Advances in Magnetically Separable Photocatalysts: Smart, Recyclable Materials for Water Pollution Mitigation

Abstract

:1. Introduction

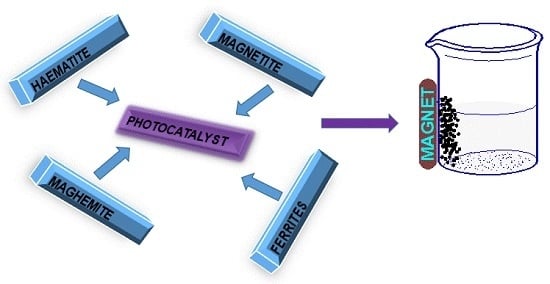

2. Recent Developments in Magnetic Photocatalysts

2.1. Haematite (α-Fe2O3)-Based Magnetic Photocatalysts

2.2. Maghemite (γ-Fe2O3)-based Magnetic Photocatalysts

2.3. Magnetite (Fe3O4)-based Magnetic Photocatalysts

2.4. Ferrites (MFe2O4)-based Magnetic Photocatalysts

3. Summary Remarks and Future Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fersi, C.; Gzara, L.; Dhahbi, M. Treatment of textile effluents by membrane technologies. Desalination 2005, 185, 399–409. [Google Scholar] [CrossRef]

- Pendergast, M.M.; Hoek, E.M.V. A review of water treatment membrane nanotechnologies. Energy Environ. Sci. 2011, 4, 1946–1971. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, X.W.; Su, J.Q.; Tian, Y.; Xiong, X.J.; Zheng, T.L. Biological decolorization of the reactive dyes Reactive Black 5 by a novel isolated bacterial strain Enterobacter sp. EC3. J. Hazard. Mater. 2009, 171, 654–659. [Google Scholar] [CrossRef] [PubMed]

- Kumari, K.; Abraham, T.E. Biosorption of anionic textile dyes by nonviable biomass of fungi and yeast. Bioresour. Technol. 2007, 98, 1704–1710. [Google Scholar] [CrossRef] [PubMed]

- Soutsas, K.; Karayannis, V.; Poulios, I.; Riga, A.; Ntampegliotis, K.; Spiliotis, X.; Papapolymerou, G. Decolorization and degradation of reactive azo dyes via heterogeneous photocatalytic processes. Desalination 2010, 250, 345–350. [Google Scholar] [CrossRef]

- Wu, J.; Doan, H.; Upreti, S. Decolorization of aqueous textile reactive dye by ozone. Chem. Eng. J. 2008, 142, 156–160. [Google Scholar] [CrossRef]

- Harsha, N.; Krishna, K.V.S.; Renuka, N.K.; Shukla, S. Facile synthesis of g–Fe2O3 nanoparticles integrated H2Ti3O7 nanotubes structure as a magnetically recyclable dye-removal catalyst. RSC Adv. 2015, 5, 30354–30362. [Google Scholar] [CrossRef]

- Li, K.; Chai, F.; Zhao, Y.; Guo, X. Facile synthesis of magnetic Fe3O4/CeCO3OH composites with excellent adsorption capability for small cationic dyes. RSC Adv. 2015, 5, 94397–94404. [Google Scholar] [CrossRef]

- Song, S.; Fan, J.; He, Z.; Zhan, L.; Liu, Z.; Chen, J.; Xu, X. Electrochemical degradation of azo dye C.I. Reactive Red 195 by anodic oxidation on Ti/SnO2-Sb/PbO2 electrodes. Electrochim. Acta 2010, 55, 3606–3613. [Google Scholar] [CrossRef]

- Faouzi, A.M.; Nasr, B.; Abdellatif, G. Electrochemical degradation of anthraquinone dye Alizarin Red S by anodic oxidation on boron-doped diamond. Dyes Pigments 2007, 73, 86–89. [Google Scholar] [CrossRef]

- Rodrigues, C.S.D.; Madeira, L.M.; Boaventura, R.A.R. Synthetic textile dyeing wastewater treatment by integration of advanced oxidation and biological processes—Performance analysis with costs reduction. J. Environ. Chem. Eng. 2014, 2, 1027–1039. [Google Scholar] [CrossRef]

- Basha, C.A.; Selvakumar, K.V.; Prabhu, H.J.; Sivashanmugam, P.; Lee, C.W. Degradation studies for textile reactive dye by combined electrochemical, microbial and photocatalytic methods. Sep. Purif. Technol. 2011, 79, 303–309. [Google Scholar] [CrossRef]

- Berberidou, C.; Avlonitis, S.; Poulios, I. Dyestuff effluent treatment by integrated sequential photocatalytic oxidation and membrane filtration. Desalination 2009, 249, 1099–1106. [Google Scholar] [CrossRef]

- Khouni, I.; Marrot, B.; Moulin, P.; Ben, R. Decolourization of the reconstituted textile effluent by different process treatments: Enzymatic catalysis, coagulation/flocculation and nanofiltration processes. Desalination 2011, 268, 27–37. [Google Scholar] [CrossRef]

- Trzcinski, A.P.; Stuckey, D.C. Inorganic fouling of an anaerobic membrane bioreactor treating leachate from the organic fraction of municipal solid waste (OFMSW) and a polishing aerobic membrane bioreactor. Bioresour. Technol. 2016, 204, 17–25. [Google Scholar] [CrossRef] [PubMed]

- Schulz, M.; Soltani, A.; Zheng, X.; Ernst, M. Effect of inorganic colloidal water constituents on combined low-pressure membrane fouling with natural organic matter (NOM). J. Membr. Sci. 2016, 507, 154–164. [Google Scholar] [CrossRef]

- Hegab, H.M.; Elmekawy, A.; Barclay, T.G.; Michelmore, A.; Zou, L.; Saint, C.P.; Ginic-Markovic, M. Effective in-situ chemical surface modification of forward osmosis membranes with polydopamine-induced graphene oxide for biofouling mitigation. Desalination 2016, 385, 126–137. [Google Scholar] [CrossRef]

- Gottlieb, A.; Shaw, C.; Smith, A.; Wheatley, A.; Forsythe, S. The toxicity of textile reactive azo dyes after hydrolysis and decolourisation. J. Biotechnol. 2003, 101, 49–56. [Google Scholar] [CrossRef]

- Kariyajjanavar, P.; Jogttappa, N.; Nayaka, Y.A. Studies on degradation of reactive textile dyes solution by electrochemical method. J. Hazard. Mater. 2011, 190, 952–961. [Google Scholar] [CrossRef] [PubMed]

- Faouzi Elahmadi, M.; Bensalah, N.; Gadri, A. Treatment of aqueous wastes contaminated with Congo Red dye by electrochemical oxidation and ozonation processes. J. Hazard. Mater. 2009, 168, 1163–1169. [Google Scholar] [CrossRef] [PubMed]

- Mohammad, N.; Arami, M. Degradation and toxicity reduction of textile wastewater using immobilized titania nanophotocatalysis. J. Photochem. Photobiol. B 2009, 94, 20–24. [Google Scholar]

- Aksu, Z.; Dönmez, G. Combined effects of molasses sucrose and reactive dye on the growth and dye bioaccumulation properties of Candida tropicalis. Process Biochem. 2005, 40, 2443–2454. [Google Scholar] [CrossRef]

- Yu, W.; Xu, D.; Peng, T. Enhanced photocatalytic activity of g-C3N4 for selective CO2 reduction to CH3OH via facile coupling of ZnO: A direct Z-scheme mechanism. J. Mater. Chem. A 2015, 3, 19936–19947. [Google Scholar] [CrossRef]

- Lu, D.; Zhang, G.; Wan, Z. Visible-light-driven g-C3N4/Ti3+-TiO2 photocatalyst co-exposed {001} and {101} facets and its enhanced photocatalytic activities for organic pollutant degradation and Cr(VI) reduction. Appl. Surf. Sci. 2015, 358, 223–230. [Google Scholar] [CrossRef]

- Li, G.; Nie, X.; Chen, J.; Jiang, Q.; An, T.; Wong, P.K.; Zhang, H.; Zhao, H.; Yamashita, H. Enhanced visible-light-driven photocatalytic inactivation of Escherichia coli using g-C3N4/TiO2 hybrid photocatalyst synthesized using a hydrothermal-calcination approach. Water Res. 2015, 86, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Ni, Y.; Li, S.; Wang, M. Chain-like Fe3O4@resorcinol-formaldehyde resins-Ag composite microstructures: Facile construction and applications in antibacterial and catalytic fields. RSC Adv. 2016, 6, 15831–15837. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.; Pei, L.; Li, X.; Fan, T.; Ji, J.; Shen, J.; Ye, M. Multifunctional photocatalytic performances of recyclable Pd-NiFe2O4/reduced graphene oxide nanocomposites via different co-catalyst strategy. Appl. Catal. B Environ. 2016, 190, 1–11. [Google Scholar] [CrossRef]

- Zeng, B.; Zhang, L.; Wan, X.; Song, H.; Lv, Y. Fabrication of α-Fe2O3/g-C3N4 composites for cataluminescence sensing of H2S. Sens. Actuators Chem. 2015, 211, 370–376. [Google Scholar] [CrossRef]

- Wang, G.; Kuang, S.; Zhang, J.; Hou, S.; Nian, S. Graphitic carbon nitride/multiwalled carbon nanotubes composite as Pt-free counter electrode for high-efficiency dye-sensitized solar cells. Electrochim. Acta 2016, 187, 243–248. [Google Scholar] [CrossRef]

- Wang, M.; Yang, X.; Bi, W. Application of magnetic graphitic carbon nitride nanocomposites for the solid-phase extraction of phthalate esters in water samples. J. Sep. Sci. 2015, 38, 445–452. [Google Scholar] [CrossRef] [PubMed]

- Baig, R.B.N.; Verma, S.; Varma, R.S.; Nadagouda, M.N. Magnetic Fe@g-C3N4: A photoactive catalyst for the hydrogenation of alkenes and alkynes. ACS Sustain. Chem. Eng. 2016, 4, 1661–1664. [Google Scholar] [CrossRef]

- Preethi, V.; Kanmani, S. Photocatalytic hydrogen production using Fe2O3-based core shell nano particles with ZnS and CdS. Int. J. Hydrogen Energy 2014, 39, 1613–1622. [Google Scholar] [CrossRef]

- Cao, M.; Wang, P.; Ao, Y.; Wang, C.; Hou, J.; Qian, J. Visible light activated photocatalytic degradation of tetracycline by a magnetically separable composite photocatalyst: Graphene oxide/magnetite/cerium-doped titania. J. Colloid Interface Sci. 2016, 467, 129–139. [Google Scholar] [CrossRef] [PubMed]

