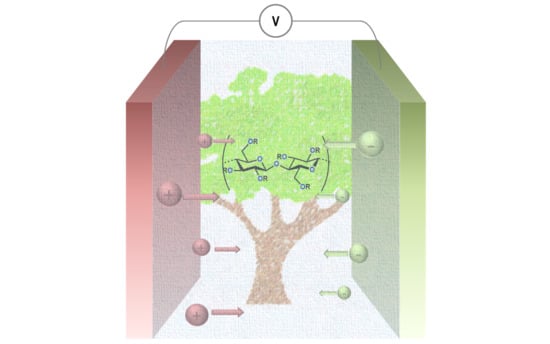

Room-Temperature Self-Standing Cellulose-Based Hydrogel Electrolytes for Electrochemical Devices

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Cellulose-Based Hydrogel (General Procedure)

2.3. Characterization Methods

2.4. Assembly of All-in-One ECDs

2.5. Assembly of Printed Batteries

3. Results and Discussion

3.1. Synthesis and Physicochemical Characterization

3.2. Rheological Characterization

3.3. Ionic Conductivity

3.4. Electrochromic Devices (ECDs)

3.5. Batteries

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jeerapan, I.; Poorahong, S. Review—Flexible and Stretchable Electrochemical Sensing Systems: Materials, Energy Sources, and Integrations. J. Electrochem. Soc. 2020, 167, 037573. [Google Scholar] [CrossRef]

- Song, W.; Yoo, S.; Song, G.; Lee, S.; Kong, M.; Rim, J.; Jeong, U.; Park, S. Recent Progress in Stretchable Batteries for Wearable Electronics. Batter. Supercaps 2019, 2, 181–199. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Tang, Z.; Liu, Z.; Ruan, Z.; Ma, L.; Yang, Q.; Wang, D.; Zhi, C. Hydrogel Electrolytes for Flexible Aqueous Energy Storage Devices. Adv. Funct. Mat. 2018, 28, 1804560. [Google Scholar] [CrossRef]

- Choudhury, N.A.; Sampath, S.; Shukla, A.K. Hydrogel-Polymer Electrolytes for Electrochemical Capacitors: An Overview. Energy Environ. Sci. 2009, 2, 55–67. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, E.M. Hydrogel: Preparation, Characterization, and Applications: A Review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Ullah, F.; Othman, M.B.H.; Javed, F.; Ahmad, Z.; Akil, H.M. Classification, Processing and Application of Hydrogels: A Review. Mat. Sci. Eng. C 2015, 57, 414–433. [Google Scholar] [CrossRef]

- Perkins, D.N.; Brune Drisse, M.N.; Nxele, T.; Sly, P.D. E-Waste: A Global Hazard. Ann. Glob. Health 2014, 4, 286–295. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Sikdar, P.P.; Haque, B.; Bhuiyan, M.A.R.; Ali, A.; Islam, M.N. Cellulose-Based Hydrogel Materials: Chemistry, Properties and Their Prospective Applications. Prog. Biomater. 2018, 7, 153–174. [Google Scholar] [CrossRef] [Green Version]

- Kang, H.; Liu, R.; Huang, Y. Cellulose-Based Gels. Macromol. Chem. Phys. 2016, 217, 1322–1334. [Google Scholar] [CrossRef]

- Kayra, N.; Aytekin, A.Ö. Synthesis of Cellulose-Based Hydrogels: Preparation, Formation, Mixture, and Modification. In Cellulose-Based Superabsorbent Hydrogels, 1st ed.; Part II, Ch. 14; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–28. [Google Scholar] [CrossRef]

- Isik, M.; Sardon, H.; Mecerreyes, D. Ionic Liquids and Cellulose: Dissolution, Chemical Modification and Preparation of New Cellulosic Materials. Int. J. Mol. Sci. 2014, 15, 11922–11940. [Google Scholar] [CrossRef]

- Sannino, A.; Demitri, C.; Madaghiele, M. Biodegradable Cellulose-Based Hydrogels: Design and Applications. Materials 2009, 2, 353–373. [Google Scholar] [CrossRef]

