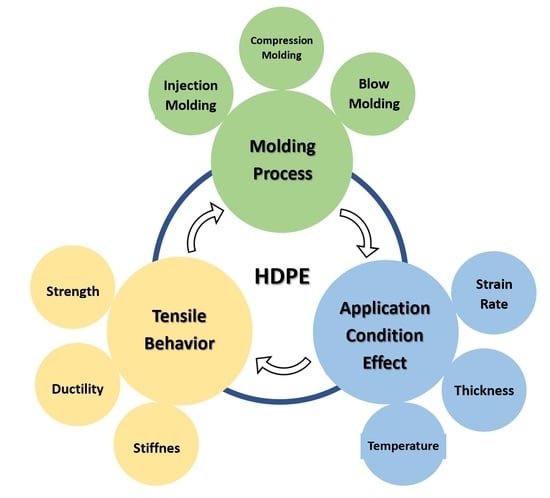

Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Technique, Thickness, Temperature, and Strain Rate

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Manufacturing Process Effect

3.2. Temperature Effect

3.3. Strain Rate Effect

3.4. Representation of Tensile Curves and an Emprical Model for Tensile Properties

4. Conclusions

- No anisotropy effect on tensile properties was observed neither for compression molded nor for injection molded HDPE.

- Processing technique and thickness affect the tensile properties of HDPE synergistically. There was no thickness effect on tensile properties for HDPE with the compression molding process, while there was a 23% increase in elastic modulus and a 21% decrease in ultimate tensile strength by increasing thickness from 2 to 4 mm in injection molding.

- A slight improvement in elastic modulus and ultimate tensile strength was observed for HDPE after the regrinding process. However, regardless of the processing technique of virgin, regrind, and laminated HDPE, there was no significant difference observed for these three HDPE material forms with 4 mm thickness in terms of tensile properties.

- Stress–strain curves were greatly influenced by temperature. An exponential reduction in tensile strength and elastic modulus was seen by increasing temperature regardless of the specimen thickness. Elastic modulus and ultimate tensile strength linearly increase at higher strain rates. However, strain at ultimate tensile strength is reduced as strain rate increases.

- Polynomial functions could be fitted to all experimental data to estimate tensile properties of HDPE as functions of temperature and strain rate.

- Yield strength and elastic modulus were correlated with ultimate tensile strength with linear functions, independent of material (virgin, regrind, or laminated HDPE), manufacturing technique (compression molding, injection molding, or blow molding), thickness (1, 2 or 4 mm), temperature (−40, 23, 53 and 82 °C), and strain rate.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alvarado, P.J. Steel vs. plastics: The competition for light-vehicle fuel tanks. J. Miner. Met. Mater. Soc. (TMS) 1996, 48, 22–25. [Google Scholar] [CrossRef]

- Dlamini, N.G.; Fujimura, K.; Yamasue, E.; Okumura, H.; Ishihara, K.N. The environmental LCA of steel vs HDPE car fuel tanks with varied pollution control. Int. J. Life Cycle Assess. 2011, 16, 410–419. [Google Scholar] [CrossRef]

- Stephens, R.D.; Williams, R.L.; Keoleian, G.A.; Spatari, S.; Beal, R. Comparative life cycle assessment of plastic and steel vehicle fuel tanks. SAE Tech. Paper 1998, 982224, 11–30. [Google Scholar] [CrossRef]

- Tavazzi, L. The Excellence of the Plastics Supply Chain in Relaunching Manufacturing in Italy and Europe. Available online: https://www.ambrosetti.eu/en/research-and-presentations/plastic-supply-chain/ (accessed on 18 August 2020).

- Ulcer, Y.; Cakmak, M.; Miao, J.; Hsiung, C.M. Structural gradients developed in injection-molded syndiotactic polystyrene (sPS). J. Appl. Polym. Sci. 1996, 60, 669–691. [Google Scholar] [CrossRef]

- Zhou, H.; Wilkes, G.L. Orientation-dependent mechanical properties and deformation morphologies for uniaxially melt-extruded high-density polyethylene films having an initial stacked lamellar texture. J. Mater. Sci. 1998, 33, 287–303. [Google Scholar] [CrossRef]

- Addiego, F.; Dahoun, A.; G’Sell, C.; Hiver, J.-M.; Godard, O. Effect of microstructure on crazing onset in polyethylene under tension. Polym. Eng. Sci. 2009, 49, 1198–1205. [Google Scholar] [CrossRef]

