3.1. Response Surface Analysis

The coded values of three individual variables and total BP hemicellulose yield under different conditions were shown in

Table 2. A second-order polynomial equation in terms of Coded Factors for total hemicellulose yield can be represented by Equation (1):

Equation (1) in Terms of Coded Factors:

where Y is the predicted total yield of hemicellulose; A, B, and C are the coded values for ultrasonic treatment time, KOH mass concentration, and extraction temperature, respectively, and so as follows.

The experimental conditions and results of 17 runs are shown in

Table A2. The results of analysis of variance (ANOVA) are presented in

Table A2.

p-values and F-values are used to verify the significance between coefficients. Specifically, Prob > F values less than 0.01 or 0.05 indicate that coefficients of the model are significant, and the values more than 0.05 indicate that coefficients of the model are not significant [

29,

30]. Therefore, F Value of 63.77 and Prob > F of less than 0.01 show that the model is significant, and there is only a 0.01% chance of such a large “Model F-value” due to noise in the model. Additionally, the linear coefficients (A, B, C), the quadratic term coefficients (A

2, B

2, C

2), and the interaction of AC between ultrasonic treatment time and extraction temperature were all significant at the lever of

p < 0.05 or

p < 0.01, and the other coefficients are not significant. Therefore, the coefficients of A, B, C, A

2, B

2, C

2, and AC were crucial factors during the BP extraction process. Above of all, it is confirmed that the experimental model is successful, and the regression equation could be used to predict the effects of ultrasonic treatment time, KOH mass fraction, and extraction temperature on BP hemicellulose yield [

14,

31]. The final equation in terms of actual factors can be described as follows:

Equation (2) in Terms of Actual Factors:

As illustrated in

Figure 2, two-dimensional and three-dimensional graphs are the curve representations for regression models, which were helpful to predict the interaction of each two variables on total hemicellulose yield. The circle center of contour map is the condition where the extremum is. The closer the contour map curve is to a circle, the lower correlation between the two factors is, and the closer it is to the ellipse, the higher the correlation between the two factors is [

28]. Response surface analysis of three-dimensional graphs is primarily based on the density and shape of contour plots. In sharp contrast, steep curve areas showed much more significant effects on response value.

Figure 2a,b shows the effects between KOH mass concentration and ultrasonic treatment time on the total hemicellulose yield under the conditions of extraction temperature of 50 °C. The total yield increased at first and then decreased with the values of two variables increasing. From

Figure 2a, the density of contour plot with the change of KOH mass concentration was larger than that of ultrasonic treatment time, which illustrated that effects of KOH mass concentrations on the hemicellulose yield were more significant than that of ultrasonic treatment time, and the

p-value of regression analysis also reflected this. From

Figure 2b, the contour plot was more like a circle, indicating a low correlation between the factors of KOH mass concentration and ultrasonic treatment time, and the

p-value of AB in regression analysis also reflected that.

Figure 2c,d indicates the impacts of ultrasonic treatment time and extraction temperature on the total hemicellulose yield under the conditions of KOH mass concentration of 3%. The total yield increased at first and then decreased with the values of two variables increasing. From

Figure 2c, the density of contour plot with the change of extraction temperature was larger than that of ultrasonic treatment time, which indicated that the effects of extraction temperature on the hemicellulose yield were more significant than that of ultrasonic treatment time, and the

p-value of regression analysis also reflected this. The contour plot was more like an ellipse, suggesting a high correlation between the factors of extraction temperature and ultrasonic treatment time, and the

p-value of AC in regression analysis also reflected that.

Figure 2e,f reveals the interaction of KOH mass concentration and extraction temperature on the total hemicellulose yield under the conditions of ultrasonic treatment time of 30 min. From

Figure 2e, the density of contour plot with the change of KOH mass concentration was larger than that of extraction temperature, which indicated that effects of KOH mass concentration on the hemicellulose yield were more significant than that of extraction temperature, and

p-value of regression analysis also reflected this. The contour plot was more like a circle, indicating a low relation between the factors of KOH mass concentration and extraction temperature, and

p-value of BC in regression analysis also reflected that.

The BP hemicellulose yield was optimized by Design-expert 8.0.6 software, and the optimum levels of the variables were ultrasonic treatment time of 28 min, KOH mass concentration of 3.7%, and extraction temperature of 53 °C, obtaining the predicted yield of 23.07%. According to the optimum conditions, the obtained hemicellulose yield was 23.05%, equivalent to the predicted value of the model, which indicates this model can be used to predict BP hemicellulose yield.

