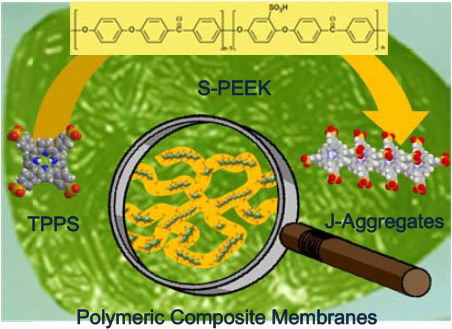

Novel Polymeric Composite TPPS/s-PEEK Membranes for Low Relative Humidity PEFC

Abstract

:1. Introduction

2. Materials and Methods

2.1. Functionalization Reaction

2.2. Membrane Preparation

2.3. Chemical-Physical Characterizations

2.3.1. UV-Vis Extinction and Fluorescence Emission spectroscopies

2.3.2. Thickness Measurements

2.3.3. Ion Exchange Capacity

2.3.4. Water Uptake, λ Parameter and Proton Concentration

2.3.5. In-plane Proton Conductivity and Effective Mobility

2.3.6. Fuel Cell Tests

3. Results

3.1. Spectroscopic Characterizations

3.2. IEC, Wup, λ and Proton Concentration

3.3. Electrochemical Characterizations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef] [Green Version]

- Nafil, R.Q.; Majeed, M.S. Fuel Cells as a Source of Green Energy. In Thermodynamics and Energy Engineering; Vizureanu, P., Ed.; Intech: London, UK, 2020. [Google Scholar] [CrossRef] [Green Version]

- Fathima, N.N.; Aravindhan, R.; Lawrence, D.; Yugandhar, U.; Moorthy, T.S.R.; Nair, B.U. SPEEK polymeric membranes for fuel cell application and their characterization: A review. J. Sci. Ind. Res. 2007, 66, 209–219. [Google Scholar]

- Gao, X.; Liu, Y.; Li, J. Review on Modification of Sulfonated Poly (-ether-ether-ketone) Membranes Used as Proton Exchange Membranes. Mat. Sci. Medziagotyra 2015, 21, 574–582. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Liu, S.; Wang, L.; Li, M.; Gao, C. Understanding of Nanophase Separation and Hydrophilic Morphology in Nafion and SPEEK Membranes: A Combined Experimental and Theoretical Studies. Nanomaterials 2019, 9, 869. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Basile, A.; Paturzo, L.; Iulianelli, A.; Gatto, I.; Passalacqua, E. Sulfonated PEEK-WC membranes for proton-exchange membrane fuel cell: Effect of the increasing level of sulfonation on electrochemical performances. J. Membr. Sci. 2006, 281, 377–385. [Google Scholar] [CrossRef]

- Sacca, A.; Carbone, A.; Pedicini, R.; Gatto, I.; Passalacqua, E. Composite sPEEK membranes for vanadium redox batteries application. Procedia Eng. 2012, 44, 1041–1043. [Google Scholar] [CrossRef] [Green Version]

- Mighani, H.; Farshchi, N. Properties of PEEK, preparation and characterization of SPEEK membranes for fuel cell applications: A review. Macromol. Indian J. 2013, 9, 102–110. [Google Scholar]

- Brush, D.; Danilczuk, M.; Schlick, S. Phase Separation in Sulfonated Poly(ether ether ketone) (SPEEK) lonomers by Spin Probe ESR: Effect of the Degree of Sulfonation and Water Content. Macromolecules 2015, 48, 637–644. [Google Scholar] [CrossRef]

- Portale, G.; Carbone, A.; Martinelli, A.; Passalacqua, E. Microstructure, state of water and proton conductivity of sulfonated poly(ether ether ketone). Solid State Ion. 2013, 252, 62–67. [Google Scholar] [CrossRef]

- Chen, B.-K.; Wu, T.-Y.; Wong, J.-M.; Chang, Y.-M.; Lee, H.-F.; Huang, W.-Y.; Chen, A.F. Highly Sulfonated Diamine Synthesized Polyimides and Protic Ionic Liquid Composite Membranes Improve PEM Conductivity. Polymers 2015, 7, 1046–1065. [Google Scholar] [CrossRef] [Green Version]

