Improving the Melt Flow Length of Acrylonitrile Butadiene Styrene in Thin-Wall Injection Molding by External Induction Heating with the Assistance of a Rotation Device

Abstract

:1. Introduction

2. Simulation and Experimental Method

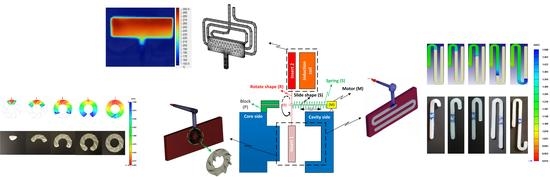

2.1. The External Induction Heating with the Assistance of a Rotation Device

2.2. Simulation Method

2.3. Experiment Method

3. Results and Discussion

3.1. Effect of the Gap between the Heating Surface and the Induction Coil

3.2. Effect of the Heating Time on the Temperature Distribution

3.3. Improving the Melt Flow Length of Front Cover Part by External Induction Heating for the Gate Temperature Control

4. Conclusions

- For an initial mold temperature of 30 °C and a gap (G) of 5 mm, it can be seen that the magnetic heating process can heat the plate to 290 °C in 5 s. However, at a distance of 15 mm, it took up to 8 s to reach 270 °C. The heating time results show that this heating strategy has almost no impact on the cycle time, which often varied from around 10 to 20 s. Therefore, depending on the cycle time, the gap (G) could be set to the greatest possible value to ensure that the heating rate is not too high and to prolong the lifetime of the coil and the insert surface.

- The temperature of line L clearly increased with a longer heating time. Due to the edge effect, the temperature on two sides of the insert quickly increased. In addition, this effect also allowed the temperature at the holding area to increase quickly. Varying the heating time from 1 to 8 s, the result shows that a lower heating rate could reduce overheating at the edge of the insert plate.

- The temperature profile of line L undergoes a change after the heating for 3 s is completed. The temperature was more uniform, and the high temperature at the two sides was clearly reduced due to the heat transfer from the higher temperature to the lower temperature. With the heating time of 5 s, the experimental results show that the temperature of line L varies around 168.0, 210, and 280 °C with a gap of 5, 10, and 15 mm, respectively. This result also demonstrates that Ex-IH could support the heating process for a cavity area of 35 mm × 95 mm and has great potential for application in the field of mold temperature control.

- According to the measurement results, when the mold heating time was increased from 0 to 5 s during the molding process, the flow length significantly increased from 71.5 to 168.1 mm, and the filling percentage of the thin-wall product also increased from 10.2% to 100%. In general, when the Ex-IH was applied during the molding cycle, the total cycle time was similar to that in the traditional case.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chung, C.-Y. Integrated Optimum Layout of Conformal Cooling Channels and Optimal Injection Molding Process Parameters for Optical Lenses. Appl. Sci. 2019, 9, 4341. [Google Scholar] [CrossRef] [Green Version]

- Loaldi, D.; Quagliotti, D.; Calaon, M.; Parenti, P.; Annoni, M.; Tosello, G. Manufacturing Signatures of Injection Molding and Injection Compression Molding for Micro-Structured Polymer Fresnel Lens Production. Micromachines 2018, 9, 653. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Lou, Y.; Shen, J. Microstructure-Forming Mechanism of Optical Sheet Based on Polymer State Transition in Injection-Rolling Process. Polymers 2021, 13, 181. [Google Scholar] [CrossRef]

- Li, K.; Huang, X.; Chen, Q.; Xu, G.; Xie, Z.; Wan, Y.; Gong, F. Flexible Fabrication of Optical Glass Micro-Lens Array by Using Contactless Hot Embossing Process. J. Manuf. Process. 2020, 57, 469–476. [Google Scholar] [CrossRef]

- Sha, B.; Dimov, S.; Griffiths, C.; Packianather, M. Investigation of Micro-Injection Moulding: Factors Affecting the Replication Quality. J. Mater. Process. Technol. 2007, 183, 284–296. [Google Scholar] [CrossRef]

