Influence of Accelerated Weathering on the Mechanical, Fracture Morphology, Thermal Stability, Contact Angle, and Water Absorption Properties of Natural Fiber Fabric-Based Epoxy Hybrid Composites

Abstract

:1. Introduction

2. Materials and Methods

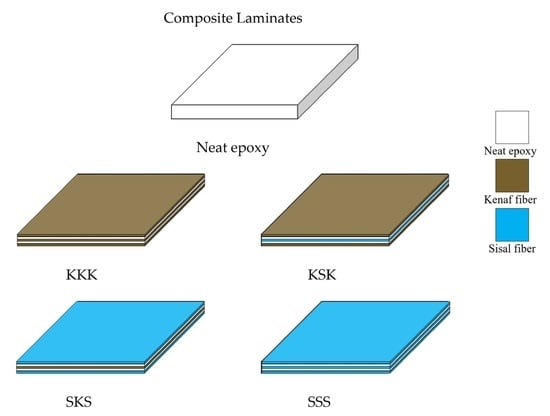

2.1. Composite Manufacturing

2.2. Accelerated Weathering

2.3. Characterization

3. Results and Discussion

3.1. Mechanical Properties

3.2. Thermal Studies

3.3. Contact Angle Measurement

3.4. Water Absorption Behavior

3.5. Dynamic Mechanical Analysis (DMA)

- E′G = storage modulus at the glassy state (at 35 °C)

- E′R = storage modulus at the rubbery state (at 120 °C).

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Y.; Guo, Y.; Zhao, J.; Chen, X.; Zhang, H.; Hu, G.; Yu, X.; Zhang, Z. Carbon fiber reinforced shape memory epoxy composites with superior mechanical performances. Compos. Sci. Technol. 2019, 177, 49–56. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, Y.; Liu, J.; Zhao, J.; Zhang, H.; Zhang, Z. Shape memory epoxy composites with high mechanical performance manufactured by multi-material direct ink writing. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105903. [Google Scholar] [CrossRef]

- Altuna, F.; Hoppe, C.; Williams, R. Shape memory epoxy vitrimers based on DGEBA crosslinked with dicarboxylic acids and their blends with citric acid. RSC Adv. 2016, 6, 88647–88655. [Google Scholar] [CrossRef] [Green Version]

- Meng, Q.; Zhao, Y.; Liu, Z.; Han, S.; Lu, S.; Liu, T.M. Flexible strain sensors based on epoxy/graphene composite film with long molecular weight curing agents. J. Appl. Polym. Sci. 2019, 136, 47906. [Google Scholar] [CrossRef]

- Huang, J.; Nie, X. A simple and novel method to design flexible and transparent epoxy resin with tunable mechanical properties. Polym. Int. 2016, 65, 835–840. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Calabrese, E.; Barra, G.; Raimondo, M.; Sorrentino, A.; Binder, W.H.; Michael, P.; Rana, S. Self-healing epoxy nanocomposites via reversible hydrogen bonding. Compos. Part B Eng. 2019, 157, 1–13. [Google Scholar] [CrossRef]

- Yuan, D.; Bonab, V.S.; Patel, A.; Manas-Zloczower, I. Self-healing epoxy coatings with enhanced properties and facile processability. Polymer 2018, 147, 196–201. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Hameed, N.; Pionteck, J.; Woo, E.M. Handbook of Epoxy Blends; Springer International Publishing: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, mechanical and thermal properties of green composites reinforced with natural fibers waste. Polymers 2020, 12, 654. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Hassan, E.; Memon, H.; Elagib, T.; Abad AllaIdris, F. Characterization of natural composites fabricated from Abutilon-fiber-reinforced Poly (Lactic Acid). Processes 2019, 7, 583. [Google Scholar] [CrossRef] [Green Version]

- Prasad, S.V.N.B.; Kumar, G.A.; Sai, K.V.P.; Nagarjuna, B. Design and optimization of natural fibre reinforced epoxy composites for automobile application. In Proceedings of the AIP Conference, Bannari Amman Institute of Technology, Sathyamangalam, Tamil Nadu, India, 8–9 March 2019; p. 020016. [Google Scholar] [CrossRef]