- Bao, X.; Qiang, Z.; Chang, J.; Ben, W.; Qu, J. Synthesis of carbon-coated magnetic nanocomposite (Fe3O4@C) and its application for sulfonamide antibiotics removal from water. J. Environ. Sci. 2014, 26, 962–969. [Google Scholar] [CrossRef]

- Zhou, L.; Deng, J.; Zhao, Y.; Liu, W.; An, L.; Chen, F. Preparation and characterization of N–I co-doped nanocrystal anatase TiO2 with enhanced photocatalytic activity under visible-light irradiation. Mater. Chem. Phys. 2009, 117, 522–527. [Google Scholar] [CrossRef]

- Nolan, N.T.; Synnott, D.W.; Seery, M.K.; Hinder, S.J.; van Wassenhoven, A.; Pillai, S.C. Effect of N-doping on the photocatalytic activity of sol-gel TiO2. J. Hazard. Mater. 2012, 211–212, 88–94. [Google Scholar] [CrossRef] [PubMed]

- Pany, S.; Parida, K.M. A facile in situ approach to fabricate N,S-TiO2/g-C3N4 nanocomposite with excellent activity for visible light induced water splitting for hydrogen evolution. Phys. Chem. Chem. Phys. 2015, 17, 8070–8077. [Google Scholar] [CrossRef] [PubMed]

- Ge, M.; Chen, Y.; Liu, M.; Li, M. Synthesis of magnetically separable Ag3PO4/ZnFe2O4 composite photocatalysts for dye degradation under visible LED light irradiation. J. Environ. Chem. Eng. 2015, 3, 2809–2815. [Google Scholar] [CrossRef]

- Xu, Y.; Huang, S.; Xie, M.; Li, Y.; Jing, L.; Xu, H. Core-shell magnetic Ag/AgCl@Fe2O3 photocatalysts with enhanced photoactivity for eliminating bisphenol A and microbial contamination. New J. Chem. 2016, 40, 3413–3422. [Google Scholar] [CrossRef]

- Yao, Y.; Lu, F.; Zhu, Y.; Wei, F.; Liu, X.; Lian, C.; Wang, S. Magnetic core-shell CuFe2O4@C3N4 hybrids for visible light photocatalysis of Orange II. J. Hazard. Mater. 2015, 297, 224–233. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.-P.; Chen, C.-C.; Lee, W.W.; Lai, Y.-Y.; Chen, J.; Chen, Y.; Fu, J.-Y. Synthesis of a SrFeO3−x/g-C3N4 heterojunction with improved visible-light photocatalytic activities in chloramphenicol and crystal violet degradation. RSC Adv. 2015, 6, 2323–2336. [Google Scholar] [CrossRef]

- Li, G.; Nie, X.; Gao, Y.; An, T. Can environmental pharmaceuticals be photocatalytically degraded and completely mineralized in water using g-C3N4/TiO2 under visible light irradiation?—Implications of persistent toxic intermediates. Appl. Catal. B Environ. 2016, 180, 726–732. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, S.; Wang, Y. A convenient method to prepare a novel alkali metal sodium doped carbon nitride photocatalyst with a tunable band structure. RSC Adv. 2014, 4, 62912–62919. [Google Scholar] [CrossRef]

- Jin, R.; Hu, S.; Gui, J.; Liu, D. A convenient method to prepare novel rare earth metal Ce-doped carbon nitride with enhanced photocatalytic activity under visible light. Bull. Korean Chem. Soc. 2015, 36, 17–23. [Google Scholar] [CrossRef]

- Akpan, U.G.; Hameed, B.H. Enhancement of the photocatalytic activity of TiO2 by doping it with calcium ions. J. Colloid Interface Sci. 2011, 357, 168–178. [Google Scholar] [CrossRef] [PubMed]

- Inturi, S.N.R.; Boningari, T.; Suidan, M.; Smirniotis, P.G. Visible-light-induced photodegradation of gas phase acetonitrile using aerosol-made transition metal (V, Cr, Fe, Co, Mn, Mo, Ni, Cu, Y, Ce, and Zr) doped TiO2. Appl. Catal. B Environ. 2014, 144, 333–342. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Zhu, K.; Ma, F.; Meng, A. Ag/g-C3N4 composite nanosheets: Synthesis and enhanced visible photocatalytic activities. Mater. Lett. 2015, 145, 167–170. [Google Scholar] [CrossRef]

- Hu, S.; Ma, L.; You, J.; Li, F.; Fan, Z.; Wang, F.; Liu, D.; Gui, J. A simple and efficient method to prepare a phosphorus modified g-C3N4 visible light photocatalyst. RSC Adv. 2014, 4, 21657–21663. [Google Scholar] [CrossRef]

- Sun, H.; Wang, S.; Ang, H.M.; Tadé, M.O.; Li, Q. Halogen element modified titanium dioxide for visible light photocatalysis. Chem. Eng. J. 2010, 162, 437–447. [Google Scholar] [CrossRef]

- Dong, G.; Ai, Z.; Zhang, L. Efficient anoxic pollutant removal with oxygen functionalized graphitic carbon nitride under visible light. RSC Adv. 2014, 4, 5553–5560. [Google Scholar] [CrossRef]

- Sharotri, N.; Sud, D. Ultrasound-assisted synthesis and characterization of visible light responsive nitrogen-doped TiO2 nanomaterials for removal of 2-Chlorophenol. Desalin. Water Treat. 2016, 57, 8776–8788. [Google Scholar] [CrossRef]

- Reszczyńska, J.; Grzyb, T.; Sobczak, J.W.; Lisowski, W.; Gazda, M.; Ohtani, B.; Zaleska, A. Visible light activity of rare earth metal doped (Er3+, Yb3+ or Er3+/Yb3+) titania photocatalysts. Appl. Catal. B: Environ. 2015, 163, 40–49. [Google Scholar] [CrossRef]

- Kaur, N.; Kaur, S.; Singh, V. Preparation, characterization and photocatalytic degradation kinetics of Reactive Red dye 198 using N, Fe codoped TiO2 nanoparticles under visible light. Desalination Water Treat. 2016, 57, 9237–9246. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, X.; Zhang, L.; Xu, L.; Ma, L.; Luo, J.; Li, M.; Zeng, L. Photoredox degradation of different water pollutants (MO, RhB, MB, and Cr(VI)) using Fe-N-S-tri-doped TiO2 nanophotocatalyst prepared by novel chemical method. Mater. Res. Bull. 2015, 70, 106–113. [Google Scholar] [CrossRef]

- Antonopoulou, M.; Vlastos, D.; Konstantinou, I. Photocatalytic degradation of pentachlorophenol by N-F-TiO2: Identification of intermediates, mechanism involved, genotoxicity and ecotoxicity evaluation. Photochem. Photobiol. Sci. 2015, 14, 520–527. [Google Scholar] [CrossRef] [PubMed]

- Mamba, G.; Mbianda, X.Y.; Mishra, A.K. Photocatalytic degradation of the diazo dye naphthol blue black in water using MWCNT/Gd,N,S-TiO2 nanocomposites under simulated solar light. J. Environ. Sci. 2015, 33, 219–228. [Google Scholar] [CrossRef] [PubMed]

- Mamba, G.; Mamo, M.A.; Mbianda, X.Y.; Mishra, A.K. Nd,N,S-TiO2 decorated on reduced graphene oxide for a visible light active photocatalyst for dye degradation: Comparison to its MWCNT/Nd,N,S-TiO2 analogue. Ind. Eng. Chem. Res. 2014, 53, 14329–14338. [Google Scholar] [CrossRef]

- Mamba, G.; Mbianda, X.Y.; Mishra, A.K. Enhanced visible light photocatalytic degradation of eriochrome black T and eosin blue shade in water using tridoped titania decorated on SWCNTs and MWCNTs: Effect of the type of carbon nanotube incorporated. Mater. Chem. Phys. 2015, 149–150, 734–742. [Google Scholar] [CrossRef]

- Apostolopoulou, V.; Vakros, J.; Kordulis, C.; Lycourghiotis, A. Preparation and characterization of [60] fullerene nanoparticles supported on titania used as a photocatalyst. Colloids Surf. A Physicochem. Eng. Asp. 2009, 349, 189–194. [Google Scholar] [CrossRef]

- Shang, J.; Zhao, F.; Zhu, T.; Li, J. Photocatalytic degradation of rhodamine B by dye-sensitized TiO2 under visible-light irradiation. Sci. China Chem. 2011, 54, 167–172. [Google Scholar] [CrossRef]

- Nam, K.; Jung, H.; Lee, W. Hollow cobalt ferrite-polyaniline nanofibers as magnetically separable visible-light photocatalyst for photodegradation of methyl orange. J. Photochem. Photobiol. A Chem. 2016, 321, 257–265. [Google Scholar]

- Kim, G.; Choi, W. Charge-transfer surface complex of EDTA-TiO2 and its effect on photocatalysis under visible light. Appl. Catal. B Environ. 2010, 100, 77–83. [Google Scholar] [CrossRef]

- Shi, W.; Lu, D.; Wang, L.; Teng, F.; Zhang, J. Core-shell structured Fe3O4@SiO2@CdS nanoparticles with enhanced visible-light photocatalytic photocatalytic activities. RSC Adv. 2015, 5, 106038–106043. [Google Scholar] [CrossRef]

- Li, J.; Liu, Z.; Zhu, Z. Enhanced photocatalytic activity in ZnFe2O4-ZnO-Ag3PO4 hollow nanospheres through the cascadal electron transfer with magnetical separation. J. Alloys Compd. 2015, 636, 229–233. [Google Scholar] [CrossRef]

- Jiang, R.; Zhu, H.; Li, J.; Fu, F.; Yao, J.; Jiang, S.; Zeng, G.-M. Fabrication of novel magnetically separable BiOBr/CoFe2O4 microspheres and its application in the efficient removal of dye from aqueous phase by an environment-friendly and economical approach. Appl. Surf. Sci. 2016, 364, 604–612. [Google Scholar] [CrossRef]

- Mi, J.; Hwan, Y.; Keun, B.; Ho, S.; Soo, B.; Bin, J. Novel immobilization of titanium dioxide (TiO2) on the fluidizing carrier and its application to the degradation of azo-dye. J. Hazard. Mater. 2006, 134, 230–236. [Google Scholar]

- Fernhndez, A.; Lassaletta, G.; Jimknez, V.M.; Justo, A. Preparation and characterization of TiO2 photocatalysts supported on various rigid supports (glass, quartz and stainless steel). Comparative studies of photocatalytic activity in water purification. Appl. Catal. B Environ. 1995, 7, 49–63. [Google Scholar] [CrossRef]

- Carlson, P.J.; Pretzer, L.A.; Boyd, J.E. Solvent deposition of titanium dioxide on acrylic for photocatalytic application. Ind. Eng. Chem. Res. 2007, 46, 7970–7976. [Google Scholar] [CrossRef]

