Unravelling the Influence of Binder Typology during the Additive Manufacturing of Hybrid Multi-Channel Cylinders for Catalytic Purposes

Abstract

:1. Introduction

2. Results and Discussion

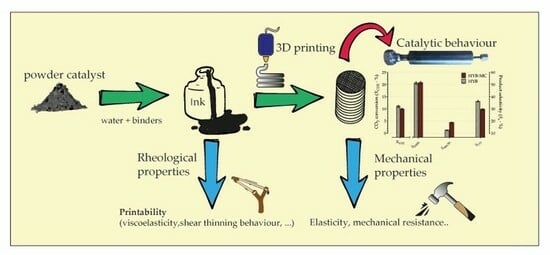

Design and Synthesis of Hybrid Monoliths

3. Materials and Methods

3.1. Catalyst Powders Synthesis and 3D Monoliths Design

3.2. Characterization

3.3. Catalytic Testing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Solarin, S.A. An environmental impact assessment of fossil fuel subsidies in emerging and developing economies. Environ. Impact Assess. Rev. 2020, 85, 106443–106451. [Google Scholar] [CrossRef]

- Kalair, A.; Abas, N.; Saleem, M.S.; Kalair, A.R.; Khan, N. Role of energy storage systems in energy transition from fossil fuels to renewables. Energy Storage 2020, 3, 135–161. [Google Scholar] [CrossRef]

- Semelsberger, T.A.; Borup, R.L.; Greene, H.L. Dimethyl ether (DME) as an alternative fuel. J. Power Sources 2006, 156, 497–511. [Google Scholar] [CrossRef]

- Azizi, Z.; Rezaeimanesh, M.; Tohidian, T.; Rahimpour, M.R. Dimethyl ether: A review of technologies and production challenges. Chem. Eng. Process. Process Intensif. 2014, 82, 150–172. [Google Scholar] [CrossRef]

- Parekh, A.; Chaturvedi, G.; Dutta, A. Sustainability analyses of CO2 sequestration and CO2 utilization as competing options for mitigating CO2 emissions. Sustain. Energy Technol. Assess. 2023, 55, 102942–102948. [Google Scholar] [CrossRef]

- Mota, N.; Ordoñes, E.M.; Pawelec, B.; Fierro, J.L.G.; Navarro, R.M. Direct Synthesis of Dimethyl Ether from CO2: Recent Advances in Bifunctional/Hybrid Catalytic Systems. Catalysts 2021, 11, 411–444. [Google Scholar] [CrossRef]

- Bonura, G.; Todaro, S.; Frusteri, L.; Majchrzak-Kucęba, I.; Wawrzyńczak, D.; Pászti, Z.; Tálas, E.; Tompos, A.; Lonyi, F.; Solt, H.; et al. Inside the reaction mechanism of direct CO2 conversion to DME over zeolite-based hybrid catalysts. Appl. Catal. B 2021, 294, 120255–120264. [Google Scholar] [CrossRef]

- Bonura, G.; Cannilla, C.; Frusteri, L.; Catizzone, E.; Todaro, S.; Migliori, M.; Giordano, G.; Frusteri, F. Interaction effects between CuO-ZnO-ZrO2 methanol phase and zeolite surface affecting stability of hybrid systems during one-step CO2 hydrogenation to DME. Catal. Today 2020, 345, 175–182. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Z. Perspective on CO2 Hydrogenation for Dimethyl Ether Economy. Catalysts 2022, 12, 1375–1394. [Google Scholar] [CrossRef]

- Bonura, G.; Frusteri, F.; Cannilla, C.; Drago Ferrante, G.; Aloise, A.; Catizzone, E.; Migliori, M.; Giordano, G. Catalytic features of CuZnZr–zeolite hybrid systems for the direct CO2-to-DME hydrogenation reaction. Catal. Today 2016, 277, 48–54. [Google Scholar] [CrossRef]

- Bonura, G.; Cannilla, C.; Frusteri, L.; Mezzapica, A.; Frusteri, F. DME production by CO2 hydrogenation: Key factors affecting the behaviour of CuZnZr/ferrierite catalysts. Catal. Today 2017, 281, 337–344. [Google Scholar] [CrossRef]

- Sathish, K.; Kumar, S.S.; Magal, R.T.; Selvaraj, V.; Narasimharaj, V.; Karthikeyan, R.; Sabarinathan, G.; Tiwari, M.; Kassa, A.E. A Comparative Study on Subtractive Manufacturing and Additive Manufacturing. Adv. Mat. Sci. Eng. 2022, 2022, 6892641–6892648. [Google Scholar] [CrossRef]

