Investigation of Interface Thermal Resistance between Polymer and Mold Insert in Micro-Injection Molding by Non-Equilibrium Molecular Dynamics

Abstract

:1. Introduction

2. Materials and Methods

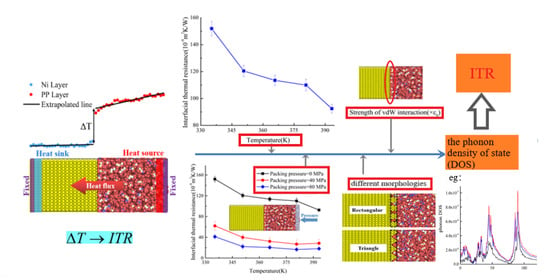

3. Results and Discussion

3.1. ITR at Different Temperatures

3.2. ITR with Different Packing Pressures

3.3. ITR Under Different Interface Morphologies

3.4. ITR with Different Interfacial Interactions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| The energy constant | |

| The distance constant | |

| Distance between the atom i and j | |

| Flux density | |

| The energy imposed on the system | |

| The cross-sectional area | |

| Temperature difference | |

| The interface thermal resistance |

References

- Yang, F.; Zhang, H.; Feng, H.; Dong, J.; Wang, C.; Liu, Q. Bionic SERS chip with super-hydrophobic and plasmonic micro/nano dual structure. Photonics Res. 2018, 6, 77–83. [Google Scholar] [CrossRef]

- Utko, P.; Persson, F.; Kristensen, A.; Larsen, N.B. Injection molded nanofluidic chips: Fabrication method and functional tests using single-molecule DNA experiments. Lab. Chip. 2011, 11, 303–308. [Google Scholar] [CrossRef]

- Ali, R.A.M.; Espulgar, W.V.; Aoki, W.; Jiang, S.; Saito, M.; Ueda, M.; Tamiya, E. One-step nanoimprinted hybrid micro-/nano-structure for in situ protein detection of isolated cell array via localized surface plasmon resonance. Jpn. J. Appl. Phys. 2018, 57, 03EC03. [Google Scholar] [CrossRef]

- Fan, P.; Zhong, M.; Bai, B.; Jin, G.; Zhang, H. Tuning the optical reflection property of metal surfaces via micro-nano particle structures fabricated by ultrafast laser. Appl. Surf. Sci. 2015, 359, 7–13. [Google Scholar] [CrossRef]

- Zhou, M.; Xiong, X.; Drummer, D.; Jiang, B. Molecular dynamics simulation and experimental investigation of the geometrical morphology development of injection-molded nanopillars on polymethylmethacrylate surface. Comput. Mater. Sci. 2018, 149, 208–216. [Google Scholar] [CrossRef]

- Weng, C.; Wang, F.; Zhou, M.; Yang, D.; Jiang, B. Fabrication of hierarchical polymer surfaces with superhydrophobicity by injection molding from nature and function-oriented design. Appl. Surf. Sci. 2018, 436, 224–233. [Google Scholar] [CrossRef]

- Dong, L.; Quan, X.-J.; Cheng, P. An experimental investigation of enhanced pool boiling heat transfer from surfaces with micro/nano-structures. Int. J. Heat Mass Transf. 2014, 71, 189–196. [Google Scholar] [CrossRef]

- Vasco, J.C.; Maia, J.; Pouzada, A. Thermo-rheological behaviour of polymer melts in microinjection moulding. J. Micromech. Microeng. 2009, 19, 105012. [Google Scholar] [CrossRef]

- Weng, C.; Bin Lee, R.; To, S.; Jiang, B.-Y. Numerical simulation of residual stress and birefringence in the precision injection molding of plastic microlens arrays. Int. Commun. Heat Mass Transf. 2009, 36, 213–219. [Google Scholar] [CrossRef]

- Somé, S.C.; Delaunay, D.; Faraj, J.; Bailleul, J.L.; Boyard, N.; Quilliet, S. Modeling of the thermal contact resistance time evolution at polymer-mold interface during injection molding: Effect of polymers’ solidification. Appl. Therm. Eng. 2015, 84, 150–157. [Google Scholar] [CrossRef]

- Hong, S.; Kang, J.; Yoon, K. Correlation between thermal contact resistance and filling behavior of a polymer melt into multiscale cavities in injection molding. Int. J. Heat Mass Transf. 2015, 87, 222–236. [Google Scholar] [CrossRef]

- Pina-Estany, J.; García-Granada, A.A. Molecular dynamics simulation method applied to nanocavities replication via injection moulding. Int. Commun. Heat Mass Transf. 2017, 87, 1–5. [Google Scholar] [CrossRef]

- Ju, S.; Liang, X.; Wang, S. Investigation of interfacial thermal resistance of bi-layer nanofilms by nonequilibrium molecular dynamics. J. Phys. D Appl. Phys. 2010, 43, 085407. [Google Scholar] [CrossRef]

- Rajabpour, A.; Allaei, S.M.V.; Kowsary, F. Interface thermal resistance and thermal rectification in hybrid graphene-graphane nanoribbons: A nonequilibrium molecular dynamics study. Appl. Phys. Lett. 2011, 99, 2011–2014. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, L.; Song, X.; Xi, T.; Zhao, Y.; Liu, J.; Yang, X.; Chen, M.; Yang, P. Investigation of thermal resistance for the graphene-Si interface by molecular dynamics. Int. J. Mater. Struct. Integr. 2012, 6, 65–73. [Google Scholar] [CrossRef]

- Barisik, M.; Beskok, A. Temperature dependence of thermal resistance at the water/silicon interface. Int. J. Therm. Sci. 2014, 77, 47–54. [Google Scholar] [CrossRef]

