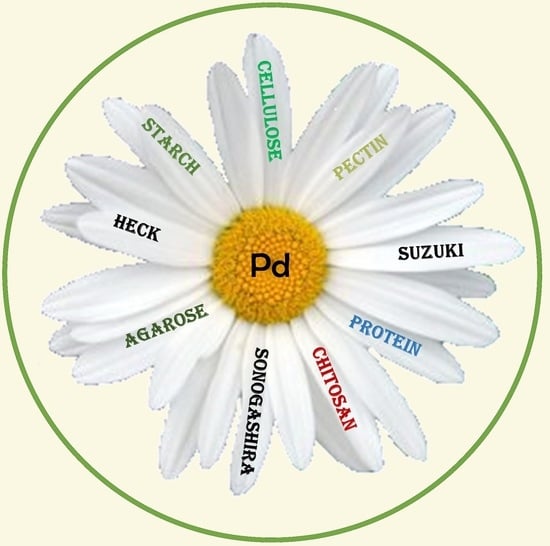

2.1. Cross-Coupling Reactions Promoted by Palladium Catalysts Supported on Cellulose

Cellulose is the most abundant natural biopolymer in the world [

21]. In cellulose, the glucose units are linked through β(1→4) glycosidic linkages (

Figure 1) and the length of the chain varies from a few hundred sugar units in wood pulp to over 10,000 in cotton.

Cellulose and its derivatives are produced on an industrial scale and used for many different applications, such as paper, construction, coatings, additives, electronics, pharmaceuticals, cosmetics, food and water purification [

22,

23,

24,

25]. However, its use in the synthesis of supported catalysts has not been deeply explored.

In 2006, Reddy and co-workers [

26] described the first example of a preparation of palladium nanoparticles supported on microcrystalline cellulose, a fine, white and odorless crystalline powder produced by treatment of biomass with aqueous sodium hydroxide to remove other constituents, followed by HCl hydrolysis. The catalyst, called CELL-Pd(0), was simply obtained by in situ reduction of a methanolic solution of PdCl

2 by means of hydrazine hydrate in the presence of cellulose support. Morphological investigation indicated the presence of palladium(0) particles in the range of 10–20 nm. CELL-Pd(0) (ca. 2 mol%) was initially tested in a Mizoroki–Heck reaction of methyl acrylate with different aryl iodides (

Scheme 1a). When the reactions were performed in DMF at 120 °C and using Et

3N as a base, very good yields of the corresponding coupling products were observed. The good catalytic activity of CELL-Pd(0) was confirmed by the synthesis of diaryl alkynes by Sonogashira reactions between aryl iodide and phenylacetylene (

Scheme 1b). In both cases, the catalyst could be recovered by simple filtration and reused four times.

A similar approach was developed a few years later by Konwar’s group [

27], who employed microcrystalline cellulose as a matrix for the preparation of Pd(0) nanoparticles. In order to improve the greenness of the process, in this case, the reduction of PdCl

2 was achieved by means of earth wood extract of

Artocarpus lakoocha Roxb containing oxyresveratrol which acted as bioreductant. A small amount (0.5 mol%) of Pd(0)Nps@cellulose particles (10–30 nm) were able to promote the Mizoroki–Heck reaction of aryl halides and olefins under microwave heating (80 °C) and in water as a solvent. After 15–20 min, the expected products were obtained in very good yields. Under the same experimental conditions, the Suzuki–Miyaura cross-coupling between phenylboronic acids and aryl bromides afforded the corresponding biaryl derivatives. The reusability of the catalyst was investigated by using the Suzuki–Miyaura reaction between phenylboronic acid and 2-bromobenzaldeyde: the experiments showed that Pd(0)Nps@cellulose could be recycled up to ten times without major loss of reactivity.

Starting from PdCl

2, bulk cellulose-supported Pd(0) was successfully prepared by Cui et al. [

28] and tested in the Mizoroki–Heck reaction of aryl iodides with styrene performed in H

2O as a solvent. The reaction could be carried out in the air and in the presence of a tiny amount of the catalyst (0.125 mol%) with almost quantitative yields (

Scheme 2).

Bulk cellulose was used also by Paul and co-workers [

29] in the synthesis of supported nanopalladium by simple reduction of Pd(OAc)

2 by means of hydrazine hydrate. The catalyst was rod shape, with uniform distribution of palladium onto cellulose. The small NPs generated (average diameter about 5 nm) resulted very efficiently in promoting the Suzuki–Miyaura coupling of benzeneboronic acid with arylbromide, performed in water at 100 °C. In order to clarify the real nature of the catalyst, a hot filtration test was performed. It revealed that no active metal particles were present into the solution, i.e., the supported catalyst could be considered a purely heterogenous species that could be used for five consecutive runs with insignificant change in the activity.

By treatment of bulk cellulose with H

2SO

4, cellulose nanocrystals (CNCs) can be isolated. CNCs exists as whiskers with a diameter in the range of 4–25 nm and length in the range of 100–1000 nm [

30]. Moreover, CNCs possess a superior mechanical strength and crystallinity with respect to bulk and microcrystalline cellulose. In 2011, Moores and co-workers [

31] described the synthesis of a new nanomaterial (PdNPs@CNCs), which was prepared by mixing PdCl

2 with a CNCs suspension, followed by exposure to H

2 pressure. Morphological investigation confirmed the formation of nanoparticles (average diameter ~4 nm) of Pd(0) uniformly distributed onto the surface of CNCs. The catalytic activity of PdNPs@CNCs was tested in the Mizoroki–Heck cross-coupling between styrene and iodobenzene as model substrates, in H

2O/CH

3CN at 100 °C, giving stilbene in 75% yield.

CNCs can act both as a support and a reduction agent. Indeed, Thielemans’ group [

32] reported the synthesis of Pd nanoparticles (PdNPs, 6–13 nm) supported on cellulose nanocrystals (PdNPs@CNXL) generated by a single step from Pd(hexafluoroacetylacetonate) (Pd(hfac)

2) and CNCs in subcritical and supercritical CO

2. PdNPs@CNXL were shown to be catalytically active in palladium-mediated Mizoroki–Heck cross-coupling of iodobenzene and terminal alkenes (

Scheme 3).

Although the major source of cellulose is plant fiber, cellulose can also be synthetized by fermentation of specific bacteria. Bacterial cellulose (BC) does not contain other components such as lignin, hemicellulose or pectin, so it can be obtained in pure form from the culture media. BC is featured by nanofibers possessing large surface area, high water retention, good mechanical properties and high chemical stability [

33]. Taking advantage of these properties, Tang and co-workers [

34] employed a BC nanofiber as a matrix for the preparation of supported Pd nanoparticles. Pd/BC was simply generated by mixing PdCl

2 or Pd(NO

3)

2 with BC nanofibers and KBH

4 as reducing agent. The catalytic performance of Pd/BC was initially explored in the Suzuki–Miyaura coupling of iodobenzene and different arylboronic acids performed in water medium. A very small amount of catalyst (0.05 mol%) was able to promote the formation of the corresponding diaryl derivatives in almost quantitative yields (

Scheme 4). Prompted by these results, the authors extended this methodology to the more challenging reaction of chlorobenzene, achieving good to excellent yields. A palladium leaching test performed after five cycles indicated negligible release of palladium into the solution, probably due to the protection effect of the BC fibers.

A novel strategy based on the immobilization of palladium nanoparticles (Pd NPs) on filter paper was described by Perez-Juste and co-workers [

35]: oleylamine-capped Pd nanoparticles, dispersed in an organic solvent, were strongly adsorbed on cellulose filter paper, which showed a great ability to wick fluids due to its microfiber structure. Two of the main advantages of the resulting catalytic material were simplified handling and easy recovery (by simply pulling the filter paper out of the liquid-phase reaction medium). The catalyst thus obtained could be easily employed in several coupling process by simply dipping the palladium-loaded paper strip into the reaction medium. In particular, Suzuki–Miyaura cross-coupling reaction of 4-halophenol with phenylboronic acid could be performed using Pd NP-doped paper as a catalyst with remarkable results. The reusability and recyclability of the Pd-doped cellulose paper was confirmed in up to five successive cross-coupling reactions, which evidenced no loss of catalytic activity through the different cycles.

