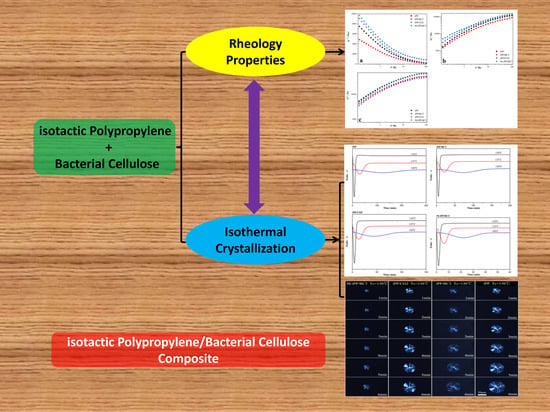

Isothermal Crystallization and Rheology Properties of Isotactic Polypropylene/Bacterial Cellulose Composite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstock

2.2. Preparation of CO

2.3. Preparation of iPP/BC Composites

2.4. Rheological Properties Test

2.5. Differential Scanning Calorimeter (DSC)

2.6. Polarized Optical Microscope (POM)

3. Result and Discussion

3.1. Rheological Properties of the iPP/BC Composites

3.2. Isothermal Crystallization Kinetics of the iPP/BC Composites

3.3. Spherulite Growth Rate of the iPP/BC Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thakur, V.K.; Vennerberg, D.; Kessler, M.R. Green aqueous surface modification of polypropylene for novel polymer nanocomposites. ACS Appl. Mater. Interfaces 2014, 6, 9349–9356. [Google Scholar] [CrossRef] [PubMed]

- Michalska-Pożoga, I.; Rydzkowski, T.; Mazur, P.; Sadowska, O.; Thakur, V.K. A study on the thermodynamic changes in the mixture of polypropylene (pp) with varying contents of technological and post-user recyclates for sustainable nanocomposites. Vacuum 2017, 146, 641–648. [Google Scholar]

- Trache, D.; Hussin, M.H.; Haafiz, M.K.; Thakur, V.K. Recent progress in cellulose nanocrystals: Sources and production. Nanoscale 2017, 9, 1763–1786. [Google Scholar] [CrossRef] [PubMed]

- Kang, G.B.; Kim, M.H.; Son, Y.; Park, O.O. Extrusion coating performances of iPP/LDPE blends. J. Appl. Polym. Sci. 2010, 111, 3121–3127. [Google Scholar] [CrossRef]

- Pang, Y.; Dong, X.; Zhao, Y.; Han, C.C.; Wang, D. Time evolution of phase structure and corresponding mechanical properties of iPP/PEOc blends in the late-stage phase separation and crystallization. Polymer 2007, 48, 6395–6403. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, F.; Endo, T.; Hirotsu, T. Preparation and characteristics of composites of high-crystalline cellulose with polypropylene: Effects of maleated polypropylene and cellulose content. J. Appl. Polym. Sci. 2003, 87, 337–345. [Google Scholar] [CrossRef]

- Nagaoka, T.; Ishiaku, U.S.; Tomari, T.; Hamada, H.; Takashima, S. Effect of molding parameters on the properties of PP/PP sandwich injection moldings. Polym. Test. 2005, 24, 1062–1070. [Google Scholar] [CrossRef]

- Thio, Y.S.; Argon, A.S.; Cohen, R.E.; Weinberg, M. Toughening of isotactic polypropylene with CaCO3 particles. Polymer 2002, 43, 3661–3674. [Google Scholar] [CrossRef]

- Garcia, M.; Vliet, G.V.; Jain, S.; Schrauwen, B.A.G.; Sarkissov, A.; Zyl, W.E.V.; Boukamp, B. Polypropylene/SiO2 nanocomposites with improved mechanical properties. Rev. Adv. Materi. Sci. 2004, 6, 169–175. [Google Scholar]

