Solvothermal Synthesis of g-C3N4/TiO2 Hybrid Photocatalyst with a Broaden Activation Spectrum

Abstract

:1. Introduction

2. Results and Discussion

2.1. X-ray Diffraction (XRD) Analysis

2.2. Brunauer-Emmett-Teller (BET) Analysis

2.3. Scanning Electron Microscopy (SEM)

2.4. Absorption Spectrum and DRS Analysis

2.5. X-ray Photoelectron Spectroscopy (XPS)

2.6. Photo Luminescence (PL)

2.7. Electron Spin Resonance Spectroscopy (ESR)

2.8. Photocatalytic Degradation of AG-25 under Solar Irradiation in Saline Water

2.9. Photocatalytic Degradation of AG-25 under Solar Irradiation in Saline Water with a UV Cutoff

3. Materials and Methods

3.1. Materials

Acid Green-25 Textile Dye

3.2. Characterization

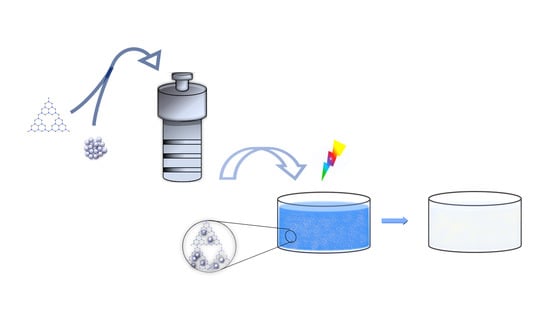

3.3. Preparation of g-C3N4

3.4. Solvothermal Method

3.5. Photocatalytic Degradation of AG-25 in Saline Water

3.6. Photocatalytic Degradation of AG-25 with UV Cutoff—LP400

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ajmal, A.; Majeed, I.; Malik, R.N.; Idriss, H.; Nadeem, M.A. Principles and mechanisms of photocatalytic dye degradation on TiO2 based photocatalysts: A comparative overview. RSC Adv. 2014, 4, 37003–37026. [Google Scholar] [CrossRef]

- Ananthashankar, A.G.R. Production, Characterization and Treatment of Textile Effluents: A Critical Review. J. Chem. Eng. Process Technol. 2013, 5, 1–18. [Google Scholar] [CrossRef]

- Arami, M.; Limaee, N.Y.; Mahmoodi, N.M. Evaluation of the adsorption kinetics and equilibrium for the potential removal of acid dyes using a biosorbent. Chem. Eng. J. 2008, 139, 2–10. [Google Scholar] [CrossRef]

- Natarajan, S.; Bajaj, H.C.; Tayade, R.J. Recent advances based on the synergetic effect of adsorption for removal of dyes from waste water using photocatalytic process. J. Environ. Sci. 2018, 65, 201–222. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.T. Azo dyes and human health: A review. J. Environ. Sci. Heal.—Part C Environ. Carcinog. Ecotoxicol. Rev. 2016, 34, 233–261. [Google Scholar] [CrossRef]

- Gita, S.; Hussan, A.; Choudhury, T.G. Impact of Textile Dyes Waste on Aquatic Environments and its Treatment. Environ. Ecol. 2017, 35, 2349–2353. [Google Scholar]

- Holkar, C.R.; Jadhav, A.J.; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A critical review on textile wastewater treatments: Possible approaches. J. Environ. Manag. 2016, 182, 351–366. [Google Scholar] [CrossRef]

- Rajeshwar, K.; Osugi, M.E.; Chanmanee, W.; Chenthamarakshan, C.R.; Zanoni, M.V.B.; Kajitvichyanukul, P.; Krishnan-Ayer, R. Heterogeneous photocatalytic treatment of organic dyes in air and aqueous media. J. Photochem. Photobiol. C Photochem. Rev. 2008, 9, 171–192. [Google Scholar] [CrossRef]

- Thiruvenkatachari, R.; Vigneswaran, S.; Moon, I.S. A review on UV/TiO2 photocatalytic oxidation process. Korean J. Chem. Eng. 2008, 25, 64–72. [Google Scholar] [CrossRef]

- Liu, C.; Mao, S.; Shi, M.; Wang, F.; Xia, M.; Chen, Q.; Ju, X. Peroxymonosulfate activation through 2D/2D Z-scheme CoAl-LDH/BiOBr photocatalyst under visible light for ciprofloxacin degradation. J. Hazard. Mater. 2021, 420, 126613. [Google Scholar] [CrossRef]

- Ajmal, A.; Majeed, I.; Malik, R.N.; Iqbal, M.; Nadeem, M.A.; Hussain, I.; Yousaf, S.; Zeshan; Mustafa, G.; Zafar, M.I.; et al. Photocatalytic degradation of textile dyes on Cu2O-CuO/TiO2 anatase powders. J. Environ. Chem. Eng. 2016, 4, 2138–2146. [Google Scholar] [CrossRef]