- Karasev, A.N.; Andreyeva, I.N.; Domareva, N.M.; Kosmatykh, K.I.; Karaseva, M.G.; Domnicheva, N.A. Relationship between the mechanical behaviour and molecular weight distribution of high density polyethylene. Polym. Sci. USSR 1970, 12, 1275–1288. [Google Scholar] [CrossRef]

- Popli, R.; Mandelkern, L. Influence of structural and morphological factors on the mechanical properties of the polyethylenes. J. Polym. Sci. Part B Polym. Phys. 1987, 25, 441–483. [Google Scholar] [CrossRef]

- Brown, N.; Ward, I.M. The influence of morphology and molecular weight on ductile-brittle transitions in linear polyethylene. J. Mater. Sci. 1983, 18, 1405–1420. [Google Scholar] [CrossRef]

- Lampman, S. Characterization and Failure Analysis of Plastics; ASM International: Novelty, OH, USA, 2003. [Google Scholar]

- Mae, H.; Omiya, M.; Kishimoto, K. Effects of strain rate and relaxation rate on elastic modulus of semi-crystalline polymer. Jpn. Soc. Comput. Methods Eng. 2008, 7, 207–212. [Google Scholar]

- Schrauwen, B.A.G. Deformation and Failure of Semi-crystalline Polymer Systems: Influence of Micro and Molecular Structure. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherland, April 2003. [Google Scholar]

- Kalay, G.; Zhong, Z.; Allan, P.; Bevis, M.J. The occurrence of the γ-phase in injection moulded polypropylene in relation to the processing conditions. Polymer 1996, 37, 2077–2085. [Google Scholar] [CrossRef]

- Spalding, M.A.; Chatterjee, A. Handbook of Industrial Polyethylene and Technology: Definitive Guide to Manufacturing, Properties, Processing, Applications and Markets; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Dusunceli, N.; Aydemir, B. The effects of loading history and manufacturing methods on the mechanical behavior of high-density polyethylene. J. Elastomers Plast. 2011, 43, 451–468. [Google Scholar] [CrossRef]

- Kalay, G.; Sousa, R.A.; Reis, R.L.; Cunha, A.M.; Bevis, M.J. The enhancement of the mechanical properties of a high-density polyethylene. J. Appl. Polym. Sci. 1999, 73, 2473–2483. [Google Scholar] [CrossRef]

- Xu, M.M.; Huang, G.Y.; Feng, S.S.; McShane, G.; Stronge, W. Static and Dynamic Properties of Semi-Crystalline Polyethylene. Polymers 2016, 8, 77. [Google Scholar] [CrossRef] [PubMed]

- Grommes, D.; Bruch, O.; Geilen, J. Investigation of the influencing factors on the process-dependent elasticity modulus in extrusion blow molded plastic containers for material modelling in the finite element simulation. AIP Conf. Proc. 2016, 1779, 1–5. [Google Scholar]

- Eftekhari, M.; Fatemi, A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects. Polym. Test. 2016, 51, 151–164. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Tensile behavior and modeling of short fiber-reinforced polymer composites including temperature and strain rate effects. J. Thermoplast. Compos. Mater. 2016, 30, 1414–1437. [Google Scholar] [CrossRef]

- Mellott, S.R. Tensile, Creep, and Fatigue Behaviors of Thermoplastics Including Thickness, Mold Flow Direction, Mean Stress, Temperature, and Loading Rate Effects; University of Toledo: Toledo, OH, USA, 2012. [Google Scholar]

- Sahputra, I.H.; Echtermeyer, A.T. Effects of temperature and strain rate on the deformation of amorphous polyethylene: A comparison between molecular dynamics simulations and experimental results. Model. Simul. Mater. Sci. Eng. 2013, 21, 065016. [Google Scholar] [CrossRef]

- Aid, A.; Bendouba, M.; Talha, A.; Benseddiq, N.; Benguediab, M.; Zengah, S. Uniaxial fatigue of HDPE-100 Pipe: Experimental analysis. Eng. Technol. Appl. Sci. Res. 2014, 4, 600–604. [Google Scholar]

- Elleuch, R.; Taktak, W. Viscoelastic behavior of HDPE polymer using tensile and compressive loading. J. Mater. Eng. Perform. 2006, 15, 111–116. [Google Scholar] [CrossRef]