A green approach to supported metal nanoparticles was developed by Patil’s group by using banana pseudostem extract for bioreduction of Pd(OAc)

2 [

36]. The presence of phenols and carboxylic acids was responsible for the formation of palladium(0) nanoparticles, which were then deposited on cellulose fibers isolated from banana waste. The activity of the resulting catalyst was investigated in the Suzuki–Miyaura coupling of phenylboronic acid with aryl halides carried out under mild experimental conditions (i.e., H

2O as the solvent, Na

2CO

3 as the base, at room temperature, under air). A wide range of functional groups were tolerated (OMe, Me, OH, F, Cl, NO

2, CN, COMe) and the catalyst could be used in 15 recycles without lacking in catalytic activity. The same group described a very similar approach starting from cellulose isolated from sugarcane bagasse [

37].

A different method for the preparation of cellulose-stabilized palladium nanoparticles was proposed in 2014 by Li and co-workers [

38], who obtained microencapsulated Pd NPs by reduction of Pd(OAc)

2 dissolved in 1-hydroxylethyl-3-methylimidazolum chloride and cellulose. Slow addition of coagulant ethanol led to the formation of capsules. The average particle size distribution of Pd particles was estimated to be in the range of 5–20 nm. Investigation on the activity of the new cellulose-entrapped catalyst CeLMcPd

0 was performed by using Suzuki–Miyaura coupling as a model reaction (

Scheme 5a). The CelMcPd

0 catalyst was highly effective for both aryl bromides and aryl iodides. Most of these reactions proceeded rapidly and were complete within 30 min. Aryl halides bearing either eletron donating or electron withdrawing substituents displayed similar reactivity, generating the corresponding products in 79–94% yields. Analogously, CelMcPd

0 was successfully employed in the Mizoroki–Heck reactions of aryl halides with functionalized olefins (

Scheme 5b).

All the examples discussed until now involved the use of natural cellulose in different morphological forms, such as bulk and microcrystalline cellulose, nanofibers and nanocrystals. The hydroxyl groups present on the sugar units could be readily functionalized by means of esterification, etherification and amine-functionalization and employed for the preparation of modified cellulose-supported palladium catalysts. One of the first approaches in this field involved the tosylation of cellulose by reaction with

p-toluensulfonylchloride (Cell-OTs). Considering the extended use of

N-heterocyclic carbenes (NHCs) as transition metal ligands, in 2014, Wei and co-workers [

39] prepared a cellulose-supported NHC (Cell-NHC) via nucleophilic substitution of Cell-OTs with

N-methylimidazole. The tosylate acted as a leaving group, allowing the SN

2 reaction with

N-methylimidazole to create Cell-NHC

+OTs

−. The tosyl group was then substituted with a chloride ion, and the resulting Cell-NHC

+-Cl

− species was coordinated with Pd(OAc)

2 to give the final catalyst Cell-NHC-Pd complex (

Scheme 6). TEM images of the catalyst revealed the presence of palladium nanoparticles of about 9 nm in size highly dispersed on cellulose surface. The catalytic activity of Cell-NHC-Pd complex was evaluated in the Suzuki–Miyaura cross-coupling of aryl halides with phenylboronic acids (

Scheme 6). Most of the aryl bromides were converted into the corresponding biaryls with good to excellent yields in reasonable reaction times. The recyclability of the Cell-NHC-Pd catalyst was also tested in the Suzuki–Miyaura cross-coupling reaction of 4-bromoanisole with phenylboronic acid. Unfortunately, the product yield decreased, going from 91% in the first run to 58% in the fifth run, probably due to the aggregation of palladium nanoparticles.

A similar catalyst was obtained by Li et al. [

40] starting from tosylated hydroxyethyl cellulose (HEC-OTs): the tosyl group was replaced by

N-methylimidazole and HEC-NHC was treated with Pd(OAc)

2 thus generating HEC-NHC-Pd species. Suzuki–Miyaura reactions between phenylboronic acid and aryl bromides performed in the presence of HEC-NHC-Pd proceeded smoothly to afford the corresponding products with moderate to good yields (38–97%). Cell-OTs was employed also by Shaabani’s group [

41] in the preparation of palladium nanoparticles supported on ethylenediamine-functionalized cellulose. In this case, the tosylate group was removed by ethylendiamine, affording EDACs (ethylendiamine cellulose) as a yellow powder. Then, EDACs was added to a solution of PdCl

2 in water and the mixture treated with NaBH

4, affording the supported PdNPs@EDACs catalyst. Palladium(0) nanoparticles with size between 4.6 and 6.8 nm were formed and uniformly distributed onto the surface of EDACs. This catalyst was successfully employed in the Mizoroki–Heck and Sonogashira couplings performed in refluxing H

2O with excellent yields.

A different approach to introduce a cellulose-linked amino ligand to be used to anchor palladium nanoparticles was proposed by Rashinkar and co-workers [

42]. In this case, cellulose was initially treated with alumina generating a cellulose–Al

2O

3 composite. Al-OH groups present on the surface could be easily reacted with aminopropyltrimethoxy silane (APTS), forming a very stable Al-O-Si bond. By reaction with Pd(OAc)

2, palladium was loaded on the composite and stabilised through the interactions with NH

2 groups, thus giving the final Pd@Al

2O

3-CELL catalyst. Its catalytic activity was investigated in the Suzuki–Miyaura reactions carried out with 1 mol% of the catalyst in a H

2O/DMF mixture. A variety of differently substituted arylbromides were converted into the corresponding products (

Scheme 7) and hot filtration test indicated that the catalyst remains on the support during the reaction. The same cellulose–Al

2O

3 composite was employed by Rashinkar et al. in the preparation of a cellulose-supported palladium complex in which the coordination of palladium was realised by means of a 2-aminopyrideine moiety [

43].

A cellulose-modified magnetite-graphene oxide nanocomposite was prepared by Masteri-Farahani and coworkers [

44] starting from graphene oxide (GO). GO was initially modified with magnetite nanoparticles to achieve GO-Fe

3O

4, then the hydroxyl groups on the surface of GO-Fe

3O

4 were reacted with 3-chloropropyltriethoxysilane, followed by the substitution of chloro groups with NaN

3 to achieve GO-Fe

3O

4-N

3. Subsequently, the click reaction of the azide group with an alkyne-functionalized cellulose afforded GO-Fe

3O

4-cellulose that, after treatment with Pd(OAc)

2, generated GO-Fe

3O

4-Cellulose-Pd. This heterogeneous catalyst resulted to be very efficient in promoting both Mizoroki–Heck and Sonogashira couplings.

Recently, Li et al. [

45] described the silylation of microcrystalline cellulose by treatment with 3-aminopropyltriethoxy silane, generating Cell-NH

2. The reaction of the amino group with pyridinyl benzaldehyde produced a Schiff base ligand (Cell-Sb) which was used to bind palladium, forming Cell-Sb-Pd(II). The catalyst displayed an excellent catalytic performance in the formation of biaryls via Suzuki–Miyaura coupling and could be recycled four times without losing activity. Cellulose nanofibers were silylated by Sui and co-workers using glycidoxypropyltrimethoxysilane and subsequently reacted with PdCl

2 in the presence of dopamine, obtaining PdNPs@CS as a supported catalyst [

46]. PdNPs@CS showed remarkable activity and excellent recyclability in Suzuki–Miyaura and Mizoroki–Heck reactions during which no palladium leaching was detected.

A few years later, Vallribera’s group [

47] described the functionalization of cellulose nanofibers employing glycidyltrimethylammonium chloride. After disintegration of the obtained cationic fibres, the isolated cationic nanofibrils (CNF) were treated with PdCl

2 in the presence of NaBH

4 as reducing agent. Pd@C-CNF featured tiny Pd(0) NPs (10 nm) which were immobilised onto the CNF network by means of the amino groups. The Suzuki–Miyaura coupling between phenylboronic acid and 4-bromoacetophenone was chosen as a model reaction to investigate the catalytic performance of Pd@C-CNF. Optimised conditions (0.1 mol% Pd, K

2CO

3 in DMF at 110 °C) were extended to different aryl halides, giving excellent yields. Finally, the same batch of catalyst could be reused three times without considerable deactivation.

Besides the deposition of palladium NPs onto cellulose decorated with amino derived functional groups, in 2011, Li et al. reported the introduction of a diphenylphosphine moiety on the sugar hydroxyl groups [

48]. This choice was based on the wide use of phosphine ligands for the coordination of palladium atoms. Diphenylphosphinite-functionalized cellulose (Cell–OPPh

2) was prepared by simple reaction of cellulose with pyridine and diphenylchlorophosphine. Subsequently, Cell–OPPh

2 was added to a PdCl

2 solution in ethanol, affording the supported palladium species, Cell–OPPh

2–Pd

0 (

Scheme 8).

