Basic Research for Additive Manufacturing of Rubber

Abstract

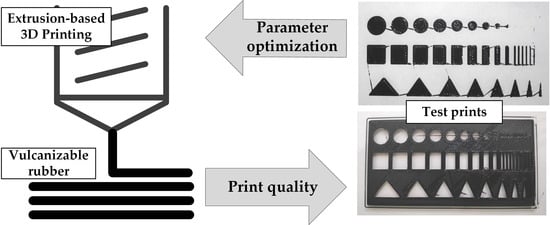

:1. Introduction

- a suitable method and process technology for processing and discharging the rubber material,

- supporting materials during the layer build-up, as well as

- material for stabilizing the shape during vulcanization.

2. Materials and Methods

2.1. Materials

2.2. Test Rig

- Open frame—for sufficient installation space and accessibility

- Few moving axes on the extruder side—the influence of the additional weight of the screw extruder on the dynamics of the printer should be reduced as far as possible

- Double extruder—this provides the possibility to build supporting structures made of other materials (for further research work)

- Possibilities of software modification—possibilities of making specific adaptations to the program sequences for rubber processing.

2.3. Experimental Tests

2.3.1. Material Processing

2.3.2. Identification of Printing Parameters

- Extrusion multiplier (flow rate)

- Extrusion width

- Traverse speed

- Layer height basic layer

- Layer height

- Nozzle temperature

- Temperature printing bed.

2.3.3. Print Quality

3. Results and Discussion

3.1. Material Processing

3.2. Identification of Printing Parameters

3.3. Print Quality

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting—Selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Smelov, V.G.; Sotov, A.V.; Murzin, S.P. Particularly selective sintering of metal powders by pulsed laser radiation. Key Eng. Mater. 2016, 685, 403–407. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct selective laser sintering and melting of ceramics: A review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Mokrane, A.; Boutaous, M.; Xin, S. Process of selective laser sintering of polymer powders: Modeling, simulation, and validation. C. R. Méc. 2018, 346, 1087–1103. [Google Scholar] [CrossRef]

- Singh, R.; Garg, H.K. Fused deposition modeling—A state of art review and future applications. Ref. Modul. Mater. Sci. Mater. Eng. 2016, 1–20. [Google Scholar] [CrossRef]

- Schmidleithner, C.; Kalaskar, D.M. Stereolithography. In 3D Printing; Intechopen: London, UK, 2018; pp. 3–22. [Google Scholar] [CrossRef] [Green Version]

- Sander, J.; Wei, S.; Pei, Z. Experimental investigation of stratasys J750 PolyJet printer: Effects of orientation and layer thickness on mechanical properties. In Proceedings of the International Mechanical Engineering Congress and Exposition IMECE, Salt Lake City, UT, USA, 12–14 November 2019. [Google Scholar] [CrossRef]

- Brandt, M. Laser Additive Manufacturing: Materials, Design, Technologies and Applications; Woodhead Publishing: Duxford, UK, 2017; pp. 439–450. [Google Scholar]

- Myer, K. Extrusion processes. In Applied Plastics Engineering Handbook; Processing and Materials, 1st ed.; Elsevier: Oxford, UK, 2011; pp. 227–266. [Google Scholar]

- Princi, E. Manufacturing and transformation technologies. In Rubber—Science and Technology, 1st ed.; Walter De Gruyter: Berlin, Germany, 2019; pp. 147–164. [Google Scholar]

- Röthemeyer, F.; Sommer, F. Verfahren zur Herstellung von Elastomerformteilen. In Kautschuk-Technologie Werkstoffe—Verarbeitung—Produkte, 3rd ed.; Hanser Verlag: Munich, Germany, 2013; pp. 823–921. [Google Scholar]

- Cohen, D.; Sargeant, M.; Somers, K. 3-D printing takes shape. McKinsey Q. 2014, 1, 1–6. [Google Scholar]

- Drobny, J.G. Elasticity and Elastomers. In Handbook of Thermoplastic Elastomers, 2nd ed.; Elsevier: Oxford, UK, 2014; pp. 1–11. [Google Scholar]

- ACEO® Technology. Available online: https://www.aceo3d.com/technology/ (accessed on 7 July 2020).

