Catalyst/Feedstock Ratio Effect on FCC Using Different Catalysts Samples

Abstract

:1. Introduction

2. Results of the Catalyst Characterization

2.1. X-Ray Diffraction Analysis

2.2. NH3-TPD (Temperature Programmed Desorption)

2.3. Pyridine-FTIR

2.4. N2 Adsorption-Desorption Isotherms

3. Thermal Cracking Runs

4. Catalytic Cracking Runs

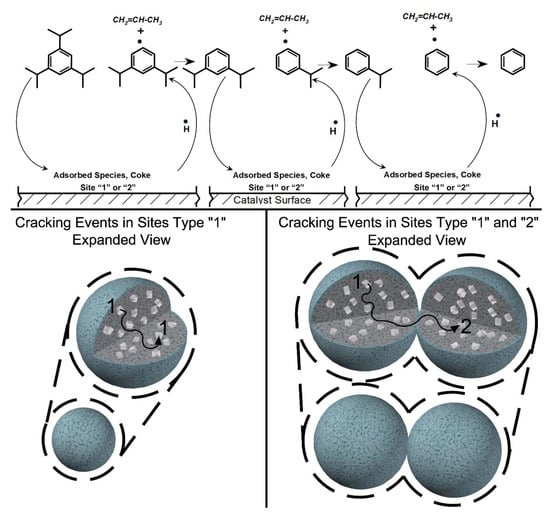

4.1. Effect of Catalyst-to-Oil Ratio (Catoil C/O Ratio) (g cat g feed −1)

4.2. Coke Selectivity

4.3. Hydrocarbon Product Selectivity

5. Materials and Methods

5.1. Feedstock and Catalysts

5.2. Catalyst Characterization

5.3. Chemical Species Analytical Methods

5.4. Catalytic Cracking Evaluation

6. Conclusions

- (a)

- It is shown that the 1,3,5-TIPB catalytic cracking displays common activity trends at increasing C/O ratios. This is shown using three Y-zeolite catalysts with different acidities and crystallinities.

- (b)

- It is proven that the 1,3,5-TIPB catalytic cracking, when using these three catalysts, displays maximum 1,3,5 TIPB conversions at C/O ratios of 2.5.

- (c)

- It is observed that the 1,3,5-TIPB cracking product selectivity shows the highest coke and the highest undesirable benzene selectivity at the maximum C/O of 5.

- (d)

- It is thus anticipated that catalyst density, which is a main parameter that determines the C/O ratio, plays a critical role in achieving the highest 1,3,5-TIPB conversions. This phenomenon is of significant importance for the operation of scaled FCC units.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| D | Pore diameter (A°) |

| Number of moles of “i” species (moles) in the gas phase | |

| Number of moles of coke collected (moles) | |

| T | Reaction temperature, K |

| t | Reaction time, s |

| Mass of catalyst (g) loaded in the riser (basket), where catalytic cracking occurs. | |

| Total mass of hydrocarbons injected (g) |

Abreviations

| BAS | Brönsted acid sites |

| BET | Brunauer–Emmett–Teller |

| CAT-A | Catalyst A |

| CAT-B | Catalyst B |

| CAT-C | Catalyst C |

| Catoil (C/O) | Catalyst-to-oil ratio (g/g) |

| CREC | Chemical Reaction Engineering Center |

| DRIFTS | Diffuse reflectance infrared Fourier transform spectroscopy |

| FCC | Fluidized catalytic cracking |

| FID | Flame ionization detector |

| FTIR | Fourier transform infrared spectroscopy |

| GC | Gas chromatography |

| LAS | Lewis acid sites |

| MSD | Mass spectrometer detector |

| MAT | Micro activity tests units |

| PSD | Pore size distribution |

| PV | Pore volume (cm3/g) |

| Selectivity-M | Moles of product “i” species/moles of 1,3,5-TIPB converted |

| Selectivity-W | Grams of coke/grams of TIPB converted. |

| SSA | Specific surface area (m2/g) |

| TCD | Thermal conductivity detector |

| 1,3,5-TIPB | 1,3,5-Tri-isopropyl benzene |

| TOC | Total organic coke (g-coke/g-cat.) |

| TPD | Temperature programmed desorption |

| VGO | Vacuum gas oil |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence |

References

- Hussain, A.I.; Palani, A.; Aitani, A.M.; Shamzhy, M.; Kub, M.; Al-khattaf, S.S. Catalytic cracking of vacuum gasoil over-SVR, ITH, and MFI zeolites as FCC catalyst additives. Fuel Process. Technol. 2017, 161, 23–32. [Google Scholar] [CrossRef]

- Vogt, E.T.C.; Weckhuyse, B.M. Fluid catalytic cracking: Recent development on the grand and old lady of zeolite catalysis. Chem. Soc. Rev. 2015, 44, 7342–7370. [Google Scholar] [CrossRef] [PubMed]

