Analysis and Optimization of the Machining Characteristics of High-Volume Content SiCp/Al Composite in Wire Electrical Discharge Machining

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Machine Tools

2.3. The Experiment Design

3. Experiment Results and Discussion

3.1. Experiment Result

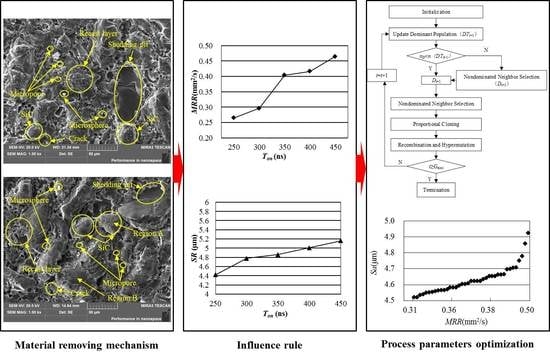

3.2. Machined Surface Characteristics

3.3. The Effects of Process Parameters on MRR and SR

3.4. The Numerical Relationship between Process Parameters on MRR/SR

4. Process Parameters Optimization

4.1. NNIA

- (1)

- Initialization

- (2)

- Update dominant groups

- (3)

- Select based on nondominated neighbor

- (4)

- Proportional clone

- (5)

- Recombination and hypermutation

- (6)

- End

4.2. Optimization Results

4.3. Verified Experiment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moreno, M.F.; Oliver, C.J.R.G. Compression creep of PM aluminum matrix composites reinforced with SiC short fibres. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2006, 418, 172–181. [Google Scholar] [CrossRef]

- Sahin, Y. Wear behaviour of aluminium alloy and its composites reinforced by SiC particles using statistical analysis. Mater. Des. 2003, 24, 95–103. [Google Scholar] [CrossRef]

- Dandekar, C.R.; Shin, Y.C. Modeling of machining of composite materials: A review. Int. J. Mach. Tools Manuf. 2012, 57, 102–121. [Google Scholar] [CrossRef]

- Wang, J.F.; Fan, X.L.; Cao, Y.W.; Chu, K.Y.; Wang, K. Experimentation investigations of surface roughness in High-speed turning of SiCp/Al composites. Chin. J. Mech. Eng. 2017, 15, 62–66. [Google Scholar]

- Yan, H.Z.; Kabongo, D.B.; Yan, Z.J.; Han, F.L.; Chen, Z. Sustainable production of high-uniformity workpiece surface quality in wire electrical discharge machining by fabricating surface microstructure on wire electrode. J. Clean. Prod. 2020, 259, 120881. [Google Scholar] [CrossRef]

- Yan, H.Z.; Kabongo, D.B.; Chen, Z.; Yan, Z.J.; Zhou, H.B.; Han, F.L. Attainment of high corner accuracy for thin-walled sharp-corner part by WEDM based on magnetic field-assisted method and parameter optimization. Int. J. Adv. Manuf. Technol. 2020, 106, 4845–4857. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, Z.J.; Yan, H.Z.; Han, F.L. Improvement of the machining characteristics in WEDM based on specific discharge energy and magnetic field–assisted method. Int. J. Adv. Manuf. Technol. 2019, 103, 3033–3044. [Google Scholar] [CrossRef]

- Chen, Z. Study on the white layer in wire electrical discharge trim cutting of bearing steel GCr15. Int. J. Adv. Manuf. Technol. 2019, 102, 2375–2386. [Google Scholar] [CrossRef]

- Shen, D.; Ming, W.; Ren, X.; Xie, Z.; Zhang, Y.; Liu, X. A Cuckoo Search Algorithm Using Improved Beta Distributing and Its Application in the Process of EDM. Crystals 2021, 11, 916. [Google Scholar] [CrossRef]

- Balasubramaniam, V.; Baskar, N.; Narayanan, C.S. Effect of process parameters on the electrical discharge machining of aluminum metal matrix composites through a response surface methodology approach. Sci. Eng. Compos. Mater. 2016, 23, 145–154. [Google Scholar] [CrossRef]

- Gu, L.; Chen, J.P.; Xu, H.; Zhao, W.S. Blasting erosion arc machining of 20 vol.% SiC/Al metal matrix composites. Int. J. Adv. Manuf. Technol. 2016, 87, 2775–2784. [Google Scholar] [CrossRef]

- Dey, A.; Debnath, S.; Pandey, K.M. Optimization of electrical discharge machining process parameters for Al6061/cenosphere composite using grey-based hybrid approach. Trans. Nonferrous Met. Soc. China 2017, 27, 998–1010. [Google Scholar] [CrossRef]