- Patel, D.K.; Sakhaei, A.M.; Layani, M.; Zhang, B.; Ge, Q.; Magdassi, S. Highly stretchable and UV curable elastomers for digital light processing based 3D printing. Adv. Mater. 2017, 29, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Scheungraber, P. Apparatus and Method for 3D Printing a Workpiece of a Rubbery Non-Thermoplastic. Material. Patent No. DE102017207737A1, 8 November 2018. [Google Scholar]

- Faes, M.; Valkenaers, H.; Vogeler, F.; Vleugels, J.; Ferraris, E. Extrusion-Based 3D printing of ceramic components. Procedia CIRP 2015, 28, 76–81. [Google Scholar] [CrossRef] [Green Version]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Placone, J.K.; Engler, A.J. Recent advances in extrusion-based 3D printing for biomedical applications. Adv. Healthc. Mater. 2018, 7, 1701161. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Taylor, S.L.; Ibeh, A.J.; Jakus, A.E.; Shah, R.N.; Dunand, D.C. NiTi-Nb micro-trusses fabricated via extrusion-based 3D-printing of powders and transient-liquid-phase sintering. Acta Biomater. 2018, 76, 359–370. [Google Scholar] [CrossRef] [PubMed]

- Pitayachaval, P.; Sanklong, N.; Thongrak, A. A review of 3D food printing technology. Matec Web Conf. 2018, 213, 1–5. [Google Scholar] [CrossRef] [Green Version]

- KRAIBURG. Available online: https://www.kraiburg.de/ (accessed on 7 July 2020).

- MAKERGEAR M3-ID 3D Printer. Available online: https://www.makergear.com/products/m3-id (accessed on 7 July 2020).

- PELLET EXTRUDER. Available online: https://mahor.xyz/ (accessed on 7 July 2020).

- SIMPLIFY3D. Available online: https://www.simplify3d.com/ (accessed on 31 July 2020).

- Domm, M. Printing of three-dimensional polymer composite structures with continuous fiber reinforcement. In Structure and Properties of Additive Manufactured Polymer Components; Part 2; Elsevier: Amsterdam, The Netherlands, 2020; pp. 333–358. [Google Scholar] [CrossRef]

- TESTPRINTS. Available online: https://all3dp.com/2/3d-printer-test-print-10-best-3d-models-to-torture-your-3d-printer/ (accessed on 7 July 2020).

- Accuracy of FDM Printing. Available online: https://www.3dhubs.com/knowledge-base/dimensional-accuracy-3d-printed-parts/#fdm (accessed on 31 July 2020).

| Natural Rubber (NR) | Ethylene-Propylene-Diene Rubber (EPDM) | Nitrile-Butadiene Rubber (NBR) | |

|---|---|---|---|

| Mooney viscosity (ML1 + 4; 100 °C) | 57 | 112 | 37 |

| Vulcanization Conditions Dumbbell specimen S2 (10 min) | 160 °C | 170 °C | 170 °C |

| Parameters | Basic Value | Parameter Variation |

|---|---|---|

| Traverse speed | 40 mm/s | 20 mm/s, 60 mm/s |

| Nozzle diameter | 0.4 mm | 0.8 mm |

| Number of layers | Basic layer + 1 layer | Basic layer + 5 layers |

| Nozzle Diameter. | Measured Diameter | Mean Value | Increase to Nozzle Diameter | |