- Arabatzis, I.M.; Antonaraki, S.; Stergiopoulos, T.; Hiskia, A. Preparation, characterization and photocatalytic activity of nanocrystalline thin film TiO2 catalysts towards 3,5-dichlorophenol degradation. J. Photochem. Photobiol. A Chem. 2002, 149, 237–245. [Google Scholar] [CrossRef]

- Anpo, M.; Zhang, S.G.; Mishima, H.; Matsuoka, M.; Yamashita, H. Design of photocatalysts encapsulated within the zeolite framework and cavities for the decomposition of NO into N2 and O2 at normal temperature. Catal. Today 1997, 39, 159–168. [Google Scholar] [CrossRef]

- Rao, N.N.; Chaturvedi, V. Photoactivity of TiO2-coated pebbles. Ind. Eng. Chem. Res. 2007, 46, 4406–4414. [Google Scholar] [CrossRef]

- Gad-allah, T.A.; Kato, S.; Satokawa, S.; Kojima, T. Treatment of synthetic dyes wastewater utilizing a magnetically separable photocatalyst (TiO2/SiO2/Fe3O4): Parametric and kinetic studies. Desalination 2009, 244, 1–11. [Google Scholar] [CrossRef]

- Wang, W.; Yao, J. Synthesis of magnetically separable Sn doped magnetite/silica core-shell structure and photocatalytic property. Mater. Res. Bull. 2010, 45, 710–716. [Google Scholar] [CrossRef]

- Belessi, V.; Lambropoulou, D.; Konstantinou, I.; Zboril, R.; Tucek, J.; Jancik, D. Structure and photocatalytic performance of magnetically separable titania photocatalysts for the degradation of propachlor. Appl. Catal. B Environ. 2009, 87, 181–189. [Google Scholar] [CrossRef]

- Linley, S.; Leshuk, T.; Gu, F.X. Synthesis of magnetic rattle-type nanostructures for use in water treatment. ACS Appl. Mater. Interfaces 2013, 5, 2540–2548. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Kumar, B.; Baruah, A.; Shanker, V. Synthesis of magnetically separable and recyclable g-C3N4–Fe3O4 hybrid nanocomposites with enhanced photocatalytic performance under visible-light irradiation. J. Phys. Chem. C 2013, 117, 26135–26143. [Google Scholar] [CrossRef]

- Yang, J.; Chen, H.; Gao, J.; Yan, T.; Zhou, F.; Cui, S.; Bi, W. Synthesis of Fe3O4/g-C3N4 nanocomposites and their application in the photodegradation of 2,4,6-trichlorophenol under visible light. Mater. Lett. 2016, 164, 183–189. [Google Scholar] [CrossRef]

- Shih, Y.; Su, C.; Chen, C.; Dong, C. Synthesis of magnetically recoverable ferrite (MFe2O4, M = Co, Ni and Fe)-supported TiO2 photocatalysts for decolorization of methylene blue. Catal. Commun. 2015, 72, 127–132. [Google Scholar] [CrossRef]

- Pang, Y.L.; Lim, S.; Ong, H.C.; Chong, W.T. Synthesis, characteristics and sonocatalytic activities of calcined α-Fe2O3 and TiO2 nanotubes/α-Fe2O3 magnetic catalysts in the degradation of Orange G. Ultrason. Sonochem. 2016, 29, 317–327. [Google Scholar]

- Zhang, D.; Pu, X.; Du, K.; Moon, Y.; Jeong, J.; Cai, P.; Kim, S., II; Seo, H.J. Combustion synthesis of magnetic Ag/NiFe2O4 composites with enhanced visible-light photocatalytic properties. Sep. Purif. Technol. 2014, 137, 82–85. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, L.; Gu, X.; Li, S.; Li, B.; Wang, H. Fe2O3-AgBr nonwoven cloth with hierarchical nanostructures as efficient and easily recyclable macroscale photocatalysts. RSC Adv. 2015, 5, 10951–10959. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, Q.; Wang, L.; Zhang, L. Magnetically separable CdFe2O4/graphene catalyst and its enhanced photocatalytic properties. J. Mater. Chem. A 2015, 3, 3576–3585. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, S.Z.; Hu, Q.H.; Qing, G.; Lu, M. Magnetic nanocomposites with mesoporous structures: Synthesis and applications. Small 2011, 7, 425–443. [Google Scholar] [CrossRef] [PubMed]

- Polshettiwar, V.; Luque, R.; Fihri, A.; Zhu, H.; Bouhrara, M.; Basset, J. Magnetically recoverable nanocatalysts. Chem. Rev. 2011, 111, 3036–3075. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Zhou, C.; Sun, Z.; Wu, L.-Z.; Tung, C.-H.; Zhang, T. Magnetically recyclable nanocatalysts (MRNCs): A versatile integration of high catalytic activity and facile recovery. Nanoscale 2012, 4, 6244–6255. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Astruc, D. Fast-growing field of magnetically recyclable nanocatalysts. Chem. Rev. 2014, 114, 6949–6985. [Google Scholar] [CrossRef] [PubMed]

- Linley, S.; Leshuk, T.; Gu, F.X. Magnetically separable water treatment technologies and their role in future advanced water treatment: A patent review. CLEAN Soil Air Water 2013, 41, 1152–1156. [Google Scholar] [CrossRef]

- Yao, H.; Fan, M.; Wang, Y. Magnetic titanium dioxide based nanomaterials: Synthesis, characteristics, and photocatalytic application in pollutant degradation. J. Mater. Chem. A 2015, 3, 17511–17524. [Google Scholar] [CrossRef]

- Liu, D.; Li, Z.; Wang, W.; Wang, G.; Liu, D. Hematite doped magnetic TiO2 nanocomposites with improved photocatalytic activity. J. Alloy Compd. 2016, 654, 491–497. [Google Scholar] [CrossRef]

- Shi, Y.; Li, H.; Wang, L.; Shen, W.; Chen, H. Novel α-Fe2O3/CdS cornlike nanorods with enhanced photocatalytic performance. ACS Appl. Mater. Interfaces 2012, 4, 4800–4806. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Jing, L.; Chen, X.; Ji, H.; Xu, H.; Li, H. Novel visible-light-driven Fe2O3/Ag3VO4 composite with enhanced photocatalytic activity toward organic pollutants degradation. RSC Adv. 2016, 6, 3600–3607. [Google Scholar] [CrossRef]

- Xu, Y.; Huang, S.; Xie, M.; Li, Y.; Xu, H.; Huang, L.; Zhang, Q.; Li, H. Magnetically separable Fe2O3/g-C3N4 catalyst with enhanced photocatalytic activity. RSC Adv. 2015, 5, 95727–95735. [Google Scholar] [CrossRef]

- Kumar, S.V.; Huang, N.M.; Yusoff, N.; Lim, H.N. High performance magnetically separable graphene/zinc oxide nanocomposite. Mater. Lett. 2013, 93, 411–414. [Google Scholar] [CrossRef]

- Wang, H.; Fei, X.; Wang, L.; Li, Y.; Xu, S. Magnetically separable iron oxide nanostructures-TiO2 nanofibers hierarchical heterostructures: Controlled fabrication and photocatalytic activity. New J. Chem. 2011, 35, 1795–1802. [Google Scholar] [CrossRef]

- Muthukrishnaraj, A.; Vadivel, S.; Kamalakannan, V.P.; Balasubramanian, N. α-Fe2O3/reduced graphene oxide nanorod as efficient photocatalyst for methylene blue degradation. Mater. Res. Innov. 2016, 19, 258–264. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, S.; Xiao, X.; Zhou, J.; Ren, F.; Sun, L.; Jiang, C. Controllable synthesis, magnetic properties, and enhanced photocatalytic activity of spindle-like mesoporous α-Fe2O3/ZnO core-shell heterostructures. ACS Appl. Mater. Interfaces 2012, 4, 3602–3609. [Google Scholar] [CrossRef] [PubMed]

- Xue, J.; Ma, S.; Zhou, Y.; Zhang, Z.; Liu, X. Fabrication of porous g-C3N4/Ag/Fe2O3 composites with enhanced visible light photocatalysis performance. RSC Adv. 2015, 5, 58738–58745. [Google Scholar] [CrossRef]

- Liu, X.; Jin, A.; Jia, Y.; Jiang, J.; Hu, N.; Chen, X. Facile synthesis and enhanced visible-light photocatalytic activity of graphitic carbon nitride decorated with ultrafine Fe2O3 nanoparticles. RSC Adv. 2015, 5, 92033–92041. [Google Scholar] [CrossRef]

- Theerthagiri, J.; Senthil, R.A.; Priya, A.; Madhavan, J.; Michael, R.J.V.; Ashokkumar, M. Photocatalytic and photoelectrochemical studies of visible-light-active α-Fe2O3-g-C3N4 nanocomposites. RSC Adv. 2014, 4, 38222–38229. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Y.X.; Zhang, W. Photoelectrochemical study on charge transfer properties of nanostructured Fe2O3 modified by g-C3N4. Int. J. Hydrogen Energy 2014, 39, 9105–9113. [Google Scholar] [CrossRef]

- Peng, L.; Xie, T.; Lu, Y.; Fan, H.; Wang, D. Synthesis, photoelectric properties and photocatalytic activity of the Fe2O3/TiO2 heterogeneous photocatalysts. Phys. Chem. Chem. Phys. 2010, 12, 8033–8041. [Google Scholar] [CrossRef] [PubMed]

- Pawar, R.C.; Pyo, Y.; Ahn, S.H.; Lee, C.S. Photoelectrochemical properties and photodegradation of organic pollutants using hematite hybrids modified by gold nanoparticles and graphitic carbon nitride. Appl. Catal. B Environ. 2015, 176–177, 654–666. [Google Scholar] [CrossRef]

- Yamauraa, M.; Camilo, R.L.; Sampaio, L.C.; Macedo, M.A.; Nakamurad, M.; Toma, H.E. Preparation and characterization of (3-aminopropyl) triethoxysilane-coated magnetite nanoparticles. J. Magn. Magn. Mater. 2004, 279, 210–217. [Google Scholar] [CrossRef]

- Tian, B.; Wang, T.; Dong, R.; Bao, S.; Yang, F.; Zhang, J. Core-shell structured–Fe2O3@SiO2@AgBr: Ag composite with high magnetic separation efficiency and excellent visible light activity for acid orange 7 degradation. Appl. Catal. B Environ. 2014, 147, 22–28. [Google Scholar] [CrossRef]

