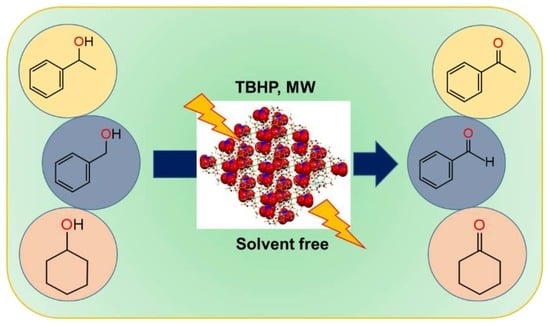

Cu(II) and Fe(III) Complexes Derived from N-Acetylpyrazine-2-Carbohydrazide as Efficient Catalysts Towards Neat Microwave Assisted Oxidation of Alcohols

Abstract

:1. Introduction

2. Results and Discussion

2.1. Synthesis and Characterizations

2.2. General Description of the Crystal Structure

2.3. Catalytic Studies

3. Materials and Methods

3.1. Synthesis of the Pro-Ligand H2L

3.2. Synthesis of [Cu(kNN’O-HL)(H2O)2] (1)

3.3. Synthesis of [Fe(kNN’O-HL)Cl2] (2) and [Fe(kNN’O-HL)Cl(µ-OMe)]2 (3)

3.4. X-Ray Measurements

3.5. Catalytic Studies

Typical Procedures for the Catalytic Oxidation of Alcohols and Product Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gupta, K.C.; Sutar, A.K. Catalytic activities of Schiff base transition metal complexes. Coord. Chem. Rev. 2008, 252, 1420–1450. [Google Scholar] [CrossRef]

- Chelucci, G. Ruthenium and osmium complexes in C-C bond-forming reactions by borrowing hydrogen catalysis. Coord. Chem. Rev. 2017, 331, 1–36. [Google Scholar] [CrossRef]

- Sutradhar, M.; Martins, L.M.D.R.S.; Guedes da Silva, M.F.C.; Pombeiro, A.J.L. Vanadium complexes: Recent progress in oxidation catalysis. Coord. Chem. Rev. 2015, 301–302, 200–239. [Google Scholar] [CrossRef]

- Sutradhar, M.; Roy Barman, T.; Pombeiro, A.J.L.; Martins, L.M.D.R.S. Ni(II)-Aroylhydrazone Complexes as Catalyst Precursors Towards Efficient Solvent-Free Nitroaldol Condensation Reaction. Catalysts 2019, 9, 554. [Google Scholar] [CrossRef] [Green Version]

- Sutradhar, M.; Kirillova, M.V.; Guedes da Silva, M.F.C.; Cai-Ming, L.; Pombeiro, A.J.L. Tautomeric effect of hydrazone Schiff bases in tetranuclear Cu(II) complexes: Magnetism and catalytic activity towards mild hydrocarboxylation of alkanes. Dalton. Trans. 2013, 42, 16578–16587. [Google Scholar] [CrossRef] [PubMed]

- Sutradhar, M.; Martins, L.M.D.R.S.; Guedes da Silva, M.F.C.; Pombeiro, A.J.L. Oxido vanadium complexes with tridentate aroylhydrazone as catalyst precursors for solvent-free microwave-assisted oxidation of alcohol. Appl. Cat. A Gen. 2015, 493, 50–57. [Google Scholar] [CrossRef]

- Sutradhar, M.; Alegria, E.C.B.A.; Mahmudov, K.T.; Guedes da Silva, M.F.C.; Pombeiro, A.J.L. Iron(III) and cobalt(III) complexes with both tautomeric (keto and enol) forms of aroylhydrazone ligands: Catalysts for the microwave assisted oxidation of alcohols. RSC Adv. 2016, 6, 8079–8088. [Google Scholar] [CrossRef]

- Sutradhar, M.; Da Silva, M.F.C.G.; Pombeiro, A.J. A new cyclic binuclear Ni(II) complex as a catalyst towards nitroaldol (Henry) reaction. Catal. Commun. 2014, 57, 103–106. [Google Scholar] [CrossRef]

