water but waiting next to the pool to continue swimming (e.g., in competitions). The polyester and polyamide materials are therefore advantageous for this use due to their short drying time (compared to other textile fibers). The comparison of total drying rate of materials exposed to aging under outdoor and indoor conditions in relation to the wetted area of the material, is shown in

Figure 12. The results confirm the influence of exposure to sunlight on the prolongation of drying period. More specifically, in 9 out of 12 cases, the drying period is longer for the materials aged outdoors. This prolongation is up to 64%. The changes in drying period cannot be explained by the changes in mass per unit area, since the correlation of these parameters is rather weak (−0.150). Therefore, these changes should be discussed in the context of the combined structural and surface changes, i.e., the described process of fibrillation (as explained in

Section 3.1) and the changes in the size of voids within the elementary units. Regarding the influence of the polymer type and the addition of the elastane content, the results confirmed that these two parameters do not have a significant influence on the total drying period.

To further explain the fluid transfer,

Figure 13 shows the identification of breakpoints marking the end of the fluid transfer phases (WP—wetting phase, SP—static phase, and ADP—active drying phase) for material KF1. This identification revealed an interesting behavior of knitted material. For both observed aging conditions, the WP phase duration is very short (up to 30 s) in all cases (0w, 6w, 12w and 18w), which is consistent with the properties of polymer materials. As aging increases, the duration of SP increases (for both outdoor and indoor aging). Finally, the duration of the active drying phase increases by increasing the exposure time. It can be seen that there is some uniformity of increase for the indoor aged materials, whereas there is no uniformity for the outdoor aged materials (as seen for the duration of ADP phase of materials aged for 6 and 12 weeks).

From the obtained spectral bands of the polyester material (sample KF1,

Figure 14), no major physicochemical changes were observed in the samples subjected to aging. Minor changes occurred on the reverse side of sample KF1-Po-18w. A more pronounced peak compared to the pre-aged sample is visible at 2898 cm

−1. The peak intensity at 1171 cm

−1 is reduced, indicating structural changes due to hydrolysis and photo oxidation within the PES polymer chain. This is also seen for sample KF2.

On the spectral bands of polyamide sample KF3 before and after aging, the presence of peaks on the back of the material caused by vibrations within the carbonyl groups is visible. On the face of sample KF3-Wa subjected to analysis, it is visible that there is no peak in this wave number, but after aging, the peak appears. This indicates the physicochemical changes in the face of the material, which is partially worn off and the response of the back of the material predominates.

Compared to the initial sample, no physicochemical changes were observed in sample KF4 subjected to aging (both face and the back of the sample).