- Idris, A.; Hassan, N.; Rashid, R.; Ngomsik, A. Kinetic and regeneration studies of photocatalytic magnetic separable beads for chromium (VI) reduction under sunlight. J. Hazard. Mater. 2011, 186, 629–635. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Liu, S.; Yu, J. Superparamagnetic γ-Fe2O3@SiO2@TiO2 composite microspheres with superior photocatalytic properties. Appl. Catal. B Environ. 2011, 104, 12–20. [Google Scholar] [CrossRef]

- Lin, Y.; Chang, C. Magnetic mesoporous iron oxide/carbon aerogel photocatalysts with adsorption ability for organic dye removal. RSC Adv. 2014, 4, 28628–28631. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Tan, J. Novel magnetically separable AgCl/iron oxide composites with enhanced photocatalytic activity driven by visible light. J. Alloy. Compd. 2013, 574, 383–390. [Google Scholar] [CrossRef]

- Ye, S.; Qiu, L.-G.; Yuan, Y.-P.; Zhu, Y.-J.; Xia, J.; Zhu, J.-F. Facile fabrication of magnetically separable graphitic carbon nitride photocatalysts with enhanced photocatalytic activity under visible light. J. Mater. Chem. A 2013, 1, 2929–3188. [Google Scholar] [CrossRef]

- He, M.; Li, D.; Jiang, D.; Chen, M. Magnetically separable γ-Fe2O3@SiO2@Ce-doped TiO2 core-shell nanocomposites: Fabrication and visible-light-driven photocatalytic activity. J. Solid State Chem. 2012, 192, 139–143. [Google Scholar] [CrossRef]

- Kaur, N.; Shahi, S.K.; Singh, V. Synthesis, characterization and photocatalytic activity of magnetically separable γ-Fe2O3/N,Fe codoped TiO2 heterojunction for degradation of Reactive Blue 4 dye. RSC Adv. 2015, 5, 61623–61630. [Google Scholar] [CrossRef]

- Yu, L.; Yang, X.; Wang, D. TiO2 incorporated in magnetic mesoporous SBA-15 by a facile inner-pore hydrolysis process toward enhanced adsorption-photocatalysis performances for As(III). J. Colloid Interface Sci. 2015, 448, 525–532. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yu, L.; Hu, Y.; Guo, C.; Wen, X.; Lou, D. A magnetically separable photocatalyst based on nest-like γ-Fe2O3/ZnO double-shelled hollow structures with enhanced photocatalytic activity. Nanoscale 2012, 4, 183–187. [Google Scholar] [CrossRef] [PubMed]

- Szeto, W.; Li, J.; Huang, H.; Xuan, J.; Leung, D.Y.C. Novel urchin-like Fe2O3@SiO2@TiO2 microparticles with magnetically separable and photocatalytic properties. RSC Adv. 2015, 5, 55363–55371. [Google Scholar] [CrossRef]

- Kumar, A.; Guo, C.; Sharma, G.; Pathania, D.; Naushad, M.; Kalia, S.; Dhiman, P. Magnetically recoverable ZrO2/Fe3O4/chitosan nanomaterials for enhanced sunlight driven photoreduction of carcinogenic Cr(VI) and dechlorination and mineralization of 4-chlorophenol from simulated waste water. RSC Adv. 2016, 6, 13251–13263. [Google Scholar] [CrossRef]

- Zhao, Y.; Tao, C.; Xiao, G.; Wei, G.; Li, L.; Liu, C.; Su, H. Controlled synthesis and photocatalysis of sea urchin-like Fe3O4@TiO2@Ag nanocomposites. Nanoscale 2016, 8, 5313–5326. [Google Scholar] [CrossRef]

- Li, G.; Wong, K.H.; Zhang, X.; Hu, C.; Yu, J.C.; Chan, R.C.Y.; Wong, P.K. Degradation of Acid Orange 7 using magnetic AgBr under visible light: The roles of oxidizing species. Chemosphere 2009, 76, 1185–1191. [Google Scholar] [CrossRef] [PubMed]

- Álvarez, P.M.; Jaramillo, J.; López-pi, F.; Plucinski, P.K. Preparation and characterization of magnetic TiO2 nanoparticles and their utilization for the degradation of emerging pollutants in water. Appl. Catal. B Environ. 2010, 100, 338–345. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, W.; Sun, S.; Sun, Y.; Gao, E.; Zhang, Z. Elimination of BPA endocrine disruptor by magnetic BiOBr@SiO2@Fe3O4 photocatalyst. Appl. Catal. B Environ. 2014, 148–149, 164–169. [Google Scholar] [CrossRef]

- Chen, F.; Yan, F.; Chen, Q.; Wang, Y.; Han, L.; Chen, Z.; Fang, S. Fabrication of Fe3O4@SiO2@TiO2 nanoparticles supported by graphene oxide sheets for the repeated adsorption and photocatalytic degradation of rhodamine B under UV irradiation. Dalton Trans. 2014, 43, 13537–13544. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, W. Synthesis of Fe3O4/N-TiO2/Ag hollow nanospheres and their application as recyclable photocatalysts. J. Cluster Sci. 2016, 27, 403–415. [Google Scholar] [CrossRef]

- Ma, J.; Guo, S.; Guo, X.; Ge, H. A mild synthetic route to Fe3O4@TiO2-Au composites: Preparation, characterization and photocatalytic activity. Appl. Surf. Sci. 2015, 353, 1117–1125. [Google Scholar] [CrossRef]

- Li, S.; Liang, W.; Zheng, F.; Zhou, H.; Lin, X. Lysine surface modified Fe3O4@SiO2@TiO2 microspheres-based preconcentration and photocatalysis for in situ selective determination of nanomolar dissolved organic and inorganic phosphorus in seawater. Sens Actuators B Chem. 2016, 224, 48–54. [Google Scholar] [CrossRef]

- Hongfei, L.I.U.; Shengfu, J.I.; Yuanyuan, Z.; Ming, L.I. Porous TiO2-coated magnetic core-shell nanocomposites: Preparation and enhanced photocatalytic activity. Chin. J. Chem. Eng. 2013, 21, 569–576. [Google Scholar]

- Ma, J.; Guo, S.; Guo, X.; Ge, H.-G. Liquid-phase deposition of TiO2 nanoparticles on core-shell Fe3O4@SiO2 spheres: Preparation, characterization, and photocatalytic activity. J. Nanopart. Res. 2015, 17, 1–11. [Google Scholar] [CrossRef]

- Rashid, J.; Barakat, M.A.; Ruzmanova, Y.; Chianese, A. Fe3O4/SiO2/TiO2 nanoparticles for photocatalytic degradation of 2-chlorophenol in simulated wastewater. Environ. Sci. Pollut. Res. 2015, 22, 3149–3157. [Google Scholar] [CrossRef] [PubMed]

- Hamzezadeh-Nakhjavani, S.; Tavakoli, O.; Akhlaghi, S.P. Efficient photocatalytic degradation of organic pollutants by magnetically recoverable nitrogen-doped TiO2 nanocomposite photocatalysts under visible light irradiation. Environ. Sci. Pollut. Res. 2015, 22, 18859–18873. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.; Wang, P.; Ao, Y.; Wang, C.; Hou, J.; Qian, J. Photocatalytic degradation of tetrabromobisphenol A by a magnetically separable graphene-TiO2 composite photocatalyst: Mechanism and intermediates analysis. Chem. Eng. J. 2015, 264, 113–124. [Google Scholar] [CrossRef]

- Li, C.; Tan, J.; Fan, X.; Zhang, B.; Zhang, H.; Zhang, Q. Magnetically separable one dimensional Fe3O4/P(MAA-DVB)/TiO2 nanochains: Preparation, characterization and photocatalytic activity. Ceram. Int. 2015, 41, 3860–3868. [Google Scholar] [CrossRef]

- Xiang, Y.; Wang, H.; He, Y.; Song, G. Efficient degradation of methylene blue by magnetically separable Fe3O4/chitosan/TiO2 nanocomposites. Desalin. Water Treat. 2015, 55, 1018–1025. [Google Scholar] [CrossRef]

- Su, W.; Zhang, T.; Li, L.; Xing, J.; He, M.; Zhong, Y.; Li, Z. Synthesis of small yolk-shell Fe3O4@TiO2 nanoparticles with controllable thickness as recyclable photocatalysts. RSC Adv. 2014, 4, 8901–8906. [Google Scholar] [CrossRef]

- Dong, X.; Shao, Y.; Zhang, X.; Ma, H.; Zhang, X.; Shi, F.; Ma, C.; Xue, M. Synthesis and properties of magnetically separable Fe3O4/TiO2/Bi2O3 photocatalysts. Res. Chem. Intermed. 2014, 40, 2953–2961. [Google Scholar] [CrossRef]

- Li, C.; Younesi, R.; Cai, Y.; Zhu, Y.; Ma, M.; Zhu, J. Photocatalytic and antibacterial properties of Au-decorated Fe3O4@mTiO2 core-shell microspheres. Appl. Catal. B Environ. 2014, 156–157, 314–322. [Google Scholar] [CrossRef]

- Su, J.; Zhang, Y.; Xu, S.; Wang, S.; Ding, H.; Pan, S. Highly efficient and recyclable triple-shelled Ag@Fe3O4@SiO2@TiO2 photocatalysts for degradation of organic pollutants and reduction of hexavalent chromium ions. Nanoscale 2014, 6, 5181–5192. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Li, L.; Wang, T.; Zhang, L.; Xing, S. A novel strategy to fabricate multifunctional Fe3O4@C@TiO2 yolk-shell structures as magnetically recyclable photocatalysts. Nanoscale 2014, 6, 6603–6608. [Google Scholar] [CrossRef] [PubMed]

- Chi, Y.; Yuan, Q.; Li, Y.; Zhao, L.; Li, N.; Li, X.; Yan, W. Magnetically separable Fe3O4@SiO2@TiO2-Ag microspheres with well-designed nanostructure and enhanced photocatalytic activity. J. Hazard. Mater. 2013, 262, 404–411. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Zhang, G.; Liu, C.; Luo, S.; Xu, X.; Chen, L.; Wang, B. Magnetic TiO2-graphene composite as a high-performance and recyclable platform for efficient photocatalytic removal of herbicides from water. J. Hazard. Mater. 2013, 252–253, 115–122. [Google Scholar] [CrossRef] [PubMed]

- Shojaei, F.A.; Shams-Nateri, A.; Ghomashpasand, M. Comparative study of photocatalytic activities of magnetically separable WO3/TiO2/Fe3O4 nanocomposites and TiO2, WO3/TiO2 and TiO2/Fe3O4 under visible light irradiation. Superlattice Microstruct. 2015, 88, 211–224. [Google Scholar] [CrossRef]

- Chidambaram, S.; Pari, B.; Kasi, N.; Muthusamy, S. ZnO/Ag heterostructures embedded in Fe3O4 nanoparticles for magnetically recoverable photocatalysis. J. Alloy Compd. 2016, 665, 404–410. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Li, X.; Wang, D.; Song, H. Synthesis of urchin-like Fe3O4@SiO2@ZnO/CdS core-shell microspheres for the repeated photocatalytic degradation of rhodamine B under visible light. Catal. Sci. Technol. 2016. [Google Scholar] [CrossRef]