To explore its efficiency, Cell–OPPh

2–Pd

0 was first used in the Suzuki–Miyaura coupling reaction for a variety of substituted aryl halides with different arylboronic acids in 95% ethanol with K

2CO

3 as base (

Scheme 8a). The cell–OPPh

2–Pd

0 catalyst was highly effective for both aryl iodides and bromides even if the reactivity of aryl bromides was slightly lower and, in these cases, a prolonged time was required. The catalytic performance was excellent for substrates with electron withdrawing groups and was only slightly lower for substrates with eletron donating groups. The reusability of the Cell–OPPh

2–Pd

0 catalyst was explored in the reaction of 4-iodoanisole with phenylboronic acid as the model reaction. The obtained results indicated that the catalyst could be reused up to six times while still retaining good activity. Afterword, Cell–OPPh

2–Pd

0 was tested in Mizoroki–Heck reactions between aryl halides and terminal alkenes (

Scheme 8b) [

49]. Reactions of electron-rich and electron-deficient substrates with styrene and acrylic acid proceeded well and gave high yield for the corresponding products.

Handa’s group used 2-(Diphenylphosphino) benzoic acid [

50] as a linker to microcrystalline cellulose. The resulting cellulose–phosphinite was then doped with palladium nanoparticles, affording a (cell-OOCPhPPh

2-Pd) catalyst which showed good activity in Suzuki–Miyaura, Mizoroki–Heck and Sonogashira cross-coupling reactions.

It is well known that sulphur can strongly coordinate metal atoms. Starting from this consideration, Zhang et al. prepared a cellulose xanthate (CX)-supported Pd(0) complex via esterification of hydroxy groups into -OCSSH moiety [

51]. Addition of a solution of PdCl

2 in EtOH to CX determined the formation of Pd(0) supported onto modified cellulose (named CX-Pd). Interestingly, CX-Pd was found to be an efficient catalyst for Mizoroki–Heck coupling of acrylic acid or styrene with aryl iodides possessing different functionalities (i.e., NO

2, OMe, Me, COOH). The reactions could be carried out in a water/NMP solution at 90 °C, under atmospheric pression and the catalyst could be reused ten times with limited loss of activity.

2.5. Cross-Coupling Reactions Promoted by Palladium Catalysts Supported on Chitosan

Chitosan is a linear polysaccharide composed of randomly distributed β-(1→4)-linked

d-glucosamine (deacetylated unit) and

N-acetyl-

d-glucosamine (acetylated unit), obtained by a partial alkaline deacetylation (>50%) of chitin, which is, in turn, a natural biopolymer typically occurring in the exoskeletons of crustaceans, cuticles of insects and cell walls of fungi (

Figure 5) [

82].

The presence of different functionalities (i.e., hydroxy, amino and acetylamino groups) in the polymeric chains provides chitosan (CS) with unique properties among all bioinspired materials: from the easy functionalization, which allows a fine tuning of the most relevant physico-chemical properties, to the easy binding of metal cations, making it very attractive as a heterogeneous support for metal catalysts [

83,

84].

In the past 20 years, palladium catalysts supported on chitosan or chitosan-based materials have found extensive use in promoting carbon–carbon bond formation reactions, such as Suzuki–Miyaura, Sonogashira and Mizoroki–Heck coupling. In this context, the first seminal work was reported in 2004 by Calò and co-workers: they used chitosan as it is, without any functionalization and/or derivatization, as a heterogeneous support for palladium nanoparticles [

85]. The Pd-NPs/chitosan catalyst was generated by a tetrabutylammonium acetate-promoted reduction of Pd(OAc)

2 or by a sacrificial anode electrolysis in the presence of chitosan: TEM analysis of the resulting material showed a surface of chitosan flakes modified by the presence of well-dispersed Pd nanoparticles (average diameter = 3.3 ± 0.7 nm). The Pd-NPs/chitosan catalyst was successfully applied in the Mizoroki–Heck coupling of aryl bromides with butyl acrylate (1.5 equiv.), carried out at 130 °C in tetrabutylammonium bromide as the solvent and tetrabutylammonium acetate as the base, affording the corresponding products in 85–98% after only 15 min; the reaction was also extended to electron-poor aryl chlorides, affording good yields (85–90%) of the corresponding cinnamate in 15–45 min (

Scheme 20).

More recently, Monopoli et al. reported the preparation of a similar Pd-NPs/chitosan catalyst by electrochemical reduction of Pd(OAc)

2 in the presence of flakes of simple chitosan and tetrabutylammonium bromide: under these conditions, core–shell nanoparticles, consisting of a metallic core surrounded by a stabilizing layer of tetrabutylammonium cations and Br

− and [PdBr

4]

2– anions, were chemisorbed on the chitosan surface by means of coordination bonds with –NH

2 and –OH groups of the biopolymer [

86]. The present catalyst was then applied (0.1 mol% of loading) in the Suzuki–Miyaura reactions of aryl iodides and bromides with electron-rich aryl boronic acids, performed in tetrabutylammonium bromide at 70–90 °C for 5 h, giving the corresponding biaryl products in 77–98% yields (determined by GLC using

n-decane as external standard) (

Scheme 21).

In 2016, Zeng et al. described the preparation of a palladium catalyst supported on chitosan gel beads (named Pd@CSGB) by the treatment of an aqueous Na

2PdCl

4 solution with pristine chitosan, which was then used in comparison with a highly porous Pd@N-C catalyst (palladium nanoparticles supported on a nitrogen-doped mesoporous carbon, in turn obtained by high-temperature carbonization of Pd@CSGB in the presence of colloidal silica as template) in the Mizoroki–Heck coupling of aryl iodides of different molecular size (iodobenzene, 1-iodonaphthalene, 2-iodofluorene) with

n-butyl acrylate [

87]. Despite the highly mesoporous Pd@N-C providing higher catalytic activity and excellent stability, the Pd@CSGB catalyst can still be used with good results in terms of product yields (36–96%) and recyclability (up to six cycles).

One of the main issues with chitosan as a heterogeneous support is its instability in solutions at pH < 4, when most of its amino groups are protonated: under these conditions, positively-charged polysaccharide chains repulse one another, resulting in a significant swelling. This problem may be solved by the covalent cross-linking of chitosan, thanks to the reaction of suitable cross-linking agents with the amino groups or the hydroxy groups of two different polymer chains. In general, cross-linked chitosan shows improved physico-chemical properties, including thermal stability and lower solubility and swelling. The most common cross-linker for chitosan is glutaraldehyde: its two -CHO groups can react with the primary amino groups of chitosan chains to give the corresponding Shiff’s bases. In 2007, Cui et al. described the first preparation of a Pd species supported on glutaraldehyde-cross-linked chitosan and its application as a catalyst for cross-coupling reactions [

88]. Cross-linked chitosan microsphere resin was obtained by a reversed phase emulsion polymerization of pristine chitosan with glutaraldehyde in liquid paraffin, followed by treatment with PdCl

2 in acetone for 72 h at room temperature to give the final material; SEM analysis of the catalyst revealed spheroidal structures with a diameter of 10–100 μm, while EDS images suggested a quite homogeneous distribution of palladium on the microsphere surface in the form of Pd(II) complexes coordinated to the amino or hydroxyl groups of chitosan. The present catalyst (named Pd/Glu-

cl-CS) was then applied in the Mizoroki–Heck coupling of few iodoarenes with acrylic acid (1.4 equiv.), carried out with 0.45 mol% of Pd loading, in the presence of Et

3N (2.4 equiv.) at 90 °C in NMP as the solvent, affording the corresponding cinnamic acids in 74–96% yields (

Scheme 22).

In 2011, Raston et al. described the preparation of glutaraldehyde-cross-linked chitosan nanofibers by the electrospinning of an equimolar solution of pristine chitosan and glutaraldehyde in CH

2Cl

2/trifluoroacetic acid, followed by the treatment with aqueous Na

2PdCl

4 to give Pd(II)-chitosan fibers [

89]. SEM images of the final material showed highly cross-linked fibers with an average diameter of 62 ± 9 nm, while the formation of the imino C=N bonds between chitosan chains and glutaraldehyde was verified by solid-state

13C-NMR spectroscopy; XPS (X-ray photoelectron spectroscopy) studies established the presence of Pd(II) species, rather than Pd(0). These Pd(II)-chitosan nanofibers were successfully used as a recyclable catalyst in the Mizoroki–Heck coupling with very low metal loading (0.17 mol%), using the reaction of iodobenzene and

n-butyl acrylate as model reagents (up to seven cycles with >99% conversion).