- Sutradhar, M.; Alegria, E.C.B.A.; Roy Barman, T.; Scorcelletti, F.; Guedes da Silva, M.F.C.; Pombeiro, A.J.L. Microwave-assisted peroxidative oxidation of toluene and 1-phenylethanol with monomeric keto and polymeric enol aroylhydrazone Cu(II) complexes. Mol. Catal. 2017, 439, 224–232. [Google Scholar] [CrossRef]

- Martins, L.M.D.R.S.; Pombeiro, A.J.L. Tris(pyrazol-1yl)methane metal complexes for catalytic mild oxidative functionalizations of alkanes, alkenes and ketones. Coord. Chem. Rev. 2014, 265, 74–88. [Google Scholar] [CrossRef]

- Martins, L.M.D.R.S. C-scorpionate complexes: Ever young catalytic tools. Coord. Chem. Rev. 2019, 396, 89–102. [Google Scholar] [CrossRef]

- Ribeiro, A.P.C.; Martins, L.M.D.R.S.; Pombeiro, A.J.L. Carbon dioxide-to-methanol single-pot conversion using a C-scorpionate iron(II) catalyst. Green Chem. 2017, 19, 4801–4962. [Google Scholar] [CrossRef]

- Ribeiro, A.P.C.; Martins, L.M.D.R.S.; Pombeiro, A.J.L. N2O-free single-pot conversion of cyclohexane to adipic acid catalysed by an iron(II) scorpionate complex. Green Chem. 2017, 19, 1499–1501. [Google Scholar] [CrossRef]

- Montoya, C.A.; Gómez, C.F.; Paninho, A.B.; Nunes, A.V.M.; Mahmudov, K.T.; Najdanovic-Visak, V.; Martins, L.M.D.R.S.; Guedes da Silva, M.F.C.; Nunes da Ponte, M.; Pombeiro, A.J.L. Cyclic carbonate synthesis from CO2 and epoxides using zinc(II) complexes of arylhydrazones of β-diketones. J. Catal. 2016, 335, 135–140. [Google Scholar] [CrossRef] [Green Version]

- Abrantes, M.; Valente, A.; Pillinger, M.; Goncalves, I.S.; Rocha, J.; Romao, C.C. Organotin–Oxometalate Coordination Polymers as Catalysts for the Epoxidation of Olefins. J. Catal. 2002, 209, 237–244. [Google Scholar] [CrossRef]

- Togni, A.; Venanzi, L.M. Nitrogen Donors in Organometallic Chemistry and Homogeneous Catalysis. Angew. Chem. Int. Ed. Engl. 1994, 33, 497–526. [Google Scholar] [CrossRef]

- Fache, F.; Dunjic, B.; Gamez, P.; Lemaire, M. Recent advances in homogeneous and heterogeneous asymmetric catalysis with nitrogen-containing ligands. Top. Catal. 1997, 4, 201–209. [Google Scholar] [CrossRef]

- Marko, I.E.; Giles, P.R.; Tsukazaki, M.; Brown, S.M. Copper-Catalyzed Oxidation of Alcohols to Aldehydes and Ketones: An Efficient, Aerobic Alternative. Science 1996, 274, 2044–2046. [Google Scholar] [CrossRef] [Green Version]

- Larock, R.C. Comprehensive Organic Transformations; Wiley-VCH: New York, NY, USA, 1999. [Google Scholar]

- Wang, X.; Wu, G.; Wei, W.; Sun, Y. Solvent-free oxidation of alcohols by hydrogen peroxide over chromium Schiff base complexes immobilized on MCM-41. Trans. Met. Chem. 2010, 35, 213–220. [Google Scholar] [CrossRef]

- Farhadi, S.; Zaidi, M. Polyoxometalate–zirconia (POM/ZrO2) nanocomposite prepared by sol-gel process: A green and recyclable photocatalyst for efficient and selective aerobic oxidation of alcohols into aldehydes and ketones. Appl. Catal. A 2009, 354, 119–126. [Google Scholar] [CrossRef]

- Brühne, F.; Wright, E. Benzaldehyde, Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; Volume 5, pp. 223–233. [Google Scholar]