- Shekofteh-Gohari, M.; Habibi-Yangjeh, A. Ultrasonic-assisted preparation of novel ternary ZnO/AgI/Fe3O4 nanocomposites as magnetically separable visible-light-driven photocatalysts with excellent activity. J. Colloid Interface Sci. 2016, 461, 144–153. [Google Scholar] [CrossRef] [PubMed]

- Shekofteh-Gohari, M.; Habibi-Yangjeh, A. Novel magnetically separable ZnO/AgBr/Fe3O4/Ag3VO4 nanocomposites with tandem n–n heterojunctions as highly efficient visible-light-driven photocatalysts. RSC Adv. 2015, 6, 2402–2413. [Google Scholar]

- Shekofteh-Gohari, M.; Habibi-Yangjeh, A. Ternary ZnO/Ag3VO4/Fe3O4 nanocomposites: Novel magnetically separable photocatalyst for efficiently degradation of dye pollutants under visible-light irradiation. Solid State Sci. 2015, 48, 177–185. [Google Scholar] [CrossRef]

- Shekofteh-Gohari, M.; Habibi-Yangjeh, A. Novel magnetically separable Fe3O4@ZnO/AgCl nanocomposites with highly enhanced photocatalytic activities under visible-light irradiation. Sep. Purif. Technol. 2015, 147, 194–202. [Google Scholar] [CrossRef]

- Shekofteh-Gohari, M.; Habibi-Yangjeh, A. Facile preparation of Fe3O4@AgBr-ZnO nanocomposites as novel magnetically separable visible-light-driven photocatalysts. Ceram. Int. 2015, 41, 1467–1476. [Google Scholar] [CrossRef]

- Jia, X.; Dai, R.; Sun, Y.; Song, H.; Wu, X. One-step hydrothermal synthesis of Fe3O4/g-C3N4 nanocomposites with improved photocatalytic activities. J. Mater. Sci. 2016, 27, 3791–3798. [Google Scholar] [CrossRef]

- Mousavi, M.; Habibi-Yangjeh, A. Magnetically separable ternary g-C3N4/Fe3O4/BiOI nanocomposites: Novel visible-light-driven photocatalysts based on graphitic carbon nitride. J. Colloid Interface Sci. 2016, 465, 83–92. [Google Scholar] [CrossRef] [PubMed]

- Akhundi, A.; Habibi-Yangjeh, A. Novel magnetic g-C3N4/Fe3O4/AgCl nanocomposites: Facile and large-scale preparation and highly efficient photocatalytic activities under visible-light irradiation. Mater. Sci. Semicond. Process. 2015, 39, 162–171. [Google Scholar] [CrossRef]

- Akhundi, A.; Habibi-Yangjeh, A. Novel magnetically separable g-C3N4/AgBr/Fe3O4 nanocomposites as visible-light-driven photocatalysts with highly enhanced activities. Ceram. Int. 2015, 41, 5634–5643. [Google Scholar] [CrossRef]

- Feng, X.; Lou, X. The effect of surfactants-bound magnetite (Fe3O4) on the photocatalytic properties of the heterogeneous magnetic zinc oxides nanoparticles. Sep. Purif. Technol. 2015, 147, 266–275. [Google Scholar] [CrossRef]

- Li, W.; Tian, Y.; Li, P.; Zhang, B.; Zhang, H.; Geng, W.; Zhang, Q. Synthesis of rattle-type magnetic mesoporous and investigation of its photoactivity in the degradation of methylene blue. RSC Adv. 2015, 5, 48050–48059. [Google Scholar] [CrossRef]

- Li, X.; Wang, G.; Cheng, Y. Preparation and characteristics of Fe3O4-BaTiO3 heterostructural nanocomposite as photocatalyst. Res. Chem. Intermed. 2015, 41, 3031–3039. [Google Scholar] [CrossRef]

- Singh, K.K.; Senapati, K.K.; Borgohain, C.; Sarma, K.C. Newly developed Fe3O4-Cr2O3 magnetic nanocomposite for photocatalytic decomposition of 4-chlorophenol in water. J. Environ. Sci. 2015. [Google Scholar] [CrossRef]

- Cao, C.; Xiao, L.; Chen, C.; Cao, Q. Magnetically separable Cu2O/chitosan–Fe3O4 nanocomposites: Preparation, characterization and visible-light photocatalytic performance. Appl. Surf. Sci. 2015, 333, 110–118. [Google Scholar] [CrossRef]

- Cao, Y.; Li, C.; Li, J.; Li, Q.; Yang, J. Magnetically separable Fe3O4/AgBr hybrid materials: Highly efficient photocatalytic activity and good stability. Nanoscale Res. Lett. 2015, 10, 952. [Google Scholar] [CrossRef] [PubMed]

- Zhong, S.; Jiang, W.; Han, M.; Liu, G.; Zhang, N.; Lu, Y. Graphene supported silver@silver chloride and ferroferric oxide hybrid, a magnetically separable photocatalyst with high performance under visible light irradiation. Appl. Surf. Sci. 2015, 347, 242–249. [Google Scholar] [CrossRef]

- Jing, J.; Zhang, Y.; Feng, J.; Li, W.; Yu, W.W. Facile preparation and high performance of magnetically separable metalloporphyrin. Chem. Eng. J. 2015, 263, 385–391. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, M.; Li, W.; Wang, L.; Zheng, J.; Gan, W. Fabrication of Au(Ag)/AgCl/Fe3O4@PDA@Au nanocomposites with enhanced visible-light-driven photocatalytic activity. Dalton Trans. 2015, 44, 17020–17025. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Ye, C.; Song, X.; He, L.; Liao, F. Theoretical calculation based synthesis of a poly(p-phenylenediamine)–Fe3O4 composite: A magnetically recyclable photocatalyst with high selectivity for acid dyes. RSC Adv. 2014, 4, 54810–54818. [Google Scholar] [CrossRef]

- An, L.; Wang, G.; Shi, X.; Su, M.; Gao, F.; Cheng, Y. Recyclable Fe3O4/ZnO/PPy composite photocatalyst: Fabrication and photocatalytic activity. Russ. J. Phys. Chem. A 2014, 88, 2419–2423. [Google Scholar] [CrossRef]

- Wang, C.; Cao, M.; Wang, P.; Ao, Y.; Hou, J.; Qian, J. Preparation of a magnetic graphene oxide-Ag3PO4 composite photocatalyst with enhanced photocatalytic activity under visible light irradiation. J. Taiwan Inst. Chem. Eng. 2014, 45, 1080–1086. [Google Scholar] [CrossRef]

- Peik-See, T.; Pandikumar, A.; Ngee, H.; Ming, N. Magnetically separable reduced graphene oxide/iron oxide nanocomposite materials for environmental remediation. Catal. Sci. Technol. 2014, 4, 4396–4405. [Google Scholar] [CrossRef]

- Li, Z.; Wen, Y.; Shang, J.; Wu, M.; Wang, L.; Guo, Y. Magnetically recoverable Cu2O/Fe3O4 composite photocatalysts: Fabrication and photocatalytic activity. Chin. Chem. Lett. 2014, 25, 287–291. [Google Scholar] [CrossRef]

- Cao, X.; Chen, Y.; Jiao, S.; Fang, Z.; Xu, M.; Liu, X.; Li, L.; Pang, G.; Feng, S. Magnetic photocatalysts with a p–n junction: Fe3O4 nanoparticle and FeWO4 nanowire heterostructures. Nanoscale 2014, 6, 12366–12370. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wei, Z.; Matsui, H.; Zhou, S. Fe3O4/carbon quantum dots hybrid nanoflower for highly active and recyclable visible-light driven. J. Mater. Chem. A 2014, 2, 15740–15745. [Google Scholar] [CrossRef]

- Zhang, D.; Pu, X.; Gao, Y.; Su, C.; Li, H.; Li, H. One-step combustion synthesis of CoFe2O4-graphene hybrid materials for photodegradation of methylene blue. Mater. Lett. 2013, 113, 179–181. [Google Scholar] [CrossRef]

- Zhu, H.; Jiang, R.; Huang, S.; Yao, J.; Fu, F.; Li, J. Novel magnetic NiFe2O4/multi-walled carbon nanotubes hybrids: Facile synthesis, characterization, and application to the treatment of dyeing wastewater. Ceram. Int. 2015, 41, 11625–11631. [Google Scholar] [CrossRef]

- Bai, S.; Shen, X. One-pot solvothermal preparation of magnetic reduced graphene oxide-ferrite hybrids for organic dye removal. Carbon 2012, 50, 2337–2346. [Google Scholar] [CrossRef]

- Sun, J.; Fu, Y.; Xiong, P.; Sun, X.; Xu, B.; Wang, X. A magnetically separable P25/CoFe2O4/graphene catalyst with enhanced adsorption capacity and visible-light-driven photocatalytic activity. RSC Adv. 2013, 3, 22490–22497. [Google Scholar] [CrossRef]

- Xiong, P.; Zhu, J.; Wang, X. Cadmium sulfide-ferrite nanocomposite as a magnetically recyclable photocatalyst with enhanced visible-light-driven photocatalytic activity and photostability. Ind. Eng. Chem. Res. 2013, 52, 17126–17133. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, Q.; He, M.; Wan, Y.; Sun, X.; Xia, H.; Wang, X. Copper ferrite-graphene hybrid: A multifunctional heteroarchitecture for photocatalysis and energy storage. Ind. Eng. Chem. Res. 2012, 51, 11700–11709. [Google Scholar] [CrossRef]

- Ji, H.; Jing, X.; Xu, Y.; Yan, J.; Li, H.; Li, Y.; Huang, L.; Zhang, Q.; Xu, H.; Li, H. Magnetic g-C3N4/NiFe2O4 hybrids with enhanced photocatalytic activity. RSC Adv. 2015, 5, 57960–57967. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, M.; Zhao, W.; Wang, B. Magnetic composite photocatalyst ZnFe2O4/BiVO4: Synthesis, characterization, and visible-light photocatalytic activity. Dalton Trans. 2013, 42, 15464–15474. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Cai, Y.; Lu, F.; Qin, J.; Wei, F.; Xu, C.; Wang, S. Magnetic ZnFe2O4-C3N4 hybrid for photocatalytic degradation of aqueous organic pollutants by visible light. Ind. Eng. Chem. Res. 2014, 53, 17294–17302. [Google Scholar] [CrossRef]