- Donmez, G.; Okutan, M.; Deligoz, H. Blend membranes of sulfonated poly (ether ether ketone) and thermoplastic poly (urethane) for fuel cells. J. Polym. Res. 2019, 26. [Google Scholar] [CrossRef]

- Mahanwar, P.; Bhattad, S.S. Preparation and Physical Characterization of Sulfonated Poly (Ether Ether Ketone) and Polypyrrole Composite Membrane. J. Membr. Sci. Res. 2019, 5, 49–54. [Google Scholar] [CrossRef]

- Carbone, A.; Pedicini, R.; Saccà, A.; Gatto, I.; Passalacqua, E. Composite S-PEEK membranes for medium temperature polymer electrolyte fuel cells. J. Power Sour. 2008, 178, 661–666. [Google Scholar] [CrossRef]

- Carbone, A.; Sacca, A.; Gatto, I.; Pedicini, R.; Passalacqua, E. Investigation on composite S-PEEK/H-BETA MEAs for medium temperature PEFC. Int. J. Hydrog. Energy 2008, 33, 3153–3158. [Google Scholar] [CrossRef]

- Da Trindade, L.G.; Borba, K.M.N.; Zanchet, L.; Lima, D.W.; Trench, A.B.; Rey, F.; Diaz, U.; Longo, E.; Bernardo-Gusmao, K.; Martini, E.M.A. SPEEK-based proton exchange membranes modified with MOF-encapsulated ionic liquid. Mat. Chem. Phys. 2019, 236. [Google Scholar] [CrossRef]

- Donnadio, A.; Pica, M.; Carbone, A.; Gatto, I.; Posati, T.; Mariangeloni, G.; Casciola, M. Double filler reinforced ionomers: A new approach to the design of composite membranes for fuel cell applications. J. Mat. Chem. A 2015, 3, 23530–23538. [Google Scholar] [CrossRef]

- Escorihuela, J.; Garcia-Bernabe, A.; Montero, A.; Andrio, A.; Sahuquillo, O.; Gimenez, E.; Compan, V. Proton Conductivity through Polybenzimidazole Composite Membranes Containing Silica Nanofiber Mats. Polymers 2019, 11, 1182. [Google Scholar] [CrossRef] [Green Version]

- Hosseinabadi, P.; Hooshyari, K.; Javanbakht, M.; Enhessari, M. Synthesis and optimization of nanocomposite membranes based on SPEEK and perovskite nanoparticles for polymer electrolyte membrane fuel cells. N. J. Chem. 2019, 43, 16232–16245. [Google Scholar] [CrossRef]

- Lim, M.-Y.; Kim, K. Sulfonated Poly(Arylene Ether Sulfone) and Perfluorosulfonic Acid Composite Membranes Containing Perfluoropolyether Grafted Graphene Oxide for Polymer Electrolyte Membrane Fuel Cell Applications. Polymers 2018, 10, 569. [Google Scholar] [CrossRef] [Green Version]

- Mazzapioda, L.; Panero, S.; Navarra, M.A. Polymer Electrolyte Membranes Based on Nafion and a Superacidic Inorganic Additive for Fuel Cell Applications. Polymers 2019, 11, 914. [Google Scholar] [CrossRef] [Green Version]

- Qu, S.; Li, M.; Zhang, C.; Sun, Y.; Duan, J.; Wang, W.; Li, J.; Li, X. Sulfonated Poly(ether ether ketone) Doped with Ammonium Ionic Liquids and Nano-Silicon Dioxide for Polymer Electrolyte Membranes. Polymers 2019, 11, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sahin, A.; Tasdemir, H.M.; Ar, I. Improved performance and durability of sulfonated polyether ether ketone/cerium phosphate composite membrane for proton exchange membrane fuel cells. Ionics 2019, 25, 5163–5175. [Google Scholar] [CrossRef]

- Wu, G.; Lin, S.-J.; Hsu, I.C.; Su, J.-Y.; Chen, D.W. Study of High Performance Sulfonated Polyether Ether Ketone Composite Electrolyte Membranes. Polymers 2019, 11, 1177. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carbone, A.; Saccà, A.; Pedicini, R.; Gatto, I.; Passalacqua, E.; Romeo, A.; Scolaro, L.M.; Castriciano, M.A. Composite sPEEK-TPyP membranes development for portable applications. Int. J. Hydrog. Energy 2015, 40, 17394–17401. [Google Scholar] [CrossRef]