- Lee, D.G.; Spitzer, U.A. Aqueous dichromate oxidation of primary alcohols. J. Org. Chem. 1970, 35, 3589–3590. [Google Scholar] [CrossRef]

- Prabhakaran, P.V.; Venkatachalam, S.; Ninan, K.N. Permanganate ion supported over crosslinked polyvinylamine as an oxidising agent for alcohols. Eur. Poly. J. 1999, 35, 1743–1746. [Google Scholar] [CrossRef]

- Abad, A.; Almela, C.; Corma, A.; García, H. Efficient chemoselective alcohol oxidation using oxygen as oxidant. Superior performance of gold over palladium catalysts. Tetrahedron 2006, 62, 6666–6672. [Google Scholar] [CrossRef]

- Tojo, G.; Fernandez, M. Oxidation of Alcohols to Aldehydes and Ketones: A Guide to Current Common Practice; Springer: New York, NY, USA, 2006. [Google Scholar]

- Ullmann’s Encyclopedia of Industrial Chemistry, 6th ed.; Wiley-VCH: Weinheim, Germany, 2002.

- Mardani, H.R.; Golchoubian, H. Effective oxidation of benzylic and aliphatic alcohols with hydrogen peroxide catalyzed by a manganese(III) Schiff-base complex under solvent-free conditions. Tetrahedron Lett. 2006, 47, 2349–2352. [Google Scholar] [CrossRef]

- Sutradhar, M.; Martins, L.M.; Roy Barman, T.; Kuznetsov, M.L.; Guedes da Silva, M.F.C.; Pombeiro, A.J.L. Vanadium complexes of different nuclearities in the catalytic oxidation of cyclohexane and cyclohexanol—An experimental and theoretical investigation. New. J. Chem. 2019, 43, 17557–17570. [Google Scholar] [CrossRef]

- Sutradhar, M.; Roy Barman, T.; Alegria, E.C.B.A.; Guedes da Silva, M.F.C.; Liu, C.-M.; Kou, H.-Z.; Pombeiro, A.J.L. Cu(II) complexes of N-rich aroylhydrazone: Magnetism and catalytic activity towards microwave-assisted oxidation of xylenes. Dalton Trans. 2019, 48, 12839–12849. [Google Scholar] [CrossRef]

- Sutradhar, M.; Alegria, E.C.B.A.; Guedes da Silva, M.F.C.; Martins, L.M.D.R.S.; Pombeiro, A.J.L. Aroylhydrazone Cu(II) complexes in keto form: Structural characterization and catalytic activity towards cyclohexane oxidation. Molecules 2016, 21, 425. [Google Scholar] [CrossRef] [Green Version]

- Sutradhar, M.; Martins, L.M.D.R.S.; Carabineiro, S.A.C.; Guedes da Silva, M.F.C.; Buijnsters, J.G.; Figueiredo, J.L.; Pombeiro, A.J.L. Oxidovanadium(V) Complexes Anchored on Carbon Materials as Catalysts for the Oxidation of 1-Phenylethanol. ChemCatChem 2016, 8, 2254–2266. [Google Scholar] [CrossRef]

- Sutradhar, M.; Martins, L.M.D.R.S.; Guedes da Silva, M.F.C.; Alegria, E.C.B.A.; Liu, C.-M.; Pombeiro, A.J.L. Mn(II,II) complexes: Magnetic properties and microwave assisted oxidation of alcohols. Dalton Trans. 2014, 43, 3966–3977. [Google Scholar] [CrossRef]

- Sutradhar, M.; Alegria, E.C.B.A.; Guedes da Silva, M.F.C.; Liu, C.-M.; Pombeiro, A.J.L. Trinuclear Cu(II) structural isomers: Coordination, magnetism, electrochemistry and catalytic activity toward oxidation of alkanes. Eur. J. Inorg. Chem. 2015, 2015, 3959–3969. [Google Scholar] [CrossRef]

