Fabrication of Quaternized Chitosan Nanoparticles Using Tripolyphosphate/Genipin Dual Cross-Linkers as a Protein Delivery System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

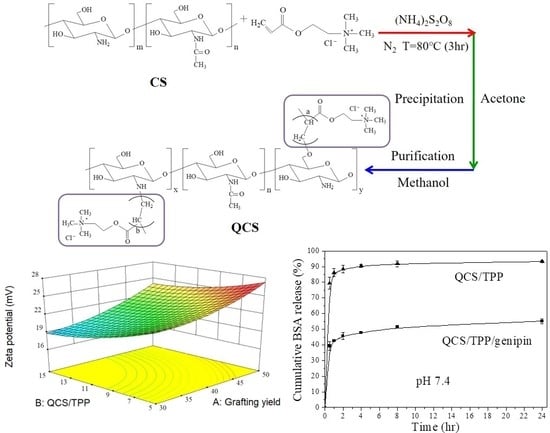

2.2. Synthesis of QCS

2.3. Preparation of BSA-Loaded QCS Nanoparticles

2.4. Experimental Design for RSM

2.5. Characterizations

2.6. In Vitro BSA Release

2.6.1. BSA Encapsulation Efficiency

2.6.2. Cumulative BSA Release

2.7. Statistical Analysis

3. Results and Discussion

3.1. QCS Characteristics

3.2. Design of Experiment

3.2.1. Effect of Variables on the Size of QCS Particles

3.2.2. Effect of Variables on the Zeta potential of QCS Particles

3.2.3. Effect of Variables on the Encapsulation Efficiency of BSA

3.2.4. Optimization and Validation

3.3. BSA Release Prolife

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qiu, Y.; Park, K. Environment-sensitive hydrogels for drug delivery. Adv. Drug Deliv. Rev. 2001, 53, 321–339. [Google Scholar] [CrossRef]

- Thandapani, G.; Prasad, S.; Sudha, P.N.; Sukumaran, A. Size optimization and in vitro biocompatibility studies of chitosan nanoparticles. Int. J. Biol. Macromol. 2017, 104, 1794–1806. [Google Scholar] [CrossRef] [PubMed]

- Cheung, R.C.F.; Ng, T.B.; Wong, J.H.; Chan, W.Y. Chitosan: An update on potential biomedical and pharmaceutical applications. Mar. Drugs 2015, 13, 5156–5186. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.R.; Muzzarelli, R.; Muzzarelli, C.; Sashiwa, H.; Domb, A.J. Chitosan chemistry and pharmaceutical perspectives. Chem. Rev. 2004, 104, 6017–6084. [Google Scholar] [CrossRef] [PubMed]

- Siafaka, P.I.; Titopoulou, A.; Koukaras, E.N.; Kostoglou, M.; Koutris, E.; Karavas, E.; Bikiaris, D.N. Chitosan derivatives as effective nanocarriers for ocular release of timolol drug. Int. J. Pharm. 2015, 495, 249–264. [Google Scholar] [CrossRef] [PubMed]

- Nanaki, S.; Tseklima, M.; Christodoulou, E.; Triantafyllidis, K.; Kostoglou, M.; Bikiaris, D. Thiolated chitosan masked polymeric microspheres with incorporated mesocellular silica foam (MCF) for intranasal delivery of paliperidone. Polymers 2017, 9, 617. [Google Scholar] [CrossRef]

- Lehr, C.M.; Bouwstra, J.A.; Boddé, H.E.; Junginger, H.E. A surface energy analysis of mucoadhesion: Contact angle measurements on polycarbophil and pig intestinal mucosa in physiologically relevant fluids. Pharm. Res. 1992, 9, 70–75. [Google Scholar] [CrossRef] [PubMed]

- Nah, J.W.; Jang, M.K. Spectroscopic characterization and preparation of low molecular, water-soluble chitosan with free-amine group by novel method. J. Polym. Sci. A 2002, 40, 3796–3803. [Google Scholar] [CrossRef]

- Kotzé, A.F.; Lueßen, H.L.; de Leeuw, B.J.; de Boer, A.G.; Verhoef, J.C.; Junginger, H.E. Chitosan for enhanced intestinal permeability: Prospects for derivatives soluble in neutral and basic environments. Eur. J. Pharm. Sci. 1999, 7, 145–151. [Google Scholar] [CrossRef]

- Sun, Y.; Wan, A. Preparation of nanoparticles composed of chitosan and its derivatives as delivery systems for macromolecules. J. Appl. Polym. Sci. 2007, 105, 552–561. [Google Scholar] [CrossRef]