A more extended investigation was carried out in 2012 by Qi, Zhang and co-workers, who described the application of a palladium catalyst supported on porous cross-linked chitosan microspheres (named as Pd/PCMS) for the Ullmann homo-coupling and Mizoroki–Heck cross-coupling reactions (

Scheme 23) [

90].

Highly porous chitosan microspheres were prepared by condensation of pristine chitosan with glutaraldehyde (used as the cross-linking agent) in the presence of polyethylene glycol (PEG) as a template, which was then simply removed by extraction with H

2O to give the cross-linked porous material; its subsequent wetness impregnation in an Na

2PdCl

4 aqueous solution allowed for a uniform dispersion of Pd(II) species, which were finally reduced to the highly active Pd(0), affording the final Pd/PCMS catalyst. Pd/PCMS was found very efficient in promoting: (i) the Ullmann-type homo-coupling of aryl iodides and bromides in DMSO at 110 °C (2.0 mol% of metal loading); (ii) the Mizoroki–Heck reaction of iodoarenes with acrylates (2.0 equiv.), carried out with 1.0 mol% of Pd in the presence of potassium acetate (7.5 equiv.) as the base, in DMSO at 110 °C for 5 h or in H

2O and

N-cetyltrimethylammonium bromide (CTAB, 5 mol%) at 90 °C for 15 h, which afforded the corresponding cross-coupling products in good yields and complete trans stereochemistry (

Scheme 23). In a following paper, the same authors extended the application of a Pd/PCMS catalyst to the C–N cross-coupling of aryl halides with secondary amines [

91].

If glutaraldehyde is definitely the most common cross-linking agent for chitosan, other bifunctional compounds have also been successfully used for the same purpose. In this context, Lee et al. reported, in 2007, a comparative study between two different cross-linked chitosan-supported palladium catalysts, obtained by using glutaraldehyde or diglycidyl ether polyethylene glycol as the cross-linkers [

92]. Interestingly, in this case pristine chitosan (in the form of beads) was first loaded with a metal catalyst by treatment with Pd(OAc)

2 in DMSO and a subsequent reduction to palladium(0) with 10% hydrazine hydrate in CH

3OH, and only the resulting Pd(0)/chitosan material was then cross-linked with glutaraldehyde or diglycidyl ether polyethylene glycol to give the two final catalysts. Both of them were successfully applied (0.5 mol% of Pd loading) in the microwave-assisted Suzuki–Miyaura cross-coupling in H

2O as the reaction medium (

Scheme 24).

Aryl iodides and bromides were treated with a slight excess (1.5 equiv.) of boronic acid in the presence of K3PO4 (3.0 equiv.) as the base and TBAB (1.0 equiv.) as a phase-transfer catalyst, affording, in only 5–15 min, the corresponding biaryl products in good yields (70–98%). The Pd(0)/chitosan catalyst cross-linked with diglycidyl ether polyethylene glycol also showed good recyclability up to five consecutive runs with no loss of activity; on the contrary, glutaraldehyde-cross-linked material exhibited unstable mechanical properties during reusability tests.

In 2012, Cravotto and co-workers described the preparation of an HDMI-CS/Pd catalyst, obtained through the simultaneous incorporation of Pd(OAc)

2 during the ultrasound-assisted cross-linking of chitosan with hexamethylene diisocyanate (HMDI), which allowed the formation of urea bridges (between the amino groups of two different chitosan chains) and urethane bridges (between the amino and the hydroxy groups bearing to two different chitosan chains) [

93]. The HDMI-CS/Pd was found very efficient in promoting the mechanochemical-assisted Suzuki–Miyaura cross-coupling of (hetero)aryl chlorides with phenylboronic acid. Reactions were carried out in a planetary ball mill (600 min

−1, milling jar and balls in stainless steel), in the presence of K

2CO

3 (2.0 equiv.) as the base and without any solvent, giving the corresponding coupling products with yields up to 99% (

Scheme 25). This procedure was very appealing from the point of view of the Green Chemistry, as it combined the use of a non-conventional, highly efficient energy source, the advantages of an easily recoverable and recyclable palladium catalyst and the absence of any reaction medium.

A further example of a cross-linking agent for chitosan is 2,2′-pyridyl, a 1,2-diketone able to form two C=N imine bonds by condensation with the primary –NH

2 groups of the biopolymer chains. In 2016, Baran et al. described the first synthesis of a cross-linked chitosan derivative based on the use of 2,2′-pyridyl as a cross-linking agent, which was then used as a support for the immobilization of palladium by treatment with an aqueous Na

2PdCl

4 solution: in fact, the bis-imine bridges between chitosan chains acted as efficient bidentate ligands to coordinate Pd(II) species, as confirmed by FT-IR and XRD measurements [

94]. This catalyst was then successfully applied in the microwave-assisted Suzuki–Miyaura cross-coupling: reactions were carried out between aryl halides and phenylboronic acid (1.67 equiv.), in the presence of K

2CO

3 (3.35 equiv.) as the base, under solvent-free conditions for 5 min at 50 °C, using only 5 × 10

−3 mol% of palladium loading. A very interesting point is that reactions with aryl bromides gave higher yields (79–99%) and Turnover Number (TON) (15,800–20,000) not only compared to aryl chlorides (yields: 14–68%; TON: 2800–13,600), but also to aryl iodides (yields: 33–82%; TON: 6600–16,400) (

Scheme 26). The reusability of the cross-linked pyridyl-chitosan-Pd(II) catalyst was also tested in the reaction of 4-bromoanisole with phenylboronic acid, demonstrating good performance up to seven consecutive runs.

A few other types of cross-linked chitosan-supported palladium catalysts have been marginally applied in promoting cross-coupling reactions. In 2014, Zeng and co-workers described the preparation of a chitosan membrane directly cross-linked by Pd(II) cations (Pd-

cr-CSM,

Scheme 27) [

95].

After dissolving pristine chitosan in H

2O/AcOH, an aqueous solution of Na

2PdCl

4 was added in order to obtain a viscous gel, which was then cast and dried on Petri dishes to form final membranes. The sol–gel transition was due to the cross-linking of chitosan chains through the palladium(II) cation chelation with the amino, carbonyl and hydroxyl groups. Although Pd-

cr-CSM did not have an open porous structure and high surface area, it showed similar catalytic activity and improved chemical stability compared to other cross-linked chitosan-supported palladium catalysts for Mizoroki–Heck reactions: the cross-coupling of aryl iodides and bromides with electron-poor alkenes (2.0 equiv.) was performed with only 0.15 mol% of catalyst loading, in the presence of potassium acetate (3.0 equiv.) as the base, in DMSO at 110 °C for 5 h or in H

2O at 90 °C for 12 h, giving the desired products in satisfactorily yields (

Scheme 27). The high chemical stability of Pd-

cr-CSM was confirmed by its excellent recyclability: up to 12 times in DMSO and up to 7 times in H

2O.

Very recently, Levy-Ontman described the incorporation of a PdCl

2(TPPTS)

2 complex into cross-linked chitosan-based hydrogel beads, obtained by the covalent immobilization of the palladium species as bridges between different polymer chains through condensation of the sulfonate group on the TPPTS ligands with the hydroxyl and/or amino groups on the biopolymer [

96]. This material, together with other Pd(II)-hydrogel beads obtained by using other different polysaccharides, was successfully tested in the Suzuki–Miyaura cross-coupling reactions of halobenzenes with arylboronic acids.

Although hydroxyl, carbonyl and amino functional groups of chitosan are capable of coordinating metal species, a more common approach for the development of chitosan-based heterogeneous palladium catalysts consists of the chemical functionalization of pristine chitosan with suitable ligands (typically, nitrogen-based), followed by treatment with palladium species that can be easily complexed. The first study based on this approach was described in 2004 by Macquarrie and co-workers: chitosan was modified by treatment with 2-pyridinecarboxaldehyde in refluxing ethanol to give the corresponding 2-pyridylimine ligands, followed by treatment with a solution of palladium acetate to give the final supported catalyst (

Scheme 28) [

97]. This catalyst was tested in both Suzuki–Miyaura and Mizoroki–Heck cross-coupling: the former was carried out between aryl bromides with different stereoelectronic features and phenylboronic acid, in the presence of K

2CO

3 as the base, for 1–6 h in refluxing

o-xylene; the latter was performed between iodoarenes and

n-butyl acrylate, in the presence of Et

3N as the base, for 20–42 h in refluxing dioxane. In the case of Suzuki–Miyaura coupling, recyclability tests were also carried out up to five times, without appreciable loss of activity.