- Barisik, M.; Beskok, A. Interface thermal resistance between liquid water and various metallic surfaces. Int. J. Precis. Eng. Manuf. 2015, 16, 1341–1346. [Google Scholar]

- Luo, T.; Lloyd, J.R. Enhancement of thermal energy transport across graphene/graphite and polymer interfaces: A molecular dynamics study. Adv. Funct. Mater. 2012, 22, 2495–2502. [Google Scholar] [CrossRef]

- Zhang, J.; Hong, Y.; Liu, M.; Yue, Y.; Xiong, Q.; Lorenzini, G. Molecular dynamics simulation of the interfacial thermal resistance between phosphorene and silicon substrate. Int. J. Heat Mass Transf. 2017, 104, 871–877. [Google Scholar] [CrossRef]

- Hu, M.; Shenogin, S.; Keblinski, P. Molecular dynamics simulation of interfacial thermal conductance between silicon and amorphous polyethylene. Appl. Phys. Lett. 2007, 91, 128–131. [Google Scholar] [CrossRef]

- Zhai, Z.; Jiang, B.; Drummer, D. Temperature-dependent response of quasi-unidirectional E-glass fabric reinforced polypropylene composites under off-axis tensile loading. Compos. B Eng. 2018, 148, 180–187. [Google Scholar] [CrossRef]

- Yang, J.; Weng, C.; Lai, J.; Ding, T.; Wang, H. Molecular Dynamics Simulation on the Influences of Nanostructure Shape, Interfacial Adhesion Energy, and Mold Insert Material on the Demolding Process of Micro-Injection Molding. Polymers 2019, 11, 1573. [Google Scholar] [CrossRef] [Green Version]

- Termentzidis, K.; Barreteau, T.; Ni, Y.; Huedro, H.; Delaye, A.-L.; Zianni, X.; Chalopin, Y.; Chantrenne, P.; Volz, S. Thermal conductivity and Kapitza resistance of diameter modulated SiC nanowires, a molecular dynamics study. J. Phys. Conf. Ser. 2012, 395, 012107. [Google Scholar] [CrossRef]

- Bin Saleman, A.R.; Chilukoti, H.K.; Kikugawa, G.; Shibahara, M.; Ohara, T. A molecular dynamics study on the thermal transport properties and the structure of the solid–liquid interfaces between face centered cubic (FCC) crystal planes of gold in contact with linear alkane liquids. Int. J. Heat Mass Transf. 2017, 105, 168–179. [Google Scholar] [CrossRef]

- Wang, S.; Liang, X. Thermal conductivity and interfacial thermal resistance in bilayered nanofilms by nonequilibrium molecular dynamics simulations. Int. J. Thermophys. 2010, 31, 1935–1944. [Google Scholar] [CrossRef]

- Pei, Q.-X.; Zhang, Y.; Sha, Z.; Shenoy, V.B. Carbon isotope doping induced interfacial thermal resistance and thermal rectification in grapheme. Appl. Phys. Lett. 2012, 100, 1–5. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Zou, R.; Hu, N.; Ning, H.; Yan, C.; Liu, Y.; Wu, L.; Mo, F.; Fu, S. Enhancement of thermal energy transport across the graphene/h-BN heterostructure interface. Nanoscale 2019, 11, 3888–3895. [Google Scholar] [CrossRef] [PubMed]

- Swartz, E.T.; Pohl, R.O. Thermal boundary resistance. Rev. Mod. Phys. 1989, 61, 605–668. [Google Scholar] [CrossRef]

- Luo, T.; Lloyd, J.R. Molecular dynamics study of thermal transport in GaAs-self-assembly monolayer-GaAs junctions with ab initio characterization of thiol-GaAs bonds. J. Appl. Phys. 2011, 109, 034301. [Google Scholar] [CrossRef]

- Dickey, J.M.; Paskin, A. Computer Simulation of the Lattice Dynamics of Solids. Phys. Rev. 1969, 188, 1407–1418. [Google Scholar] [CrossRef]

- Zhu, L.-Y.; Wu, W.-Q.; Jiang, L.; Jiang, B.-Y. Research on Influencing Factors of the Thermal Contact Resistance in Thin-Wall Injection Molding. Int. Polym. Process. 2019, 34, 2–8. [Google Scholar] [CrossRef]

- Liu, C.; Wei, Z.; Chen, W.; Bi, K.; Yang, J.; Chen, Y. Pressure effects on the thermal resistance of few-layer grapheme. Phys. Lett. A 2016, 380, 248–254. [Google Scholar] [CrossRef]

| Atom Type | Energy Constant ε [eV] | Distance Constant σ [Å] |

|---|---|---|

| H | 0.038 | 2.450 |

| C | 0.039 | 3.875 |

| Ni | 11.983 | 2.282 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, C.; Li, J.; Lai, J.; Liu, J.; Wang, H. Investigation of Interface Thermal Resistance between Polymer and Mold Insert in Micro-Injection Molding by Non-Equilibrium Molecular Dynamics. Polymers 2020, 12, 2409. https://doi.org/10.3390/polym12102409

Weng C, Li J, Lai J, Liu J, Wang H. Investigation of Interface Thermal Resistance between Polymer and Mold Insert in Micro-Injection Molding by Non-Equilibrium Molecular Dynamics. Polymers. 2020; 12(10):2409. https://doi.org/10.3390/polym12102409

Chicago/Turabian StyleWeng, Can, Jiangwei Li, Jun Lai, Jiangwen Liu, and Hao Wang. 2020. "Investigation of Interface Thermal Resistance between Polymer and Mold Insert in Micro-Injection Molding by Non-Equilibrium Molecular Dynamics" Polymers 12, no. 10: 2409. https://doi.org/10.3390/polym12102409