- Hasan, A.M.A.; Abdel-Raouf, M.E.-S. Cellulose-Based superabsorbent hydrogels. In Cellulose-Based Superabsorbent Hydrogels, 1st ed.; Part I, Ch. 8; Springer International Publishing: Cham, Switzerland, 2018; pp. 246–264. [Google Scholar] [CrossRef]

- Jabbour, L.; Bongiovanni, R.; Chaussy, D.; Gerbaldi, C.; Beneventi, D. Cellulose-Based Li-Ion Batteries: A Review. Cellulose 2013, 20, 1523–1545. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Liu, X.; Zhang, S. Towards a Molecular Understanding of Cellulose Dissolution in Ionic Liquids: Anion/Cation Effect, Synergistic Mechanism and Physicochemical Aspects. Chem. Sci. 2018, 9, 4027–4043. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kasprzak, D.; Stępniak, I.; Galiński, M. Electrodes and Hydrogel Electrolytes Based on Cellulose: Fabrication and Characterization as EDLC Components. J. Solid State Electrochem. 2018, 22, 3035–3047. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Song, L.; Feng, Y.; Cao, M.; Zhang, P.; Zhang, X.; Yao, J. Zinc Ion Trapping in Cellulose Hydrogel as Solid Electrolyte for Safe and Flexible Supercapacitor. J. Mater. Chem. A 2020, 8, 12314–12318. [Google Scholar] [CrossRef]

- Navarra, M.A.; Dal Bosco, C.; Moreno, J.S.; Vitucci, F.M.; Paolone, A.; Panero, S. Synthesis and Characterization of Cellulose-Based Hydrogels to Be Used as Gel Electrolytes. Membranes 2015, 5, 810–823. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Wu, J.; Qiu, J.; Zhang, K.; Shao, J.; Yan, L. In Situ Formation of a Renewable Cellulose Hydrogel Electrolyte for High-Performance Flexible All-Solid-State Asymmetric Supercapacitors. Sustain. Energy Fuels 2019, 3, 3109–3115. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, Q.; Zhang, Y.; Jia, L.; Xu, X. Promising and Reversible Electrolyte with Thermal Switching Behavior for Safer Electrochemical Storage Devices. ACS Appl. Mater. Interfaces 2018, 10, 7171–7179. [Google Scholar] [CrossRef]

- Gajewski, P.; Béguin, F. Hydrogel–Polymer Electrolyte for Electrochemical Capacitors with High Volumetric Energy and Life Span. ChemSusChem 2020, 13, 1876–1881. [Google Scholar] [CrossRef]

- Sannino, A.; Esposito, A.; De Rosa, A.; Cozzolino, A.; Ambrosio, L.; Nicolais, L. Biomedical Application of a Superabsorbent Hydrogel for Body Water Elimination in the Treatment of Edemas. J. Biomed. Mater. Res. Part A 2003, 67, 1016–1024. [Google Scholar] [CrossRef]

- Del Agua, I.; Marina, S.; Pitsalidis, C.; Mantione, D.; Ferro, M.; Iandolo, D.; Sanchez-Sanchez, A.; Malliaras, G.G.; Owens, R.M.; Mecerreyes, D. Conducting Polymer Scaffolds Based on Poly(3,4-Ethylenedioxythiophene) and Xanthan Gum for Live-Cell Monitoring. ACS Omega 2018, 3, 7424–7431. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mantione, D.; Del Agua, I.; Schaafsma, W.; Elmahmoudy, M.; Uguz, I.; Sanchez-Sanchez, A.; Sardon, H.; Castro, B.; Malliaras, G.G.; Mecerreyes, D. Low-Temperature Cross-Linking of PEDOT:PSS Films Using Divinylsulfone. ACS Appl. Mater. Interfaces 2017, 9, 18254–18262. [Google Scholar] [CrossRef] [PubMed]

- Ko, H.F.; Sfeir, C.; Kumta, P.N. Novel Synthesis Strategies for Natural Polymer and Composite Biomaterials as Potential Scaffolds for Tissue Engineering. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 1981–1997. [Google Scholar] [CrossRef] [PubMed]