- Beuguel, Q.; Ville, J.; Crepin-Leblond, J.; Mederic, P.; Aubry, T. Influence of formulation on morphology and rheology of polypropylene/polyamide blends filled with nanoclay mineral particles. Appl. Clay Sci. 2017, 147. [Google Scholar] [CrossRef]

- Zeng, F.; Peng, H.; Chen, J.; Kang, J.; Yang, F.; Cao, Y.; Xiang, M. Investigation on the crystallization behavior and morphology of β-nucleated isotactic polypropylene/glass fiber composites. Soft Mater. 2017, 15, 229–240. [Google Scholar] [CrossRef]

- Wang, V.; Chen, C.C. Interfacial strength of PTFE fiber/i-PP composites with transcrystalline layers of different thickness. Polym. Compos. 2010, 23, 104–109. [Google Scholar] [CrossRef]

- Couto, E.; Tan, I.H.; Demarquette, N.; Caraschi, J.C.; Leão, A. Oxygen plasma treatment of sisal fibers and polypropylene: Effects on mechanical properties of composites. Polym. Eng. Sci. 2002, 42, 790–797. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, S.M.; Anwer, T.; Jawaid, M.; Hoque, M.E. Natural fiber reinforced conductive polymer composites as functional materials: A review. Synth. Met. 2015, 206, 42–54. [Google Scholar] [CrossRef]

- Koivuranta, E.; Hietala, M.; Ämmälä, A.; Oksman, K.; Illikainen, M. Improved durability of lignocellulose-polypropylene composites manufactured using twin-screw extrusion. Compos. Part A 2017, 101, 265–272. [Google Scholar] [CrossRef]

- Wang, L.; Gardner, D.J.; Bousfield, D.W. Cellulose nanofibril–reinforced polypropylene composites for material extrusion: Rheological properties. Polym. Eng. Sci. 2017, 58, 793–801. [Google Scholar] [CrossRef]

- Qi, G.X.; Luo, M.T.; Huang, C.; Guo, H.J.; Chen, X.F.; Xiong, L.; Wang, B.; Lin, X.Q.; Peng, F.; Chen, X.D. Comparison of bacterial cellulose production by Gluconacetobacter xylinus on bagasse acid and enzymatic hydrolysates. J. Appl. Polym. Sci. 2017, 134, 45066. [Google Scholar] [CrossRef]

- Huang, C.; Yang, X.Y.; Xiong, L.; Guo, H.J.; Luo, J.; Wang, B.; Zhang, H.R.; Lin, X.Q.; Chen, X.D. Utilization of corncob acid hydrolysate for bacterial cellulose production by Gluconacetobacter xylinus. Appl. Biochem. Biotechnol. 2015, 175, 1678–1688. [Google Scholar] [CrossRef] [PubMed]

- Shoda, M.; Sugano, Y. Recent advances in bacterial cellulose production. Biotechnol. Bioproc. Eng. 2005, 10, 1–8. [Google Scholar] [CrossRef]

- Cai, X.; Riedl, B.; Ait-Kadi, A. Cellulose fiber/poly(ethylene-co-methacrylic acid) composites with ionic interphase. Compos. Part A 2003, 34, 1075–1084. [Google Scholar] [CrossRef]

- Canché-Escamilla, G.; Rodriguez-Laviada, J.; Cauich-Cupul, J.I.; Mendizábal, E.; Puig, J.E.; Herrera-Franco, P.J. Flexural, impact and compressive properties of a rigid-thermoplastic matrix/cellulose fiber reinforced composites. Compos. Part A 2002, 33, 539–549. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Dufresne, A.; Gandini, A. Modification of cellulose fibers with functionalized silanes: Effect of the fiber treatment on the mechanical performances of cellulose–thermoset composites. J. Appl. Polym. Sci. 2010, 98, 974–984. [Google Scholar] [CrossRef]