A similar synthesis of a chitosan 2-pyridylimine palladium catalyst was reported in 2021 by Chauhan et al.: in this case, a condensation reaction of the –NH

2 groups of pristine chitosan with 2-acetylpyridine afforded the so-called chitosan 2-pyridylimine (also named CPI), which was then treated with Pd(OAc)

2 in acetone for 8 h at room temperature to give the final chitosan 2-pyridyl imine palladium (CPIP) complex catalyst (

Scheme 29) [

98].

FT-IR spectra confirmed a complete conversion of the free amino groups of pristine chitosan into pyridylimines, while a change in the intensity of chitosan peaks of the XRD pattern after the addition of Pd(OAc)

2 suggested the complexation of a palladium(II) species. Thanks to its high thermal and chemical stability, the CPIP catalyst was successfully applied: (i) in the Suzuki–Miyaura coupling of bromo arenes with phenylboronic acid (1.2 equiv.), performed in the presence of potassium carbonate (3.0 equiv.) at 70–75 °C in EtOH/H

2O (1:1

v/

v) for 3 h, affording the desired biaryl coupling products in excellent yields (97–98%) (

Scheme 29a); (ii) in the Mizoroki–Heck coupling of aryl iodides and bromides with 3,3-dimethyl-1-butene (1.2 equiv.), carried out in the presence of cesium carbonate (3.0 equiv.) as the base and toluene as the solvent, in a sealed tube at 100–105 °C for 3 h, giving trans-vinylarene products in 75–92% yields (

Scheme 29b). Similarly to other chitosan-supported Pd catalysts, CPIP also showed good recyclability: with both Suzuki–Miyaura and Mizoroki–Heck reactions, the CPIP catalyst can be easily recovered and reused up to five times with no loss of catalytic activity.

The incorporation of salicylimine ligands into the polymer chains of chitosan is a further strategy for the development of efficient heterogeneous supports for palladium catalysts. In 2005, Cui and co-workers described the preparation of a CL-S-CTS-Pd catalyst through a three-step procedure: (i) condensation of the primary amino groups of pristine chitosan with salicylaldehyde in refluxing ethanol to give salicylimine-functionalized chitosan (S-CTS); (ii) cross-linking of the chitosan chains of S-CTS with epoxy chloropropane, carried out in 0.5% NaOH solution in the presence of cetyltrimethyl ammonium bromide, affording the desired cross-linked material CL-S-CTS; (iii) treatment with PdCl

2 in acetone at 60 °C for 72 h, which gave the final palladium supported on salicylimine-functionalized cross-linked chitosan (that is, CL-S-CTS-Pd catalyst) (

Scheme 30) [

99]. This material was then tested at the 0.2 mol% of loading in the Mizoroki–Heck coupling of aryl iodides with styrene or acrylic acid (1.2 equiv.) at 90 °C in DMF for 3 h and in the presence of tributylamine (1.2 equiv.). In all cases, coupling products were obtained in excellent yield (up to 97%). Interestingly, as a comparison, the authors also tested a similar palladium catalyst supported on an epoxy chloropropane-cross-linked chitosan (CL-CTS-Pd), i.e., without salicylimine ligands: a lower catalytic activity was found working under the same experimental conditions, thus confirming the central role of the salicylimine ligands in the biopolymer chains.

A different palladium catalyst supported on salicylimine-chitosan was developed by Liu et al. in 2006. In this case, after grafting salicylaldehyde on pristine chitosan to form the corresponding chitosan–Schiff base material, it was directly treated with a Pd species (Li

2PdCl

4 in methanol) without any cross-linking to give the final palladium catalyst [

100]. Both FT-IR and XPS analysis of the final material suggested the formation of an imine palladacycle, able to catalyze the Mizoroki–Heck reaction of iodoarenes with electron poor alkenes (acrylic acid, acrylates, styrene, acrylamide) to give the corresponding coupling products in good yields and complete stereoselectivity trans. In the specific case of Mizoroki–Heck coupling of iodobenzene with acrylic acid, a turnover number (TON) of 494 and a turnover frequency (TOF) of 247 were calculated for the catalyst.

In 2010, Ondruschka and co-workers proposed a more comparative study, where the performance of a salicylimine-functionalized chitosan-supported palladium catalyst in different cross-coupling reactions was compared with those of a 2-pyridylimine-functionalized chitosan-supported palladium catalyst and of two different palladium catalysts supported on pristine chitosan (prepared by co-precipitation and adsorption, respectively) [

101]. Working under microwave irradiation, for the Mizoroki–Heck coupling, the best results were obtained with the salicylimine-chitosan/Pd catalyst, while the 2-pyridylimine-chitosan/Pd catalyst showed the highest catalytic activity in the case of Suzuki–Miyaura coupling, thus confirming the central role played by the chemical functionalization of pristine chitosan with suitable ligands in the development of more efficient catalytic systems. However, all four catalysts worked quite well (although with longer reaction times) in the case of the same reactions under conventional thermal heating. The Sonogashira coupling was also investigated, but in this case, all the catalysts were less selective and gave significant amounts of side products beside the desired coupling product.

A biguanidine-functionalized chitosan was developed in 2016 by Veisi et al. as a support for a heterogeneous palladium catalyst applied in the Suzuki–Miyaura coupling (

Scheme 31) [

102]. First of all, chitosan was treated with cyanoguanidine in refluxing aqueous HCl for 2 h and then stirred with NaOH (10 wt%) to remove hydrochloride from the polymer, affording the desired biguanidine-functionalized chitosan; then, an acetonitrile solution of PdCl

2 was added and stirred for 10 h at room temperature, affording a biguanidine-chitosan/Pd(II) system, which was finally reduced to the corresponding biguanidine-chitosan/Pd(0) catalyst by reaction with hydrazine hydrate.

Several characterization techniques indicated the formation of palladium nanoparticles throughout the biopolymer: TEM images showed evenly dispersed palladium nanoparticles embedded in membranous light grey chitosan–biguanidine shells, while SEM revealed that the morphology of the final biguanidine-chitosan/Pd(0) catalyst was different from that of starting chitosan, with a more regular stacked structure. The final catalyst was successfully applied for the synthesis of biaryls in the Suzuki–Miyaura cross-coupling of aryl iodides, bromides and chlorides with phenylboronic acid: reactions were performed in a sustainable reaction medium (EtOH:H

2O = 1:1

v/

v) at 40 °C, in the presence of 2.0 equiv. of K

2CO

3 as the base and 0.15 mol% as palladium loading. In the case of aryl iodides, reactions were very fast (0.25–1 h), affording the corresponding products in excellent yields (96–98%), while in the case of aryl bromides, 1–4 h were required to give the desired biaryls in 90–98% yields; preliminary tests with aryl chlorides were carried out in longer times (10–12 h), but afforded the coupling products in satisfactory yields (70–75%) (

Scheme 31).

In the latest studies mentioned above, pristine chitosan was first covalently functionalized with the suitable ligand (typically, nitrogen-based) and then treated with a palladium species to be coordinated on the resulting ligand-modified biopolymer. A different approach was described in 2011 by Pombeiro and co-workers: in this case, palladium complexes bearing the desired ligand (Δ

4-1,2,4-oxadiazoline-based and ketoimine-based compounds) were first synthesized and then anchored to chitosan through coordination bonds to give the final Δ

4-1,2,4-oxadiazoline-Pd(II)-chitosan and ketoimine-Pd(II)-chitosan catalysts (

Figure 6) [

103]. The two chitosan-supported catalysts were tested in the microwave-assisted Suzuki–Miyaura cross-coupling reaction, carried out in H

2O as a sustainable reaction medium: on the one hand, the effect of palladium loading, temperature, time, base and phase-transfer agent was studied, as well as the possibility of recyclability (up to seven times); on the other hand, a severe limitation of this work is the absence of any investigation on the substrate scope, since only the reaction of

p-bromoanisole with phenylboronic acid was considered here.

The chemical functionalization of pristine chitosan through the covalent anchoring of suitable ligands does not represent the only way to increase its affinity as a support with Pd species. In fact, the hydroxyl, carbonyl and/or amino moieties can be easily converted into other functional groups (e.g., carboxylic acid, thiourea, etc.) with greater metal coordinating ability; at the same time, chitosan can also be grafted with oligo/polymers showing different molecular weight and polarity, in order to modify its physico-chemical properties. Palladium catalysts supported on all these chemically-modified chitosans have been successfully synthesized and applied in carbon–carbon bond formation reactions.