- Alesanco, Y.; Palenzuela, J.; Viñuales, A.; Cabañero, G.; Grande, H.J.; Odriozola, I. Polyvinyl Alcohol-Borax Slime as Promising Polyelectrolyte for High-Performance, Easy-to-Make Electrochromic Devices. ChemElectroChem 2015, 2, 218–223. [Google Scholar] [CrossRef]

- Shimojo, A.A.M.; Pires, A.M.B.; Lichy, R.; Santana, M.H.A. The Performance of Crosslinking with Divinyl Sulfone as Controlled by the Interplay between the Chemical Modification and Conformation of Hyaluronic Acid. J. Braz. Chem. Soc. 2015, 26, 506–512. [Google Scholar] [CrossRef]

- Sannino, A.; Madaghiele, M.; Conversano, F.; Mele, G.; Maffezzoli, A.; Netti, P.A.; Ambrosio, L.; Nicolais, L. Cellulose Derivative-Hyaluronic Acid-Based Microporous Hydrogels Cross-Linked through Divinyl Sulfone (DVS) to Modulate Equilibrium Sorption Capacity and Network Stability. Biomacromolecules 2004, 5, 92–96. [Google Scholar] [CrossRef]

- Anbergen, U.; Oppermann, W. Elasticity and Swelling Behaviour of Chemically Crosslinked Cellulose Ethers in Aqueous Systems. Polymer 1990, 31, 1854–1858. [Google Scholar] [CrossRef]

- Orhan, B.; Ziba, C.A.; Morcali, M.H.; Dolaz, M. Synthesis of hydroxyethyl cellulose from industrial waste using microwave irradiation. Sustain. Environ. Res. 2018, 6, 403–411. [Google Scholar] [CrossRef]

- Sun, N.; Wang, T.; Yan, X. Synthesis and investigation of a self-assembled hydrogel based on hydroxyethyl cellulose and its in vivo ibuprofen drug release characteristics. RSC Adv. 2017, 7, 9600. [Google Scholar] [CrossRef] [Green Version]

- Astrini, N.; Anah, L.; Haryono, A. Crosslinking Parameter on the Preparation of Cellulose Based Hydrogel with Divynilsulfone. Procedia Chem. 2012, 4, 275–281. [Google Scholar] [CrossRef] [Green Version]

- Zuidema, J.M.; Rivet, C.J.; Gilbert, R.J.; Morrison, F.A. A Protocol for Rheological Characterization of Hydrogels for Tissue Engineering Strategies. J. Biomed. Mater. Res. Part B Appl. Biomater. 2014, 102, 1063–1073. [Google Scholar] [CrossRef] [PubMed]

- Bhosale, P.S.; Berg, J.C. Acoustic Spectroscopy of Colloids Dispersed in a Polymer Gel System. Langmuir 2010, 26, 14423–14426. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Xie, D.; Shi, F.; Wang, D.H.; Ge, X.; Xia, X.H.; Wang, X.L.; Gu, C.D.; Tu, J.P. Crystalline/amorphous tungsten oxide core/shell hierarchical structures and their synergistic effect for optical modulation. J. Colloid Interface Sci. 2015, 460, 200–208. [Google Scholar] [CrossRef] [PubMed]

- Hajzeri, M.; Colovic, M.; Vuk, A.S.; Posset, U.; Orel, B. Semi-Solid Gel Electrolytes for Electrochromic Devices. Mater Technol. 2011, 45, 433–438. [Google Scholar]

- Alesanco, Y.; Viñuales, A.; Ugalde, J.; Azaceta, E.; Cabañero, G.; Rodriguez, J.; Tena-Zaera, R. Consecutive anchoring of symmetric viologens: Electrochromic devices providing colorless to neutral-color switching. Sol. Energy Mater. Sol. Cells 2018, 177, 110–119. [Google Scholar] [CrossRef]

- Alesanco, Y.; Viñuales, A.; Cabañero, G.; Rodriguez, J.; Tena-Zaera, R. Colorless-to-Black/Gray Electrochromic Devices Based on a Single 1-Alkyl-1′-Aryl Asymmetric Viologen-Modified Monolayered Electrodes. Adv. Opt Mater. 2017, 5, 1600989. [Google Scholar] [CrossRef]