- Major, R.; Gawlikowski, M.; Sanak, M.; Lackner, J.M.; Kapis, A. Design, Manufacturing Technology and In-Vitro Evaluation of Original, Polyurethane, Petal Valves for Application in Pulsating Ventricular Assist Devices. Polymers 2020, 12, 2986. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Quan, L.; Zhang, H. Research on Energy Consumption of Injection Molding Machine Driven by Five Different Types of Electro-Hydraulic Power Units. J. Clean. Prod. 2020, 242, 118355. [Google Scholar] [CrossRef]

- Lou, Y.; Xiong, J. Micro-Ultrasonic Viscosity Model Based on Ultrasonic-Assisted Vibration Micro-Injection for High-Flow Length Ratio Parts. Polymers 2020, 12, 522. [Google Scholar] [CrossRef] [Green Version]

- Ye, S.; Mo, W.; Lv, Y.; Wang, Z.; Kwok, C.T.; Yu, P. The Technological Design of Geometrically Complex Ti-6Al-4V Parts by Metal Injection Molding. Appl. Sci. 2019, 9, 1339. [Google Scholar] [CrossRef] [Green Version]

- Pomázi, Á.; Szolnoki, B.; Toldy, A. Flame Retardancy of Low-Viscosity Epoxy Resins and Their Carbon Fibre Reinforced Composites via a Combined Solid and Gas Phase Mechanism. Polymers 2018, 10, 1081. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muszyński, P.; Poszwa, P.; Gessner, A.; Mrozek, K. Application of Selective Induction Heating for Improvement of Mechanical Properties of Elastic Hinges. Materials 2021, 14, 2543. [Google Scholar] [CrossRef] [PubMed]

- Monti, M.; Zaccone, M.; Frache, A.; Torre, L.; Armentano, I. Dielectric Spectroscopy of PP/MWCNT Nanocomposites: Relationship with Crystalline Structure and Injection Molding Condition. Nanomaterials 2021, 11, 550. [Google Scholar] [CrossRef] [PubMed]

- Murata, Y.; Kanno, R. Effects of Heating and Cooling of Injection Mold Cavity Surface and Melt Flow Control on Properties of Carbon Fiber Reinforced Semi-Aromatic Polyamide Molded Products. Polymers 2021, 13, 587. [Google Scholar] [CrossRef]

- Lin, C.-C.; Chen, K.-C.; Yeh, H.-C. Influence of Heat Sink on the Mold Temperature of Gypsum Mold Used in Injection Molding. Polymers 2020, 12, 701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oliveira, E.; Silva, J.P.; Laranjeira, J.; Macedo, F.; Lanceros-Mendez, S.; Vaz, F.; Ferreira, A. Fabrication, Characterization and Implementation of Thermo Resistive TiCu(N,O) Thin Films in a Polymer Injection Mold. Materials 2020, 13, 1423. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Yang, Q.; Mao, H.; Meng, Z.; Hua, L.; He, B. A Combined In-Mold Decoration and Microcellular Injection Molding Method for Preparing Foamed Products with Improved Surface Appearance. Polymers 2019, 11, 778. [Google Scholar] [CrossRef] [Green Version]

- Liparoti, S.; Speranza, V.; Titomanlio, G.; Pantani, R. Effect of Rapid Mold Heating on the Structure and Performance of Injection-Molded Polypropylene. Polymers 2020, 12, 341. [Google Scholar] [CrossRef] [Green Version]

- Torres-Alba, A.; Mercado-Colmenero, J.M.; Diaz-Perete, D.; Martin-Doñate, C. A New Conformal Cooling Design Procedure for Injection Molding Based on Temperature Clusters and Multidimensional Discrete Models. Polymers 2020, 12, 154. [Google Scholar] [CrossRef] [Green Version]

- Nian, S.-C.; Wu, C.-Y.; Huang, M.-S. Warpage Control of Thin-Walled Injection Molding Using Local Mold Temperatures. Int. Commun. Heat Mass Transf. 2015, 61, 102–110. [Google Scholar] [CrossRef]