In 2015, Pitchumani and co-workers proposed the use of palladium nanoparticles supported on thiourea-modified chitosan as a green and heterogeneous catalyst for a Suzuki–Miyaura cross-coupling reaction in water [

104]. Thiourea-modified chitosan (TMC) was easily prepared by the treatment of chitosan powder with ammonium thiocyanate in refluxing ethanol for 12 h; after that, palladium nanoparticles were deposited by mixing TMC with an aqueous solution of palladium acetate in the presence of ellagic acid as a natural and green reducing source. The final PdNPs/TMC catalyst was characterized by FT-IR, powder XRD and TEM analysis, which confirmed the presence of spherically shaped palladium nanoparticles uniformly dispersed on the surface of the biopolymer, with average size of 4.6 nm. Suzuki–Miyaura cross-coupling reactions catalyzed by PdNPs/TMC were carried out between an aryl halide (iodobenzene or bromobenzene, 1.0 equiv.) and arylboronic acids (1.2 equiv.) with different stereoelectronic properties, in the presence of K

2CO

3 (4.0 equiv.) as the base, in water at 80 °C for 14–18 h, affording the corresponding biaryl products in 78–99% yields (

Scheme 32). The recyclability of PdNPs/TMC was proved up to five consecutive runs, while hot filtration tests indicated no appreciable metal leaching under reaction conditions, thus demonstrating the occurrence of a heterogeneous mechanism.

O-carboxymethyl chitosan is more commonly used as a support for palladium catalysts: it can be easily synthesized by the reaction of pristine chitosan with monochloroacetic acid, although it is also commercially available from various suppliers in light of its wide use for several applications. In this context, Zhang and Lv described, in 2017, the preparation of palladium supported on

O-carboxymethyl chitosan (named Pd-OCMCS,

Scheme 33): the modified biopolymer was first treated with a KOH aqueous solution (60 °C, 1 h), then a PdCl

2 aqueous solution was dropped and mixed for further 12 h at 60 °C [

105].

FT-IR analysis of Pd-OCMCS showed a shift of the asymmetric C=O stretching vibration peak from 1644 cm

−1 to 1654 cm

−1, suggesting that Pd ions were coordinated by the carboxylate groups of

O-carboxymethyl chitosan; this indication was then further confirmed by the XRD patterns of the catalyst. Its catalytic activity was then tested in the Mizoroki–Heck coupling of aryl halides (i.e., iodides, bromides and few examples of chlorides) with

n-butyl acrylate (1.1 equiv.): reactions were carried out with 2 mol% of Pd loading and triethylamine (1.5 equiv.) in DMF as the solvent at 140 °C for 12 h, affording the corresponding coupling products with complete stereoselectivity trans (yields: 94–99% in the case of aryl iodides; 89–94% in the case of aryl bromides; 6–51% in the case of aryl chlorides) (

Scheme 33).

Interestingly,

O-carboxymethyl chitosan was also further functionalized by the covalent immobilization of suitable imine ligands. In 2015 and 2016, Mentes et al. reported two studies where four different

O-carboxymethyl chitosan-Schiff base-Pd(II)-supported catalysts were synthesized (

Figure 7) [

106,

107]. In this case, FT-IR and XRD powder analysis showed that palladium immobilization took place by coordination on the nitrogen atoms of imine ligands, rather than on the carboxylate groups of

O-carboxymethyl chitosan (as in the previous work Zhang and Lv). The four catalysts were successfully tested in the Suzuki–Miyaura coupling of aryl halides (iodides, bromides and also chlorides with different steric and electronic features) with phenylboronic acid (1.7 equiv.), performed with 0.02–0.04 mol% of palladium loading and K

2CO

3 (3.35 equiv.) as the base, in toluene at 100 °C for 48–60 h. Moreover, it is worth emphasizing the improved recyclability of these four

O-carboxymethyl chitosan-Schiff base-Pd(II) with respect to the Pd-OCMCS system of Zhang and Lv: this result could be explained in terms of lower leaching from the support, confirming the improved coordinating ability of imine ligands compared to the carboxylate groups of

O-carboxymethyl chitosan.

Very recently, Li and co-workers described the application to the Suzuki–Miyaura cross-coupling reaction of a new palladium(II) catalyst supported on vanillin-modified

O-carboxymethyl chitosan (named OCMCS-SB-Pd(II) by the authors). [

108] In this case, the free amino groups of pristine chitosan were first functionalized with vanillin to give the corresponding Schiff bases by condensation reaction in refluxing methanol; the resulting vanillin-modified chitosan (CS-SB) was then treated with monochloroacetic acid in methanol to give OCMCS-SB, which was finally added to a solution of Na

2PdCl

4 in water and mixed for 24 h at 50 °C in order to generate the final OCMCS-SB-Pd(II) catalyst. Both

13C CP-MAS NMR and FT-IR spectra of OCMCS-SB-Pd(II) clearly confirmed the condensation of CS with vanillin and the subsequent carboxymethylation step; moreover, both XRD patterns and TEM images excluded the presence of Pd(0) nanoparticles, which was in agreement with the XPS results of a Pd(II) oxidation state for this catalyst. Suzuki–Miyaura reactions were successfully performed between bromoarenes (1.0 equiv.) and arylboronic acids (1.5 equiv.) bearing functional groups with different stereoelectronic properties in the presence of potassium carbonate (2.0 equiv.) as the base and EtOH/H

2O (3:2

v/

v) as the reaction medium, using only 0.46 mol% of OCMCS-SB-Pd(II); in only 1.5–3 h, the corresponding biaryl products were obtained in yields up to 99%.

In 2010, Lee and co-workers reported the preparation of two different palladium catalysts, supported on a chitosan grafted with methoxy triethylene glycol (CS-

g-mTEG) and on a chitosan grafted with methoxy polyethylene glycol (CS-

g-mPEG), to be used in the Suzuki–Miyaura cross-coupling reaction in water (

Scheme 34) [

109].

In this case, beads of pristine chitosan were first treated with Pd(OAc)

2 in DMSO at 80 °C for 10 min and then at room temperature for 2 h, to give brown chitosan-supported Pd(II) beads; the subsequent reduction to Pd(0) was carried out with hydrazine in H

2O, testified by the change of beads’ colour from brown to black. After a cross-linking step with a glutaraldehyde aqueous solution, the resulting imine groups were reduced with NaBH

4 in order to prevent their hydrolysis. The subsequent grafting was carried out in two steps: reaction with 2,4,6-trichlorotriazine in the presence of DIPEA as the base, to obtain a dichlorotriazine-modified cross-linked chitosan; the two remaining chlorides of triazine units were then grafted by reaction with mTEG or mPEG350, performed in pyridine as the solvent, at 60 °C for 19 h (

Scheme 34). Both final catalysts were used (0.5 mol% of Pd loading) in the Suzuki–Miyaura cross-coupling reaction of aryl halides with phenylboronic acid (1.5 equiv.), performed in water as green solvent and in the presence of NaOH (3.0 equiv.) as the base. Compared to simple palladium(0) nanoparticles supported on chitosan beads, CS-

g-mTEG/Pd and CS-

g-mPEG/Pd catalysts showed significantly higher catalytic activity (in terms of reaction times and product yields), suggesting that the grafted mTEG and mPEG groups worked as effective phase transfer catalysts, facilitating reagents’ migration from water to the chitosan surface.

In 2022, Seyedi et al. described the preparation of a palladium catalyst deposited on a poly(

o-phenylenediamine)-grafted chitosan in a two-step procedure: first, an aqueous solution of chitosan was treated with

o-phenylenediamine for 1 h at room temperature in the presence of sulfuric acid, in order to allow the in situ polymerization of

o-phenylenediamine, giving the grafted biopolymer (indicated as CS-PoPD); the resulting CS-PoPD was then added to a solution of PdCl

2 in methanol, and the resulting suspension was stirred for 24 h at room temperature to give the final supported catalyst (named CS-PoPD-Pd) [

110]. In particular, the immobilization of palladium occurred in the form of Pd(II) complexes, as confirmed by the XRD pattern: no new diffraction peaks appeared after the treatment of the CS-PoPD support with PdCl

2; moreover, SEM images showed that the

o-phenylenediamine polymerization led to a flake-like structure. The CS-PoPD-Pd catalyst was then applied (at 0.28 mol% of Pd loading) for the synthesis of biaryls in the Suzuki–Miyaura cross-coupling reaction of aryl iodides and bromides with phenyl boronic acid (1.5 equiv.): working in the presence of K

2CO

3 (1.0 equiv.) as the base, at 70 °C in a water/ethanol (1:1

v/

v) mixture, the corresponding products were obtained in 70–97% yields. The reactions seem to suffer little from the stereoelectronic features of the aryl halides: CS-PoPD-Pd showed a turnover number between 250 and 346, while its turnover frequency ranged between 7.1 and 10 (

Scheme 35). At the same time, the catalyst also showed good recyclability: CS-PoPD-Pd was used for five consecutive runs with no loss of catalytic activity.