- Castriciano, M.A.; Carbone, A.; Sacca, A.; Donato, M.G.; Micali, N.; Romeo, A.; De Luca, G.; Scolaro, L.M. Optical and sensing features of TPPS4 J-aggregates embedded in Nafion membranes: Influence of casting solvents. J. Mat. Chem. 2010, 20, 2882–2886. [Google Scholar] [CrossRef]

- Cheng, T.; Zhang, X.; Ma, Y.; Huang, Y.; Liu, X. Constructing Continuous Proton-Conducting Highways within Sulfonated Poly (Arylene Ether Nitrile) Composite Membrane by Incorporating Amino-Sulfo-Bifunctionalized GO. Polymers 2018, 10, 1005. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Liu, X.; Zhang, Y.; Dong, J.; Wang, J.; Yang, Z.; Cheng, H. Fabrication of Sulfonated Poly (ether ether ketone)/Sulfonated Fully Aromatic Polyamide Composite Membranes for Direct Methanol Fuel Cells (DMFCs). Energy Technol. 2019, 7, 71–79. [Google Scholar] [CrossRef]

- Quan, Y.; Wang, G.; Li, A.; Wei, X.; Li, F.; Zhang, J.; Chen, J.; Wang, R. Novel sulfonated poly(ether ether ketone)/triphenylamine hybrid membrane for vanadium redox flow battery applications. RSC Adv. 2019, 9, 3838–3846. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Yu, S.; Zhu, Q.; Zhao, L. Enhanced anhydrous proton conductivity of SPEEK/IL composite membrane embedded with amino functionalized mesoporous silica. Int. J. Hydrog. Energy 2019, 44, 6148–6159. [Google Scholar] [CrossRef]

- Carbone, A.; Gaeta, M.; Romeo, A.; Portale, G.; Pedicini, R.; Gatto, I.; Castriciano, M.A. Porphyrin/sPEEK Membranes with Improved Conductivity and Durability for PEFC Technology. ACS Appl. Energy Mat. 2018, 1, 1664–1673. [Google Scholar] [CrossRef]

- Kalyanasundaram, K. Photochemistry of Polypyridine and Porphyrin Complexes; Academic Press: London, UK, 1992. [Google Scholar]

- Kobayashi, T. J-Aggregates; World Scientific Publishing Company: Singapore, 2012; Volume 2. [Google Scholar]

- Kobayashi, T. J-Aggregates; World Scientific Publishing Company: Singapore, 1996. [Google Scholar]

- Ribo, J.M.; Crusats, J.; Farrera, J.A.; Valero, M.L. Aggregation in Water Solutions of Tetrasodium Diprotonated Meso-Tetrakis(4-sulfonatophenyl)Porphyrin. J. Chem. Soc. Chem. Commun. 1994, 681–682. [Google Scholar] [CrossRef]

- Gandini, S.C.M.; Gelamo, E.L.; Itri, R.; Tabak, M. Small angle X-ray scattering study of meso-tetrakis (4-sulfonatophenyl) porphyrin in aqueous solution: A self-aggregation model. Biophys. J. 2003, 85, 1259–1268. [Google Scholar] [CrossRef] [Green Version]

- Schwab, A.D.; Smith, D.E.; Rich, C.S.; Young, E.R.; Smith, W.F.; de Paula, J.C. Porphyrin nanorods. J. Phys. Chem. B 2003, 107, 11339–11345. [Google Scholar] [CrossRef]

- Micali, N.; Villari, V.; Castriciano, M.A.; Romeo, A.; Scolaro, L.M. From fractal to nanorod porphyrin J-aggregates. Concentration-induced tuning of the aggregate size. J. Phys. Chem. B 2006, 110, 8289–8295. [Google Scholar] [CrossRef]

- Castriciano, M.A.; Romeo, A.; Villari, V.; Micali, N.; Scolaro, L.M. Structural rearrangements in 5,10,15,20-tetrakis(4-sulfonatophenyl)porphyrin J-aggregates under strongly acidic conditions. J. Phys. Chem. B 2003, 107, 8765–8771. [Google Scholar] [CrossRef]