- Drozdov, A.D.; Christiansen, J.d. Thermo-viscoelastic and viscoplastic behavior of high-density polyethylene. Int. J. Solids Struct. 2008, 45, 4274–4288. [Google Scholar] [CrossRef] [Green Version]

- Djebli, A.; Bendouba, M.; Aid, A.; Talha, A.; Benseddiq, N.; Benguediab, M. Experimental analysis and damage modeling of high-density polyethylene under fatigue loading. Acta Mech. Solida Sin. 2016, 29, 133–144. [Google Scholar] [CrossRef] [Green Version]

- Dasari, A.; Duncan, S.J.; Misra, R.D.K. Microstructural aspects of tensile deformation of high density polyethylene. Mater. Sci. Technol. 2003, 19, 244–252. [Google Scholar] [CrossRef]

- Addiego, F.; Dahoun, A.; G’Sell, C.; Hiver, J.M. Volume variation process of high-density polyethylene during tensile and creep tests. Oil Gas Sci. Technol. Rev. IFP 2006, 61, 715–724. [Google Scholar] [CrossRef] [Green Version]

- Merah, N.; Saghir, F.; Khan, Z.; Bazoune, A. Effect of temperature on tensile properties of HDPE pipe material. Plast. Rubber Compos. 2006, 35, 226–230. [Google Scholar] [CrossRef]

- Bucknall, C.B. Application of fracture mechanics to the prediction of the ductile-brittle transition. Pure Appl. Chem. 1986, 58, 999–1014. [Google Scholar] [CrossRef]

- ASTM D638-14. Standard Test Method for Tensile Properties of Plastics; ASM International: Novelty, OH, USA, 2014. [Google Scholar]

- ISO 527-1. Plastics-Determination of Tensile Properties; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Andreassen, E.; Nord Varhaug, K.; Hinrichsen, E.L.; Persson, A.-M. Impact fracture toughness of polyethylene materials for injection moulding. In Proceedings of the Polymer Processing Society Conference, Gothenburg, Sweden, 28–30 August 2007. [Google Scholar]

- Persson, J.; Zhou, J.; Ståhl, J.-E. Characterizing the mechanical properties of skin-core structure in polymer molding process by nanoindentation. In Proceedings of the Swedish Production Symposium, Gothenburg, Sweden, 16–18 September 2014; pp. 1–9. [Google Scholar]

- Mortazavian, S.; Fatemi, A. Tensile and fatigue behaviors of polymers for automotive applications. Mater. Werkst. 2015, 46, 204–213. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of fiber orientation and anisotropy on tensile strength and elastic modulus of short fiber reinforced polymer composites. Compos. Part B Eng. 2015, 72, 116–129. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A.; Khosrovaneh, A. Effect of water absorption on tensile and fatigue behaviors of two short glass fiber reinforced thermoplastics. SAE Int. J. Mater. Manuf. 2015, 8, 435–443. [Google Scholar] [CrossRef]

- ASTM E646-16. Standard Test Method for Tensile Strain-Hardening Exponents (n-Values) of Metallic Sheet Materials; ASM International: Novelty, OH, USA, 2015. [Google Scholar]

- The Math Works, Inc. MATLAB. Version 2019b, Computer Software; The Mathworks, Inc.: Natick, MA, US, 2019. [Google Scholar]

| Property | Symbol | RMSE | |||||

|---|---|---|---|---|---|---|---|

| Elastic Modulus, MPa | 0.11 | −27.7 | 192.4 | 2253 | 0.94 | 157 | |

| Ultimate Tensile Strength, MPa | 8.75 × 10−4 | −0.341 | 2.68 | 36.0 | 0.98 | 1.06 | |

| Tensile Yield Strength, MPa | 6.65 × 10−4 | −0.189 | 1.22 | 15.4 | 0.94 | 1.18 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amjadi, M.; Fatemi, A. Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Technique, Thickness, Temperature, and Strain Rate. Polymers 2020, 12, 1857. https://doi.org/10.3390/polym12091857

Amjadi M, Fatemi A. Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Technique, Thickness, Temperature, and Strain Rate. Polymers. 2020; 12(9):1857. https://doi.org/10.3390/polym12091857

Chicago/Turabian StyleAmjadi, Mohammad, and Ali Fatemi. 2020. "Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Technique, Thickness, Temperature, and Strain Rate" Polymers 12, no. 9: 1857. https://doi.org/10.3390/polym12091857