- Meister, S.; Drummer, D. Affecting the Ageing Behaviour of Injection-Moulded Microparts Using Variothermal Mould Tempering. Adv. Mech. Eng. 2013, 5, 407964. [Google Scholar] [CrossRef]

- Li, K.; Yan, S.-L.; Pan, W.-F.; Zhao, G. Optimization of Fiber-Orientation Distribution in Fiber-Reinforced Composite Injection Molding by Taguchi, Back Propagation Neural Network, and Genetic Algorithm–Particle Swarm Optimization. Adv. Mech. Eng. 2017, 9, 168781401771922. [Google Scholar] [CrossRef]

- Maghsoudi, K.; Jafari, R.; Momen, G.; Farzaneh, M. Micro-Nanostructured Polymer Surfaces Using Injection Molding: A Review. Mater. Today Commun. 2017, 13, 126–143. [Google Scholar] [CrossRef]

- Vázquez, M.; Paull, B. Review on Recent and Advanced Applications of Monoliths and Related Porous Polymer Gels in Micro-Fluidic Devices. Anal. Chim. Acta 2010, 668, 100–113. [Google Scholar] [CrossRef]

- Venkatesh, G.Y.; Ravi Kumar, Y.; Raghavendra, G. Comparison of Straight Line to Conformal Cooling Channel in Injection Molding. Mater. Today Proc. 2017, 4, 1167–1173. [Google Scholar] [CrossRef]

- Lucchetta, G.; Fiorotto, M.; Bariani, P.F. Influence of Rapid Mold Temperature Variation on Surface Topography Replication and Appearance of Injection-Molded Parts. CIRP Ann. 2012, 61, 539–542. [Google Scholar] [CrossRef]

- Sánchez, R.; Martinez, A.; Mercado, D.; Carbonel, A.; Aisa, J. Rapid Heating Injection Moulding: An Experimental Surface Temperature Study. Polym. Test. 2021, 93, 106928. [Google Scholar] [CrossRef]

- Liparoti, S.; Speranza, V.; Pantani, R. Replication of Micro- and Nanofeatures in Injection Molding of Two PLA Grades with Rapid Surface-Temperature Modulation. Materials 2018, 11, 1442. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Multi-Objective Optimization Design of the Heating/Cooling Channels of the Steam-Heating Rapid Thermal Response Mold Using Particle Swarm Optimization. Int. J. Therm. Sci. 2011, 50, 790–802. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Research of Thermal Response Simulation and Mold Structure Optimization for Rapid Heat Cycle Molding Processes, Respectively, with Steam Heating and Electric Heating. Mater. Des. 2010, 31, 382–395. [Google Scholar] [CrossRef]

- Chen, S.-C.; Lin, C.-Y.; Chang, J.-A.; Minh, P.S. Gas-Assisted Heating Technology for High Aspect Ratio Microstructure Injection Molding. Adv. Mech. Eng. 2013, 5, 282906. [Google Scholar] [CrossRef] [Green Version]

- Minh, P.S.; Do, T.T.; Uyen, T.M.T. The Feasibility of External Gas-Assisted Mold-Temperature Control for Thin-Wall Injection Molding. Adv. Mech. Eng. 2018, 10, 168781401880610. [Google Scholar] [CrossRef] [Green Version]

- Yao, D.; Kimerling, T.E.; Kim, B. High-Frequency Proximity Heating for Injection Molding Applications. Polym. Eng. Sci. 2006, 46, 938–945. [Google Scholar] [CrossRef]

- Do, T.T.; Uyen, T.M.T.; Minh, P.S. The Feasibility of an Internal Gas-Assisted Heating Method for Improving the Melt Filling Ability of Polyamide 6 Thermoplastic Composites in a Thin Wall Injection Molding Process. Polymers 2021, 13, 1004. [Google Scholar] [CrossRef]

- Chen, S.-C.; Minh, P.S.; Chang, J.-A.; Huang, S.-W.; Huang, C.-H. Mold Temperature Control Using High-Frequency Proximity Effect Induced Heating. Int. Commun. Heat Mass Transf. 2012, 39, 216–223. [Google Scholar] [CrossRef]