- Xiong, K.; Lu, C.; Wang, Z.; Gao, X. Quantitative correlations of cracking performance with physiochemical properties of FCC catalysts by a novel lump kinetic modelling method. Fuel 2015, 161, 113–119. [Google Scholar] [CrossRef]

- Corma, A.; Sauvanaud, L. FCC testing at bench scale: New units, new processes, new feeds. Catal. Today 2013, 218–219, 107–114. [Google Scholar] [CrossRef]

- Passamonti, F.; de la Puente, G.; Gilbert, W.; Morgado, E.; Sedran, U. Comparison between fixed fluidized bed (FFB) and batch fluidized bed reactors in the evaluation of FCC catalysts. Chem. Eng. J. 2012, 183, 433–447. [Google Scholar] [CrossRef]

- Marin, G.B. Rigorous Kinetic Models for Catalyst Deactivation by Coke Deposition: Application to Butene Dehydrogenation. J. Catal. 1986, 426, 416–426. [Google Scholar] [CrossRef]

- Cerqueira, H.S.; Caeiro, G.; Costa, L.; Ribeiro, F.R. Deactivation of FCC catalysts. J. Mol. Catal. Chem. 2008, 292, 1–13. [Google Scholar] [CrossRef]

- Bai, T.; Zhang, X.; Wang, F.; Qu, W.; Liu, X.; Duan, C. Coking behaviors and kinetics on HZSM-5/SAPO-34 catalysts for conversion of ethanol to propylene. J. Energy Chem. 2016, 25, 545–552. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kumar, V.; Srivastava, V.K. Modeling of Fluid Catalytic Cracking Riser Reactor: A Review. Int. J. Chem. React. Eng. 2010, 8, 1–40. [Google Scholar] [CrossRef]

- Han, I.; Riggs, J.B.; Chung, C. Modeling and optimization of a fluidized catalytic cracking process under full and partial combustion modes. Chem. Eng. Process. Process Intensif. 2004, 43, 1063–1084. [Google Scholar] [CrossRef]

- Al-Khattaf, S.; Saeed, M.R.; Aitani, A.; Klein, M.T. Catalytic cracking of light crude oil to Light Olefins and naphtha over E-Cat and MFI: Microactivity Test versus Advanced cracking evaluation and the effect of high reaction temperature. Energy Fuels 2018, 32, 6189–6199. [Google Scholar] [CrossRef]

- Wallensteln, D. Rational assessment of FCC catalyst performance by utilization of micro-activity testing. Appl. Catal. A Gen. 1998, 167, 141–155. [Google Scholar] [CrossRef]

- Shan, H.; Dong, H.; Zhang, J.; Niu, G. Experimental study of two-stage riser FCC reactions. Fuel 2001, 80, 1179–1185. [Google Scholar] [CrossRef]

- Gianetto, A.; Farag, H.I.; Blasetti, A.P.; de Lasa, H. Fluid Catalytic Cracking Catalyst for Reformulated Gasolines. Kinet. Modeling 1994, 33, 3053–3062. [Google Scholar]

- Delattre, C.; Forissier, M.; Pitault, I.; Schweich, D.; Bernard, J.R. Improvement of the microactivity test for kinetic and deactivation studies involved in catalytic cracking. Chem. Eng. Sci. 2001, 56, 1337–1345. [Google Scholar] [CrossRef]

- Fernandes, J.L.; Domingues, L.H.; Pinheiro, C.I.C.; Oliveira, N.M.C.; Ramôa, F. Influence of different catalyst deactivation models in a validated simulator of an industrial UOP FCC unit with high-efficiency regenerator. Fuel 2012, 97, 97–108. [Google Scholar] [CrossRef]

- Pinheiro, C.I.; Fernandes, J.L.; Domingues, L.; Chambel, A.J.; Graca, I.; Oliveira, N.M.; Cerqueira, H.S.; Ribeiro, F.R. Fluid Catalytic Cracking (FCC) Process Modeling, Simulation, and Control. Ind. Eng. Chem. Res. 2012, 51, 1–29. [Google Scholar] [CrossRef]

- Dupain, X.; Makkee, M.; Moulijn, J.A. Optimal conditions in fluid catalytic cracking: A mechanistic approach. Appl. Catal. A Gen. 2006, 297, 198–219. [Google Scholar] [CrossRef]

- Lappas, A.A.; Iatridis, D.K.; Papapetrou, M.C.; Kopalidou, E.P.; Vasalos, I.A. Feedstock and catalyst effects in fluid catalytic cracking—Comparative yields in bench scale and pilot plant reactors. Chem. Eng. J. 2015, 278, 140–149. [Google Scholar] [CrossRef]