- Antova, G.; Vasvasova, P.; Zlatanov, M. Studies upon the synthesis of cellulose stearate under microwave heating. Carbohydr. Polym. 2004, 57, 131–134. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, W.T.; Wang, X.L.; Li, B.; Wang, Y.Z. Green synthesis of a novel biodegradable copolymer base on cellulose and poly(-dioxanone) in ionic liquid. Carbohydr. Polym. 2009, 76, 139–144. [Google Scholar] [CrossRef]

- Phisalaphong, M.; Jatupaiboon, N. Biosynthesis and characterization of bacteria cellulose–chitosan film. Carbohydr. Polym. 2008, 74, 482–488. [Google Scholar] [CrossRef]

- Girones, J.; Vo, L.T.T.; Haudin, J.M.; Freire, L.; Navard, P.; Girones, J.; Vo, L.T.T.; Haudin, J.M.; Freire, L.; Navard, P. Crystallization of polypropylene in the presence of biomass-based fillers of different compositions. Polymer 2017, 127, 220–231. [Google Scholar] [CrossRef]

- Wang, B.; Yang, D.; Zhang, H.R.; Huang, C.; Xiong, L.; Luo, J.; Chen, X.D. Preparation of esterified bacterial cellulose for improved mechanical properties and the microstructure of isotactic polypropylene/bacterial cellulose composites. Polymers 2016, 8, 129. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, H.R.; Huang, C.; Xiong, L.; Luo, J.; Chen, X.D. Mechanical and rheological properties of isotactic polypropylene/bacterial cellulose composites. Polymer (Korea) 2017, 41, 460–464. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, F.B.; Wu, K.C.; Wang, J.C. Shear rheology and melt compounding of compatibilized-polypropylene nanocomposites: Effect of compatibilizer molecular weight. Polym. Eng. Sci. 2006, 46, 289–302. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, H.R.; Huang, C.; Xiong, L.; Luo, J.; Chen, X.D. Study on non-isothermal crystallization behavior of isotactic polypropylene/bacterial cellulose composites. RSC Adv. 2017, 7, 42113–42122. [Google Scholar] [CrossRef] [Green Version]

- Souza, A.M.; Demarquette, N.R. Influence of composition on the linear viscoelastic behavior and morphology of PP/HDPE blends. Polymer 2002, 43, 1313–1321. [Google Scholar] [CrossRef]

- Cui, L.; Zhou, Z.; Zhang, Y.; Zhang, Y.; Zhang, X.; Zhou, W. Rheological behavior of polypropylene/novolac blends. J. Appl. Polym. Sci. 2010, 106, 811–816. [Google Scholar] [CrossRef]

- Han, C.D. Rheology and Processing of Polymeric Materials; Oxford University Press: New York, NY, USA, 2007. [Google Scholar]

- Wei, Z.; Chen, G.; Shi, Y.; Song, P.; Zhan, M.; Zhang, W. Isothermal crystallization and mechanical properties of poly(butylene succinate)/layered double hydroxide nanocomposites. J. Polym. Res. 2012, 19, 9930. [Google Scholar] [CrossRef]

- Naffakh, M.; Marco, C.; Gómezfatou, M.A. Isothermal crystallization kinetics of novel isotactic polypropylene /MoS2 inorganic nanotube nanocomposites. J. Phys. Chem. B 2011, 115, 2248. [Google Scholar] [CrossRef] [PubMed]

- Vilanova, P.C.; Ribas, S.M.; Guzman, G.M. Isothermal crystallization of poly(ethylene-terephthalate) of low molecular weight by differential scanning calorimetry: 1. crystallization kinetics. Polymer 1985, 26, 423–428. [Google Scholar] [CrossRef]

- Hobbs, J.K.; Mcmaster, T.J.; Miles, M.J.; Barham, P.J. Direct observations of the growth of spherulites of poly(hydroxybutyrate-co-valerate) using atomic force microscopy. Polymer 1998, 39, 2437–2446. [Google Scholar] [CrossRef]