- Wu, S.; Wang, P.; Cai, Y.; Liang, D.; Ye, Y.; Tian, Z.; Liu, J.; Linag, C. Reduced graphene oxide anchored magnetic ZnFe2O4 nanoparticles with enhanced visible-light photocatalytic activity. RSC Adv. 2015, 5, 9069–9074. [Google Scholar] [CrossRef]

- Yang, D.; Feng, J.; Jiang, L.; Wu, X.; Sheng, L.; Jiang, Y.; Wei, T.; Fan, Z. Photocatalyst interface engineering: Spatially confined growth of ZnFe2O4 within graphene networks as excellent visible-light-driven photocatalysts. Adv. Funct. Mater. 2015, 25, 7080–7087. [Google Scholar] [CrossRef]

- Khadgi, N.; Li, Y.; Upreti, A.R.; Zhang, C.; Zhang, W.; Wang, Y.; Wang, D. Enhanced photocatalytic degradation of 17 α-ethinylestradiol exhibited by multifunctional ZnFe2O4-Ag/rGO nanocomposite under visible light. Photochem. Photobiol. 2016, 92, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Dai, Y.; Guo, J.; Liu, T.; Wang, X. Novel magnetically separable reduced graphene oxide (RGO)/ZnFe2O4/Ag3PO4 nanocomposites for enhanced photocatalytic performance toward 2,4-dichlorophenol under visible light. Ind. Eng. Chem. Res. 2016, 55, 568–578. [Google Scholar] [CrossRef]

- Kulkarni, S.D.; Kumbar, S.; Menon, S.G.; Choudhari, K.S.; Santhosh, C. Magnetically separable core-shell ZnFe2O4@ZnO nanoparticles for visible light photodegradation of methyl orange. Mater. Res. Bull. 2016, 77, 70–77. [Google Scholar] [CrossRef]

- Yao, Y.; Qin, J.; Chen, H.; Wei, F.; Liu, X.; Wang, J.; Wang, S. One-pot approach for synthesis of N-doped TiO2/ZnFe2O4 hybrid as an efficient photocatalyst for degradation of aqueous organic pollutants. J. Hazard. Mater. 2015, 291, 28–37. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Shen, X.; Zhu, G.; Zhou, H.; Ji, Z.; Chen, K. Synthesis of ternary Ag/ZnO/ZnFe2O4 porous and hollow nanostructures with enhanced photocatalytic activity. Appl. Catal. B Environ. 2016, 184, 328–336. [Google Scholar] [CrossRef]

- Ren, A.; Liu, C.; Hong, Y.; Shi, W.; Lin, S.; Li, P. Enhanced visible-light-driven photocatalytic activity for antibiotic degradation using magnetic NiFe2O4/Bi2O3 heterostructures. Chem. Eng. J. 2014, 258, 301–308. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, H.; Sun, X.; Wang, X. Graphene-supported nickel ferrite: A magnetically separable photocatalyst with high activity under visible light. Am. Inst. Chem. Eng. J. 2012, 58, 3298–3305. [Google Scholar] [CrossRef]

- Patil, S.S.; Tamboli, M.S.; Deonikar, V.G.; Umarji, G.G.; Ambekar, J.D.; Kulkarni, M.V.; Kolekar, S.S.; Kale, B.B.; Patil, D.R. Magnetically separable Ag3PO4/NiFe2O4 composites with enhanced photocatalytic activity. Dalton Trans. 2015, 44, 20426–20434. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Kim, D.; Kwak, S.B.; Han, B.G.; Um, M.; Kang, M. Synthesis of magnetically separable core@shell structured NiFe2O4@TiO2 nanomaterial and its use for photocatalytic hydrogen production by methanol/water splitting. Chem. Eng. J. 2014, 243, 272–279. [Google Scholar] [CrossRef]

- Ge, M.; Hu, Z. Novel magnetic AgBr/NiFe2O4 composite with enhanced visible light photocatalytic performance. Ceram. Int. 2016, 42, 6510–6514. [Google Scholar] [CrossRef]

- Xiong, P.; Fu, Y.; Wang, L.; Wang, X. Multi-walled carbon nanotubes supported nickel ferrite: A magnetically recyclable photocatalyst with high photocatalytic activity on degradation of phenols. Chem. Eng. J. 2012, 195–196, 149–157. [Google Scholar] [CrossRef]

- Li, C.; Wang, J.; Wang, B.; Ru, J.; Lin, Z. A novel magnetically separable TiO2/CoFe2O4 nanofiber with high photocatalytic activity under UV-vis light. Mater. Res. Bull. 2012, 47, 333–337. [Google Scholar] [CrossRef]

- Wilson, A.; Mishra, S.R.; Gupta, R.; Ghosh, K. Preparation and photocatalytic properties of hybrid core-shell reusable CoFe2O4-ZnO nanospheres. J. Magn. Magn. Mater. 2012, 324, 2597–2601. [Google Scholar] [CrossRef]

- Pongwan, P.; Inceesungvorn, B.; Phanichphant, S.; Wetchakun, N. Synthesis and characterization of a magnetically separable CoFe2O4/TiO2 nanocomposite for the photomineralization of formic acid. Ferroelectrics 2013, 453, 133–140. [Google Scholar] [CrossRef]

- Wetchakun, N.; Chaiwichain, S.; Wetchakun, K. Synthesis and characterization of novel magnetically separable CoFe2O4/CeO2 nanocomposite photocatalysts. Mater. Lett. 2013, 113, 76–79. [Google Scholar] [CrossRef]

- Gan, L.; Shang, S.; Wah, C.; Yuen, M.; Jiang, S.; Hu, E. Hydrothermal synthesis of magnetic CoFe2O4/graphene nanocomposites with improved photocatalytic activity. Appl. Surf. Sci. 2015, 351, 140–147. [Google Scholar] [CrossRef]

- Singh, S.; Khare, N. Magnetically separable, CoFe2O4 decorated CdS nanorods for enhanced visible light driven photocatalytic activity. Mater. Lett. 2015, 161, 64–67. [Google Scholar] [CrossRef]

- Haw, C.; Chiu, W.; Rahman, S.A.; Khiew, P.; Radiman, S.; Shukor, R.A.; Hamid, M.A.A.; Ghazali, N. The design of new magnetic-photocatalyst nanocomposites (CoFe2O4-TiO2) as smart nanomaterials for recyclable-photocatalysis applications. New J. Chem. 2016, 40, 1124–1136. [Google Scholar] [CrossRef]

- Choi, Y.I.; Kim, Y.; Cho, D.W.; Kang, J.; Leung, K.T.; Sohn, Y. Recyclable magnetic CoFe2O4/BiOX (X = Cl, Br and I) microflowers for photocatalytic treatment of water contaminated with methyl orange, rhodamine B, methylene blue, and a mixed dye. RSC Adv. 2015, 5, 79624–79634. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, T.; Huang, S.; Xie, M.; Li, H.; Xu, H. Preparation of magnetic Ag/AgCl/CoFe2O4 composites with high photocatalytic and antibacterial ability. RSC Adv. 2015, 5, 41475–41483. [Google Scholar] [CrossRef]

- Shi, B.; Wan, J.; Liu, C.; Yu, X. Synthesis of CoFe2O4/MCM-41/TiO2 composite microspheres and its performance in degradation of phenol. Mater. Sci. Semicond. Process. 2015, 37, 241–249. [Google Scholar] [CrossRef]

- Gaikwad, P.N.; Hankare, P.P.; Wandre, T.M.; Garadkar, K.M.; Sasikala, R. Photocatalytic performance of magnetically separable Fe,N co-doped TiO2-cobalt ferrite nanocomposite. Mater. Sci. Eng. B 2016, 205, 40–45. [Google Scholar] [CrossRef]

- Manikandan, A.; Durka, M.; Seevakan, K.; Antony, S.A. A novel one-pot combustion synthesis and opto-magnetic properties of magnetically separable spinel MnxMg1−xFe2O4 (0.0 ≤ x ≤ 0.5) nanophotocatalysts. J. Supercond. Novel Magn. 2015, 28, 1405–1416. [Google Scholar] [CrossRef]

- Tio, A.; Nife, O.; Nicola, D.; Vanags, M. Ag sensitized TiO2 and NiFe2O4 three-component nanoheterostructures: Synthesis, electronic structure and strongly enhanced visible light. RSC Adv. 2016, 6, 18834–18842. [Google Scholar]

- Chen, C.-C.; Fu, Y.-P.; Hu, S.-H. Characterizations of TiO2/SiO2/Ni-Cu-Zn ferrite composite for magnetic photocatalysts. J. Am. Chem. Soc. 2015, 98, 2803–2811. [Google Scholar] [CrossRef]

- Sathishkumar, P.; Viswanathan, R. CoFe2O4/TiO2 nanocatalysts for the photocatalytic degradation of Reactive Red 120 in aqueous solutions in the presence and absence of electron acceptors. Chem. Eng. J. 2013, 220, 302–310. [Google Scholar] [CrossRef]

- Kadi, M.W.; Mohamed, R.M. Environmental remediation of aqueous cyanide by photocatalytic oxidation using a NiFe2O4/TiO2-SiO2 core-shell nanocomposite. Desalin. Water Treat. 2016, 56, 1940–1948. [Google Scholar] [CrossRef]

- Su, R.N.; Lv, P.; Li, M.; Zhang, X.; Li, M.; Niu, J. Fabrication of MgFe2O4-ZnO heterojunction photocatalysts for application of organic pollutants. Mater. Lett. 2014, 122, 201–204. [Google Scholar] [CrossRef]

- Leng, C.; Wei, J.; Liu, Z. Facile synthesis of PANI-modified CoFe2O4-TiO2 hierarchical flower-like nanoarchitectures with high photocatalytic activity. J. Nanopart. Res. 2013, 15, 1643. [Google Scholar] [CrossRef]

- Sun, A.; Chen, H.; Song, C.; Jiang, F.; Wang, X.; Fu, Y. Magnetic Bi25FeO40-graphene catalyst and its high visible-light photocatalytic performance. RSC Adv. 2013, 3, 4332–4340. [Google Scholar] [CrossRef]

- Xie, T.; Xu, L.; Liu, C.; Yang, J.; Wang, M. Magnetic composite BiOCl-SrFe12O19:A novel p–n type heterojunction with enhanced photocatalytic activity. Dalton Trans. 2014, 43, 2211–2220. [Google Scholar] [CrossRef] [PubMed]

- Bhukal, S.; Bansal, S.; Singhal, S. Magnetic Mn substituted cobalt zinc ferrite systems: Structural, electrical and magnetic properties and their role in photo-catalytic degradation of methyl orange azo dye. Physica B 2014, 445, 48–55. [Google Scholar] [CrossRef]