- Sutradhar, M.; Alegria, E.C.B.A.; Guedes da Silva, M.F.C.; Liu, C.-M.; Pombeiro, A.J.L. Peroxidative oxidation of alkanes and alcohols under mild conditions by di- and tetranuclear copper(II) complexes of bis(2-hydroxybenzylidene)isophthalohydrazide. Molecules 2018, 23, 2699. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sutradhar, M.; Roy Barman, T.; Pombeiro, A.J.L.; Martins, L.M.D.R.S. Catalytic Activity of Polynuclear vs. Dinuclear Aroylhydrazone Cu(II) Complexes in Microwave-Assisted Oxidation of Neat Aliphatic and Aromatic Hydrocarbons. Molecules 2019, 24, 47. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Timokhin, I.; Pettinari, C.; Marchetti, F.; Pettinari, R.; Condello, F.; Galli, S.; Alegria, E.C.B.A.; Martins, L.M.D.R.S.; Pombeiro, A.J.L. Novel Coordination Polymers with (Pyrazolato)-based Tectons: Catalytic Activity in the Peroxidative Oxidation of Alcohols and Cyclohexane. Cryst. Growth Des. 2015, 15, 2303–2317. [Google Scholar] [CrossRef]

- Alexandru, M.; Cazacu, M.; Arvinte, A.; Shova, S.; Turta, C.; Simionescu, B.C.; Dobrov, A.; Alegria, E.C.B.A.; Martins, L.M.D.R.S.; Pombeiro, A.J.L.; et al. Chlorido-bridged dimanganese(II) complexes of the Schiff base derived from [2+2]condensation of 2,6-diformyl-4-methylphenol and 1,3-bis(3-aminopropyl)tetramethyldisiloxane: Structure, Magnetism, Electrochemical Behaviour and Catalytic Oxidation of Secondary Alcohols. Eur. J. Inorg. Chem. 2014, 2014, 120–131. [Google Scholar]

- Ribeiro, A.P.C.; Martins, L.M.D.R.S.; Hazra, S.; Pombeiro, A.J.L. Catalytic Oxidation of Cyclohexane with Hydrogen Peroxide and a Tetracopper(II) Complex in an Ionic Liquid. C. R. Chim. 2015, 18, 758–765. [Google Scholar] [CrossRef]

- Silva, T.F.S.; Martins, L.M.D.R.S.; Guedes da Silva, M.F.; Kuznetsov, M.L.; Fernandes, A.R.; Silva, A.; Santos, S.; Pan, C.-J.; Lee, J.-F.; Hwang, B.-J.; et al. Cobalt complexes with pyrazole ligands as catalysts for the peroxidative oxidation of cyclohexane. XAS studies and biological applications. Chem. Asian J. 2014, 9, 1132–1143. [Google Scholar] [CrossRef]

- Roy Barman, T.; Sutradhar, M.; Alegria, E.C.B.A.; Guedes da Silva, M.F.C.; Kuznetsov, M.L.; Pombeiro, A.J.L. Efficient Solvent-Free Friedel-Crafts Benzoylation and Acylation of m-Xylene Catalyzed by N-Acetylpyrazine-2-carbohydrazide-Fe(III)-chloro Complexes. ChemistrySelect 2018, 3, 8349–8355. [Google Scholar] [CrossRef]

- Sutradhar, M.; Kirillova, M.V.; Guedes da Silva, M.F.C.; Martins, L.M.D.R.S.; Pombeiro, A.J.L. A hexanuclear oxovanadium(IV,V) complex bearing N,O-ligand as a highly efficient alkane oxidation catalyst. Inorg. Chem. 2012, 51, 11229–11231. [Google Scholar] [CrossRef] [Green Version]

- Sutradhar, M.; Guedes da Silva, M.F.C.; Pombeiro, A.J.L. Synthesis and chemical reactivity of an Fe(III) metallacrown-6 towards N-donor Lewis bases. Inorg. Chem. Commun. 2013, 30, 42–45. [Google Scholar] [CrossRef]

- Sutradhar, M.; Guedes da Silva, M.F.C.; Nesterov, D.S.; Jezierska, J.; Pombeiro, A.J.L. 1D coordination polymer with octahedral and square-planar nickel(II) centers. Inorg. Chem. Commun. 2013, 29, 82–84. [Google Scholar] [CrossRef]