- Daneshmand, S.; Masoudi, B. Investigation and optimization of the electro-discharge machining parameters of 2024 aluminum alloy and Al/7.5% Al2O3 particulate-reinforced metal matrix composite. Sci. Eng. Compos. Mater. 2018, 25, 159–172. [Google Scholar] [CrossRef]

- Shelvaraj, S.G.; Naveen, S.A. Optimization of EDM Parameters for Al-TiC Composites Prepared through Powder Metallurgy Route. Mechanika 2018, 24, 135–142. [Google Scholar]

- Singh, B.; Kumar, J.; Kumar, S. Investigation of the Tool Wear Rate in Tungsten Powder-Mixed Electric Discharge Machining of AA6061/10%SiCp Composite. Mater. Manuf. Process. 2016, 31, 456–466. [Google Scholar] [CrossRef]

- Pramanik, A. Electrical Discharge Machining of MMCs Reinforced with Very Small Particles. Mater. Manuf. Process. 2016, 31, 397–404. [Google Scholar] [CrossRef] [Green Version]

- Kumar, N.M.; Kumaran, S.S.; Kumaraswamidhas, L.A. High temperature investigation on EDM process of Al 2618 alloy reinforced with Si3N4, ALN and ZrB2 in-situ composites. J. Alloys Compd. 2016, 663, 755–768. [Google Scholar] [CrossRef]

- Bains, P.S.; Sidhu, S.S.; Payal, H.S. Magnetic Field Assisted EDM: New Horizons for Improved Surface Properties. Silicon 2018, 10, 1275–1282. [Google Scholar] [CrossRef]

- Kumar, T.T.S.; Subramanian, R.; Velmurugan, C.; Vinoth, K.S. Experimental investigations on wire electrical discharge machining characteristics of aluminum hybrid composites. Indian J. Eng. Mater. Sci. 2018, 25, 281–290. [Google Scholar]

- Uthayakumar, M.; Babu, K.V.; Kumaran, S.T.; Kumar, S.S.; Jappes, J.T.W.; Rajan, T.P.D. Study on the machining of Al–SiC functionally graded metal matrix composite using die-sinking EDM. Part Sci. Technol. 2019, 37, 103–109. [Google Scholar] [CrossRef]

- Senthilkumar, T.S.; Muralikannan, R. Role of TiC and h-BN particles on morphological characterization and surface effects of Al 4032 hybrid composites using EDM process. J. Mech. Sci. Technol. 2019, 33, 4255–4264. [Google Scholar] [CrossRef]

- Paswan, K.; Pramanik, A.; Chattopadhyaya, S.; Basak, A.K. A novel approach towards sustainable electrical discharge machining of metal matrix composites (MMCs). Int. J. Adv. Manuf. Technol. 2020, 106, 1477–1486. [Google Scholar] [CrossRef]

- Devi, M.B.; Sameer, M.D.; Birru, A.K. EDM machining characteristics of bamboo leaf ash and alumina reinforced aluminum hybrid metal matrix composite using Multi-response optimization by grey relational analysis. Mater. Res. Express 2021, 8, 016518. [Google Scholar] [CrossRef]

- Sokołowski, D.; Kamiński, M. Probabilistic homogenization of hyper-elastic particulate composites with random interface. Compos. Struct. 2020, 241, 112118. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, H.B.; Yan, Z.J.; Han, F.L.; Yan, H.Z. Machining characteristics of 65 vol.% SiCp/Al composite in micro-WEDM. Ceram Int. 2020, 47, 13533–13543. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, G.J.; Han, F.L.; Zhang, Y.M.; Rong, Y.M. Determination of the optimal servo feed speed by thermal model during multi-pulse discharge process of WEDM. Int. J. Mech. Sci. 2018, 142, 359–369. [Google Scholar] [CrossRef]

- Pan, H.W.; Liu, Z.D.; Li, C.R.; Zhang, Y.Q.; Qiu, M.B. Enhanced debris expelling in high-speed wire electrical discharge machining. Int. J. Adv. Manuf. Technol. 2017, 93, 2913–2920. [Google Scholar] [CrossRef]

- Perumal, A.; Azhagurajan, A.; Baskaran, S.; Prithivirajan, R.; Narayansamy, P. Statistical evaluation and performance analysis of electrical discharge machining (EDM) characteristics of hard Ti-6Al-2Sn-4Zr-2Mo alloy. Mater. Res. Express 2019, 6, 056552. [Google Scholar] [CrossRef]