- Qasim, M.; Asghar, K.; Raj, B.; Prathapani, S.; Khan, W.; Naqvi, A.H.; Das, D. Magnetically recyclable Ni0.5Zn0.5Fe2O4/Zn0.95Ni0.05O nano-photocatalyst: Structural, optical, magnetic and photocatalytic properties. Spectrochim. Acta A 2015, 137, 1348–1356. [Google Scholar] [CrossRef] [PubMed]

- Manikandan, A.; Antony, S.A. Magnetically separable MnxZn1−xFe2O4; (0.0 ≤ x ≤ 0.5) nanostructures: Structural, morphological, opto-magnetic and photocatalytic properties. Synth. React. Inorg. Met-Org. Nano-Met. Chem. 2016. [Google Scholar] [CrossRef]

- Shakir, I.; Sarfraz, M.; Ali, Z.; Aboud, M.F.A. Magnetically separable and recyclable graphene-MgFe2O4 nanocomposites for enhanced photocatalytic applications. J. Alloy. Compd. 2016, 660, 450–455. [Google Scholar] [CrossRef]

- Bhukal, S.; Singhal, S. Magnetically separable copper substituted cobalt-zinc nano-ferrite photocatalyst with enhanced photocatalytic activity. Mater. Sci. Semicond. Process. 2014, 26, 467–476. [Google Scholar] [CrossRef]

- Liu, F.; Xie, Y.; Yu, C.; Liu, X.; Dai, Y. Novel hybrid Sr-doped TiO2/magnetic Ni0.6Zn0.4Fe2O4 for enhanced separation and photodegradation of organics under visible light. RSC Adv. 2015, 5, 24056–24063. [Google Scholar] [CrossRef]

- Vignesh, K.; Suganthi, A.; Min, B.-K.; Kang, M. Photocatalytic activity of magnetically recoverable MnFe2O4/g-C3N4/TiO2 nanocomposite under simulated solar light irradiation. J. Mol. Catal. A Chem. 2014, 395, 373–383. [Google Scholar] [CrossRef]

- He, H.-Y. Photocatalytic degradations of dyes on magnetically separable Ni1−xCoxFe2O4 nanoparticles synthesized by a hydrothermal process. Part. Sci. Technol. 2016, 34, 143–151. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, L.; Liu, C. Preparation and characterization of composite magnetic photocatalyst MnxZn1−xFe2O4/β-Bi2O3. RSC Adv. 2015, 5, 79997–80004. [Google Scholar] [CrossRef]

- He, H.; Yan, Y.; Huang, J.; Lu, J. Rapid photodegradation of methyl blue on magnetic Zn1−xCoxFe2O4 nanoparticles synthesized by hydrothermal process. Sep. Purif. Technol. 2014, 136, 36–41. [Google Scholar] [CrossRef]

- Shi, Y.; Zhou, K.; Wang, B.; Jiang, S.; Qian, X.; Gui, Z.; Yuen, R.K.K.; Hu, Y. Ternary graphene-CoFe2O4/CdS nanohybrids: Preparation and application as recyclable photocatalysts. J. Mater. Chem. A 2014, 2, 535–544. [Google Scholar] [CrossRef]

- Sathishkumar, P.; Pugazhenthiran, N. ZnO supported CoFe2O4 nanophotocatalysts for the mineralization of Direct Blue 71 in aqueous environments. J. Hazard. Mater. 2013, 252–253, 171–179. [Google Scholar] [CrossRef] [PubMed]

| Sample | Preparation Method | Application | Catalyst Dose | Pollutant Concentration | Degradation Efficiency | Saturation Magnetisation | Reference |

|---|---|---|---|---|---|---|---|

| Fe3O4/GO/Ce-TiO2 | Low-temperature sol-gel/ultrasonication | Degradation of tetracycline (TC)/Vis/300 W Xe lamp/400 nm UV filter | 0.050 g | 25 ppm | 82.9% in 60 min | No data | [33] |

| Fe3O4/RGO/TiO2 | Reduction-deposition | Degradation of MB and tetrabromobisphenol A (TBBPA)/UV/230 W Hg lamp | 0.025 g | 10 ppm | 99.5% in 60 min/TBBPA, 95.9% in 60 min/MB | 1.14 emu/g | [128] |

| Fe3O4/P(MAA-DVB)/TiO2 | Magnetic field induced assembly/precipitation-polymerisation | Degradation of RhB/UV/250 W Hg lamp | 0.040 g | 4.43 ppm | 71.5% in 120 min | 35.2 emu/g | [129] |

| Fe3O4@SiO2@N-TiO2 | Sol-gel | Degradation of phenol/Vis/15 W florescent lamp | 0.800 g | 100 ppm | 46% in 480 min | ~2 emu/g | [127] |

| Fe3O4/chitosan/TiO2 | Hydrothermal/crosslinking | Degradation of MB/UV/8 W UV lamp | 1.00 g | 1.28 ppm | 93% in 40 min | 4.2 emu/g | [130] |

| Fe3O4/TiO2 | Reverse microemulsion/sol-gel | Degradation of RhB/UV/50 W Xe lamp | 0.004 g | 22.12 ppm | 100% in 100 min | 21.68 emu/g | [131] |

| Ag3PO4/TiO2/Fe3O4 | In situ hydrolysis/deposition | Degradation of acid orange 7 (AO 7)/50 mW diode blue laser and E. coli/Vis/300 W Xe lamp/420 nm UV filter | 0.100 g | 5.25 ppm/AO7 and 107 CFU/mL/E. coli | ~100% in 2.5 min/AO 7, 99.8% in 5 min/E. coli | No data | [38] |

| Fe3O4/TiO2/Bi2O3 | Sol-gel | Degradation of MO/Simulated solar light/350 W Xe lamp | 0.200 g | No data | 69% in 150 min | No data | [132] |

| Fe3O4/TiO2/Au | Sol-gel/hydrothermal | Degradation of MB and E. coli/UV/4 × 9 W black lights | 0.015 g/MB and 0.010 g/E. coli | 8.00 ppm/MB and 108 CFU/mL/E. coli | 78% in 4 h/MB, 89.3% in 60 min/E. coli | No data | [133] |

| Ag@Fe3O4@SiO2@TiO2 | Solvothermal | Degradation of MB and Cr(VI) reduction/Vis/500 W Xe lamp/425 UV filter | 0.020 g | 50 ppm/MB and 22.24 ppm/K2Cr2O7 | 99.9% in 4 h/Cr(VI), ~90 mg/g/MB | 13.92 emu/g | [134] |

| Fe3O4@SiO2@TiO2@GO | Reverse microemulsion/sol-gel/amide conjugation | Degradation of RhB/UV/400 W column high pressure Hg lamp | 0.050 g | 8.85 ppm | 92% in 120 min | 16.90 emu/g | [120] |

| Fe3O4@C@TiO2 | Solvothermal/calcination | Degradation of RhB/UV/125 W high pressure Hg lamp | 0.020 g | 10 ppm | ~100% in 80 min | 6.04 emu/g | [135] |

| Fe3O4@SiO2@TiO2 | Stobber process/sol-gel/chemical precipitation | Degradation of RhB/UV/50 W high pressure Hg lamp | 0.010 g | 8.85 ppm | 100% in 10 min | 30.60 emu/g | [136] |

| Fe3O4/TiO2 | Hydrothermal | Degradation of MB/UV/9 W UV lamp | 0.002 g | 1.00 ppm | 100% in 10 min | No data | [75] |

| Fe3O4@TiO2@GR | Sol-gel/assembly route | Degradation of 2,4-dichlorophenoxy-acetic acid (2,4-D)/simulated solar light/500 W Xe arc lamp | 0.020 g | 20 ppm | 100% in 40 min | 13.00 emu/g | [137] |

| WO3/TiO2/Fe3O4 | Sol-gel | Degradation of direct blue 71 (DB 71)/Vis/200 W Xe lamp | 0.030 g | 50 ppm | 98% in 35 min | 18.20 emu/g | [138] |

| Sample | Preparation Method | Application | Catalyst Dose | Pollutant Concentration | Degradation Efficiency | Magnetisation Saturation | Reference |

|---|---|---|---|---|---|---|---|

| Fe3O4@SiO2@CdS | Stobber method/chelating assisted growth | Degradation of MB and TC/Vis | 0.010 g | 10 ppm/MB and 100 ppm/TC | 80% in 21 min/TC, 94% in 140 min/MB | 22.00 emu/g | [63] |

| Fe3O4(TAMH)/ZnO | Solvothermal | Degradation of phenol/Vis/575 W MSR metal halide lamp | 0.325 g | 20 ppm | 71.3% in 150 min | No data | [150] |

| Fe3O4@mSiO2@BiOBr | Solvothermal | Degradation of MB/Vis/500 W Xe lamp/420 nm UV filter | 0.100 g | 20 ppm | 96% in 120 min | 40.00 emu/g | [151] |

| Fe3O4/BaTiO3 | Solvothermal/sol-gel | Degradation of MO and orange II/UV/150 W UV lamp | 0.002 g | 10 ppm | 71.2% in 20 h/MO, 43.7% in 20 h/orange II | 60.50 emu/g | [152] |

| Fe3O4/Cr2O3 | Wet chemical/ultrasonication | Degradation of 4-CP/UV/12 W low-pressure Hg lamp | 0.100 g | 1.29 ppm | 100% in 150 min | ~20 emu/g | [153] |

| Cu2O/chitosan/Fe3O4 | Precipitation-reduction | Degradation of Reactive Brilliant red X-3B (X-3B)/Vis/500 W W-halogen lamp | 0.100 g | 50 ppm | 99.7% in 50 min | 15.1 emu/g | [154] |

| Fe3O4/AgBr | Precipitation route | Degradation of MO/Vis/300 W Xe arc lamp/420 nm UV filter | 0.100 g | 20 ppm | 85% in 12 min | No data | [155] |

| RGO/Ag/AgCl/Fe3O4 | Solvothermal/deposition-precipitation | Degradation of MB and RhB/Vis/500 W Xe arc/10 cm water filter | 0.100 g | 10 ppm | 97.4% in 100 min/MB, 97.9% in 120 min/RhB | 18.8 emu/g | [156] |

| Metalloporphyrin/Fe3O4 | Covalent conjugation | Degradation of AO 7/Vis/125 W W-halogen lamp | 0.444 g | 17.5 ppm | 69.0% in 5 h | 61.45 emu/g | [157] |

| Au(Ag)/AgCl/Fe3O4@PDA@Au | Solvothermal/galvanic replacement | Degradation of MB/Vis | 0.004 g | 5 ppm | 100% in 20 min | 5.40 emu/g | [158] |

| Fe3O4@resorcinol-formaldehyde–Ag | In situ polymerisation/reduction | Inactivation of S. aureus, E. coli and degradation of 4-nitrophenol (4-NP), MB and RhB/Vis/No data on light source | 0.010 g | 16 ppm/RhB/MB/4-NP and 107 CFU/mL/ bacteria | 1.5 < OD in 6 h/E. coli, ~1.0 OD in 6 h, S. aureus, ~100% in 3 min/4-NP, ~100% in 4 min/MB and ~100% in 3 min/RhB | ~30 emu/g | [26] |