- Kamal, M.R.; Feng, L. Non-linear crystalline spherulitic growth behavior for LLDPE. Int. Polym. Process. 1976, 20, 78–85. [Google Scholar] [CrossRef]

- Vona, A.; Romano, C. The effects of undercooling and deformation rates on the crystallization; kinetics of Stromboli and Etna basalts. Contrib. Mineral. Petrol. 2013, 166, 491–509. [Google Scholar] [CrossRef]

- Feng, J.; Yang, W.; Zhang, R.; Wu, J.; Wang, L.; Zhang, C.; Yang, M. Effect of viscosity ratio on the crystalline morphologies and mechanical property of multi-melt multi-injection molded parts. Polym.-Plast. Technol. Eng. 2014, 53, 1272–1282. [Google Scholar] [CrossRef]

- Lorenzo, M.L.D. Spherulite growth rates in binary polymer blends. Prog. Polym. Sci. 2003, 28, 663–689. [Google Scholar] [CrossRef]

| Sample | iPP (g) | BC (g) | CO (g) | MAPP (g) |

|---|---|---|---|---|

| iPP | 10 | – | – | – |

| iPP/BC2 | 10 | 0.2 | – | – |

| iPP/CO2 | 10 | – | 0.2 | – |

| M-iPP/BC3 | 10 | 0.3 | – | 0.7 |

| Sample | Tc (oC) | n | logk | t1/2 (min) | t1/2’ (min) |

|---|---|---|---|---|---|

| iPP | 130 | 1.7 | −5.23 | 7.35 | 7.0 |

| 135 | 2.2 | −7.34 | 26.33 | 25.09 | |

| 140 | 2.4 | −8.48 | 97.52 | 87.52 | |

| iPP/BC2 | 130 | 2.0 | −3.34 | 4.62 | 4.3 |

| 135 | 2.1 | −5.95 | 21.67 | 20.03 | |

| 140 | 2.2 | −8.60 | 88.56 | 76.01 | |

| iPP/CO2 | 130 | 2.1 | −4.36 | 4.18 | 4.0 |

| 135 | 2.3 | −5.94 | 14.34 | 13.21 | |

| 140 | 2.4 | −11.01 | 48.87 | 40.28 | |

| M-iPP/BC3 | 130 | 2.2 | −8.22 | 1.67 | 1.26 |

| 135 | 2.3 | −9.47 | 6.43 | 6.04 | |

| 140 | 2.4 | −11.55 | 22.85 | 19.78 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Lin, F.-h.; Li, X.-y.; Zhang, Z.-w.; Xue, X.-r.; Liu, S.-x.; Ji, X.-r.; Yu, Q.; Yuan, Z.-q.; Chen, X.-d.; et al. Isothermal Crystallization and Rheology Properties of Isotactic Polypropylene/Bacterial Cellulose Composite. Polymers 2018, 10, 1284. https://doi.org/10.3390/polym10111284

Wang B, Lin F-h, Li X-y, Zhang Z-w, Xue X-r, Liu S-x, Ji X-r, Yu Q, Yuan Z-q, Chen X-d, et al. Isothermal Crystallization and Rheology Properties of Isotactic Polypropylene/Bacterial Cellulose Composite. Polymers. 2018; 10(11):1284. https://doi.org/10.3390/polym10111284

Chicago/Turabian StyleWang, Bo, Fu-hua Lin, Xiang-yang Li, Zhong-wei Zhang, Xiao-rong Xue, Si-xiao Liu, Xu-ran Ji, Qian Yu, Zheng-qiu Yuan, Xin-de Chen, and et al. 2018. "Isothermal Crystallization and Rheology Properties of Isotactic Polypropylene/Bacterial Cellulose Composite" Polymers 10, no. 11: 1284. https://doi.org/10.3390/polym10111284