- Mouliprasanth, B.; Hariharan, P. An Experimental Study and Analysis of Different Dielectrics in Electrical Discharge Machining of Al 6063 Alloy. J. Polym. Mater. 2019, 36, 351–369. [Google Scholar] [CrossRef]

- Kong, L.L.; Liu, Z.D.; Qiu, M.B.; Wang, W.Z.; Han, Y.X.; Bai, S.K. Machining characteristics of submersed gas-flushing electrical discharge machining of Ti6Al4V alloy. J. Manuf. Process. 2019, 41, 188–196. [Google Scholar] [CrossRef]

- Das, S.; Joshi, S.N. Estimation of wire strength based on residual stresses induced during wire electric discharge machining. J. Manuf. Process. 2020, 53, 406–419. [Google Scholar] [CrossRef]

- Ming, W.Y.; Jia, H.J.; Zhang, H.M.; Zhang, Z.; Liu, K.; Du, J.G.; Shen, F.; Zhang, G.J. A comprehensive review of electric discharge machining of advanced ceramics. Ceram Int. 2020, 46, 21813–21838. [Google Scholar] [CrossRef]

- Sergey, N.G.; Khaled, H.; Marina, A.V.; Anna, A.O.; Sergey, V.F. Electrical discharge machining of oxide and nitride ceramics: A review. Mater. Design 2021, 209, 109965. [Google Scholar]

| Properties | Value |

|---|---|

| Thermal conductivity | 180 W/mK |

| Thermal expansivity | 7.42 ppm/K |

| Young modulus | 230 GPa |

| Shear modulus | 75 GPa |

| Flexure strength | 350 MPa |

| Density | 2.96 g/cm3 |

| Reinforced particle size | 5–50 μm |

| Parameters | Unit | Level | ||||

|---|---|---|---|---|---|---|

| Ton | ns | 250 | 300 | 350 | 400 | 450 |

| Ton | μs | 8 | 9 | 10 | 11 | 12 |

| SV | V | 41 | 43 | 45 | 47 | 49 |

| WF | mm/s | 8 | 9 | 10 | 11 | 12 |

| WT | N | 10 | 11 | 12 | 13 | 14 |

| No. | Ton (ns) | Toff (μs) | SV (V) | WF (mm/s) | WT (N) |

|---|---|---|---|---|---|

| 1 | 250 | 10 | 45 | 10 | 12 |

| 2 | 300 | 10 | 45 | 10 | 12 |

| 3 | 350 | 10 | 45 | 10 | 12 |

| 4 | 400 | 10 | 45 | 10 | 12 |

| 5 | 450 | 10 | 45 | 10 | 12 |

| 6 | 350 | 8 | 45 | 10 | 12 |

| 7 | 350 | 9 | 45 | 10 | 12 |

| 8 | 350 | 11 | 45 | 10 | 12 |

| 9 | 350 | 12 | 45 | 10 | 12 |

| 10 | 350 | 10 | 41 | 10 | 12 |

| 11 | 350 | 10 | 43 | 10 | 12 |

| 12 | 350 | 10 | 47 | 10 | 12 |

| 13 | 350 | 10 | 49 | 10 | 12 |

| 14 | 350 | 10 | 45 | 8 | 12 |

| 15 | 350 | 10 | 45 | 9 | 12 |

| 16 | 350 | 10 | 45 | 11 | 12 |

| 17 | 350 | 10 | 45 | 12 | 12 |

| 18 | 350 | 10 | 45 | 10 | 10 |

| 19 | 350 | 10 | 45 | 10 | 11 |

| 20 | 350 | 10 | 45 | 10 | 13 |

| 21 | 350 | 10 | 45 | 10 | 14 |

| No. | Ton (ns) | Toff (μs) | SV (V) | WF (mm/s) | WT (N) | MRR (mm2/s) | SR (µm) |