- Castriciano, M.A.; Donato, M.G.; Villari, V.; Micali, N.; Romeo, A.; Scolaro, L.M. Surfactant-like Behavior of Short-Chain Alcohols in Porphyrin Aggregation. J. Phys. Chem. B 2009, 113, 11173–11178. [Google Scholar] [CrossRef]

- Occhiuto, I.G.; Zagami, R.; Trapani, M.; Bolzonello, L.; Romeo, A.; Castriciano, M.A.; Collini, E.; Monsu Scolaro, L. The role of counter-anions in the kinetics and chirality of porphyrin J-aggregates. Chem. Commun. 2016, 52, 11520–11523. [Google Scholar] [CrossRef]

- Trapani, M.; Mazzaglia, A.; Piperno, A.; Cordaro, A.; Zagami, R.; Castriciano, M.A.; Romeo, A.; Monsù Scolaro, L. Novel Nanohybrids Based on Supramolecular Assemblies of Meso-tetrakis-(4-sulfonatophenyl) Porphyrin J-aggregates and Amine-Functionalized Carbon Nanotubes. Nanomaterials 2020, 10, 669. [Google Scholar] [CrossRef] [Green Version]

- Trapani, M.; Castriciano, M.A.; Romeo, A.; De Luca, G.; Machado, N.; Howes, B.D.; Smulevich, G.; Scolaro, L.M. Nanohybrid Assemblies of Porphyrin and Au-10 Cluster Nanoparticles. Nanomaterials 2019, 9, 1026. [Google Scholar] [CrossRef] [Green Version]

- Zagami, R.; Trapani, M.; Castriciano, M.A.; Romeo, A.; Mineo, P.G.; Scolaro, L.M. Synthesis, characterization and aggregation behavior of room temperature ionic liquid based on porphyrin- trihexyl(tetradecyl)phosphonium adduct. J. Mol. Liq. 2017, 229, 51–57. [Google Scholar] [CrossRef]

- Trapani, M.; De Luca, G.; Romeo, A.; Castriciano, M.A.; Scolaro, L.M. Spectroscopic investigation on porphyrins nano-assemblies onto gold nanorods. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 173, 343–349. [Google Scholar] [CrossRef] [PubMed]

- Castriciano, M.A.; Leone, N.; Cardiano, P.; Manickam, S.; Scolaro, L.M.; Lo Schiavo, S. A new supramolecular polyhedral oligomeric silsesquioxanes (POSS)-porphyrin nanohybrid: Synthesis and spectroscopic characterization. J. Mat. Chem. C 2013, 1, 4746–4753. [Google Scholar] [CrossRef]

- Villari, V.; Mazzaglia, A.; Castriciano, M.A.; Luca, G.D.; Romeo, A.; Scolaro, L.M.; Micali, N. Optical enhancement and structural properties of a hybrid organic-inorganic ternary nanocomposite. J. Phys. Chem. C 2011, 115, 5435–5439. [Google Scholar] [CrossRef]

- Castriciano, M.A.; Romeo, A.; Scolaro, L.M. Aggregation of meso-tetrakis(4-sulfonatophenyl)porphyrin on polyethyleneimine in aqueous solutions and on a glass surface. J. Porphyr. Phthalocyanines 2002, 6, 431–438. [Google Scholar] [CrossRef]

- Romeo, A.; Castriciano, M.A.; Zagami, R.; Pollicino, G.; Monsu Scolaro, L.; Pasternack, R.F. Effect of zinc cations on the kinetics for supramolecular assembling and the chirality of porphyrin J-aggregates. Chem. Sci. 2017, 8, 961–967. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romeo, A.; Castriciano, M.A.; Occhiuto, I.; Zagami, R.; Pasternack, R.F.; Scolaro, L.M. Kinetic Control of Chirality in Porphyrin J-Aggregates. J. Am. Chem. Soc. 2014, 136, 40–43. [Google Scholar] [CrossRef]

- Angjeli, K.; Nicotera, I.; Baikousi, M.; Enotiadis, A.; Gournis, D.; Sacca, A.; Passalacqua, E.; Carbone, A. Investigation of layered double hydroxide (LDH) Nafion-based nanocomposite membranes for high temperature PEFCs. Energy Convers. Manag. 2015, 96, 39–46. [Google Scholar] [CrossRef]