- Chauhan, A.; Sharma, M.; Kumar, S.; Thirumalai, S.; Kumar, R.V.; Vaish, R. TiO2@C core@shell nanocomposites: A single precursor synthesis of photocatalyst for efficient solar water treatment. J. Hazard. Mater. 2020, 381, 2019. [Google Scholar] [CrossRef] [PubMed]

- Mortazavian, S.; Saber, I.; James, D.E. Optimization of Photocatalytic Degradation of Acid Suspension System: Application of Response Surface. Catalysts 2019, 9, 360. [Google Scholar] [CrossRef] [Green Version]

- Rizzo, L.; della Sala, A.; Fiorentino, A.; Puma, G.L. ScienceDirect Disinfection of urban wastewater by solar driven and UV lamp e TiO2 photocatalysis: Effect on a multi drug resistant Escherichia coli strain. Water Res. 2014, 53, 145–152. [Google Scholar] [CrossRef]

- Teh, C.M.; Mohamed, A.R. Roles of titanium dioxide and ion-doped titanium dioxide on photocatalytic degradation of organic pollutants (phenolic compounds and dyes) in aqueous solutions: A review. J. Alloys Compd. 2011, 509, 1648–1660. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, L.; Chen, Z.; Hu, J.; Li, S. Semiconductor heterojunction photocatalysts: Design, construction, and photocatalytic. Chem. Soc. Rev. 2014, 43, 5234–5244. [Google Scholar] [CrossRef]

- Junwang, S. Visible-light driven heterojunction photocatalysts for water splitting—A critical review. Energy Environ. Sci. 2015, 8, 731–759. [Google Scholar] [CrossRef]

- Gong, S.; Jiang, Z.; Zhu, S. enhanced visible-light photocatalytic activities heterojunctions with enhanced visible-light photocatalytic activities. J. Nanopart. Res. 2018, 20, 310. [Google Scholar] [CrossRef]

- Hou, W.; Cronin, S.B. A review of surface plasmon resonance-enhanced photocatalysis. Adv. Funct. Mater. 2013, 23, 1612–1619. [Google Scholar] [CrossRef]

- Liu, C.; Mao, S.; Wang, H.; Wu, Y.; Wang, F.; Xia, M.; Chen, Q. Peroxymonosulfate-assisted for facilitating photocatalytic degradation performance of 2D/2D WO3/BiOBr S-scheme heterojunction. Chem. Eng. J. 2022, 430, 2021. [Google Scholar] [CrossRef]

- Caudillo-Flores, U.; Muñoz-Batista, M.J.; Luque, R.; Fernández-García, M.; Kubacka, A. g-C3N4/TiO2 composite catalysts for the photo-oxidation of toluene: Chemical and charge handling effects. Chem. Eng. J. 2019, 378, 122228. [Google Scholar] [CrossRef]

- Jiang, X.H.; Xing, Q.J.; Luo, X.B.; Li, F.; Zou, J.P.; Liu, S.S.; Li, X.; Wang, X.K. Simultaneous photoreduction of Uranium(VI) and photooxidation of Arsenic(III) in aqueous solution over g-C3N4/TiO2 heterostructured catalysts under simulated sunlight irradiation. Appl. Catal. B Environ. 2018, 228, 29–38. [Google Scholar] [CrossRef]

- Luan, S.; Qu, D.; An, L.; Jiang, W.; Gao, X.; Hua, S.; Miao, X.; Wen, Y.; Sun, Z. Enhancing photocatalytic performance by constructing ultrafine TiO2 nanorods/g-C3N4 nanosheets heterojunction for water treatment. Sci. Bull. 2018, 63, 683–690. [Google Scholar] [CrossRef]

- Miranda, C.; Mansilla, H.; Yáñez, J.; Obregón, S.; Colón, G. Improved photocatalytic activity of g-C3N4/TiO2 composites prepared by a simple impregnation method. J. Photochem. Photobiol. A Chem. 2013, 253, 16–21. [Google Scholar] [CrossRef]

- Kočí, K.; Reli, M.; Troppová, I.; Šihor, M.; Kupková, J.; Kustrowski, P.; Praus, P. Photocatalytic decomposition of N2O over TiO2 /g-C3N4 photocatalysts heterojunction. Appl. Surf. Sci. 2017, 396, 1685–1695. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Li, H.; Chen, C. Fabrication of g-C3N4/TiO2 composite photocatalyst with extended absorption wavelength range and enhanced photocatalytic performance. J. Photochem. Photobiol. A Chem. 2016, 317, 151–160. [Google Scholar] [CrossRef]

- Zhou, B.; Hong, H.; Zhang, H.; Yu, S.; Tian, H. Heterostructured Ag/g-C3N4/TiO2 with enhanced visible light photocatalytic performances. J. Chem. Technol. Biotechnol. 2019, 94, 3806–3814. [Google Scholar] [CrossRef]

- Liu, C.; Mao, S.; Shi, M.; Hong, X.; Wang, D.; Wang, F.; Xia, M.; Chen, Q. Enhanced photocatalytic degradation performance of BiVO4/BiOBr through combining Fermi level alteration and oxygen defect engineering. Chem. Eng. J. 2022, 449, 137757. [Google Scholar] [CrossRef]