- Alesanco, Y.; Viñuales, A.; Rodriguez, J.; Tena-Zaera, R. All-in-One Gel-Based Electrochromic Devices: Strengths and Recent Developments. Materials 2018, 11, 414. [Google Scholar] [CrossRef] [Green Version]

- Alesanco, Y.; Viñuales, A.; Palenzuela, J.; Odriozola, I.; Cabañero, G.; Rodriguez, J.; Tena-Zaera, R. Multicolor Electrochromics: Rainbow-Like Devices. ACS Appl. Mater. Interfaces 2016, 8, 14795–14801. [Google Scholar] [CrossRef]

- Alesanco, Y.; Viñuales, A.; Cabañero, G.; Rodriguez, J.; Tena-Zaera, R. Colorless to Neutral Color Electrochromic Devices Based on Asymmetric Viologens. ACS Appl. Mater. Interfaces 2016, 8, 29619–29627. [Google Scholar] [CrossRef]

- Ledwon, P.; Andrade, J.R.; Lapkowski, M.; Pawlicka, A. Hydroxypropyl Cellulose-Based Gel Electrolyte for Electrochromic Devices. Electrochim. Acta 2015, 159, 227–233. [Google Scholar] [CrossRef]

- Lin, S.Y.; Chen, Y.C.; Wang, C.M.; Wen, C.Y.; Shih, T.Y. Study of MoO 3-NiO Complementary Electrochromic Devices Using a Gel Polymer Electrolyte. Solid State Ion. 2012, 212, 81–87. [Google Scholar] [CrossRef]

- Kiristi, M.; Bozduman, F.; Gulec, A.; Teke, E.; Oksuz, L.; Oksuz, A.U.; Deligöz, H. Complementary All Solid State Electrochromic Devices Using Carboxymethyl Cellulose Based Electrolytes. J. Macromol. Sci. Part A Pure Appl. Chem. 2014, 51, 481–487. [Google Scholar] [CrossRef]

- Ramos, A.M.; Pereira, S.; Cidade, M.T.; Pereira, G.; Branquinho, R.; Pereira, L.; Martins, R.; Fortunato, E. Preparation and Characterization of Cellulose Nanocomposite Hydrogels as Functional Electrolytes. Solid State Ion. 2013, 242, 26–32. [Google Scholar] [CrossRef]

- Ngamaroonchote, A.; Chotsuwan, C. Performance and Reliability of Cellulose Acetate-Based Gel Electrolyte for Electrochromic Devices. J. Appl. Electrochem. 2016, 46, 575–582. [Google Scholar] [CrossRef]

- Xiao, S.; Zhang, Y.; Ma, L.; Zhao, S.; Wu, N.; Xiao, D. Easy-to-Make Sulfonatoalkyl Viologen/Sodium Carboxymethylcellulose Hydrogel-Based Electrochromic Devices with High Coloration Efficiency, Fast Response and Excellent Cycling Stability. Dye. Pigment. 2020, 174. Ahead of Print. [Google Scholar] [CrossRef]

- Mortimer, R.J.; Varley, T.S. Quantification of Colour Stimuli through the Calculation of CIE Chromaticity Coordinates and Luminance Data for Application to in Situ Colorimetry Studies of Electrochromic Materials. Displays 2011, 32, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Mortimer, R.J.; Varley, T.S. In Situ Spectroelectrochemistry and Colour Measurement of a Complementary Electrochromic Device Based on Surface-Confined Prussian Blue and Aqueous Solution-Phase Methyl Viologen. Sol. Energy Mater. Sol. Cells 2012, 99, 213–220. [Google Scholar] [CrossRef] [Green Version]

- Mortimer, R.J.; Varley, T.S. Novel Color-Reinforcing Electrochromic Device Based on Surface-Confined Ruthenium Purple and Solution-Phase Methyl Viologen. Chem. Mater. 2011, 23, 4077–4082. [Google Scholar] [CrossRef]

- Yao, D.D.; Rani, R.A.; O’Mullane, A.P.; Zadeh, K.K.; Ou, J.Z. Enhanced Coloration Efficiency for Electrochromic Devices Based on Anodized Nb2O5/Electrodeposited MoO3 Binary Systems. J. Phys. Chem. C 2014, 118, 10867–10873. [Google Scholar] [CrossRef]

- Su, Y.; Yang, F.; Zhou, L.; Geng, Y.; Zhang, J.; Jiang, M. Flexible and Tailorable Alkylviologen/Cellulose Nanocrystals Composite Films for Sustainable Applications in Electrochromic Devices. ChemElectroChem 2018, 5, 1407–1414. [Google Scholar] [CrossRef]

- INNPAPER. Available online: https://innpaper.eu/ (accessed on 5 November 2020).