- Guo, R.; Chen, L.; Cai, S.; Liu, Z.; Zhu, Y.; Xue, W.; Zhang, Y. Novel alginate coated hydrophobically modified chitosan polyelectrolyte complex for the delivery of BSA. J. Mater. Sci. Mater. Med. 2013, 24, 2093–2100. [Google Scholar] [CrossRef] [PubMed]

- Kean, T.; Roth, S.; Thanou, M. Trimethylated chitosans as non-viral gene delivery vectors: Cytotoxicity and transfection efficiency. J. Control. Release 2005, 103, 643–653. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Dai, H.; Leong, K.W.; Goh, S.H.; Mao, H.Q.; Yang, Y.Y. Chitosan-g-PEG/DNA complexes deliver gene to the rat liver via intrabiliary and intraportal infusions. J. Gene Med. 2006, 8, 477–487. [Google Scholar] [CrossRef] [PubMed]

- Upadhyaya, L.; Singh, J.; Agarwal, V.; Tewari, R.P. Biomedical applications of carboxymethyl chitosans. Carbohydr. Polym. 2013, 91, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Na, L.; Wang, J.; Wang, L.; Mao, S. A novel permeation enhancer: N-succinyl chitosan on the intranasal absorption of isosorbide dinitrate in rats. Eur. J. Pharm. Sci. 2013, 48, 301–306. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.; Li, D.; Dai, C.; Cheng, G.; Wang, X.; Zhao, K. Response of live Newcastle disease virus encapsulated in N-2-hydroxypropyl dimethylethyl ammonium chloride chitosan nanoparticles. Carbohydr. Polym. 2017, 171, 267–280. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Chu, C.H. Dual stimuli responsive glycidyl methacrylate chitosan-quaternary ammonium hybrid hydrogel and its bovine serum albumin release. J. Appl. Polym. Sci. 2013, 130, 3736–3745. [Google Scholar] [CrossRef]

- Thanou, M.M.; Kotzé, A.F.; Scharringhausen, T.; Lueßen, H.L.; de Boer, A.G.; Verhoef, J.C.; Junginger, H.E. Effect of degree of quaternization of N-trimethyl chitosan chloride for enhanced transport of hydrophilic compounds across intestinal Caco-2 cell monolayers. J. Control. Release 2000, 64, 15–25. [Google Scholar] [CrossRef]

- Singh, R.; Lillard, J.W. Nanoparticle-based targeted drug delivery. Exp. Mol. Pathol. 2009, 86, 215–223. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gan, Q.; Wang, T. Chitosan nanoparticle as protein delivery carrier–systematic examination of fabrication conditions for efficient loading and release. Colloids Surf. B 2007, 59, 24–34. [Google Scholar] [CrossRef] [PubMed]

- Rampino, A.; Borgogna, M.; Blasi, P.; Bellich, B.; Cesàro, A. Chitosan nanoparticles: Preparation, size evolution and stability. Int. J. Pharm. 2013, 455, 219–228. [Google Scholar] [CrossRef] [PubMed]

- Gomathi, T.; Sudha, P.N.; Florence, J.A.K.; Venkatesan, J.; Anil, S. Fabrication of letrozole formulation using chitosan nanoparticles through ionic gelation method. Int. J. Biol. Macromol. 2017, 104, 1820–1832. [Google Scholar] [CrossRef] [PubMed]

- Bugnicourt, L.; Ladavière, C. Interests of chitosan nanoparticles ionically cross-linked with tripolyphosphate for biomedical applications. Prog. Polym. Sci. 2016, 60, 1–17. [Google Scholar] [CrossRef]

- Gaspar, M.C.; Sousa, J.J.; Pais, A.A.; Cardoso, O.; Murtinho, D.; Serra, M.E.S.; Tewes, F.; Olivier, J.C. Optimization of levofloxacin-loaded cross-linked chitosan microspheres for inhaled aerosol therapy. Eur. J. Pharm. Biopharm. 2015, 96, 65–75. [Google Scholar] [CrossRef] [PubMed]

- Sedyakina, N.E.; Zakharov, A.N.; Krivoshchepov, A.F.; Pribytkova, A.P.; Bogdanova, Y.A.; Feldman, N.B.; Lutsenko, S.V.; Avramenko, G.V. Effect of carbon chain length of dicarboxylic acids as cross-linking agents on morphology, encapsulation, and release features of protein-loaded chitosan microparticles. Colloid Polym. Sci. 2017, 295, 1915–1924. [Google Scholar] [CrossRef]

