Performance of Nano- and Microcalcium Carbonate in Uncrosslinked Natural Rubber Composites: New Results of Structure–Properties Relationship

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites

2.3. Characterizations

2.4. Finite Element Analysis

3. Results and Discussion

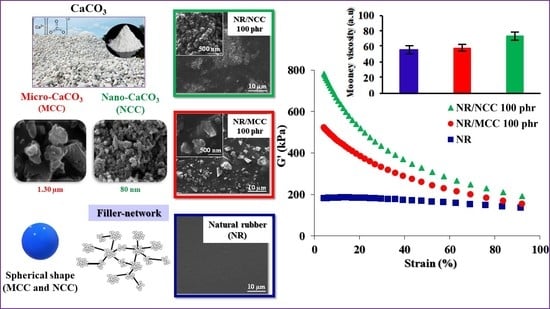

3.1. Morphological Properties

3.2. Physical Properties

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Smitthipong, W.; Suethao, S.; Shah, D.; Vollrath, F. Interesting green elastomeric composites: Silk textile reinforced natural rubber. Polym. Test. 2016, 55, 17–24. [Google Scholar]

- Chollakup, R.; Suwanruji, P.; Tantatherdtam, R.; Smitthipong, W. New approach on structure-property relationships of stabilized natural rubbers. J. Polym. Res. 2019, 26, 37. [Google Scholar] [CrossRef]

- Suksup, R.; Sun, Y.; Sukatta, U.; Smitthipong, W. Foam rubber from centrifuged and creamed latex. J. Polym. Eng. 2019, 39, 336–342. [Google Scholar] [CrossRef]

- Kohjiya, S.; Ikeda, Y. Reinforcement of general-purpose grade rubbers by silica generated in situ. Rubber Chem. Technol. 2000, 73, 534–550. [Google Scholar] [CrossRef]

- Findik, F.; Yilmaz, R.; Köksal, T. Investigation of mechanical and physical properties of several industrial rubbers. Mater. Des. 2004, 25, 269–276. [Google Scholar] [CrossRef]

- Granda, L.A.; Oliver-Ortega, H.; Fabra, M.J.; Tarres, Q.; Pelach, M.A.; Lagaron, J.M.; Mendez, J.A. Improved process to obtain nanofibrillated cellulose (CNF) reinforced starch films with upgraded mechanical properties and barrier character. Polymers 2020, 12, 1071. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Model progress for tensile power of polymer nanocomposites reinforced with carbon nanotubes by percolating interphase zone and network aspects. Polymers 2020, 12, 1047. [Google Scholar] [CrossRef]

- Prioglio, G.; Agnelli, S.; Conzatti, L.; Balasooriya, W.; Schrittesser, B.; Galimberti, M. Graphene layers functionalized with a Janus pyrrole-based compound in natural rubber nanocomposites with improved ultimate and fracture properties. Polymers 2020, 12, 944. [Google Scholar] [CrossRef] [Green Version]

- Jin, J.; Noordermeer, J.W.M.; Dierkes, W.K.; Blume, A. The effect of silanization temperature and time on the marching modulus of silica-filled tire tread compounds. Polymers 2020, 12, 209. [Google Scholar] [CrossRef] [Green Version]

- Roberson, C.G.; Tunnicliffe, L.B.; Maciag, L.; Bauman, M.A.; Miller, K.; Herd, C.R.; Mars, W.V. Characterizing distributions of tensile strength and crack precursor size to evaluate filler dispersion effects and reliability of rubber. Polymers 2020, 12, 203. [Google Scholar] [CrossRef] [Green Version]

- Abate, L.; Bottino, F.A.; Cicala, G.; Chiacchio, M.A.; Ognibene, G.; Blamco, I. Polystyrene nanocomposites reinforced with novel dumbbell-shaped phenyl-POSSs: Synthesis and thermal characterization. Polymers 2019, 11, 1475. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hejna, A.; Barczewski, M.; Andrzejewski, J.; Kosmela, P.; Piasecki, A.; Szostak, M.; Kuang, T. Rotational molding of linear low-density polyethylene composites filled with wheat bran. Polymers 2020, 12, 1004. [Google Scholar] [CrossRef] [PubMed]