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for printing sensors and electronics over large flexible substrates: A review. IEEE Sens. J. 2015, 6, 3164–3185. [Google Scholar] [CrossRef]

- Mainar, A.R.; Iruin, E.; Colmenares, L.C.; Kvasha, A.; de Meatza, I.; Bengoechea, M.; Leonet, O.; Boyano, I.; Zhang, Z.; Blazquez, J.A. An Overview of Progress in Electrolytes for Secondary Zinc-Air Batteries and Other Storage Systems Based on Zinc. J. Energy Storage 2018, 15, 304–328. [Google Scholar] [CrossRef]

- Tang, B.; Shan, L.; Liang, S.; Zhou, J. Issues and Opportunities Facing Aqueous Zinc-Ion Batteries. Energy Environ. Sci. 2019, 12, 3288–3304. [Google Scholar] [CrossRef]

- Huang, S.; Zhu, J.; Tian, J.; Niu, Z. Recent Progress in the Electrolytes of Aqueous Zinc-Ion Batteries. Eur. J. Chem. 2019, 25, 14480–14494. [Google Scholar] [CrossRef]

| Cellulose-Based Hydrogels (CBH) ID | Carboxymethyl Cellulose (CMC) | Hydroxyethyl Cellulose (HEC) | Divinyl Sulfone (DVS) | KOH | Observation |

|---|---|---|---|---|---|

| Wt. % | Wt. % | Wt. % | mM | ||

| CBH-1 | 0 | 4 | 2 | 20 | Gelled, release of water |

| CBH-2 | 1 | 3 | Full gel formed, no release of water | ||

| CBH-3 | 2 | 2 | |||

| CBH-4 | 3 | 1 | |||

| CBH-5 | 4 | 0 | Not gelled |

| Gel ID | CMC | HEC | DVS | KOH | Gel Time | G′ | ξ | σ (mS/cm) | |

|---|---|---|---|---|---|---|---|---|---|

| wt. % | wt. % | wt. % | mM | min | Pa | nm | Gel | KOH sol. | |

| CBH-6 | 2 | 2 | 2 | 10 | 45 | 1100 | 15.52 | 5.2 | 0.82 |

| CBH-3 | 20 | 12 | 3100 | 10.99 | 4.7 | 1.63 | |||

| CBH-7 | 30 | 8.3 | 7300 | 8.26 | 5.8 | 2.41 | |||

| CBH-8 | 40 | 7.4 | 9100 | 7.67 | 6.0 | 3.25 | |||

| CBH-9 | 2 | 1 | 3 | 20 | 21 | 1100 | 15.52 | 5.0 | 1.63 |

| CBH-10 | 3 | 1 | 13 | 3500 | 10.55 | 3.3 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gomez, I.; Alesanco, Y.; Blázquez, J.A.; Viñuales, A.; Colmenares, L.C. Room-Temperature Self-Standing Cellulose-Based Hydrogel Electrolytes for Electrochemical Devices. Polymers 2020, 12, 2686. https://doi.org/10.3390/polym12112686

Gomez I, Alesanco Y, Blázquez JA, Viñuales A, Colmenares LC. Room-Temperature Self-Standing Cellulose-Based Hydrogel Electrolytes for Electrochemical Devices. Polymers. 2020; 12(11):2686. https://doi.org/10.3390/polym12112686

Chicago/Turabian StyleGomez, Iñaki, Yolanda Alesanco, Jose Alberto Blázquez, Ana Viñuales, and Luis C. Colmenares. 2020. "Room-Temperature Self-Standing Cellulose-Based Hydrogel Electrolytes for Electrochemical Devices" Polymers 12, no. 11: 2686. https://doi.org/10.3390/polym12112686