- Revelo, C.F.; Colorado, H.A. 3D printing of kaolinite clay ceramics using the Direct Ink Writing (DIW) technique. Ceram. Int. 2018, 44, 5673–5682. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Peng, S.; Liu, D.; Yan, W.; Shang, X.; Zhang, B.; Yao, Y.; Hui, Y.; Zhou, N. A Generalized Polymer Precursor Ink Design for 3D Printing of Functional Metal Oxides. Nano-Micro Lett. 2023, 15, 180–195. [Google Scholar] [CrossRef] [PubMed]

- Zoude, C.; Gremillard, L.; Prud’Homme, E. Combination of Chemical Foaming and Direct Ink Writing for Lightweight Geopolymers. Open Ceram. 2023, 16, 123211–123224. [Google Scholar] [CrossRef]

- Murphy, R.D.; Delaney, C.; Kolagatla, S.; Florea, L.; Hawker, C.J.; Heise, A. Design of Statistical Copolypeptides as Multipurpose Hydrogel Resins in 3D Printing. Adv. Funct. Mater. 2023, 33, 2306710–2306718. [Google Scholar] [CrossRef]

- Gharaie, S.; Zolfagharian, A.; Moghadam, A.A.A.; Shukur, N.; Bodaghi, M.; Mosadegh, B.; Kouzani, A. Direct 3D Printing of a Two-Part Silicone Resin to Fabricate Highly Stretchable Structures. Prog. Addit. Manuf. 2023, 8, 1555–1571. [Google Scholar] [CrossRef]

- Cagirici, M.; Xun, Y.; Zhang, D.; Xu, X.; Ding, J. Direct Ink Writing of Ni Structures for Electrocatalytic Water Splitting Applications. Mater. Chem. Phys. 2024, 311, 128574–128580. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, S.; Chen, G.; Li, K.; Fei, Z.; Mummery, P.; Yang, Z. High-Strength, Multifunctional and 3D Printable Mullite-Based Porous Ceramics with a Controllable Shell-Pore Structure. Adv. Powder Mater. 2024, 3, 100153–100164. [Google Scholar] [CrossRef]

- von Szczepanski, J.; Roels, E.; Siqueira, G.; Danner, P.M.; Wolf, J.; Legrand, J.; Brancart, J.; Terryn, S.; van Assche, G.; Vanderborght, B.; et al. Printable Polar Silicone Elastomers for Healable Supercapacitive Strain Sensors. Adv. Mater. Technol. 2023, 8, 2301310–2301319. [Google Scholar] [CrossRef]

- van Hazendonk, L.S.; Vonk, C.F.; van Grondelle, W.; Vonk, N.H.; Friedrich, H. Towards a Predictive Understanding of Direct Ink Writing of Graphene-Based Inks. Appl. Mater. Today 2024, 36, 102014–102025. [Google Scholar] [CrossRef]

- Tay, R.Y.; Song, Y.; Yao, D.R.; Gao, W. Direct-Ink-Writing 3D-Printed Bioelectronics. Mater. Today 2023, 71, 135–151. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, L.; Stehle, Y.; Lin, M.; Wang, C.; Zhang, R.; Huang, M.; Li, Y.; Zou, Q. Extrusion-Based 3D-Printed “Rolled-up” Composite Scaffolds with Hierarchical Pore Structure for Bone Growth and Repair. J. Mater. Sci. Technol. 2024, 171, 222–234. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, S.; Li, M.; Zhu, C.; Yang, H.; Dong, P.; Lu, M.; Wang, W.; Cao, J.; Liu, Q.; et al. Boosting CO2 Hydrogenation of Fe-Based Monolithic Catalysts via 3D Printing Technology-Induced Heat/Mass-Transfer Enhancements. Appl. Catal. B Environ. 2024, 340, 123211. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Chapiro, M. Current achievements and future outlook for composites in 3D printing. Reinf. Plast. 2016, 60, 372–375. [Google Scholar] [CrossRef]

- Tubío, C.R.; Azuaje, J.; Escalante, L.; Coelho, A.; Guitián, F.; Sotelo, E.; Gil, A. 3D printing of a heterogeneous copper-based catalyst. J. Catal. 2016, 334, 110–115. [Google Scholar] [CrossRef]