- Addison, W.; Rao, T.N.; Reedijk, J.; van Rijn, J.; Verschoor, G.C. Synthesis, structure, and spectroscopic properties of copper(II) compounds containing nitrogen–sulphur donor ligands; the crystal and molecular structure of aqua[1,7-bis(N-methylbenzimidazol-2′-yl)-2,6-dithiaheptane]copper(II) perchlorate. J. Chem. Soc. Dalton Trans. 1984, 1349–1356. [Google Scholar] [CrossRef]

- Moiseeva, I.N.; Gekham, A.E.; Minin, V.V.; Larin, G.M.; Bashtanov, M.E.; Krasnovskii, A.A.; Moiseev, I.I. Free radical/singlet dioxygen system under the conditions of catalytic hydrogen peroxide decomposition. Kinet. Catal. 2000, 41, 170–177. [Google Scholar] [CrossRef]

- Figiel, P.J.; Leskelä, M.; Repo, T. TEMPO-Copper(II) Diimine-Catalysed Oxidation of Benzylic Alcohols in Aqueous Media. Adv. Synth. Catal. 2007, 349, 1173–1179. [Google Scholar] [CrossRef]

- Ahmad, J.U.; Figiel, P.J.; Räisänen, M.T.; Leskelä, M.; Repo, T. Aerobic oxidation of benzylic alcohols with bis(3,5-di-tert-butylsalicylaldimine)copper(II) complexes. Appl. Catal. A 2009, 371, 17–21. [Google Scholar] [CrossRef]

- Xu, B.; Lumb, J.-P.; Arndtsen, B.A. A TEMPO-Free Copper-Catalyzed Aerobic Oxidation of Alcohols. Angew. Chem. Int. Ed. 2015, 54, 1–5. [Google Scholar]

- Gao, J.; Ren, Z.-G.; Lang, J.-P. Oxidation of benzyl alcohols to benzaldehydes in water catalyzed by a Cu(II) complex with a zwitterionic calix[4]arene ligand. J. Organometall. Chem. 2015, 792, 88–92. [Google Scholar] [CrossRef]

- Jlassia, R.; Ribeiro, A.P.C.; Mendes, M.; Rekik, W.; Tiago, G.A.O.; Mahmudov, K.T.; Naïli, H.; Guedes da Silva, M.F.C.; Pombeiro, A.J.L. Arylhydrazone Cd(II) and Cu(II) complexes as catalysts for secondary alcohol oxidation. Polyhedron 2017, 129, 182–188. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, C.; Wu, S.; Zhang, W.; Xue, W.; Zeng, Z. Synthesis of Benzaldehyde and Benzoic Acid by Selective Oxidation of Benzyl Alcohol with Iron(III) Tosylate and Hydrogen Peroxide: A Solvent-Controlled Reaction. Catal. Lett. 2018, 148, 3082–3092. [Google Scholar] [CrossRef]

- Pramanick, R.; Bhattacharjee, R.; Sengupta, D.; Datta, A.; Goswami, S. An Azoaromatic Ligand as Four Electron Four Proton Reservoir: Catalytic Dehydrogenation of Alcohols by Its Zinc(II) Complex. Inorg. Chem. 2018, 57, 6816–6824. [Google Scholar] [CrossRef]

- Bruker, A.X.S. APEX2 & SAINT.; AXS Inc.: Madison, WI, USA, 2004. [Google Scholar]

- Altomare, A.; Burla, M.C.; Camalli, M.; Cascarano, G.L.; Giacovazzo, C.; Guagliardi, A.; Moliterni, A.G.G.; Polidori, G.; Spagna, R. SIR97: A New Tool for Crystal Structure Determination and Refinement. J. Appl. Cryst. 1999, 32, 115–119. [Google Scholar] [CrossRef]