- Hui, P.C.L.; Wang, W.Y.; Kan, C.W.; Ng, F.S.F.; Zhou, C.E.; Wat, E.; Zhang, V.X.; Chan, C.L.; Lau, C.B.S.; Leung, P.C. Preparation and characterization of chitosan/sodium alginate (CSA) microcapsule containing Cortex Moutan. Colloids Surf. A Physicochem. Eng. Asp. 2013, 434, 95–101. [Google Scholar] [CrossRef]

- Ballantyne, B.; Jordan, S.L. Toxicological, medical and industrial hygiene aspects of glutaraldehyde with particular reference to its biocidal use in cold sterilization procedures. J. Appl. Toxicol. 2001, 21, 131–151. [Google Scholar] [CrossRef] [PubMed]

- Fujikawa, S.; Yokota, T.; Koga, K.; Kumada, J.I. The continuous hydrolysis of geniposide to genipin using immobilized β-glucosidase on calcium alginate gel. Biotechnol. Lett. 1987, 9, 697–702. [Google Scholar] [CrossRef]

- Razi, M.A.; Wakabayashi, R.; Tahara, Y.; Goto, M.; Kamiya, N. Genipin-stabilized caseinate-chitosan nanoparticles for enhanced stability and anti-cancer activity of curcumin. Colloids Surf. B 2018, 164, 308–315. [Google Scholar] [CrossRef] [PubMed]

- Manickam, B.; Sreedharan, R.; Elumalai, M. ‘Genipin’—The natural water soluble cross-linking agent and its importance in the modified drug delivery systems: An overview. Curr. Drug Deliv. 2014, 11, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Bhattarai, N.; Ramay, H.R.; Gunn, J.; Matsen, F.A.; Zhang, M. PEG-grafted chitosan as an injectable thermosensitive hydrogel for sustained protein release. J. Control. Release 2005, 103, 609–624. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Chesnutt, B.M.; Utturkar, G.; Haggard, W.O.; Yang, Y.; Ong, J.L.; Bumgardner, J.D. The effect of cross-linking of chitosan microspheres with genipin on protein release. Carbohydr. Polym. 2007, 68, 561–567. [Google Scholar] [CrossRef]

- Karnchanajindanun, J.; Srisa-ard, M.; Baimark, Y. Genipin-cross-linked chitosan microspheres prepared by a water-in-oil emulsion solvent diffusion method for protein delivery. Carbohydr. Polym. 2011, 85, 674–680. [Google Scholar] [CrossRef]

- Nath, S.D.; Abueva, C.; Kim, B.; Lee, B.T. Chitosan–hyaluronic acid polyelectrolyte complex scaffold crosslinked with genipin for immobilization and controlled release of BMP-2. Carbohydr. Polym. 2015, 115, 160–169. [Google Scholar] [CrossRef] [PubMed]

- Mi, F.L.; Sung, H.W.; Shyu, S.S.; Su, C.C.; Peng, C.K. Synthesis and characterization of biodegradable TPP/genipin co-crosslinked chitosan gel beads. Polymer 2003, 44, 6521–6530. [Google Scholar] [CrossRef]

- Yang, C.Y.; Hsu, C.H.; Tsai, M.L. Effect of cross-linked condition on characteristics of chitosan/tripolyphosphate/genipin beads and their application in the selective adsorption of phytic acid from soybean whey. Carbohydr. Polym. 2011, 86, 659–665. [Google Scholar] [CrossRef]

- Walke, S.; Srivastava, G.; Nikalje, M.; Doshi, J.; Kumar, R.; Ravetkar, S.; Doshi, P. Fabrication of chitosan microspheres using vanillin/TPP dual crosslinkers for protein antigens encapsulation. Carbohyd. Polym. 2015, 128, 188–198. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Zhang, J.; He, N.; Li, Z. Investigation of Sonic hedgehog loading chitosan/sodium tripolyphosphate microspheres with genipin as cross-linker. J. Bionanosci. 2015, 9, 341–345. [Google Scholar] [CrossRef]

- Chen, K.Y.; Zeng, S.Y. Preparation and characterization of quaternized chitosan coated alginate microspheres for blue dextran delivery. Polymers 2017, 9, 210. [Google Scholar] [CrossRef]

- Li, G.; Guo, L.; Wen, Q.; Zhang, T. Thermo-and pH-sensitive ionic-cross-linked hollow spheres from chitosan-based graft copolymer for 5-fluorouracil release. Int. J. Biol. Macromol. 2013, 55, 69–74. [Google Scholar] [CrossRef] [PubMed]