| Poly(p-phenylenediamine)–Fe3O4 | Chemical oxidation polymerisation | Degradation of bromocresol green (BG), blue (BB), purple (BP), RhB, neutral red (NR), MB, Sudan III (SIII), MO and Congo red (CR)/UV (500 W Hg)/Vis (500 W Xe lamp/420 nm UV filter) | 0.025 g | 50 ppm | ~95% in 1100 min/BB/UV, ~80% in 1100 min/BB/Vis, ~100% in 1100 min/BG/UV, ~90% in 1100 min/BG/Vis | No data | [159] |

| Polypyrrole (PPY)/Fe3O4/ZnO | In situ polymerisation | Degradation of MB/UV/8 W germicidal lamp | 0.200 g | 10 ppm | 85.2% in 4 h | No data | [160] |

| Fe3O4/GO/Ag3PO4 | Co-precipitation/ultrasonication | Degradation of MB/Vis/250 W halogen lamp/400 nm UV filter | 0.025 g | 20 ppm | 100% in 10 min | 12.56 emu/g | [161] |

| RGO/Fe3O4 | In situ chemical synthesis | Degradation of MB/natural sunlight/bright sunny days/9.00 am to 2.00 pm | 0.002 g | 10 ppm | 100% in 60 min | 30.30 emu/g | [162] |

| ZrO2/Fe3O4/chitosan | Co-precipitation/refluxing | Reduction of Cr(VI) and degradation of 4-CP/natural sunlight | 0.050 g/Cr(III), 0.010 g/4-CP | 70 ppm/K2Cr2O7, 20 ppm/4-CP | 88.6% in 180 min/4-CP, 90.2% in 180 min/Cr(VI) | 42.00 emu/g | [115] |

| Cu2O/Fe3O4 | Solvothermal/precipitation | Degradation of MO/Vis/500 W Xe lamp/420 nm UV filter | 0.100 g | 30 ppm | 90% in 90 min | 41.70 emu/g | [163] |

| FeWO4/Fe3O4 | Hydrothermal | Degradation of MB/UV-Vis/500 W Xe lamp | 0.020 g | 20 ppm | 97.1% in 60 min | 9.00 emu/g | [164] |

| Fe3O4@carbon quantum dots (CQDs) | Hydrothermal | Degradation of MB/Vis75 W Xe lamp/420 UV filter | 0.001 g | 1.00 ppm | 94.4% in 30 min | 33.80 emu/g | [165] |

| BiOBr@SiO2@Fe3O4 | Hydrothermal/Stobber method | 2,2-bis(4-hydroxyphenyl)propane (BPA)/500 W Xe lamp/420 UV filter | 0.100 g | 20 ppm | 87.0% in 50 min | No data | [119] |

| Sample | Preparation Method | Application | Catalyst Dose | Pollutant Concentration | Degradation Efficiency | Magnetisation Saturation | Reference |

|---|---|---|---|---|---|---|---|

| P25/CoFe2O4/RGO | Hydrothermal | Degradation of MB, MO, neutral dark yellow (NDY)/Vis/500 W Xe lamp/420 nmUV filter | 0.010 g | 40 ppm | ~90 mg/g in 60 min/MB, ~20 mg/g in 60 min and 10 mg/g in 60 min | ~35 emu/g | [169] |

| MnxMg1−xFe2O4 (0.0 ≤ x ≤ 0.5) | Microwave-assisted combustion | Degradation of 4-CP/Vis/8 × 8 W medium pressure Hg lamps | 0.030 g | 200 ppm | ~98% in 300 min | 64.67 emu/g | [199] |

| Ag/TiO2/NiFe2O4 | Photodeposition/solvothermal | Degradation of MO/Vis/100 W LED | 0.100 g | 10 ppm | 100% in 120 min | No data | [200] |

| TiO2@SiO2@Ni-Cu-ZnFe2O4 | Chemical co-precipitation | Degradation of MB/simulated solar light/35 W Xe arc lamp | 0.400 g | 10 ppm | 83.9% in 6 h | 37.45 emu/g | [201] |

| CoFe2O4/TiO2 | Co-precipitation | Degradation of Reactive Red 120 (RR 120)/Vis/150 W W-halogen lamp | 0.400 g | 14.70 ppm | 4.98 × 10−9 S−1 | ~0.2 emu/g | [202] |

| Ag/NiFe2O4 | Combustion | Degradation of MB/Vis/300 W Xe lamp/450 nm UV filter | 0.025 g | 20 ppm | ~80% in 120 min | ~20 emu/g | [80] |

| NiFe2O4/TiO2-SiO2 | Modified sol-gel/solvothermal | Degradation of cyanide/Vis/150 W blue fluorescent lamp/420 nm UV filter | No data | 100 ppm | 100% in 60 min | 42.7 emu/g | [203] |

| MgFe2O4-ZnO | Solution method/chemical co-precipitation | Degradation of RhB/Vis/500 W Xe lamp/420 nm UV filter | 0.050 g | 4.40 ppm | 100% in 120 min | 21.37 emu/g | [204] |

| PANI-CoFe2O4-TiO2 | Hydrothermal/in situ chemical deposition | Degradation of MB/UV (500 W Xe lamp)/Vis/500 W Xe lamp/400 nm UV filter | 0.100 g | 50 ppm | 0.0962/min/UV and 0.0110/min/Vis | 11.4 emu/g | [205] |

| Bi25FeO40-RGO | Hydrothermal | Degradation of MB/Vis/500 W Xe lamp/400 nm UV filter | 0.080 g | 28.80 ppm | 92.8% in 180 min | 10.50 emu/g | [206] |

| BiOCl-SrFe12O19 | Hydrothermal | Degradation of MB/UV/Vis/No data on light source | 0.400 g | 10 ppm | 99% in 50 min/UV, 67.8% in 8 h/Vis | 15.13 emu/g | [207] |

| CuFe2O4@C3N4 | Self-assembly route | Degradation of orange II/Vis/500 W Xe lamp/420 nm UV filter | 0.010 g | 9.81 ppm | 100% in 90 min | No data | [40] |

| Co0.6Zn0.4MnxFe2-xO4 (x = 0.2–1.0) | Sol-gel auto-combustion | Degradation of MO/Vis/400 W Hg lamp | 0.100 g | 30 ppm | 94% in 60 min | 39.51 emu/g | [208] |

| Ni0.5Zn0.5Fe2O4/Zn0.95Ni0.05 | Egg albumen assisted sol-gel | Degradation of RhB/natural sunlight/sunny days/11 am to 3 pm. | 0.010 g | 20 ppm | ~90% in 4 h | 8.00 emu/g | [209] |

| CdFe2O4/GR | Hydrothermal | Degradation of MB/Vis/500 W Xe lamp/420 nm UV filter | 0.100 g | 10 ppm | 89.2% in 4 h | 14.26 emu/g | [82] |

| MnxZn1−xFe2O4-TiO2 (0.0 ≤ x ≤ 0.5) | Auto-combustion | Degradation of 4-CP/UV/8 × 8 W low pressure Hg lamps | 0.030 g | 200 ppm | ~98% in 270 min | 45.17 emu/g | [210] |

| Co0.6Zn0.4CuxFe2-xO4 | Sol-gel auto-combustion | Degradation of MO/Vis/400 W Hg lamp | 0.100 g | 30 ppm | 86% in 60 min | 38.02 emu/g | [211] |

| CoxZn1−xFe2O4-GR | Chemical co-precipitation/ultrasonication | Degradation of MB/Vis/No data on light source | 0.100 g | 5 ppm | >95% in 60 min | No data | [212] |

| Sr-TiO2/Ni0.6Zn0.4Fe2O4 | Combustion/sol-gel | Degradation of BPA/UV (10 W low pressure Hg lamp)/Vis/500 W Xe arc lamp | 0.150 g | 10 ppm | 100% in 4 h/UV, 90% in 4 h/Vis | 19.04 emu/g | [213] |

| CoFe2O4-GR | Combustion | Degradation of MB/Vis/300 W Xe lamp/450 nm UV filter | 0.025 g | 20 ppm | 100% in 120 min | 5.3 emu/g | [166] |

| MnFe2O4/g-C3N4/TiO2 | Chemical impregnation | Degradation of MO/Simulated solar light/150 W Xe arc lamp | 0.050g | 10 ppm | 99.3% in 180 min | 0.065 emu/g | [214] |

| Ni1−xCoxFe2O4 | Hydrothermal | Degradation of malachite green (MG)/natural sunlight (200–250 Wm−2) | 0.025 g | 0.365 ppm | ~100% in 60 min | ~50.7–64.2 emu/g. | [215] |

| MnxZn1−xFe2O4/β-Bi2O3 | Dip-calcination | Degradation of RhB/Simulated solar light/300 W Xe lamp | 0.200g | 10 ppm | 99.1% in 150 min | 7.01 emu/g | [216] |

| Zn1−xCoxFe2O4 | Hydrothermal | Degradation of MB/Natural sunlight | 0.050 g | 3.20 ppm | ~88% in 270 min | ~50 emu/g | [217] |

| SrFeO3−x/g-C3N4 | Sintering method | Degradation of chloramphenicol (CAP) and crystal violet (CV)/Vis/150 W Xe arc lamp | 0.010 g | 10 ppm | 91.3% in 96 h/CAP, 99.9% in 12 h/CV | ~0.17 emu/g | [41] |

| CoFe2O4/GR/CdS | Solvothermal | Degradation of MB/daylight/40 W daylight lamp | 0.025 g | 20 ppm | 80% in 180 min | 18.00 emu/g | [218] |

| ZnO/CoFe2O4 | Co-precipitation | Degradation of direct blue 71 (BD 71)/150 W W-halogen lamp | 0.160 g | 38.64 ppm | ~100% in 30 min | ~0.040 emu/g | [219] |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamba, G.; Mishra, A. Advances in Magnetically Separable Photocatalysts: Smart, Recyclable Materials for Water Pollution Mitigation. Catalysts 2016, 6, 79. https://doi.org/10.3390/catal6060079

Mamba G, Mishra A. Advances in Magnetically Separable Photocatalysts: Smart, Recyclable Materials for Water Pollution Mitigation. Catalysts. 2016; 6(6):79. https://doi.org/10.3390/catal6060079

Chicago/Turabian StyleMamba, Gcina, and Ajay Mishra. 2016. "Advances in Magnetically Separable Photocatalysts: Smart, Recyclable Materials for Water Pollution Mitigation" Catalysts 6, no. 6: 79. https://doi.org/10.3390/catal6060079