3.2. FT-IR Spectra

The FT-IR spectra of AH and WH were illustrated in

Figure 3. The following analyses were based on previous reports [

20,

28,

32,

33]. It can be seen that the typical peaks of hemicelluloses were 3420, 1630, 1407, 1043, and 898 cm

−1 [

34,

35]. The peaks of 3420 and 2924 cm

−1 were ascribed to the O–H and C–H stretching of hemicellulose, respectively, while the absorption peak at 1407 cm

−1 was C–H stretching, and the absorption peak at 1043 cm

−1 corresponded to the C–O, C–C stretching or C–OH bending of typical xylose pyran ring. The characteristic band at 898 cm

−1 assigned to the symmetric stretching vibration of C–O–C, indicating that xylan structure was linked by β-1,4 glycosidic bonds [

36,

37]. A characteristic band at 1243 cm

−1 appeared corresponding to O–H or C–O–C bending, which confirmed the existence of xylan. Otherwise, there were no significant differences on the structure of AH and WH from Fourier-transform infrared spectra after ultrasound assisted treatment, demonstrating that ultrasonic treatment was a physical process, which keeps the basic chemistry bonds intact after ultrasound treatment.

3.3. The Effect of Ultrasound-Assisted Extraction on Hemicellulose Yield and Sugar Analysis

The hemicellulose yields and monosaccharide compositions of WH and AH are implied in

Table 3. The hemicellulose extracted by alkaline extraction by means of ultrasound-assistant has a much higher yield, which is 23.05%, compared to that of without ultrasound-assisted extraction that is 19.81%. These results were higher than those reported by Liu [

38]: under conditions of NaOH charge 10%, extraction temperature of 120 °C, extraction time of 60 min, the hemicellulose yield of bagasse pith was 15.37%. In addition, several researchers have investigated the positive effect of ultrasonic treatment on the hemicellulose extraction yield from different agricultural biomass. A total of 41.4% of the wheat straw hemicelluloses were obtained (absolute yield increase by 1.8 using ultrasound) [

39], and 16.5% total buckwheat hulls hemicelluloses were isolated (absolute yield increase by 5.3% using ultrasound) [

20]. Moreover, the yield of AH and WH treated with ultrasound-assisted extraction is higher than that of without ultrasound-assisted extraction. It demonstrates that ultrasonic treatment is suitable for solubilizing hemicellulose. The total yield of hemicellulose increased from 19.81% to 23.05% when the ultrasonic treatment time was increased to 28 min. Making BP cell walls swell and hydrate may result from the cavition of ultrasound [

27]. This also makes it easier for the KOH solution to reach the BP cell wall. Beyond that, ultrasound can loosen and destroy the chemical bonds among hemicellulose, cellulose, lignin and other substances, making hemicellulose filled with alkali solution, then accelerating the dissolution of hemicellulose, which could also be attributed to the growth of hemicellulose yield. During the ultrasound-assisted process, there is a section of hemicellulose degradation, which may be caused by radical reaction induced by ultrasonic treatment, resulting in the fracture of glycosidic bonds among the sugars [

28,

40,

41]. In the process of ultrasonic assistance, the extraction yield of hemicellulose has increased a lot with low energy consumption of ultrasound. In our work, a fabricated method for industrial extraction and separation of hemicellulose from agricultural and forest wastes is developed, that is, ultrasound-assisted alkaline, and it has a promising application [

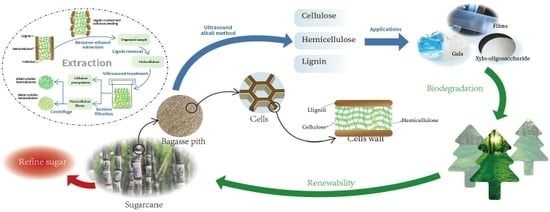

42].

Table 3 also shows that xylose was the dominant component sugar in WH and AH, whether or not they were ultrasound assisted, which was followed by arabinose and glucose. Small amounts of galactose and glucuronic acid and minor amounts of galacturonic acid were observed as well. Nevertheless, some differences of chemical composition between the two hemicellulosic components were observed. The content of xylose was up to 85.83% of the total fractions in the AH obtained by sonication. In contrast to AH, the content of xylose in WH was only 69.05% of the total fractions, whereas other hemicellulosic mosaccharides were also significant in WH. The ratio of arabinose to xylose (Ara/Xyl) reflected the degree of branching of hemicellulose, and the higher ratio indicated the higher degree of branching [

24]. The Ara/Xyl ratios of WH were higher than those of AH, which suggested the AH was more homogeneous than WH.

In addition, the xylose content of the hemicellulose obtained by ultrasonic treatment was slightly lower than that of without ultrasound. This was the opposite as the variation of arabinose and galactose. The results might be attribute to the fact that the various cell walls position of hemicellulose components and the different accessibility of ultrasound-assisted alkaline extraction. The effect of ultrasound on BP cell wall can improve cell accessibility, contributing to an increase of sugar content [

28]. Besides, the Ara/Xyl ratio of WH by ultrasonic treatment was higher than that of without ultrasound. This indicated that ultrasonic treatment had no apparent effect on original molecular structure of hemicellulose from BP. Since more hydrophilic sidechains were kept from WH, they were more active in chemical reaction, which was good for hemicellulose modification and for producing functional polymers.