- Gönen, S.Ö.; Taygun, M.E.; Aktürk, A.; Küçükbayrak, S. Fabrication of nanocomposite mat through incorporating bioactive glass particles into gelatin/poly(ε-caprolactone) nanofibers by using Box–Behnken design. Mater. Sci. Eng. C 2016, 67, 684–693. [Google Scholar] [CrossRef] [PubMed]

- Zou, X.; Zhao, X.; Ye, L. Synthesis of cationic chitosan hydrogel and its controlled glucose-responsive drug release behavior. Chem. Eng. J. 2015, 273, 92–100. [Google Scholar] [CrossRef]

- Subbiah, R.; Ramalingam, P.; Ramasundaram, S.; Park, K.; Ramasamy, M.K.; Choi, K.J. N,N,N-Trimethyl chitosan nanoparticles for controlled intranasal delivery of HBV surface antigen. Carbohydr. Polym. 2012, 89, 1289–1297. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Cai, K.; Zhang, J.; Shen, Y.; Wang, S.; Tian, X. Synthesis of a novel water-soluble chitosan derivative for flocculated decolorization. J. Hazard. Mater. 2011, 185, 1482–1488. [Google Scholar] [CrossRef] [PubMed]

- Salama, H.E.; Saad, G.R.; Sabaa, M.W. Synthesis, characterization and biological activity of Schiff bases based on chitosan and arylpyrazole moiety. Int. J. Biol. Macromol. 2015, 79, 996–1003. [Google Scholar] [CrossRef] [PubMed]

- Bulmer, C.; Margaritis, A.; Xenocostas, A. Production and characterization of novel chitosan nanoparticles for controlled release of rHu-Erythropoietin. Biochem. Eng. J. 2012, 68, 61–69. [Google Scholar] [CrossRef]

- de Pinho Neves, A.L.; Milioli, C.C.; Müller, L.; Riella, H.G.; Kuhnen, N.C.; Stulzer, H.K. Factorial design as tool in chitosan nanoparticles development by ionic gelation technique. Colloids Surf. A 2014, 445, 34–39. [Google Scholar] [CrossRef]

- Kiaie, N.; Aghdam, R.M.; Tafti, S.H.; Emami, S.H. Statistical optimization of chitosan nanoparticles as protein vehicles, using response surface methodology. J. Appl. Biomater. Funct. Mater. 2016, 14, e413–e422. [Google Scholar] [CrossRef] [PubMed]

- Rawal, T.; Parmar, R.; Tyagi, R.K.; Butani, S. Rifampicin loaded chitosan nanoparticle dry powder presents an improved therapeutic approach for alveolar tuberculosis. Colloids Surf. B 2017, 154, 321–330. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; Pan, C.; Sun, Y.; Hou, Z.; Ye, H.; Hu, B.; Zeng, X. Optimization of fabrication parameters to produce chitosan-tripolyphosphate nanoparticles for delivery of tea catechins. J. Agric. Food Chem. 2008, 56, 7451–7458. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yang, Y.; Guo, T. Genipin-crosslinked hydrophobical chitosan microspheres and their interactions with bovine serum albumin. Carbohydr. Polym. 2011, 83, 2016–2021. [Google Scholar] [CrossRef]

- Liu, S.; Ho, P.C. Formulation optimization of scutellarin-loaded HP-β-CD/chitosan nanoparticles using response surface methodology with Box–Behnken design. Asian J. Pharm. Sci. 2017, 12, 378–385. [Google Scholar] [CrossRef]

- Papadimitriou, S.; Bikiaris, D.; Avgoustakis, K.; Karavas, E.; Georgarakis, M. Chitosan nanoparticles loaded with dorzolamide and pramipexole. Carbohydr. Polym. 2008, 73, 44–54. [Google Scholar] [CrossRef]

- Koukaras, E.N.; Papadimitriou, S.A.; Bikiaris, D.N.; Froudakis, G.E. Insight on the formation of chitosan nanoparticles through ionotropic gelation with tripolyphosphate. Mol. Pharm. 2012, 9, 2856–2862. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.Q.; Cheng, L.Y.; Xiao, J.X.; Wang, S.Q.; Han, X.N. Genipin-cross-linked O-carboxymethyl chitosan–gum Arabic coacervate as a pH-sensitive delivery system and microstructure characterization. J. Biomater. Appl. 2016, 31, 193–204. [Google Scholar] [CrossRef] [PubMed]