|---|---|---|---|---|---|---|---|

| 1 | 250 | 10 | 45 | 10 | 12 | 0.265 | 4.42 ± 0.32 |

| 2 | 300 | 10 | 45 | 10 | 12 | 0.296 | 4.78 ± 0.25 |

| 3 | 350 | 10 | 45 | 10 | 12 | 0.404 | 4.86 ± 0.16 |

| 4 | 400 | 10 | 45 | 10 | 12 | 0.417 | 5.01 ± 0.28 |

| 5 | 450 | 10 | 45 | 10 | 12 | 0.465 | 5.16 ± 0.19 |

| 6 | 350 | 8 | 45 | 10 | 12 | 0.374 | 4.78 ± 0.1 |

| 7 | 350 | 9 | 45 | 10 | 12 | 0.392 | 4.86 ± 0.45 |

| 8 | 350 | 11 | 45 | 10 | 12 | 0.320 | 4.7 ± 0.36 |

| 9 | 350 | 12 | 45 | 10 | 12 | 0.315 | 4.77 ± 0.31 |

| 10 | 350 | 10 | 41 | 10 | 12 | 0.408 | 4.83 ± 0.5 |

| 11 | 350 | 10 | 43 | 10 | 12 | 0.430 | 4.97 ± 0.41 |

| 12 | 350 | 10 | 47 | 10 | 12 | 0.333 | 4.52 ± 0.38 |

| 13 | 350 | 10 | 49 | 10 | 12 | 0.308 | 4.69 ± 0.16 |

| 14 | 350 | 10 | 45 | 8 | 12 | 0.364 | 4.89 ± 0.25 |

| 15 | 350 | 10 | 45 | 9 | 12 | 0.354 | 4.71 ± 0.19 |

| 16 | 350 | 10 | 45 | 11 | 12 | 0.364 | 4.81 ± 0.26 |

| 17 | 350 | 10 | 45 | 12 | 12 | 0.351 | 4.88 ± 0.38 |

| 18 | 350 | 10 | 45 | 10 | 10 | 0.348 | 4.59 ± 0.45 |

| 19 | 350 | 10 | 45 | 10 | 11 | 0.360 | 4.82 ± 0.26 |

| 20 | 350 | 10 | 45 | 10 | 13 | 0.354 | 4.88 ± 0.29 |

| 21 | 350 | 10 | 45 | 10 | 14 | 0.364 | 4.77 ± 0.22 |

| Element | Region A | Region B | ||

|---|---|---|---|---|

| Weight% | Atomic% | Weight% | Atomic% | |

| C | 31.05 | 46.79 | 18.90 | 32.41 |

| O | 18.31 | 20.72 | 11.23 | 14.47 |

| Al | 3.36 | 2.25 | 63.19 | 48.24 |

| Si | 46.66 | 30.07 | 6.63 | 4.86 |

| Cu | 0.61 | 0.17 | 0.05 | 0.01 |

| Totals | 100.00 | 100.00 | 100.00 | 100.00 |

| No. | Ton (ns) | Toff (μs) | SV (V) | WF (mm/s) | WT (N) | MRR (mm2/s) | SR (µm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Exp. | Fit. | Re. (%) | Exp. | Fit. | Re. (%) | ||||||

