First, rheological tests are performed in the LVE (SAOS) and non-LVE (HPCR) deformation range of gum NBR. The material properties obtained from these measurements are storage (G’) and loss (G”) moduli, both in dependence of the angular frequency (ω) as well as steady-state shear (η) and uniaxial elongational () viscosities, which are in dependence of the shear () and strain () rate, respectively. These material properties are used to determine the model parameters of the K-BKZ/Wagner, Cross (GNF), and power-law (GNF) models. Additionally, the influence of normal force applied on the sample in SAOS testing as well as the influence of the model parameter θ (Equation (2)) is analyzed by performing in total three K-BKZ fits. Finally, CFD simulations are performed aiming to compare predicted with recorded pressure data of the high pressure capillary rheometer experiment.

3.1. Rheological Testing and Constitutive Modeling

In rubber rheology a testing instrument called Rubber Process Analyzer is widely employed to determine viscoelastic properties before, during, and after curing. This rotational shear rheometer consists of a closed and sealed die system, where the tested rubber is compressed by a pre-defined clamping pressure leading to normal forces on the sample during the measurement. This setup aims to prevent any slippage and differs from conventional dynamic rheometers like the MCR 501 device, where test specifications recommend keeping normal forces at a minimum. Comparing the complex viscosity (

) of gum NBR, normal forces applied on the sample did not affect the shape of the curve but shifted measured data to higher values (

Figure 3a). Applying a normal force of 10 N using the MCR 501 device,

corresponded to RPA data. On the other hand, neither sample preparation (roller milled vs. compression molded) nor pre-shearing the sample for 240 s with a strain amplitude of 42% and constant angular frequency of 31.42 rad/s (recommended by Fasching [

30] for highly filled rubber compounds) had any effect on

(

Figure 3). The detected insensitivity of gum NBR validated the listed set of pre-shearing parameters, as they did not damage macromolecular chains and may serve for highly filled rubber compounds as a fixed precondition to break down filler networks and minimize their impact on measured LVE properties [

25]. The mean measurement deviations of the four settings displayed in

Figure 3 (RPA; RPA, presheared; MCR, F

n < 1 N; MCR 501, F

n = 10 N) are 0.3, 0.3, 1.8, and 3.4%, respectively. In the present study, both MCR setups (F

n < 1 N, F

n = 10 N) were further used to determine G’ and G” aiming to fit the memory function in Equation (3) and finally analyze the influence of normal force in SAOS testing to viscoelastic modeling and pressure prediction in CFD simulation.

Next, time-temperature superposition was applied, to extend the frequency range of LVE modeling. From a thermo-rheological point of view, rubber materials are complex fluids, where vertical shifting may be necessary in order to construct a master curve for G’ and G”. Consequently, a guideline presented in [

25] was followed, where horizontal shift factors (

) were obtained by mastering first the loss factor (

, which is intrinsically invariant to vertical shifting (

):

Figure 4a displays the mastered dissipation factor at the reference temperature of 100 °C. Moreover, natural logarithms of

were plotted against the inverse temperature, resulting in the so-called “Arrhenius Plot”.

The calculated activation energy (E

a) of 68 kJ/mol corresponded well with values obtained for NBR and HNBR compounds [

25,

26] and was insensitive to F

n (

Figure A3a). Second, vertical shifting was applied to G’ and G’’ measured at 60, 80, and 120 °C, minimizing any deviations to the reference temperature segment (

Figure 4b). Over the whole measured angular frequency range, G’ exceeded G” (no crossover point), proving a material response that was dominated by elasticity. Finally, LVE moduli were used to determine relaxation moduli

of the memory function in Equation (3). A fit was performed, which minimized the sum of squared differences according to Equations (4) and (5), keeping pre-defined relaxation times

and modes (N = 8) constant. To give the fit a physical meaning, a constraint was added, which ensured that relaxation moduli would not decrease with increasing corresponding relaxation time (

≥

). The obtained material parameters (

Table A1) well described the LVE material behavior of gum NBR in a frequency range of almost five decades (

Figure 4b). The mean measurement deviations of the three recorded properties G’, G”, and tan (δ) were 2.6, 3.1, and 0.6%, respectively.

Next, the exact same procedure was carried out for the second rheological characterization setup (F

n = 10 N).

Table A2 lists corresponding material parameters and

Figure A3b compares model predictions with measured data. The mean measurement deviations of G’, G”, and tan (δ) with an applied normal force of 10 N were 3.9, 3.9, and 0.8%, respectively. In the present study “K-BKZ fit 1” represented LVE data measured according to conventional test specifications (F

n < 1 N) and “K-BKZ fit 2” represented LVE data, where a normal force of 10 N was applied on the sample during the measurement. The latter was similar to conditions in a Rubber Process Analyzer for gum NBR.