- Sheldrick, G.M. A Short History of SHELX. Acta Crystallogr. Sect. A 2008, 64, 112–122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farrugia, L.J. WinGX and ORTEP for Windows: An Update. J. Appl. Cryst. 2012, 45, 849–854. [Google Scholar] [CrossRef]

| 1 | |

|---|---|

| Empirical formula | C7H11CuN5O7 |

| Formula Weight | 340.75 |

| Crystal system | Monoclinic |

| Space group | C2/c |

| Temperature/K | 297 (2) |

| a/Å | 13.8799 (9) |

| b/Å | 16.9433 (10) |

| c/Å | 11.9900 (7) |

| α/° | 90 |

| β/° | 117.763 (2) |

| γ/° | 90 |

| V (Å3) | 2495.1 (3) |

| Z | 8 |

| Dcalc (g cm−3) | 1.814 |

| μ(Mo Kα) (mm−1) | 1.79 |

| Rfls. collected/unique/observed | 15921/2292/1997 |

| Rint | 0.029 |

| Final R1a, wR2b (I ≥ 2σ) | 0.027, 0.072 |

| Goodness-of-fit on F2 | 1.07 |

| Cu1—N9 | 1.8900 (18) |

| Cu1—O14 | 1.9066 (17) |

| Cu1—O12 | 2.0111 (15) |

| Cu1—N1 | 2.0813 (18) |

| Cu1—O15 | 2.260 (2) |

| N9—Cu1—O14 | 166.20 (10) |

| N9—Cu1—O12 | 80.33 (7) |

| O14—Cu1—O12 | 94.01 (7) |

| N9—Cu1—N1 | 79.43 (7) |

| O14—Cu1—N1 | 103.48 (8) |

| O12—Cu1—N1 | 157.54 (7) |

| N9—Cu1—O15 | 97.24 (8) |

| O14—Cu1—O15 | 96.11 (9) |

| O12—Cu1—O15 | 99.49 (7) |

| N1—Cu1—O15 | 92.63 (7) |

| Entry | Catalyst | Substrate | Temperature (°C) | Reaction Time (h) | Additive | Yield (%) b | TON (TOF (h-1)) c |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 1-phenyl ethanol | 80 | 0.5 | - | 32.3 | 162 (324) |