- Jiménez-García, G.; Quintana-Solórzano, R.; Maya-Yescas, R. Improving accuracy in the estimation of kinetic frequency factors from laboratory data to model industrial catalytic cracking risers. Ind. Eng. Chem. Res. 2011, 50, 2736–2745. [Google Scholar] [CrossRef]

- de Lasa, H.I. Riser Simulator. U.S. Patent No. 5,102,628, 7 April 1992. [Google Scholar]

- Passamonti, F.J.; Puente, G.D.; Sedran, U. Comparison between MAT flow fixed bed and batch fluidized bed reactors in the evaluation of FCC catalysts. 2. Naphtha composition. Energy Fuels 2009, 23, 3510–3516. [Google Scholar] [CrossRef]

- Pruski, J.; Pekediz, A.; de Lasa, H. Catalytic cracking of hydrocarbons in a novel Riser Simulator: Lump Adsorption parameters under reaction conditions. Chem. Eng. Sci. 1996, 5, 1799–1806. [Google Scholar] [CrossRef]

- Kraemer, D.W. Modelling Catalytic Cracking in A Novel Riser Simulator (volumes I and Ii). Ph.D. Thesis, Western University, London, ON, Canada, 1991. [Google Scholar]

- Bartholomew, C.H.; Argyle, M.D. Advances in Catalyst Deactivation and Regeneration. Catalysts 2015, 5, 949–954. [Google Scholar] [CrossRef]

- Jarullah, A.T.; Awad, N.A.; Mujtaba, I.M. Optimal design and operation of an industrial fluidized catalytic cracking reactor. Fuel 2017, 206, 657–674. [Google Scholar] [CrossRef] [Green Version]

- Al-Sabawi, M.; Atias, J.A.; de Lasa, H. Kinetic modeling of catalytic cracking of gas oil feedstocks: Reaction and diffusion phenomena. Ind. Eng. Chem. Res. 2006, 45, 1583–1593. [Google Scholar] [CrossRef]

- Usman, A.; Bari, M.A.; Hussain, A.; Aitani, A.; Al-khattaf, S. Chemical engineering research and design catalytic cracking of crude oil to light olefins and naphtha: Experimental and kinetic modeling. Chem. Eng. Res. Des. 2017, 120, 121–137. [Google Scholar] [CrossRef]

- Yang, G.-F.; Wang, G.; Gao, J.S.; Xu, C.M. Coke formation and olefins conversion in FCC naphthaolefin reformulation at low reaction temperature. J. Fuel Chem. Technol. 2007, 35, 572–577. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Zhang, J.; Yang, C. Effects of temperature and catalyst to oil weight ratio on the catalytic conversion of heavy oil to propylene using ZSM-5 and USY catalysts. J. Nat. Gas Chem. 2007, 16, 92–99. [Google Scholar] [CrossRef]

- Alkhlel, A.; de Lasa, H. Catalytic Cracking of Hydrocarbons in a CREC Riser Simulator Using a Y—Zeolite-Based Catalyst: Assessing the Catalyst/Oil Ratio Effect. Ind. Eng. Chem. Res. 2018, 57, 13627–13638. [Google Scholar] [CrossRef]

- Alkhlel, A. Catalytic Conversion of Hydrocarbon 1,3,5-TIPB Over Y-Zeolite based Catalysts, Catalyst/oil ratio(C/O) Effect, and a Kinetic Model. Ph.D. Thesis. Disertatoion University of Western Ontario to be submitted August 2019.

- Jimeńez-García, G.; de Lasa, H.; Quintana-Soloŕzano, R.; Maya-Yescas, R. Catalyst activity decay due to pore blockage during catalytic cracking of hydrocarbons. Fuel 2013, 110, 89–98. [Google Scholar] [CrossRef]

- Atias, J.; Tonetto, G.M.; de Lasa, H. Modeling fluid catalytic cracking in a novel CREC Riser Simulator: Adsorption parameters under reaction conditions. Int. J. Chem. React. Eng. 2003, 1, 1–23. [Google Scholar] [CrossRef]

- Al-Khattaf, S.; de Lasa, H. The role of diffusion in alkyl-benzenes catalytic cracking. Appl. Catal. A Gen. 2002, 226, 139–153. [Google Scholar] [CrossRef]

- Mi, S.; Wei, T.; Sun, J.; Liu, P.; Li, X.; Zheng, Q.; Gong, K.; Liu, X. Catalytic function of boron to creating interconnected mesoporosity in microporous Y zeolites and its high performance in hydrocarbon cracking. J. Catal. 2017, 347, 116–126. [Google Scholar] [CrossRef]