A key assumption in rheological testing is no slip at the wall, which indicates adhesion of the investigated fluid to the capillary die or to the plates, in cases of SAOS testing. However, as reviewed by Hatzikiriakos [

31], this classic boundary condition is not always valid for polymer melts, especially at higher wall shear stresses. A popular method for detection was introduced by Mooney [

32], who proved that for a wall slipping fluid the observed flow curves become dependent on the diameter of the capillary die. Comparing flow curves recorded with two dies of same L/D ratio but different geometry, gum NBR exhibits no clear dependency on the die diameter (

Figure 5).

If in fact slip was present in HPCR experiments, one would expect the wall shear stress in the L/D = 20/2 die to be larger than in the L/D = 10/1 die, especially at higher apparent shear rate levels, and the calculated steady-state shear viscosity to be substantially lower than the complex viscosity. Comparing the aforementioned material properties (

Figure A4), the steady-state shear viscosity of gum NBR even exceeded the complex viscosity (F

n < 1 N). For the second SAOS testing setup, where a normal force of 10 N was applied on the sample during the measurement, the Cox–Merz rule [

33] (

= η(

) was obeyed. Moreover, at the highest apparent shear rate level the wall shear stress in the L/D = 20/2 capillary die was lower than in the L/D = 10/1 die. These observations indicated no slippage at the wall for gum NBR.

Furthermore, strong extrudate swelling was observed even at low apparent shear rate levels (

Figure A5). This non-linear flow phenomenon arises from stored energy of uncoiled polymer molecules due to shear and elongational stresses in the capillary die. These uncoiled molecules strive to reach the former state of higher entropy resulting in additional forces that press the fluid in the capillary against the wall and may prevent slippage. Thus, a no slip BC was applied in CFD simulations.

Next, the detected pressure drops of the 1 mm die set were plotted in dependence of the capillary length (Bagley plot [

34]), with mean measurement deviations of 1.5, 3.1, 1.1, and 1.4% for the L/D = 0.2, 5, 10, and 20 capillary dies, respectively. The apparent shear rate was calculated applying Equation (13):

where Q is the volumetric flow rate and D the diameter of the capillary die.

All apparent shear rate levels exhibited high linearity of the pressure drop, despite some observed pressure fluctuations (

Figure A6), with coefficients of determination (R

2) exceeding 98% (

Figure 6).

A highly linear Bagley plot indicated that pressure and temperature dependencies of the viscosity effectively leveled off each other [

25,

26]. Since Ansys POLYFLOW offers no rheological model, which accounts for the pressure dependency of the viscosity, the best option was to consider neither of them. Consequently, isothermal flow conditions were assumed in CFD simulations, and η was modeled as a simple shear rate dependent function.

Next to the two damping parameters

and

, the material constant

also needed to be determined to complete the K-BKZ modeling. For most polymeric melts small negative values are reported for

[

35]. Since no experimental data of the second normal stress difference were available for gum NBR, this study tested the sensitivity of

with respect to pressure prediction in CFD simulation. Thus, a third fit (K-BKZ fit 3) was performed, which maintained the relaxation spectrum of K-BKZ fit 1 and set

to –0.15 (

Table A3). K-BKZ fit 1 (

Table A1) and K-BKZ fit 2 (

Table A2) both assumed

to be zero.

In a simple shear flow, Equation (6) depends only on one parameter, so the steady-state shear viscosity was used next to determine

. The final model parameter

was obtained from uniaxial elongational viscosity data calculated from entrance pressure losses according to Binding [

29]. In general, extensional rheometers developed by Sentmanat [

36], Meissner [

37,

38], or Münstedt [

39] are recommended to characterize the elongational behavior of polymeric melts. However, in the present study we preferred material properties obtained with the HPCR to fit damping parameters

and

, since recorded pressure drops of the exact same measurement device are aimed to be predicted in CFD simulations. All fits were performed in MATLAB minimizing the sum of squared differences to measured data.

Despite applying different relaxation spectra (fit 1 vs. fit 2) and different values for the material constant

(fit 1 vs. fit 3), model predictions of all fits described the steady-state shear viscosity of gum NBR well (

Figure 7).

A higher damping parameter

compensated for the vertical shifted LVE data of K-BKZ fit 2 (F

n = 10 N). However, all fits overestimated the uniaxial elongational viscosity at low strain rates and underestimated

at higher ones. To improve K-BKZ modeling of elongational properties, Luo and Tanner [

40] proposed an approach that assigns a different value of

to each mode (

). As multiple betas are not implemented in Ansys POLYFLOW, a best-fitted single value of

was employed despite the observed deviations.

Finally, coefficients (

Table A4 and

Table A5) of the two selected GNF models were determined applying the fitting tool implemented in Ansys POLYFLOW.

Figure A7 proves the ability of both models to describe the steady-state shear viscosity of gum NBR well. However, the Cross model assumes a Newtonian plateau, resulting in differences between the two models in the lower shear rate region.