- Bonura, G.; Todaro, S.; Middelkoop, V.; de Vos, Y.; Abbenhuis, H.C.L.; Gerritsen, G.; Koekkoek, A.J.J.; Cannilla, C.; Frusteri, F. Effectiveness of the 3D-printing procedure in the synthesis of hybrid catalysts for the direct hydrogenation of CO2 into dimethyl ether. J. CO2 Util. 2023, 70, 102458–102463. [Google Scholar] [CrossRef]

- Koltsakidis, S.; Koidi, V.; Lappas, A.; Heracleous, E.; Tzetzis, D. Influence of binder concentration in zeolitic ZSM-5/bentonite 3D-printed monoliths manufactured through robocasting for catalytic applications. Int. J. Adv. Manuf. Technol. 2023, 126, 259–271. [Google Scholar] [CrossRef]

- Chen, C.H.; Chang, Y.; Wang, C.C.; Huang, C.H.; Huang, C.C.; Yeh, Y.C.; Hwang, S.M.; Sung, H.W. Construction and characterization of fragmented mesenchymal-stem-cell sheets for intramuscular injection. Biomaterials 2007, 28, 4643–4651. [Google Scholar] [CrossRef]

- Polamapllya, P.; Chengb, Y.; Shib, X.; Manikandana, K.; Kremera, G.E.; Qin, H. 3D Printing and Characterization of Hydroxypropyl Methylcellulose and Methylcellulose for Biodegradable Support Structures. Procedia Manuf. 2019, 34, 552–559. [Google Scholar] [CrossRef]

- Finny, A.S.; Cheng, N.; Popoola, O.; Andreescu, S. 3D printable polyethyleneimine based hydrogel adsorbents for heavy metal ions removal. Environ. Sci. Adv. 2022, 1, 443–456. [Google Scholar] [CrossRef]

| Sample | Status | Diameter (mm) | Height (mm) | Row (mm) | (a) |

| |||||

| HYB-PEI | As printed | 17.00 | 32.00 | 1.12 | |

| HYB-PEI | Dried | 15.83 | 28.63 | 1.06 | |

| HYB-PEI | Calcined | 15.63 | 28.33 | 1.01 | |

| HYB-HPMC | As printed | 17.00 | 32.00 | 1.12 | (b) |

| HYB-HPMC | Dried | 15.82 | 28.03 | 1.01 |  |

| HYB-HPMC | Calcined | 15.47 | 27.49 | 0.98 | |

| HYB-MC | As printed | 17.00 | 32.00 | 1.12 | |

| HYB-MC | Dried | 15.69 | 27.27 | 1.05 | |

| HYB-MC | Calcined | 15.35 | 27.05 | 1.01 |

| Sample | SALang (a) | PV (a) |

|---|---|---|

| (m2 g−1) | (cm3 g−1) | |

| HYB-PEI | 217 ± 3.4 | 0.21 |

| HYB-HPMC | 219 ± 2.8 | 0.21 |

| HYB-MC | 220 ± 3.1 | 0.22 |

| HYB | 235 ± 3.0 | 0.24 |

| Sample | Mc (MPa) | σmax (MPa) |

|---|---|---|

| HYB-PEI | 0.125 ± 0.002 | 0.27 |

| HYB-HPMC | 0.169 ± 0.002 | 0.41 |

| HYB-MC | 0.201 ± 0.001 | 0.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Todaro, S.; Bonura, G.; Cajumi, A.; Santoro, M.; Randazzo, F.; Giacoppo, G.; Frusteri, F.; Cannilla, C. Unravelling the Influence of Binder Typology during the Additive Manufacturing of Hybrid Multi-Channel Cylinders for Catalytic Purposes. Catalysts 2024, 14, 101. https://doi.org/10.3390/catal14020101

Todaro S, Bonura G, Cajumi A, Santoro M, Randazzo F, Giacoppo G, Frusteri F, Cannilla C. Unravelling the Influence of Binder Typology during the Additive Manufacturing of Hybrid Multi-Channel Cylinders for Catalytic Purposes. Catalysts. 2024; 14(2):101. https://doi.org/10.3390/catal14020101

Chicago/Turabian StyleTodaro, Serena, Giuseppe Bonura, Alessandro Cajumi, Mariarita Santoro, Fabrizio Randazzo, Giosuè Giacoppo, Francesco Frusteri, and Catia Cannilla. 2024. "Unravelling the Influence of Binder Typology during the Additive Manufacturing of Hybrid Multi-Channel Cylinders for Catalytic Purposes" Catalysts 14, no. 2: 101. https://doi.org/10.3390/catal14020101