- Toth, L.F.; Baets, P.; Szebenyl, G. Thermal, viscoelastic, mechanical and wear behavior of nanoparticle filled polytetrafluoroethylene: A comparison. Polymers 2020, 12, 1940. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.; Bhat, A.H. Micro and nano calcium carbonate filled natural rubber composites and nanocomposites. Nat. Rubber Mater. 2013, 2, 467–487. [Google Scholar]

- Prasertsri, S.; Vudjung, C.; Inthisaeng, W.; Srichan, S.; Sapprasert, K.; Kongon, J. Comparison of reinforcing efficiency between calcium carbonate/carbon black and calcium carbonate/silica hybrid filled natural rubber composites. Defect Diffus. Forum 2018, 382, 94–98. [Google Scholar] [CrossRef]

- Gopinath, C.S.; Hegde, S.G.; Ramaswamy, A.V.; Mahapatra, S. Photoemission studies of polymorphic CaCO3 materials. Mater. Res. Bull. 2002, 37, 1323–1332. [Google Scholar] [CrossRef]

- Meng, L.; Wang, J.; Liu, Q.; Fan, Z. Hydrophobic calcium carbonate with hierarchical micro–/nanostructure for improving foaming capacity. Mater. Res. Express 2020, 6, 1250–1258. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, J.; Zhao, X.; Bala, H.; Wang, Z. Synthesis of nanosized calcium carbonate (aragonite) via a polyacrylamide inducing process. Powder Technol. 2006, 163, 134–138. [Google Scholar] [CrossRef]

- Wu, D.; Wang, X.; Song, Y.; Jin, R. Nanocomposites of poly(vinyl chloride) and nanometric calcium carbonate particles: Effects of chlorinated polyethylene on mechanical properties, morphology, and rheology. J. Appl. Polym. Sci. 2004, 92, 2714–2723. [Google Scholar] [CrossRef]

- Fang, Q.; Song, B.; Tee, T.-T.; Sin, L.; Hui, D.; Bee, S.-T. Investigation of dynamic characteristics of nano-size calcium carbonate added in natural rubber vulcanizate. Compos. Part B Eng. 2014, 60, 561–567. [Google Scholar] [CrossRef]

- Liu, W.; Yang, Z.; Zheng, Y.; Wang, H. The effect of OMNT on the properties of vehicle damping carbon black-natural rubber composites. Polymers 2020, 12, 1983. [Google Scholar] [CrossRef]

- Yan, X.; Hamed, G.R.; Jia, L. Modulating silica-rubber interface by a biorenewable urushiol derivative. Synthesis, surface modification, and mechanical and dynamic mechanical properties of vulcanizates therefrom. J. Appl. Polym. Sci. 2018, 135, 45937. [Google Scholar] [CrossRef]

- Smitthipong, W.; Nardin, M.; Schultz, J.; Nipithakul, T.; Suchiva, K. Study of tack properties of uncrosslinked natural rubber. J. Adhes. Sci. Technol. 2004, 18, 1449–1463. [Google Scholar] [CrossRef]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- Mase, G.; Ronald, E.; George, E. Continuum Mechanics for Engineers; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Wedin, P.; Lewis, J.A.; Bergstrom, L. Soluble organic additive effects on stress development during drying of calcium carbonate suspension. J. Colloid Interface Sci. 2005, 290, 134–144. [Google Scholar] [CrossRef]

- Fröhlich, J.; Niedermeier, W.; Luginsland, H.D. The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos. Part A Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Levy, I.; Wormser, E.M.; Varenik, M.; Buzaglo, M.; Nadiv, R.; Regev, O. Graphene–graphite hybrid epoxy composites with controllable workability for thermal management. Beilstein J. Nanotechnol. 2019, 10, 95–104. [Google Scholar] [CrossRef] [Green Version]

- Mullins, L. Effect of Stretching on the Properties of Rubber. Rubber Chem. Technol. 1948, 21, 281–300. [Google Scholar] [CrossRef]

- Bee, S.T.; Hassan, A.; Ratnam, C.T.; Tee, T.T.; Sin, L.T. Effects of montmorillonite on the electron beam irradiated alumina trihydrate added polyethylene and ethylene vinyl acetate nanocomposite. Polym. Compos. 2012, 33, 1883–1892. [Google Scholar] [CrossRef]

- Robinson, H.W.H.; Vodden, H.A. Stress relaxation in rubber-evaluation of antioxidants. Ind. Eng. Chem. 1955, 47, 1477–1481. [Google Scholar] [CrossRef]