- Ranjithkumar, R.; Lakshmanan, P.; Devendran, P.; Nallamuthu, N.; Sudhahar, S.; Kumar, M.K. Investigations on effect of graphitic carbon nitride loading on the properties and electrochemical performance of g-C3N4/TiO2 nanocomposites for energy storage device applications. Mater. Sci. Semicond. Process. 2021, 121, 105328. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, S.; Liu, J.; Xie, S.; Liu, Y. Synthesis of g-C3N4/TiO2nanostructures for enhanced photocatalytic reduction of U(vi) in water. RSC Adv. 2021, 11, 4810–4817. [Google Scholar] [CrossRef]

- Kumar, V.; Avisar, D.; Betzalel, Y.; Mamane, H. Rapid visible-light degradation of EE2 and its estrogenicity in hospital wastewater by crystalline promoted g-C3N4. J. Hazard. Mater. 2020, 398, 122880. [Google Scholar] [CrossRef]

- Zhao, S.; Chen, S.; Yu, H.; Quan, X. G-C3N4/TiO2 hybrid photocatalyst with wide absorption wavelength range and effective photogenerated charge separation. Sep. Purif. Technol. 2012, 99, 50–54. [Google Scholar] [CrossRef]

- Zhang, Y.; Thomas, A.; Antonietti, M.; Wang, X. Activation of carbon nitride solids by protonation: Morphology changes, enhanced ionic conductivity, and photoconduction experiments. J. Am. Chem. Soc. 2009, 131, 50–51. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Sun, Z.; Xue, Y.; Yao, G.; Zheng, S. A facile synthesis of g-C3N4/TiO2 hybrid photocatalysts by sol-gel method and its enhanced photodegradation towards methylene blue under visible light. Adv. Powder Technol. 2016, 27, 330–337. [Google Scholar] [CrossRef]

- Li, J.; Wu, X.; Pan, W.; Zhang, G.; Chen, H. Vacancy-Rich Monolayer BiO2−x as a Highly Efficient UV, Visible, and Near-Infrared Responsive Photocatalyst. Angew. Chemie—Int. Ed. 2018, 57, 491–495. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; Meng, X.; Wang, Z.; Zhou, J.; Tang, H. In Situ Microwave-Assisted Synthesis of Porous N-TiO2/g-C3N4 Heterojunctions with Enhanced Visible-Light Photocatalytic Properties. Appl. Surf. Sci. 2018, 430, 253–262. [Google Scholar] [CrossRef]

- Ren, H.T.; Liang, Y.; Han, X.; Liu, Y.; Wu, S.H.; Bai, H.; Jia, S.Y. Photocatalytic oxidation of aqueous ammonia by Ag2O/TiO2 (P25): New insights into selectivity and contributions of different oxidative species. Appl. Surf. Sci. 2020, 504, 2019. [Google Scholar] [CrossRef]

- Ishibashi, K.I.; Fujishima, A.; Watanabe, T.; Hashimoto, K. Detection of active oxidative species in TiO2 photocatalysis using the fluorescence technique. Electrochem. Commun. 2000, 2, 207–210. [Google Scholar] [CrossRef]

- Wen, J.; Li, X.; Liu, W.; Fang, Y.; Xie, J.; Xu, Y. Photocatalysis fundamentals and surface modification of TiO2 nanomaterials. Cuihua Xuebao Chin. J. Catal. 2015, 36, 2049–2070. [Google Scholar] [CrossRef]

- Adly, M.S.; El-Dafrawy, S.M.; El-Hakam, S.A. Application of nanostructured graphene oxide/titanium dioxide composites for photocatalytic degradation of rhodamine B and acid green 25 dyes. J. Mater. Res. Technol. 2019, 8, 5610–5622. [Google Scholar] [CrossRef]

| Catalyst | Percent Degradation of AG-25 (%) | Rate of AG-25 Degradation (min−1) × 10−3 |

|---|---|---|

| g-C3N4 | 59% | 10.6 |

| TiO2 | 86% | 21.5 |

| Composite | 98% | 40.1 |

| g-C3N4—LP400 | 37% | 5.8 |

| TiO2—LP400 | 0% | 0 |

| Composite—LP400 | 31% | 4.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imbar, A.; Vadivel, V.K.; Mamane, H. Solvothermal Synthesis of g-C3N4/TiO2 Hybrid Photocatalyst with a Broaden Activation Spectrum. Catalysts 2023, 13, 46. https://doi.org/10.3390/catal13010046

Imbar A, Vadivel VK, Mamane H. Solvothermal Synthesis of g-C3N4/TiO2 Hybrid Photocatalyst with a Broaden Activation Spectrum. Catalysts. 2023; 13(1):46. https://doi.org/10.3390/catal13010046

Chicago/Turabian StyleImbar, Amit, Vinod Kumar Vadivel, and Hadas Mamane. 2023. "Solvothermal Synthesis of g-C3N4/TiO2 Hybrid Photocatalyst with a Broaden Activation Spectrum" Catalysts 13, no. 1: 46. https://doi.org/10.3390/catal13010046