Despite its invaluable advantages, the use of chitosan as a support for metal catalysts is often associated with limiting factors that could not be ignored: poor thermal stability, modest mechanical property, solvent-induced swelling and so on. If a possible solution to this problem is presented by its covalent cross-linking with suitable bifunctional reagents (as we have already described above), more recently chitosan-based nanocomposites have attracted significant attention: the introduction of inorganic nanosized fillers (clay minerals, silica, iron oxides) into the chitosan matrix can combine the physico-chemical properties of both organic and inorganic components. In this context, chitosan/montmorillonite nanocomposites represent definitely the most used supports for palladium species. Montmorillonite (MMT) is a natural clay mineral belonging to the group of phyllosilicates, whose interlayers typically contain metal cations (in particular, Na+, Ca2+ and Mg2+) that can be exchanged by other cations, including the polycationic polymer chains of chitosan (due to the –NH3+ groups under acidic conditions). Moreover, the hydroxyl, carbonyl and amino functional groups of chitosan can form hydrogen bonds with Si-O-Si groups of silicate multilayer and silicate hydroxylated end groups of MMT. The occurrence of strong interactions between chitosan and montmorillonite can easily generate nanocomposites with improved mechanical, thermal, antimicrobial and anticorrosion properties.

The first application of a palladium catalyst supported on chitosan/montmorillonite nanocomposites in the field of cross-coupling reactions was reported in 2015 by Qi et al.: in this case, pristine chitosan was dissolved in a 2 wt% acetic acid aqueous solution, then, montmorillonite and an aqueous Na

2PdCl

4 solution were sequentially added; the resulting mixture was finally precipitated into a 5 wt% NaOH aqueous solution to give microspheres of chitosan/montmorillonite/palladium nanocomposites (CS/MMT/Pd,

Scheme 36) [

111].

FT-IR of freshly prepared CS/MMT/Pd revealed strong hydrogen bonding of the amino and hydroxyl groups of the biopolymer, not only with the Si-OH end groups, but also with the internal Si-O-Si groups of MMT; moreover, HR-TEM images showed good dispersion of MMT into the chitosan matrix, although at the same time, no individual separated Pd species were found, suggesting the presence of palladium(II) cations dispersed at the molecular level. Interestingly, the authors found that freshly prepared CS/MMT/Pd microspheres can be activated by treatment with an alcohol, capable of reducing palladium(II) species into palladium(0): this was confirmed by HR-TEM images of the supported catalyst after activation, showing the appearance of metal nanoclusters (average diameter of about 5 nm) homogeneously dispersed in both the inorganic and organic matrices. The activated CS/MMT/Pd catalyst was applied in the Sonogashira coupling of aryl iodides with aryl alkynes (1.2 equiv.): using 0.3 mol% of palladium catalyst, 3.0 equiv. of potassium acetate as the base, in DMSO as the solvent at 110 °C for 5 h, the corresponding coupling products were obtained in 69–94% yields (

Scheme 36). A further strength of this catalyst is its high recyclability: CS/MMT/Pd was used for ten consecutive runs with no significant loss of catalytic activity; the strong interactions between chitosan chains, MMT layers and palladium species allowed a reduction in the metal leaching from the support.

In a following study, Zeng and co-workers reported the synthesis of a very similar metal catalyst, i.e., palladium nanoparticles supported on chitosan/montmorillonite nanocomposites (named Pd@MMT/CS) [

112]. The only difference from the previous work of Qi et al. is the final step, in which palladium(II) species complexed to chitosan/montmorillonite were reduced to Pd(0) nanoparticles by using ethylene glycol at 80 °C for 0.5 h, giving final Pd@MMT/CS. This catalyst was widely applied to the Mizoroki–Heck reaction of aryl iodides with terminal alkenes: working under conditions quite similar to the previous work of Qi et al. (0.2 mol% of Pd@MMT/CS, 3.0 equiv. of KOAc, DMSO, 110 °C, 4 h), the corresponding trans-disubstituted alkenes were obtained in excellent yields (89–96%). Moreover, the reusability of Pd@MMT/CS in a model Mizoroki–Heck reaction was tested in comparison with those of commercial Pd/C and palladium nanoparticles deposited on pristine montmorillonite (Pd@MMT). Interestingly, if Pd@MMT showed the worst performance (only six runs) and Pd/C a moderate stability (ten runs), Pd@MMT/CS was successfully recycled up to thirty consecutive runs. This result clearly demonstrated the exceptional physical and chemical stability of Pd@MMT/CS nanocomposites, as well as very low metal leaching (

Scheme 37). In 2017, the same catalytic system was used for the preparation of a palladium–carbon/montmorillonite (Pd-C/MMT) heterogeneous catalysts: Pd@MMT/CS nanocomposites underwent carbonization at 250–650 °C under N

2 to give Pd-C/MMT, which was then tested in Mizoroki–Heck cross-coupling reactions [

113].

As is well known, Pd-catalyzed Sonogashira cross-coupling reactions often require the use of a copper species as co-catalyst. Starting from this consideration, in 2018 Zeng, Cao and co-workers developed a new bimetallic catalyst consisting of palladium(0) nanoparticles and copper(II) cations supported on chitosan/montmorillonite nanocomposites (indicated as Pd

0/Cu

2+@MMT/CS) [

114]. The synthesis of Pd

0/Cu

2+@MMT/CS involved three steps: (i) treatment of chitosan in 2 wt% acetic acid aqueous solution with a montmorillonite suspension to give the usual chitosan/montmorillonite nanocomposite; (ii) addition of an aqueous solution of Na

2PdCl

4 and CuCl

2, which afforded the bimetallic palladium(II) and copper(II) deposited on CS/MMT nanocomposites; (iii) reduction of Pd(II) species with ethylene glycol at 80 °C for 15 min to give the final Pd

0/Cu

2+@MMT/CS material. The Sonogashira couplings were carried out between iodoarenes and aryl alkynes (1.2 equiv.) in the presence of 1 mol% of bimetallic Pd

0/Cu

2+@MMT/CS catalyst, PPh

3 (3 mol%) as the ligand and sodium carbonate (3.0 equiv.) as the base, in H

2O/dimethoxyethane as reaction medium at 80 °C for 8 h (

Scheme 38). The Pd

0/Cu

2+@MMT/CS can be recycled up to six times, although a gradual decrease in the yields of cross-coupling product was observed, due to significant metal leaching (in particular of Cu species).

A more recent approach for the development of efficient and stable supports for palladium catalysts is based on the use of chitosan-based nanocomposites with iron oxides. In fact, one of the most attractive features of these magnetic systems is their easy separation without the need to utilize filtration or centrifugation techniques, by simply using a magnet. In this context, in 2021, Baran et al. described the preparation of palladium nanoparticles supported on chitosan/

δ-FeOOH microspheres (Pd NPs@CS/

δ-FeOOH) as an eco-friendly, low cost and magnetic heterogeneous catalyst for Suzuki–Miyaura cross-coupling [

115].

The catalyst preparation involved three main steps: (i) preparation of

δ-FeOOH by the treatment of (NH

4)

2Fe(SO

4)

2·6 H

2O with H

2O

2 in a NaOH environment; (ii) reaction of

δ-FeOOH with pristine chitosan in 2 wt% acetic acid (2 h, rt) followed by precipitation under basic conditions (NaOH, H

2O/ethanol) to form spherical gel beads, which were then treated with glutaraldehyde (ethanol, 70 °C, 5 h) for the cross-linking procedure, affording CS/

δ-FeOOH nanocomposite; (iii) treatment of a CS/

δ-FeOOH suspension in ethanol with PdCl

2 (reflux, 3 h) to give the final Pd NPs@CS/

δ-FeOOH microspheres (

Scheme 39). TEM images confirmed the immobilization of palladium nanoparticles (average diameters of 10 nm) homogeneously dispersed on the surface of hybrid chitosan/iron oxides microspheres. The catalytic performance of Pd NPs@CS/

δ-FeOOH was checked in the Suzuki–Miyaura coupling of aryl iodides and bromides with phenylboronic acid (1.5 equiv.); working with 0.05 mol% of palladium loading, 2.5 equiv. of K

2CO

3 as the base, in water/ethanol solvent mixture, after 3 h at 70 °C the corresponding biaryl products were obtained in 85–99% yields. The Pd NPs@CS/

δ-FeOOH performance was found to be independent of the stereoelectronic characteristics of the aryl halide: the turnover number (TON) ranged between 1700 and 1980, while the turnover frequency was between 587 and 660.