| 1 | 250 | 10 | 45 | 10 | 12 | 0.265 | 0.258 | −2.69 | 4.42 | 4.47 | 1.06 |

| 2 | 300 | 10 | 45 | 10 | 12 | 0.296 | 0.316 | 6.81 | 4.78 | 4.65 | −2.76 |

| 3 | 350 | 10 | 45 | 10 | 12 | 0.404 | 0.370 | −8.34 | 4.86 | 4.82 | −0.77 |

| 4 | 400 | 10 | 45 | 10 | 12 | 0.417 | 0.420 | 0.80 | 5.01 | 4.99 | −0.40 |

| 5 | 450 | 10 | 45 | 10 | 12 | 0.465 | 0.466 | 0.27 | 5.16 | 5.15 | −0.17 |

| 6 | 350 | 8 | 45 | 10 | 12 | 0.374 | 0.381 | 1.78 | 4.78 | 4.80 | 0.50 |

| 7 | 350 | 9 | 45 | 10 | 12 | 0.392 | 0.382 | −2.45 | 4.86 | 4.83 | −0.68 |

| 8 | 350 | 11 | 45 | 10 | 12 | 0.320 | 0.344 | 7.62 | 4.7 | 4.79 | 1.93 |

| 9 | 350 | 12 | 45 | 10 | 12 | 0.315 | 0.305 | −3.28 | 4.77 | 4.73 | −0.80 |

| 10 | 350 | 10 | 41 | 10 | 12 | 0.408 | 0.421 | 3.13 | 4.83 | 4.89 | 1.27 |

| 11 | 350 | 10 | 43 | 10 | 12 | 0.430 | 0.398 | −7.50 | 4.97 | 4.88 | −1.89 |

| 12 | 350 | 10 | 47 | 10 | 12 | 0.333 | 0.338 | 1.61 | 4.52 | 4.73 | 4.65 |

| 13 | 350 | 10 | 49 | 10 | 12 | 0.308 | 0.302 | −1.96 | 4.69 | 4.60 | −1.93 |

| 14 | 350 | 10 | 45 | 8 | 12 | 0.364 | 0.359 | −1.43 | 4.89 | 4.85 | −0.80 |

| 15 | 350 | 10 | 45 | 9 | 12 | 0.354 | 0.368 | 4.02 | 4.71 | 4.83 | 2.45 |

| 16 | 350 | 10 | 45 | 11 | 12 | 0.364 | 0.365 | 0.28 | 4.81 | 4.84 | 0.65 |

| 17 | 350 | 10 | 45 | 12 | 12 | 0.351 | 0.352 | 0.40 | 4.88 | 4.88 | 0.05 |

| 18 | 350 | 10 | 45 | 10 | 10 | 0.348 | 0.349 | 0.15 | 4.59 | 4.61 | 0.45 |

| 19 | 350 | 10 | 45 | 10 | 11 | 0.360 | 0.364 | 0.99 | 4.82 | 4.75 | −1.48 |

| 20 | 350 | 10 | 45 | 10 | 13 | 0.354 | 0.369 | 4.17 | 4.88 | 4.83 | −0.97 |

| 21 | 350 | 10 | 45 | 10 | 14 | 0.364 | 0.359 | −1.40 | 4.77 | 4.78 | 0.19 |

| No. | Ton (ns) | Toff (μs) | SV (V) | WF (mm/s) | WT (N) | MRR (mm2/s) | SR (µm) |

