Physical and Morphological Properties of Tough and Transparent PMMA-Based Blends Modified with Polyrotaxane

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Methods

2.2. Sample Preparation

2.3. Characterization

2.3.1. Differential Scanning Calorimetry (DSC)

2.3.2. Melt Flow Rate (MFR) Measurements

2.3.3. Transmission Electron Microscopy (TEM)

2.3.4. Transmittance Evaluation

2.3.5. Mechanical Properties

Surface Hardness Measurements

Tensile Strength

Impact Strength

2.3.6. Analysis of Deformation Behavior

3. Results and Discussion

3.1. Thermal Characterization

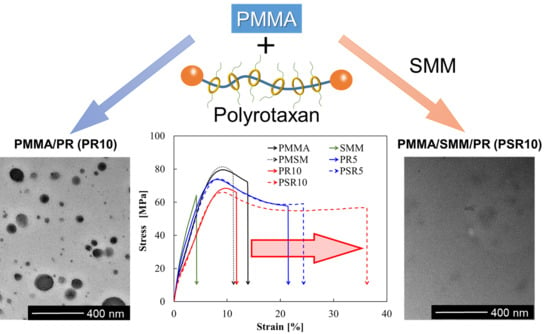

3.2. Transparency and Morphological Properties

3.3. Evaluation of Mechanical Properties

3.3.1. Surface Hardness

3.3.2. Tensile Tests

3.3.3. Notched Charpy Impact Tests

3.4. Analysis of Deformation Behavior

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ali, U.; Karmin, K.; Buang, N. A review of the properties and applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Taylor, D.; Merlo, M.; Pegley, R.; Cavatorta, M.P. The effect of stress concentrations on the fracture strength of polymethylmethacrylate. Mater. Sci. Eng. A 2004, 382, 288–294. [Google Scholar] [CrossRef]

- Laatsch, J.; Kim, G.; Michler, G.H.; Arndt, S.T. Investigation of the micromechanical deformation behavior of transparent toughened Poly(methylmethacrylate) Modified with Core-Shell Particles. Polym. Adv. Technol. 1998, 9, 716–720. [Google Scholar] [CrossRef]

- Li, Y.; Shimizu, H. Fabrication of nanostructured polycarbonate/poly(methyl methacrylate) blends with improved optical and mechanical properties by high-shear processing. Polym. Eng. Sci. 2011, 51, 1437–1445. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Mark, L.; Wang, G.; Yu, K.; Wang, C.; Park, C.B.; Zhao, G. Ultra-tough and super thermal-insulation nanocellular PMMA/TPU. Chem. Eng. J. 2017, 325, 632–646. [Google Scholar] [CrossRef]

- Mao, Z.; Jiang, T.; Zhang, X.; Jiang, G.; Zhang, J. Co-continuous phase structure formed in melt processing inducing shear bands to prevent crack propagation: Significant improvement in impact toughness of PMMA. Polym. Test. 2020, 85, 106425. [Google Scholar] [CrossRef]

- Shah, N. Effect of modifier concentration on the fracture behaviour of rubber-modified PMMA. J. Mater. Sci. 1988, 23, 3623–3629. [Google Scholar] [CrossRef]

- Gong, S.; Bandyopadhyay, S. Mechanical properties and fracture surface morphologies in unnotched specimens of rubber-PMMA composites. J. Mater. Eng. Perform. 2007, 16, 601–606. [Google Scholar] [CrossRef]

- Poomalai, P. Siddaramaiah. Studies on poly(methyl methacrylate) (PMMA) and thermoplastic polyurethane (TPU) blends. J. Macromol. Sci. Pure Appl. Chem. 2005, 42, 1399–1407. [Google Scholar] [CrossRef]

- Zhou, C.; Si, Q.; Ao, Y.; Tan, Z.; Sun, S.; Zhang, M.; Zhang, H. Effect of matrix composition on the fracture behavior of rubber-modified PMMA/PVC blends. Polym. Bull. 2007, 58, 979–988. [Google Scholar] [CrossRef]