|---|---|---|---|---|

| Min | Max | |||

| (mm) | (mm) | (mm) | (mm) | (%) |

| 0.25 | 0.33 | 0.34 | 0.334 | 34 |

| 0.3 | 0.36 | 0.37 | 0.364 | 21 |

| 0.4 | 0.52 | 0.54 | 0.524 | 31 |

| 0.5 | 0.64 | 0.67 | 0.654 | 31 |

| 0.6 | 0.73 | 0.77 | 0.746 | 24 |

| 0.8 | 0.94 | 0.95 | 0.948 | 19 |

| 1 | 1.2 | 1.22 | 1.212 | 21 |

| 1.5 | 1.81 | 1.82 | 1.816 | 21 |

| NBR | Polylactide (PLA) (Default Values of the Software [26]) | |

|---|---|---|

| Extrusion multiplier | 5.0 | 0.9 |

| Extrusion width | Results from Table 3 | Nozzle diameter + 20% |

| Traverse speed | 40 mm/s | 40 mm/s |

| Layer height basic layer | 20% Nozzle diameter | 90% Nozzle diameter |

| Layer height | 50% Nozzle diameter | 50% Nozzle diameter |

| Temperature pressure bed | 50 °C | 60 °C |

| Printing surface | Glass | Glass |

| Parameters | Effects on Printing |

|---|---|

| Decreased traverse speed 20 mm/s | The lower traverse speed caused worse results compared to the base value (40 mm/s). A good basic layer could be produced. However, in the subsequent layer, deviations in the contours occurred more frequently when the contour direction was changed. This could not be noticed with the base value. The reason for this could be that a minimum discharge speed from the nozzle is required for a good layer-on-layer adhesion with rubber. Therefore, if a strand is placed on another strand with less pressure, the adhesion will be reduced and the strands will tilt or shift. |

| Increased traverse speed 60 mm/s | The higher traverse speed caused a worse result than the base value (40 mm/s). A higher traverse speed also leads to a higher material transport in the screw. However, this leads to a steady blocking of the screw and thus to reduced material discharge and strand interruptions. The reason for this is assumed to be that the material feed into the screw could not be heated up fast enough in the extruder to the nozzle outlet. As a result, the viscosity is not lowered far enough for further transport in the screw. A solution is to extend the screw length and thus the temperature control zone. It would also be possible to increase the drive power of the screw extruder or to heat the rubber before feeding it into the screw. |

| Increased extrusion width 0.8 mm | For the nozzle diameter of 0.8 mm, both the basic layer height of 0.2 mm and the layer height of 0.4 mm (the half nozzle diameter) were tested. As expected, the smaller geometric shapes were not manufactured as precisely. Furthermore, with the layer height of 0.4 mm the same problem occurred as observed with increasing the traversing speed. The screw extruder was not able to process the increased rubber quantity. |

| Basic layer + 5 layers | The printing of the basic layer and the first layer showed a visually good result. From layer 2 on, first deviations occurred, which increased significantly from layer to layer: The smaller the dimensions of the geometric form, the greater the deviations. As an example, Figure 5 shows the manufactured shapes. Further research should investigate whether modified nozzle geometries produce better results. In general, the viscous material has to be supplemented by another, all-round supporting material to produce higher structures. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drossel, W.-G.; Ihlemann, J.; Landgraf, R.; Oelsch, E.; Schmidt, M. Basic Research for Additive Manufacturing of Rubber. Polymers 2020, 12, 2266. https://doi.org/10.3390/polym12102266

Drossel W-G, Ihlemann J, Landgraf R, Oelsch E, Schmidt M. Basic Research for Additive Manufacturing of Rubber. Polymers. 2020; 12(10):2266. https://doi.org/10.3390/polym12102266

Chicago/Turabian StyleDrossel, Welf-Guntram, Jörn Ihlemann, Ralf Landgraf, Erik Oelsch, and Marek Schmidt. 2020. "Basic Research for Additive Manufacturing of Rubber" Polymers 12, no. 10: 2266. https://doi.org/10.3390/polym12102266