- Benzarti, K.; Chlela, R.; Quiertant, M.; Zombre, W.; Curtil, L. Durability of flax/bio-epoxy composites intended for structural strengthening. In Proceedings of the MATEC Web of Conference, Cape Town, South Africa, 19–21 November 2018; Volume 37, pp. 420–425. [Google Scholar] [CrossRef]

- Kumar, G.R.; Hariharan, V.; Saravanakumar, S.S. Enhancing the free vibration characteristics of epoxy polymers using sustainable phoenix sp. fibers and nano-clay for machine tool applications. J. Nat. Fibers 2019, 1636740, 1–8. [Google Scholar] [CrossRef]

- Garcia Filho, F.D.C.; Oliveira, M.S.; Pereira, A.C.; Nascimento, L.F.C.; Matheus, J.R.G.; Monteiro, S.N. Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition. J. Mater. Res. Technol. 2020, 9, 1734–1741. [Google Scholar] [CrossRef]

- Giridharan, R. Preparation and property evaluation of Glass/Ramie fibers reinforced epoxy hybrid composites. Compos. Part B Eng. 2019, 167, 342–345. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvalho, J.P.R.G.; Vieira, C.M.F.; Lopes, F.P.D.; Simonassi, N.T.; da Luz, F.S.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2020, 9, 1296–1304. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Compressive characteristics of unmodified and nanoclay treated banana fiber reinforced epoxy composite cylinders. Compos. Part B Eng. 2019, 169, 118–125. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and dynamic mechanical properties of bamboo/woven kenaf mat reinforced epoxy hybrid composites. Compos. Part B Eng. 2019, 163, 165–174. [Google Scholar] [CrossRef]

- Khan, A.; Asiri, A.M.; Jawaid, M.; Saba, N.; Inamuddin. Effect of cellulose nano fibers and nano clays on the mechanical, morphological, thermal and dynamic mechanical performance of kenaf/epoxy composites. Carbohydr. Polym. 2020, 239, 116248. [Google Scholar] [CrossRef]

- Mostafa, N.H. Tensile and fatigue properties of Jute-Glass hybrid fibre reinforced epoxy composites. Mater. Res. Express 2019, 6, 085102. [Google Scholar] [CrossRef]

- Saba, N.; Alothman, O.Y.; Almutairi, Z.; Jawaid, M. Magnesium hydroxide reinforced kenaf fibers/epoxy hybrid composites: Mechanical and thermomechanical properties. Constr. Build. Mater. 2019, 201, 138–148. [Google Scholar] [CrossRef]

- Kashyap, S.; Nath, D.; Das, D. Characterization, weathering and modeling of natural fibre based composites. Mater. Today Proc. 2020, 26, 963–971. [Google Scholar] [CrossRef]

- Pulikkalparambil, H.; Rangappa, S.M.; Krishnasamy, S.; Radoor, S.; Hameed, N.; Siengchin, S.; Parameswaranpillai, J. Accelerated weathering studies of bioepoxy/ionic liquid blends: Influence on physical, thermo-mechanical, morphology and surface properties. Mater. Res. Express 2020, 7, 025302. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Accelerated weathering and soil burial effects on colour, biodegradability and thermal properties of bamboo/kenaf/epoxy hybrid composites. Polym. Test. 2019, 79, 106054. [Google Scholar] [CrossRef]

- Yorseng, K.; Rangappa, S.M.; Pulikkalparambil, H.; Siengchin, S.; Parameswaranpillai, J. Accelerated weathering studies of kenaf/sisal fiber fabric reinforced fully biobased hybrid bioepoxy composites for semi-structural applications: Morphology, thermo-mechanical, water absorption behavior and surface hydrophobicity. Constr. Build. Mater. 2020, 235, 117464. [Google Scholar] [CrossRef]

- Kanchanomai, C.; Thammaruechuc, A. Effects of stress ratio on fatigue crack growth of thermoset epoxy resin. Polym. Degrad. Stab. 2009, 94, 1772–1778. [Google Scholar] [CrossRef]