- Sung, Y.-T.; Hwang, S.-J.; Lee, H.-H.; Huang, D.-Y. Study on Induction Heating Coil for Uniform Mold Cavity Surface Heating. Adv. Mech. Eng. 2014, 6, 349078. [Google Scholar] [CrossRef] [Green Version]

- Huang, P.-W.; Peng, H.-S.; Choong, W.-H. Mold-Face Heating Mechanism, Overflow-Well Design, and Their Effect on Surface Weldline and Tensile Strength of Long-Glass-Fiber-Reinforced Polypropylene Injection Molding. Polymers 2020, 12, 2474. [Google Scholar] [CrossRef]

- Kim, Y.H.; Lim, K.R.; Kim, W.T.; Kim, D.H.; Choi, Y.S.; Na, Y.S. Rapid Heating Blow Molding of Metallic Glasses by Infrared Heating. Results Mater. 2019, 3, 100045. [Google Scholar] [CrossRef]

- Erchiqui, F. Application of Genetic and Simulated Annealing Algorithms for Optimization of Infrared Heating Stage in Thermoforming Process. Appl. Therm. Eng. 2018, 128, 1263–1272. [Google Scholar] [CrossRef]

- Mrozek, K.; Muszyński, P.; Poszwa, P. Application of Magnetic Concentrator for Improvement in Rapid Temperature Cycling Technology. Polymers 2021, 13, 91. [Google Scholar] [CrossRef]

| Material | Property | Value | Unit |

|---|---|---|---|

| Copper | Relative permeability (μ/μ0) | 1 | 1 |

| Electrical conductivity | 5.87 × 107 | S/m | |

| Coefficient of thermal expansion | 17 × 10−6 | 1/K | |

| Heat capacity at constant pressure | 387 | J/(kg·K) | |

| Density | 8940 | kg/m3 | |

| Thermal conductivity | 398 | W/(m·K) | |

| Young’s modulus | 128 × 109 | Pa | |

| Poisson’s ratio | 0.34 | 1 | |

| Reference resistivity | 1.72 × 10−8 | Ω·m | |

| Resistivity temperature coefficient | 3.9 × 10−3 | 1/K | |

| Reference temperature | 273.15 | K | |

| Steel | Electrical conductivity | 1 × 107 | S/m |

| Relative permeability (μ/μ0) | 100 | 1 | |

| Thermal conductivity | 68 | W/(m·K) | |

| Density | 7210 | kg/m3 | |

| Heat capacity at constant pressure | 448 | J/(kg·K) |

| Molding Parameters | Unit | Melt Flow Length Testing | Thin-Wall Product |

|---|---|---|---|

| Injection speed | cm3/sec | 23 | 25 |

| Injection pressure | Bar | 38 | 42 |

| Injection time | s | 1.5 | 1.0 |

| Packing time | s | 2.5 | 3.0 |

| Packing pressure | Bar | 35 | 40 |

| Cooling time | s | 12 | |

| Initial mold temperature | °C | 35 | |

| Melt temperature | °C | 260 | 270 |

| Preheating time by Ex-IH | s | 2–5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minh, P.S.; Le, M.-T. Improving the Melt Flow Length of Acrylonitrile Butadiene Styrene in Thin-Wall Injection Molding by External Induction Heating with the Assistance of a Rotation Device. Polymers 2021, 13, 2288. https://doi.org/10.3390/polym13142288

Minh PS, Le M-T. Improving the Melt Flow Length of Acrylonitrile Butadiene Styrene in Thin-Wall Injection Molding by External Induction Heating with the Assistance of a Rotation Device. Polymers. 2021; 13(14):2288. https://doi.org/10.3390/polym13142288

Chicago/Turabian StyleMinh, Pham Son, and Minh-Tai Le. 2021. "Improving the Melt Flow Length of Acrylonitrile Butadiene Styrene in Thin-Wall Injection Molding by External Induction Heating with the Assistance of a Rotation Device" Polymers 13, no. 14: 2288. https://doi.org/10.3390/polym13142288