- Zou, X.; Zhao, X.; Ye, L.; Wang, Q.; Li, H. Preparation and drug release behavior of pH-responsive bovine serum albumin-loaded chitosan microspheres. J. Ind. Eng. Chem. 2015, 21, 1389–1397. [Google Scholar] [CrossRef]

| Independent Variables | Symbol | Levels | ||

|---|---|---|---|---|

| Low (−1) | Medium (0) | High (+1) | ||

| Grafting yield (%) | A | 30 | 40 | 50 |

| QCS: TPP (weight ratio) | B | 5:1 | 10:1 | 15:1 |

| QCS: Genipin (weight ratio) | C | 20:1 | 40:1 | 60:1 |

| Dependent Variables | Symbol | Constraints | ||

| Particle size (nm) | Y1 | <200 | ||

| PDI | Y2 | <0.3 | ||

| Zeta potential (mV) | Y3 | |||

| Encapsulation efficiency (%) | Y4 | Maximize | ||

| Materials | Transmittance (%) | |

|---|---|---|

| pH = 6.0 | pH = 7.0 | |

| CS | 99.0 | 71.9 |

| QCS-30 | 97.2 | 89.0 |

| QCS-40 | 96.5 | 92.6 |

| QCS-50 | 98.6 | 97.3 |

| Run | Variables | Responses | |||||

|---|---|---|---|---|---|---|---|

| Grafting Yield (%) | QCS: TPP (Weight Ratio) | QCS: Genipin (Weight Ratio) | Particle Size (nm) | PDI | Zeta Potential (mV) | Encapsulation Efficiency (%) | |

| 1 | 30 | 10:1 | 60:1 | 227.91 | 0.229 | 20.50 | 40.28 |

| 2 | 30 | 10:1 | 20:1 | 185.12 | 0.230 | 17.10 | 43.66 |

| 3 | 30 | 5:1 | 40:1 | 2101.53 | 0.571 | 23.28 | 51.59 |

| 4 | 30 | 15:1 | 40:1 | 201.88 | 0.214 | 20.03 | 27.65 |

| 5 | 40 | 10:1 | 40:1 | 171.90 | 0.125 | 22.45 | 41.79 |

| 6 | 40 | 15:1 | 60:1 | 179.64 | 0.211 | 20.33 | 23.87 |

| 7 | 40 | 15:1 | 20:1 | 179.25 | 0.219 | 17.95 | 29.76 |

| 8 | 40 | 5:1 | 60:1 | 296.36 | 0.238 | 23.78 | 44.66 |

| 9 | 40 | 10:1 | 40:1 | 181.55 | 0.225 | 20.58 | 39.71 |

| 10 | 40 | 5:1 | 20:1 | 2519.73 | 0.525 | 18.74 | 65.26 |

| 11 | 40 | 10:1 | 40:1 | 181.07 | 0.209 | 21.47 | 44.01 |

| 12 | 50 | 15:1 | 40:1 | 146.65 | 0.217 | 23.82 | 2.23 |

| 13 | 50 | 10:1 | 60:1 | 167.00 | 0.224 | 25.16 | 27.45 |

| 14 | 50 | 5:1 | 40:1 | 190.72 | 0.226 | 26.02 | 67.76 |

| 15 | 50 | 10:1 | 20:1 | 148.48 | 0.219 | 18.97 | 32.02 |

| Response Variables | Experimental Values | Predicted Values | Error (%) a |

|---|---|---|---|

| Particle size (nm) | 193.68 ± 44.92 | 199.69 | −3.01 |

| PDI | 0.232 | 0.218 | +6.42 |

| Zeta potential (mV) | 23.97 | 25.81 | −7.13 |

| Encapsulation efficiency (%) | 46.37 ± 2.89 | 41.6 | +11.47 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, K.-Y.; Zeng, S.-Y. Fabrication of Quaternized Chitosan Nanoparticles Using Tripolyphosphate/Genipin Dual Cross-Linkers as a Protein Delivery System. Polymers 2018, 10, 1226. https://doi.org/10.3390/polym10111226

Chen K-Y, Zeng S-Y. Fabrication of Quaternized Chitosan Nanoparticles Using Tripolyphosphate/Genipin Dual Cross-Linkers as a Protein Delivery System. Polymers. 2018; 10(11):1226. https://doi.org/10.3390/polym10111226

Chicago/Turabian StyleChen, Kuo-Yu, and Si-Ying Zeng. 2018. "Fabrication of Quaternized Chitosan Nanoparticles Using Tripolyphosphate/Genipin Dual Cross-Linkers as a Protein Delivery System" Polymers 10, no. 11: 1226. https://doi.org/10.3390/polym10111226