- Liu, X.Y. Surface modification and micromechanical properties of jute fiber mat reinforced polypropylene composites. Express Polym. Lett. 2007, 1, 299–307. [Google Scholar] [CrossRef]

- Parbin, S.; Waghmare, N.K.; Singh, S.K.; Khan, S. Mechanical properties of natural fiber reinforced epoxy composites: A review. Procedia Comput. Sci. 2019, 152, 375–379. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Naveen, J. Void content, tensile, vibration and acoustic properties of kenaf/bamboo fiber reinforced epoxy hybrid composites. Materials 2019, 12, 2094. [Google Scholar] [CrossRef] [Green Version]

- Jawaid, M.; Saba, N.; Alothman, O.Y.; Tahir, P.M. Effect of accelerated environmental aging on tensile properties of oil palm/jute hybrid composites. In Proceedings of the AIP Conference, New York, NY, USA, 30 November 2016; Volume 1787, p. 040007. [Google Scholar] [CrossRef]

- Chang, L.N.; Chow, W.S. Accelerated weathering on glass fiber/epoxy/organo-montmorillonite nanocomposites. J. Compos. Mater. 2010, 44, 1421–1434. [Google Scholar] [CrossRef]

- Sogancioglu, M.; Yel, E.; Ahmetli, G. Behaviour of waste polypropylene pyrolysis char-based epoxy composite materials. Environ. Sci. Pollut. Res. 2020, 27, 3871–3884. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Senthamaraikannan, P.; Kathiresan, M.; Balaji, S.; Yogesha, B. The hybrid effect of Jute/Kenaf/E-glass woven fabric epoxy composites for medium load applications: Impact, inter-laminar strength, and failure surface characterization. J. Nat. Fibers 2018, 16, 600–612. [Google Scholar] [CrossRef]

- Liu, M.; Guo, B.; Du, M.; Lei, Y.; Jia, D. Natural inorganic nanotubes reinforced epoxy resin nanocomposites. J. Polym. Res. 2008, 15, 205–212. [Google Scholar] [CrossRef]

- Nuruddin, M.; Hosur, M.; Mahdi, T.; Jeelani, S. Flexural, viscoelastic and thermal properties of epoxy polymer composites modified with cellulose nanofibers extracted from wheat straw. Sens. Transducers 2017, 210, 1–8. [Google Scholar]

- Khan, Z.I.; Arsad, A.; Mohamad, Z.; Habib, U.; Zaini, M.A.A. Comparative study on the enhancement of thermo-mechanical properties of carbon fiber and glass fiber reinforced epoxy composites. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Rathod, V.T.; Kumar, J.S.; Jain, A. Polymer and ceramic nanocomposites for aerospace applications. Appl. Nanosci. 2017, 7, 519–548. [Google Scholar] [CrossRef]

- Puliyalil, H.; Filipič, G.; Cvelbar, U. Selective plasma etching of polymers and polymer matrix composites. In Non-Thermal Plasma Technology for Polymeric Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 241–259. [Google Scholar] [CrossRef]

- Gladunova, O.I.; Fedorova, Y.E.; Astashkina, O.V.; Lisenko, A.A. Composites with hydrophobic surfaces. Fibre Chem. 2015, 47, 317–319. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Mechanical properties and water absorption behaviour of recycled cellulose fibre reinforced epoxy composites. Polym. Test. 2012, 31, 620–628. [Google Scholar] [CrossRef]

- Muñoz, E.; García-Manrique, J.A. Water Absorption Behaviour and Its Effect on the Mechanical Properties of Flax Fibre Reinforced Bioepoxy Composites. Int. J. Polym. Sci. 2015, 2015, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Goertzen, W.K.; Kessler, M.R. Dynamic mechanical analysis of carbon/epoxy composites for structural pipeline repair. Compos. Part B Eng. 2007, 38, 1–9. [Google Scholar] [CrossRef]