|---|---|---|---|---|---|---|---|

| 1 | 271.503 | 9.037 | 48.087 | 10.120 | 10.375 | 0.265 | 4.432 |

| 2 | 293.039 | 8.878 | 46.924 | 9.782 | 10.107 | 0.300 | 4.473 |

| 3 | 303.687 | 8.902 | 46.584 | 9.682 | 10.035 | 0.313 | 4.497 |

| 4 | 308.969 | 9.061 | 45.788 | 10.124 | 10.000 | 0.325 | 4.517 |

| 5 | 308.969 | 9.061 | 45.788 | 10.124 | 10.000 | 0.325 | 4.517 |

| 6 | 310.998 | 8.809 | 45.450 | 10.036 | 10.028 | 0.333 | 4.532 |

| 7 | 295.618 | 9.320 | 43.293 | 10.054 | 10.116 | 0.340 | 4.538 |

| 8 | 311.623 | 8.928 | 44.688 | 9.789 | 10.000 | 0.342 | 4.546 |

| 9 | 315.157 | 8.629 | 45.099 | 9.829 | 10.033 | 0.344 | 4.550 |

| 10 | 315.690 | 8.649 | 45.042 | 9.813 | 10.015 | 0.345 | 4.550 |

| 11 | 317.643 | 8.565 | 44.972 | 9.811 | 10.015 | 0.348 | 4.556 |

| 12 | 320.783 | 8.710 | 45.017 | 9.801 | 10.000 | 0.349 | 4.562 |

| 13 | 320.520 | 8.703 | 44.966 | 9.816 | 10.018 | 0.349 | 4.564 |

| 14 | 320.672 | 8.626 | 45.016 | 9.799 | 10.010 | 0.350 | 4.562 |

| 15 | 313.245 | 8.994 | 43.829 | 10.169 | 10.052 | 0.353 | 4.568 |

| 16 | 326.959 | 8.637 | 44.950 | 9.826 | 10.014 | 0.356 | 4.579 |

| 17 | 319.949 | 8.593 | 44.392 | 9.892 | 10.092 | 0.357 | 4.579 |

| 18 | 319.949 | 8.593 | 44.392 | 9.892 | 10.092 | 0.357 | 4.579 |

| 19 | 330.657 | 8.633 | 44.827 | 9.804 | 10.020 | 0.361 | 4.591 |

| 20 | 335.113 | 8.751 | 44.907 | 9.781 | 10.008 | 0.363 | 4.601 |

| 21 | 324.903 | 9.258 | 43.583 | 10.096 | 10.057 | 0.364 | 4.602 |

| 22 | 340.553 | 8.626 | 45.175 | 9.803 | 10.000 | 0.366 | 4.606 |

| 23 | 345.196 | 8.826 | 45.208 | 9.803 | 10.000 | 0.368 | 4.620 |

| 24 | 345.196 | 8.826 | 45.208 | 9.803 | 10.000 | 0.368 | 4.620 |

| 25 | 334.903 | 9.164 | 43.983 | 10.296 | 10.028 | 0.368 | 4.620 |

| 26 | 334.903 | 9.164 | 43.983 | 10.296 | 10.028 | 0.368 | 4.620 |

| 27 | 343.686 | 8.265 | 45.408 | 10.111 | 10.272 | 0.370 | 4.632 |

| 28 | 349.621 | 8.904 | 44.750 | 10.081 | 10.000 | 0.376 | 4.640 |

| 29 | 353.985 | 9.032 | 44.959 | 9.742 | 10.000 | 0.377 | 4.650 |

| 30 | 353.985 | 9.032 | 44.959 | 9.742 | 10.000 | 0.377 | 4.650 |

| 31 | 347.267 | 9.367 | 43.899 | 10.134 | 10.012 | 0.379 | 4.652 |

| 32 | 357.445 | 9.079 | 44.922 | 9.689 | 10.000 | 0.380 | 4.661 |

| 33 | 357.445 | 9.079 | 44.922 | 9.689 | 10.000 | 0.380 | 4.661 |

| 34 | 359.978 | 9.020 | 45.061 | 9.821 | 10.000 | 0.381 | 4.663 |

| 35 | 369.428 | 9.133 | 44.810 | 10.144 | 10.000 | 0.391 | 4.693 |

| 36 | 370.827 | 8.977 | 44.749 | 9.950 | 10.000 | 0.395 | 4.695 |

| 37 | 362.786 | 9.330 | 43.388 | 10.522 | 10.037 | 0.399 | 4.703 |

| 38 | 370.103 | 8.954 | 43.861 | 10.475 | 10.000 | 0.403 | 4.706 |

| 39 | 384.842 | 9.333 | 43.913 | 10.422 | 10.000 | 0.413 | 4.748 |

| 40 | 394.872 | 8.616 | 44.836 | 9.349 | 10.214 | 0.421 | 4.777 |

| 41 | 382.195 | 8.022 | 44.406 | 9.470 | 11.378 | 0.444 | 4.856 |

| 42 | 426.537 | 10.934 | 41.986 | 10.369 | 10.366 | 0.501 | 4.921 |

| No. | Original | Optimized | Improvement | ||

|---|---|---|---|---|---|

| MRR (mm2/s) | SR (µm) | MRR (mm2/s) | SR (µm) | ||

| 1 | 0.296 | 4.78 | 0.3 | 4.473 | −6.4% SR |

| 2 | 0.354 | 4.88 | 0.353 | 4.568 | −6.3% SR |

| 3 | 0.308 | 4.69 | 0.395 | 4.695 | +28% MRR |

| 4 | 0.315 | 4.77 | 0.421 | 4.777 | +34% MRR |

| No. | Process Parameters | Ra | MRR | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ton (ns) | Toff (μs) | SV (V) | WF (mm2/s) | WT (N) | Exp. | Pre. | Re. (%) | Exp. | Pre. | Re. (%) | |

| 1 | 300 | 9 | 47 | 10 | 10 | 4.75 | 4.49 | 5.79 | 0.341 | 0.313 | 8.95 |

| 2 | 350 | 9 | 45 | 10 | 10 | 4.9 | 4.65 | 5.38 | 0.417 | 0.377 | 10.61 |

| 3 | 400 | 9 | 45 | 9 | 10 | 4.92 | 4.77 | 3.14 | 0.449 | 0.421 | 6.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Kabongo, B.D.; Zhou, H.; Wu, C.; Chen, Z. Analysis and Optimization of the Machining Characteristics of High-Volume Content SiCp/Al Composite in Wire Electrical Discharge Machining. Crystals 2021, 11, 1342. https://doi.org/10.3390/cryst11111342

Yan H, Kabongo BD, Zhou H, Wu C, Chen Z. Analysis and Optimization of the Machining Characteristics of High-Volume Content SiCp/Al Composite in Wire Electrical Discharge Machining. Crystals. 2021; 11(11):1342. https://doi.org/10.3390/cryst11111342

Chicago/Turabian StyleYan, Hongzhi, Bakadiasa Djo Kabongo, Hongbing Zhou, Cheng Wu, and Zhi Chen. 2021. "Analysis and Optimization of the Machining Characteristics of High-Volume Content SiCp/Al Composite in Wire Electrical Discharge Machining" Crystals 11, no. 11: 1342. https://doi.org/10.3390/cryst11111342