- Da Rocha, E.B.D.; Linhares, F.N.; Gabriel, C.F.S.; de Sousa, A.M.F.; Furtado, C.R.G. Stress relaxation of nitrile rubber composites filled with a hybrid metakaolin/carbon black filler under tensile and compressive forces. Appl. Clay Sci. 2018, 151, 181–188. [Google Scholar] [CrossRef]

- Maria, H.J.; Lyczko, N.; Nzihou, A.; Joseph, K.; Mathew, C.; Thomas, S. Stress relaxation behavior of organically modified montmorillonite filled natural rubber/nitrile rubber nanocomposites. Appl. Clay Sci. 2014, 87, 120–128. [Google Scholar] [CrossRef]

- Payne, A.R.; Whittaker, R.E. Low strain dynamic properties of filled rubbers. Rubber Chem. Technol. 1971, 44, 440–478. [Google Scholar] [CrossRef]

- Ghari, H.S.; Jalali-Arani, A. Nanocomposites based on natural rubber, organoclay and nano-calcium carbonate: Study on the structure, cure behavior, static and dynamic-mechanical properties. Appl. Clay Sci. 2016, 119, 348–357. [Google Scholar] [CrossRef]

- Promhuad, K.; Smitthipong, W. Effect of stabilizer states (solid vs. liquid) on properties of stabilized natural rubbers. Polymers 2020, 12, 741. [Google Scholar] [CrossRef] [Green Version]

| Ingredients | Parts Per Hundred of Rubber (phr) for Each Formulation | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| NR | NR/NCC | NR/NCC | NR/NCC | NR/NCC | NR/MCC | NR/MCC | NR/MCC | NR/MCC | |

| NR | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| NCC | - | 25 | 50 | 75 | 100 | - | - | - | - |

| MCC | - | - | - | - | - | 25 | 50 | 75 | 100 |

| (10−3) | (10−7) | (10−10) | (10−14) | (10−18) | (10−3) | ||

|---|---|---|---|---|---|---|---|

| NR | 2.12 | 6.59 | −1.60 | 1.79 | −0.95 | 0.0 | 4.24 |

| NR/MCC 25 phr | 3.01 | 0.02 | −0.39 | 0.55 | −0.32 | 0.0 | 6.01 |

| NR/MCC 50 phr | 3.55 | 2.71 | −1.14 | 1.41 | −0.77 | 0.0 | 7.10 |

| NR/MCC 75 phr | 3.47 | 4.90 | −1.71 | 2.08 | −1.13 | 0.0 | 6.94 |

| NR/MCC 100 phr | 3.83 | 6.10 | −2.07 | 2.50 | −1.36 | 0.0 | 7.65 |

| NR/NCC 25 phr | 3.41 | 6.05 | −1.96 | 2.33 | −1.25 | 0.0 | 6.82 |

| NR/NCC 50 phr | 4.15 | 2.96 | −1.40 | 1.80 | −1.00 | 0.0 | 8.31 |

| NR/NCC 75 phr | 4.60 | 3.39 | −1.40 | 1.82 | −1.03 | 0.0 | 9.19 |

| NR/NCC 100 phr | 4.63 | 7.64 | −2.53 | 3.07 | −1.67 | 0.0 | 9.27 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phuhiangpa, N.; Ponloa, W.; Phongphanphanee, S.; Smitthipong, W. Performance of Nano- and Microcalcium Carbonate in Uncrosslinked Natural Rubber Composites: New Results of Structure–Properties Relationship. Polymers 2020, 12, 2002. https://doi.org/10.3390/polym12092002

Phuhiangpa N, Ponloa W, Phongphanphanee S, Smitthipong W. Performance of Nano- and Microcalcium Carbonate in Uncrosslinked Natural Rubber Composites: New Results of Structure–Properties Relationship. Polymers. 2020; 12(9):2002. https://doi.org/10.3390/polym12092002

Chicago/Turabian StylePhuhiangpa, Nantikan, Worachai Ponloa, Saree Phongphanphanee, and Wirasak Smitthipong. 2020. "Performance of Nano- and Microcalcium Carbonate in Uncrosslinked Natural Rubber Composites: New Results of Structure–Properties Relationship" Polymers 12, no. 9: 2002. https://doi.org/10.3390/polym12092002