| 2 | 100 | 0.5 | - | 44.8 | 224 (448) | ||

| 3 | 120 | 0.5 | - | 51.4 | 257 (514) | ||

| 4 | 120 | 1.0 | - | 86.4 | 432 (432) | ||

| 5 | 120 | 1.5 | - | 69.8 | 349 (233) | ||

| 6 | 120 | 2.0 | - | 65.4 | 327 (164) | ||

| 7 d | 120 | 1 | - | 67.6 | 338 (338) | ||

| 8 d | 120 | 4 | 87.2 | 436 (109) | |||

| 8 e | 120 | 1 | HPCA | 51.8 | 259 (259) | ||

| 9 f | 120 | 1 | HNO3 | 25.6 | 128 (128) | ||

| 10 g | 120 | 1 | TEMPO | 91.3 | 457 (457) | ||

| 11 h | 120 | 1 | Ph2NH | 5.9 | 30 (30) | ||

| 12 | benzyl alcohol | 120 | 1 | - | 33.4 | 167 (167) | |

| 13 d | 120 | 1 | - | 19.5 | 98 (98) | ||

| 14 g | 120 | 1 | TEMPO | 41.2 | 206 (206) | ||

| 15 h | 120 | 1 | Ph2NH | 3.6 | 18 (18) | ||

| 16 | cyclohexanol | 120 | 1 | - | 65.6 | 328 (328) | |

| 17 d | 120 | 1 | - | 23.9 | 120 (120) | ||

| 18 g | 120 | 1 | TEMPO | 67.9 | 274 (274) | ||

| 19 h | 120 | 1 | Ph2NH | 3.9 | 20 (20) | ||

| 20 | 2 | 1-phenyl ethanol | 80 | 0.5 | - | 20.1 | 101 (101) |

| 21 | 100 | 0.5 | - | 24.6 | 123 (123) | ||

| 22 | 120 | 0.5 | - | 46.2 | 193 (385) | ||

| 23 | 120 | 1.0 | - | 77.7 | 389 (389) | ||

| 24 | 120 | 1.5 | - | 69.3 | 347 (231) | ||

| 25 | 120 | 2.0 | - | 66.9 | 335 (167) | ||

| 26 g | 120 | 1.0 | TEMPO | 83.8 | 419 (419) | ||

| 27 h | 120 | 1.0 | Ph2NH | 4.7 | 24 (24) | ||

| 28 | benzyl alcohol | 120 | 1.0 | - | 26.7 | 133 (133) | |

| 29 | cyclohexanol | 120 | 1.0 | - | 35.8 | 179 (179) | |

| 30 | 3 | 1-phenyl ethanol | 80 | 0.5 | - | 11.2 | 56 (112) |

| 31 | 100 | 0.5 | - | 20.3 | 102 (204) | ||

| 32 | 120 | 0.5 | - | 28.6 | 143 (286) | ||

| 33 | 120 | 1.0 | - | 65.2 | 326 (326) | ||

| 34 | 120 | 1.5 | - | 60.4 | 302 (201) | ||

| 35 | 120 | 2.0 | - | 56.8 | 284 (142) | ||

| 36 g | 120 | 1.0 | TEMPO | 71.3 | 377 (377) | ||

| 37 h | 120 | 1.0 | Ph2NH | 2.8 | 14 (14) | ||

| 38 | benzyl alcohol | 120 | 1.0 | - | 18.9 | 95 (95) | |

| 39 | cyclohexanol | 120 | 1.0 | - | 36.7 | 184 (184) | |

| 40 | Cu(NO3).2.5 H2O | 1-phenyl ethanol | 120 | 1.0 | - | 6.2 | 31 (31) |

| 41 | benzyl alcohol | 120 | 1.0 | - | 2.7 | 14 (14) | |

| 42 | cyclohexanol | 120 | 1.0 | - | 4.3 | 22 (22) | |

| 43 | FeCl3 | 1-phenyl ethanol | 120 | 1.0 | - | 4.9 | 25 (25) |

| 44 | benzyl alcohol | 120 | 1.0 | - | 2.2 | 11 (11) | |

| 45 | cyclohexanol | 120 | 1.0 | - | 3.4 | 17 (17) |

| Catalyst | Amount (mol%) | Substrate | Oxidant | Temp (°C) | Time (h) | Yield (%) | Ref |

|---|---|---|---|---|---|---|---|

| [Cu(II)L1(H2O)]I2 | 0.25 | Benzyl alcohol | H2O2 (in the presence of TEMPO and K2CO3) | 60 | 24 | 99 | 51 |

| [Cu(im)(µ-HL2-1κO:2κNOO′)]2 | 0.15 | 1-phenylethanol | H2O2 (in the presence of TEMPO) | 80 (MW irradiation) | 1 | 74 | 52 |

| Fe(OTs)3·6H2O | 0.1 | Benzyl alcohol | H2O2 | 60 | 16 | 85.6 | 53 |

| ZnL3Cl2 | 5 | Benzyl alcohol | O2 (in the presence of KtBuO, Zn dust) | 60 | 24 | 76 | 54 |

| [Cu(kNN′O-HL)(H2O)2] | 0.2 | Benzyl alcohol | TBHP (in the presence of TEMPO) | 120 (MW irradiation) | 1 | 91.3 | This work |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sutradhar, M.; Roy Barman, T.; Pombeiro, A.J.L.; Martins, L.M.D.R.S. Cu(II) and Fe(III) Complexes Derived from N-Acetylpyrazine-2-Carbohydrazide as Efficient Catalysts Towards Neat Microwave Assisted Oxidation of Alcohols. Catalysts 2019, 9, 1053. https://doi.org/10.3390/catal9121053

Sutradhar M, Roy Barman T, Pombeiro AJL, Martins LMDRS. Cu(II) and Fe(III) Complexes Derived from N-Acetylpyrazine-2-Carbohydrazide as Efficient Catalysts Towards Neat Microwave Assisted Oxidation of Alcohols. Catalysts. 2019; 9(12):1053. https://doi.org/10.3390/catal9121053

Chicago/Turabian StyleSutradhar, Manas, Tannistha Roy Barman, Armando J. L. Pombeiro, and Luísa M. D. R. S. Martins. 2019. "Cu(II) and Fe(III) Complexes Derived from N-Acetylpyrazine-2-Carbohydrazide as Efficient Catalysts Towards Neat Microwave Assisted Oxidation of Alcohols" Catalysts 9, no. 12: 1053. https://doi.org/10.3390/catal9121053