3.2. Numerical Modeling and Evaluation

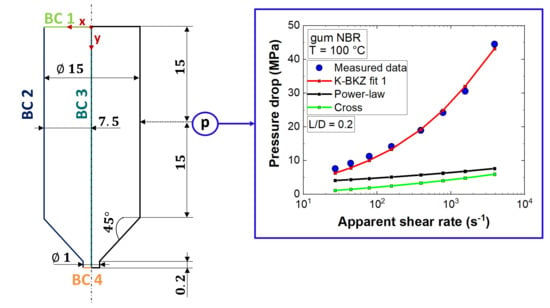

The overall goal of this study was to test the ability of the K-BKZ/Wagner model to correctly predict pressure drops of an unfilled gum rubber in CFD simulation. Thus, four different capillary dies applied in HPCR tests with varying L/D ratios (0.2/1, 5/1, 10/1, 20/1) were modeled in Ansys POLYFLOW (

Figure 1). At the inlet a fully developed normal velocity profile with a pre-defined volumetric flow rate

Q was imposed (BC 1). Moreover, a normal and tangential velocity of zero was assigned at the capillary walls (BC 2). Next, use was made of the axisymmetric die geometry by applying a tangential force and normal velocity of zero at the axis of symmetry (BC 3). Since extruded strands of gum NBR clearly exhibited die swelling at all apparent shear rate levels (

Figure A5), a “zero force” boundary condition (BC 4) was applied. This BC considered non-zero normal stresses at the outlet and, as a consequence, exit pressure dropped associated with die swelling.

First, the influence of normal forces applied on the sample in SAOS testing (K-BKZ fit 2) as well as the influence of the model parameter

(K-BKZ fit 3) were analyzed. For this purpose,

Figure 8 compares recorded HPCR data with CFD simulation results, which proved the excellent pressure prediction accuracy of all three K-BKZ fits for gum NBR.

Mean deviations of K-BKZ fit 1, fit 2, and fit 3 to recorded pressure data were 8.6, 10.1, and 8.3%, respectively, indicating an insensitivity to the applied normal force and to the model parameter .

The tapered orifice (L/D = 0.2/1) represented an extreme condition, which was dominated by the contraction flow from the larger reservoir (

= 15 mm) in the small die (

= 1 mm). Thus, its measured pressure level was strongly affected by both entrance and exit pressure drops and consequently by the viscoelasticity of the material. The K-BKZ/Wagner model was able to correctly predict these extreme conditions for gum NBR with mean deviations (compared to recorded pressure drops of the L/D = 0.2/1 die) of 7.5, 5.9, and 9.3% for K-BKZ fit 1, fit 2, and fit 3, respectively. In contrast, pressure drops in the L/D = 20/1 die were dominated by the capillary flow and consequently by shear deformation. However, the K-BKZ model predicted also the second condition well with mean deviations (compared to recorded pressure drops of the L/D = 20/1 die) of 8.4, 7.6, and 8.0% for K-BKZ fit 1, fit 2, and fit 3, respectively. These results proved that the K-BKZ/Wagner was in fact able to correctly predict pressure drops of an unfilled gum rubber in both contraction and shear-dominated geometries. Thus, the observed deviations in our recent studies for two highly carbon black filled rubber compounds [

25,

26] can now be attributed to the inability of the K-BKZ/Wagner model to reflect the decreasing molecular mobility with increasing filler content. As a consequence, the K-BKZ/Wagner model is not applicable to highly filled polymer systems. The research groups of Walter Friesenbichler, Evan Mitsoulis, Ines Kühnert, and Sven Wießner have agreed to address this issue, aiming to develop a holistic viscoelastic–plastic constitutive rheological model for particle-filled, multiphase polymer systems based on the original K-BKZ equations.

Finally, the influence of viscoelastic modeling was assessed by comparing CFD simulation results of K-BKZ fit 1 to pressure predictions of two generalized Newtonian fluid flow models (

Figure 9).

Both GNF models (BCs listed in

Table 1) underestimated measured pressure data distinctly. Deviations increased with rising apparent shear rate level and decreasing L/D ratio. Any GNF model considers viscous stresses only and intrinsically assumes a ratio of three between steady-state shear and uniaxial elongational viscosities. However, gum NBR exhibited a material response dominated by elasticity (

Figure 4b), leading to an additional pressure drop at the exit and a ratio between η and

clearly exceeding three (

Figure 7), leading to an enhanced pressure level at the entrance. With decreasing L/D ratio these two factors became more and more important and mean deviations increased accordingly.

Moreover,

Figure 7 displays an increasing ratio between η and

with rising apparent shear rate level (

). Thus, the largest deviations between measured data and GNF predictions were expected and found to be true for the orifice die (L/D = 0.2) at the highest apparent shear rate level. Considering all dies as well as apparent shear rate levels, mean deviations to recorded pressure data were 8.6, 49, and 39.3% for K-BKZ, Cross, and power-law models, respectively (

Figure 9). These values highlighted the importance of viscoelastic modeling to correctly predict pressure drops of an unfilled gum rubber especially in contraction flow-dominated geometries.