- Ornaghi, H.L., Jr.; Neves, R.M.; Monticeli, F.M.; Almeida, J.H.S., Jr. Viscoelastic characteristics of carbon fiber-reinforced epoxy filament wound laminates. Compos. Commun. 2020, 21, 100418. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R. Thermoplastic composites for fused deposition modeling filament: Challenges and applications. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

| Composites | Tensile Strength (MPa) | Elongation at Break (%) | Tensile Modulus (MPa) | Impact Strength KJ/m2 |

|---|---|---|---|---|

| Neat | 44.68 ± 4.00 | 3.69 ± 0.41 | 1463.8 ± 61.5 | 28.12 ± 5.02 |

| KKK | 37.00 ± 1.16 | 2.60 ± 0.12 | 1390.0 ± 61.9 | 9.32 ± 1.72 |

| KSK | 39.33 ± 0.62 | 2.43 ± 0.14 | 1588.4 ± 42.3 | 9.39 ± 0.9 |

| SKS | 37.25 ± 2.98 | 2.33 ± 0.11 | 1647.0 ± 36.3 | 11.11 ± 1.53 |

| SSS | 37.15 ± 0.86 | 2.17 ± 0.10 | 1561.5 ± 68.2 | 10.14 ± 1.11 |

| Neat (W) | 37.37 ± 4.08 | 2.12 ± 0.10 | 1571.5 ± 66.0 | 7.30 ± 0.67 |

| KKK (W) | 33.51 ± 3.33 | 2.07 ± 0.10 | 1514.2 ± 68.9 | 8.97 ± 0.79 |

| KSK (W) | 35.34 ± 2.30 | 2.06 ± 0.18 | 1586.3 ± 73.4 | 8.30 ± 0.88 |

| SKS (W) | 37.47 ± 2.80 | 2.03 ± 0.03 | 1632.6 ± 46.1 | 11.03 ± 1.91 |

| SSS (W) | 33.86 ± 2.79 | 2.02 ± 0.13 | 1614.2 ± 60.3 | 8.72 ± 1.25 |

| Composites | (Ton) | (Tmax) | (Tf) | Char Residue (700 °C) |

|---|---|---|---|---|

| Neat | 326.74 | 362.33 | 395.47 | 7.17 |

| KKK | 329.03 | 359.50 | 392.89 | 11.27 |

| KSK | 329.76 | 361.00 | 391.30 | 11.12 |

| SKS | 328.97 | 356.33 | 391.45 | 11.83 |

| SSS | 331.42 | 359.83 | 393.92 | 11.43 |

| Neat (W) | 326.02 | 360.50 | 395.53 | 5.24 |

| KKK (W) | 325.91 | 356.50 | 395.59 | 12.57 |

| KSK (W) | 328.50 | 358.17 | 397.13 | 12.03 |

| SKS (W) | 325.53 | 356.17 | 396.14 | 13.12 |

| SSS (W) | 327.10 | 358.00 | 395.17 | 11.67 |

| Samples | C |

|---|---|

| Neat epoxy | 1 |

| SKS | 0.35 |

| Neat epoxy (W) | 1 |

| SKS (W) | 0.38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yorseng, K.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Influence of Accelerated Weathering on the Mechanical, Fracture Morphology, Thermal Stability, Contact Angle, and Water Absorption Properties of Natural Fiber Fabric-Based Epoxy Hybrid Composites. Polymers 2020, 12, 2254. https://doi.org/10.3390/polym12102254

Yorseng K, Mavinkere Rangappa S, Parameswaranpillai J, Siengchin S. Influence of Accelerated Weathering on the Mechanical, Fracture Morphology, Thermal Stability, Contact Angle, and Water Absorption Properties of Natural Fiber Fabric-Based Epoxy Hybrid Composites. Polymers. 2020; 12(10):2254. https://doi.org/10.3390/polym12102254

Chicago/Turabian StyleYorseng, Krittirash, Sanjay Mavinkere Rangappa, Jyotishkumar Parameswaranpillai, and Suchart Siengchin. 2020. "Influence of Accelerated Weathering on the Mechanical, Fracture Morphology, Thermal Stability, Contact Angle, and Water Absorption Properties of Natural Fiber Fabric-Based Epoxy Hybrid Composites" Polymers 12, no. 10: 2254. https://doi.org/10.3390/polym12102254