- Guo, D.; Shen, B.; Qin, Y.; Sun, J.; Guo, Q.; Ren, S.; Gao, X.; Pang, X.; Wang, B.; Zhao, H. Microporous and Mesoporous Materials USY zeolites with tunable mesoporosity designed by controlling framework Fe content and their catalytic cracking properties. Microporous Mesoporous Mater. 2015, 211, 192–199. [Google Scholar] [CrossRef]

- Atias, J.A.; de Lasa, H. Adsorption, diffusion, and reaction phenomena on FCC catalysts in the CREC riser simulator. Ind. Eng. Chem. Res. 2004, 43, 4709–4720. [Google Scholar] [CrossRef]

- Bazyari, A.; Khodadadi, A.A.; Hosseinpour, N.; Mortazavi, Y. Effects of steaming-made changes in physicochemical properties of Y-zeolite on cracking of bulky 1,3,5-triisopropylbenzene and coke formation. Fuel Process. Technol. 2009, 90, 1226–1233. [Google Scholar] [CrossRef]

- White, M.G. Heterogeneous Catalysis; Prentice Hall: Upper Saddle River, NJ, USA, 1992. [Google Scholar]

- Tonetto, G.; Atias, J.; de Lasa, H. FCC catalysts with different zeolite crystallite sizes: Acidity, structural properties and reactivity. Appl. Catal. A Gen. 2004, 270, 9–25. [Google Scholar] [CrossRef]

- Arandes, J.M.; Abajo, I.; Fernández, I.; Azkoiti, M.J.; Bilbao, J. Effect of HZSM-5 Zeolite Addition to a Fluid Catalytic Cracking Catalyst. Study in a Laboratory Reactor Operating under Industrial Conditions. Ind. Eng. Chem. Res. 2000, 39, 1917–1924. [Google Scholar] [CrossRef]

| Sample | Particle SiO2/Al2O3(mol/mol) | Unit Cell Size (A°) | Crystallinity |

|---|---|---|---|

| CAT-A | 0.86 | 24.30 | 0.094 |

| CAT-B | 0.72 | 24.30 | 0.077 |

| CAT-C | 0.92 | 24.29 | 0.078 |

| CAT-A | CAT-B | CAT-C | |

|---|---|---|---|

| Sample | NH3 uptake (cm3 STP/g) | NH3 uptake (cm3 STP/g) | NH3 uptake (cm3 STP/g) |

| Free of Coke | 3.36 | 1.73 | 1.47 |

| Catoil = 1.25 | 2.48 | 1.24 | 1.14 |

| Catoil = 2.5 | 2.31 | 1.24 | 1.13 |

| Catoil = 3.75 | 2.24 | 1.04 | 0.94 |

| Catoil = 5 | 2.23 | 0.95 | 0.84 |

| Sample Catalyst | Brönsted/Lewis Acid Sites Ratio |

|---|---|

| CAT-A | 0.298 |

| CAT-B | 0.334 |

| CAT-C | 0.321 |

| CAT-A | CAT-B | CAT-C | |

|---|---|---|---|

| BET (SSA) | 99.6 | 118.5 | 102 |

| Pore Volume (PV) (cm3/g) | 0.158 | 0.196 | 0.140 |

| Mesopores Volume (cm3/g) | 0.112 | 0.142 | 0.0916 |

| Micropores Volume (cm3/g) | 0.0468 | 0.0540 | 0.0491 |

| CAT-B Catalyst Samples | ||||||

|---|---|---|---|---|---|---|

| Free Coke | C/O = 0.6 | C/O = 0.8 | C/O = 1.25 | C/O = 2.5 | C/O = 3.75 | |

| BET (Specific Surface Area) | 102 | 93.37 | 91.88 | 89.18 | 88.92 | 81.56 |

| Pore Volume (PV) cm3/g | 0.140 | 0.129 | 0.137 | 0.121 | 0.122 | 0.120 |

| Mesopores-Macropores Volume, cm3/g | 0.0916 | 0.0864 | 0.0936 | 0.0785 | 0.0795 | 0.0815 |

| Micropores Volume cm3/g | 0.0491 | 0.0435 | 0.0439 | 0.0430 | 0.0425 | 0.0390 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkhlel, A.; de Lasa, H. Catalyst/Feedstock Ratio Effect on FCC Using Different Catalysts Samples. Catalysts 2019, 9, 542. https://doi.org/10.3390/catal9060542

Alkhlel A, de Lasa H. Catalyst/Feedstock Ratio Effect on FCC Using Different Catalysts Samples. Catalysts. 2019; 9(6):542. https://doi.org/10.3390/catal9060542

Chicago/Turabian StyleAlkhlel, Abdualkaber, and Hugo de Lasa. 2019. "Catalyst/Feedstock Ratio Effect on FCC Using Different Catalysts Samples" Catalysts 9, no. 6: 542. https://doi.org/10.3390/catal9060542