- Poomali; Siddaramaiah; Suresha, B.; Lee, J. Mechanical and three-body abrasive wear behaviour of PMMA/TPU blends. Mater. Sci. Eng. A 2008, 492, 486–490. [Google Scholar] [CrossRef]

- Lovell, P.; Mcdonald, J.; Saunders, D.; Young, R. Studies of rubber-toughened poly(methyl methacrylate): 1. Preparation and thermal properties of blends of poly(methyl methacrylate) with multiple-layer toughening particles. Polymer 1993, 34, 61–69. [Google Scholar] [CrossRef]

- Nelliappan, V.; El-Aasser, M.S.; Klein, A.; Daniels, E.S.; Roberts, J.E.; Pearson, R.A. Effect of the core /shell latex particle interphase on the mechanical behavior of rubber-toughened Poly (methyl methacrylate). J. Appl. Polym. Sci. 1995, 65, 581–593. [Google Scholar] [CrossRef]

- Ren, L.; Zhang, M.; Han, Y.; Gui, Y.; Song, L. Core-shell particles for design of high-performance polymeric materials with good transparency and toughness. J. Polym. Res. 2014, 21, 613. [Google Scholar] [CrossRef]

- Harada, A.; Li, J.; Kamachi, M. The molecular necklace: A rotaxane containing many threaded α-cyclodextrins. Nature 1992, 356, 325–327. [Google Scholar] [CrossRef]

- Okumura, Y.; Ito, K. The polyrotaxane gel: A topological gel by figure-of-eight cross-links. Adv. Mater. 2001, 13, 485–487. [Google Scholar] [CrossRef]

- Imran, A.; Seki, T.; Kataoka, T.; Kidowaki, M.; Ito, K.; Takeoka, Y. Fabrication of mechanically improved hydrogels using a movable cross-linker based on vinyl modified polyrotaxane. Chem. Commun. 2008, 41, 5227–5229. [Google Scholar] [CrossRef]

- Gotoh, H.; Liu, C.; Imran, A.B.; Hara, M.; Seki, T.; Mayumi, K.; Ito, K.; Takeoka, Y. Optically transparent, high-toughness elastomer using a polyrotaxane cross-linker as a molecular pulley. Sci. Adv. 2018, 4, eaat7629. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Kang, H.; Shen, J.; Zhang, L.; Nishi, T.; Ito, K.; Zhao, C.; Coates, P. Highly toughened polylactide with novel sliding graft copolymer by in situ reactive compatibilization, crosslinking and chain extension. Polymer 2014, 55, 4313–4323. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Kato, K.; Mayumi, K.; Yokoyama, H.; Ito, K. Efficient mechanical toughening of polylactic acid without substantial decreases in stiffness and transparency by the reactive grafting of polyrotaxanes. J. Incl. Phenom. Macrocycl. Chem. 2019, 93, 107–116. [Google Scholar] [CrossRef]

- Nishino, K.; Shindo, Y.; Kurokawa, Y.; Takayama, T.; Ito, H. Development of styrenic copolymers for improving heat resistance of poly(methyl methacrylate). Int. Polym. Process. 2016, 31, 321–326. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Mitra, S.; Ranjith, P.; Gopalakrishnan, S.; Parthipan, P.; Al-Farhood, B. High heat resistant blends of poly(methyl methacrylate) and styrenic copolymers via post reactor modification. J. Appl. Polym. Sci. 2018, 18, 46220. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Liu, Z.; Xiao, G.; Yuan, G.; Shu, X. Sensitivity of PMMA nanoindentation measurements to strain rate. J. Appl. Polym. Sci. 2015, 132, 41896. [Google Scholar] [CrossRef]

- Fox, T.G. Influence of diluent and of copolymer composition on the glass temperature of a polymer system. Bull. Am. Phys. Soc. 1956, 1, 123. [Google Scholar]