- Gouterman, M. The Porphyrins; Dolphin, D., Ed.; Academic Press: New York, NY, USA, 1978; Volume 3, pp. 1–165. [Google Scholar]

- Kreuer, K.D. On the development of proton conducting materials for technological applications. Solid State Ion. 1997, 97, 1–15. [Google Scholar] [CrossRef]

- Smitha, B.; Sridhar, S.; Khan, A.A. Polyelectrolyte complexes of chitosan and poly(acrylic acid) as proton exchange membranes for fuel cells. Macromolecules 2004, 37, 2233–2239. [Google Scholar] [CrossRef]

- Paul, D.K.; McCreery, R.; Karan, K. Proton Transport Property in Supported Nafion Nanothin Films by Electrochemical Impedance Spectroscopy. J. Electrochem. Soc. 2014, 161, F1395–F1402. [Google Scholar] [CrossRef] [Green Version]

| Membranes | TPPS Loading, % |

|---|---|

| s-PEEK-0 | 0 |

| s-PEEK-0.35 | 0.35 |

| s-PEEK-0.77 | 0.77 |

| s-PEEK-1.5 | 1.5 |

| Temperature | Samples | IEC, meq g−1 | Wup, % | λ, mol (H2O/SO3H) | [H+], M |

|---|---|---|---|---|---|

| 30 °C | s-PEEK-0 | 1.49 | 16.2 | 6 | 1.43 |

| s-PEEK-0.35 | 1.77 | 20.1 | 6 | 1.12 | |

| s-PEEK-0.77 | 1.69 | 30.3 | 10 | 1.52 | |

| s-PEEK-1.5 | 1.46 | 20.6 | 8 | 1.39 | |

| 80 °C | s-PEEK-0 | - | 20.4 | 8 | 1.26 |

| s-PEEK-0.35 | - | 30.2 | 9 | 1.25 | |

| s-PEEK-0.77 | - | 66.9 | 22 | 1.32 | |

| s-PEEK-1.5 | - | 36.4 | 14 | 1.22 |

| Samples | Eatt/kJ mol−1 |

|---|---|

| s-PEEK-0 | 31 |

| s-PEEK-0.35 | 38 |

| s-PEEK-0.77 | 21 |

| s-PEEK-1.5 | 32 |

| 80 °C 100% RH | 80 °C 75% RH | 80 °C 50% RH | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Samples | OCV, V | R, Ωcm2 | C.D. @0.6 V Acm−2, | OCV, V | R, Ωcm2 | C.D. @0.6 V Acm−2, | OCV, V | R, Ωcm2 | C.D. @0.6 V Acm−2, |

| s-PEEK-0 | 0.960 | 0.184 | 0.854 | 0.941 | 0.207 | 0.650 | 0.958 | 0.325 | 0.552 |

| s-PEEK-0.35 | 1.000 | 0.258 | 0.550 | 1.000 | 0.425 | 0.500 | - | - | - |

| s-PEEK-0.77 | 0.991 | 0.214 | 0.803 | 0.991 | 0.238 | 0.650 | 0.991 | 0.245 | 0.602 |

| s-PEEK-1.5 | 1.007 | 0.275 | 0.650 | 0.991 | 0.500 | 0.275 | - | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carbone, A.; Castriciano, M.A.; Monsù Scolaro, L.; Gatto, I. Novel Polymeric Composite TPPS/s-PEEK Membranes for Low Relative Humidity PEFC. Polymers 2020, 12, 1431. https://doi.org/10.3390/polym12061431

Carbone A, Castriciano MA, Monsù Scolaro L, Gatto I. Novel Polymeric Composite TPPS/s-PEEK Membranes for Low Relative Humidity PEFC. Polymers. 2020; 12(6):1431. https://doi.org/10.3390/polym12061431

Chicago/Turabian StyleCarbone, Alessandra, Maria Angela Castriciano, Luigi Monsù Scolaro, and Irene Gatto. 2020. "Novel Polymeric Composite TPPS/s-PEEK Membranes for Low Relative Humidity PEFC" Polymers 12, no. 6: 1431. https://doi.org/10.3390/polym12061431