- Mina, M.; Ania, F.; Calleja, F.; Asano, T. Microhardness studies of PMMA/natural rubber blends. J. Appl. Polym. Sci. 2004, 91, 205–210. [Google Scholar] [CrossRef]

- Sue, H.; Yee, A. Study of fracture mechanisms of multiphase polymers using the double-notch four-point-bending method. J. Mater. Sci. 1993, 28, 2975–2980. [Google Scholar] [CrossRef] [Green Version]

- Sugimoto, M.; Ishiwaka, M.; Hatada, K. Toughness of polypropylene. Polymer 1995, 36, 3675–3682. [Google Scholar] [CrossRef]

- Ishikawa, M.; Ushui, K.; Hatada, K. Stability of plastic deformation in polyolefins. Polymer 1996, 37, 1601–1605. [Google Scholar] [CrossRef]

- Torabi, A.; Rahimi, A.; Ayatollahi, M. Tensile fracture analysis of a ductile polymeric material weakened by U-notches. Polym. Test. 2017, 64, 117–126. [Google Scholar] [CrossRef]

- Ishigami, A.; Konno, T.; Kurose, T.; Nishitsuji, S.; Ishikawa, M.; Ito, H. Comparative study on polyamide 6 toughness using multiple melt-kneading techniques. Acad. J. Polym. Sci. 2018, 1, 555563. [Google Scholar] [CrossRef] [Green Version]

- Ng, C.; Susmel, L. Notch static strength of additively manufactured acrylonitrile butadiene styrene (ABS). Addit. Manuf. 2020, 34, 101212. [Google Scholar] [CrossRef]

| Code | PMMA/SMM/PR (wt %) | Tm (°C) | Tg (°C) | MFR (g/10 min) |

|---|---|---|---|---|

| PMMA | 100/0/0 | - | 114.1 | 2.5 |

| SMM | 0/100/0 | - | 132.7 | 4.2 |

| PMSM | 79/21/0 | - | 118.6 | 2.9 |

| PR | 0/0/100 | 50.0 | - | - |

| PR5 | 95/0/5 | - | 112.0 | 3.9 |

| PR10 | 90/0/10 | 39.7 | 111.9 | 5.0 |

| PSR5 | 75/20/5 | - | 113.7 | 0.6 |

| PSR10 | 70/20/10 | - | 111.3 | 0.2 |

| Code | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) | Breaking Energy (J/m3) |

|---|---|---|---|---|

| PMMA | 79.7 | 14.8 | 2296 | 8.3 |

| SMM | 63.8 | 4.0 | 2557 | 1.6 |

| PMSM | 81.5 | 11.6 | 2290 | 6.3 |

| PR5 | 74.3 | 21.3 | 2188 | 12.6 |

| PR10 | 68.4 | 13.0 | 2069 | 5.6 |

| PSR5 | 74.3 | 24.4 | 2024 | 14.1 |

| PSR10 | 67.0 | 37.6 | 1916 | 19.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishigami, A.; Watanabe, K.; Kurose, T.; Ito, H. Physical and Morphological Properties of Tough and Transparent PMMA-Based Blends Modified with Polyrotaxane. Polymers 2020, 12, 1790. https://doi.org/10.3390/polym12081790

Ishigami A, Watanabe K, Kurose T, Ito H. Physical and Morphological Properties of Tough and Transparent PMMA-Based Blends Modified with Polyrotaxane. Polymers. 2020; 12(8):1790. https://doi.org/10.3390/polym12081790

Chicago/Turabian StyleIshigami, Akira, Kazuki Watanabe, Takashi Kurose, and Hiroshi Ito. 2020. "Physical and Morphological Properties of Tough and Transparent PMMA-Based Blends Modified with Polyrotaxane" Polymers 12, no. 8: 1790. https://doi.org/10.3390/polym12081790