In the same year, Pamidimukkala and co-worker reported an eco-friendly methodology for the impregnation of Pd nanostructures on the surface of magnetic hybrid chitosan/iron oxides nanoparticles as a reusable catalyst (Pd@IO-Chitosan) [

116]. Chitosan/iron oxides nanoparticles (IO-Chitosan) were prepared by co-precipitation of FeSO

4 · 7H

2O, FeCl

3 · 2H

2O and chitosan under alkaline conditions; PdCl

2 was then added to an IO-Chitosan suspension and stirred for 12 h at room temperature, giving the final catalyst. Unlike Pd NPs@CS/

δ-FeOOH microspheres from the previous work of Baran et al., where only palladium(0) species were found, in this case XPS, XRD and HR-TEM analysis indicated the presence of both Pd(II) and Pd(0) in the Pd@IO-Chitosan catalyst. However, this was not detrimental to its catalytic performance: it was successfully applied at very low loading (0.005 mol%) in the Suzuki–Miyaura coupling of aryl halides with phenylboronic acid, performed in refluxing water with K

2CO

3 (2.0 equiv.) as the base. Interestingly, under these experimental conditions, the reaction took place very well not only with aryl iodides with different stereoelectronic features (yields 83–99%, 6–12 h), but also in few tests with bromobenzene and chlorobenzene (product yields 93–99%, 7–11 h). The Pd@IO-Chitosan catalyst showed not only easy recovery by simply using a magnet, but also excellent recyclability, working for 12 consecutive runs with no loss of activity (

Scheme 40).

Hajipour et al. proposed the preparation of palladium nanoparticles supported on magnetic methionine-functionalized chitosan, used as an efficient catalyst for Suzuki–Miyaura and Sonogashira coupling reactions in water [

117]. The route for the catalyst preparation (named ImmPd(0)-MNPs) consisted of three steps: (i) methionine-functionalized chitosan was obtained by the reaction between methyl methioninate and chitosan in DMF; (ii) it was then treated with Fe

3O

4 nanoparticles, in turn obtained by mixing FeCl

3 · 6H

2O and FeSO

4 to give the hybrid inorganic/organic support: methionine-functionalized chitosan-coated Fe

3O

4 nanoparticles; (iii) Pd(OAc)

2 was added to a suspension of this magnetic support in ethanol, giving, after 3 days at room temperature, the final ImmPd(0)-MNPs catalyst (

Scheme 41).

TEM images show that the synthesized Pd nanoparticles on the Fe3O4@CS–methionine are near-spherical and well distributed, with an average diameter of ~6–7 nm. The versatility of ImmPd(0)-MNPs as the catalyst in the field of carbon–carbon bond formation under sustainable conditions was verified in two different reactions: Suzuki–Miyaura and Sonogashira coupling. The former was successfully performed using iodo- and bromoarenes with different stereoelectronic properties, in the presence of K2CO3 (2.0 equiv.) as the base and TBAB (0.5 equiv.) as additive in water at room temperature for 0.3–2 h; some explorative tests were also carried out with aryl chlorides, giving the desired coupling products in good yields but longer times (2.5–3.5 h). The latter was carried out with an equimolar amount of phenylacetylene and aryl halides (iodides and bromides) at 0.14 mol% of Pd loading in water at room temperature, with K2CO3 (2.0 equiv.) and TBAB (0.5 equiv.).

The use of palladium nanoparticles supported on methyl salicylate-modified magnetic chitosan (named Fe

3O

4@CS@MS@Pd) in both Suzuki–Miyaura and Mizoroki–Heck coupling has been described in 2020 by Hasan [

118]. The preparation of this catalyst was quite similar to other above described palladium species supported on chitosan-based nanocomposites with iron oxides: (i) preparation of Fe

3O

4 nanoparticles from FeSO

4 · 7H

2O and FeCl

3 · 6H

2O in water (90 °C, 30 min), followed by their precipitation upon addition of an ammonia solution; (ii) formation of chitosan-coated magnetic nanoparticles, obtained by stirring at room temperature a suspension of Fe

3O

4 with chitosan; (iii) functionalization of the –NH

2 groups of chitosan-coated magnetic nanoparticles with methyl salicylate, carried out in refluxing ethanol for 24 h; (iv) deposition of palladium nanoparticles by treatment with Pd(OAc)

2 in ethanol (2 h, room temperature) in the presence of NaBH

4 as reducing agent. The Suzuki–Miyaura coupling was performed between haloarenes (1.0 equiv.) and phenylboronic acid (1.1 equiv.) in the presence of 0.1 mol% of Pd loading and 2.0 equiv. of K

2CO

3 as the base in H

2O/EtOH 4:1 (

v/

v) at 80 °C, giving the corresponding biaryl products in excellent yields (70–98%) after 1–4 h (

Scheme 42a). The Mizoroki–Heck coupling was carried out between iodoarenes (1.0 equiv.) and

tert-butyl acrylate (1.1 equiv.), in the presence of 0.1 mol% of Pd loading and 2.0 equiv. of Et

3N as the base in H

2O/EtOH 4:1 (

v/

v) at 80 °C, giving the corresponding disubstituted alkenes in 25–98% yields and complete stereoselectivity trans after 1–8 h (

Scheme 42b).

Although most of the palladium catalysts supported on chitosan-based nanocomposites with iron oxides involved the use of palladium(0) species, in 2021 Shokouhimehr et al. described the preparation of a similar catalyst based on a palladium(II) species: Fe

3O

4–CS@tet–Pd(II), where palladium(II) cations were coordinated to 5-amino-1

H-tetrazole ligands covalently attached to chitosan-coated iron oxide nanoparticles [

119]. The 5-amino-1

H-tetrazole ligand was treated with (3-chloropropyl)trimethoxysilane for 24 h under refluxing ethanol, then magnetic Fe

3O

4–CS nanoparticles (prepared by mixing Fe

3O

4 with a chitosan solution in aqueous acetic acid at room temperature for 1 h) were added and stirred for a further 24 h at 60 °C; finally, the resulting hybrid inorganic/organic material (named Fe

3O

4–CS@tet) was used as a support for palladium(II) complexation (PdCl

2, ethanol, reflux, 24 h) to give the heterogeneous Fe

3O

4–CS@tet–Pd(II) catalyst. The formation of palladium(II) complexes on the surface of the catalyst was also confirmed by several characterization techniques, such as EDS, FT-IR and XRD analysis. Fe

3O

4–CS@tet–Pd(II) was then applied in the Suzuki–Miyaura coupling of aryl halides with phenyboronic acid (1.1 equiv.) carried out in water/ethanol (1:1) at 90 °C and in the presence of K

2CO

3 (2.0 equiv.) as the base. In the case of iodides as substrates, reactions occurred in 70 min, affording biaryl products in 85–92% yields; using bromides reactions required 130 min and afforded the coupling products in 78–91% yields; lower yields (65–76%) and longer reaction times (5 h) were required in the case of aryl chlorides as substrates (

Scheme 43). Fe

3O

4–CS@tet–Pd(II) showed good recyclability (up to five consecutive runs with no loss of activity) and easy recovery thanks to its magnetic properties (by simply using a magnet).

To conclude this overview on palladium catalysts supported on chitosan-based nanocomposites with iron oxides, in 2020, Veisi and co-workers described the preparation of Pd nanoparticles deposited on chitosan-encapsulated Fe

3O

4/SiO

2 microspheres (which were named Fe

3O

4/SiO

2–NH

2@CS/Pd) [

120]. In this case, Fe

3O

4 nanoparticles were prepared from FeCl

3 · 6H

2O and FeCl

2 · 4H

2O by the co-precipitation method, then were treated with tetraethyl orthosilicate to give silica-coated Fe

3O

4 nanostructures; the subsequent addition of 3-aminopropyl trimethoxysilane allowed the authors to modify their surface with aminopropyl groups (Fe

3O

4/SiO

2–NH

2). These particles were suspended on a chitosan solution in the presence of glutaraldehyde as cross-linking agent, affording the hybrid magnetic support (Fe

3O

4/SiO

2–NH

2@CS). The last step was metal deposition, carried out by using an aqueous solution of Na

2PdCl

4 (24 h, reflux). HR-TEM microscopy images of Fe

3O

4/SiO

2–NH

2@CS/Pd revealed a quite homogeneous dispersion of palladium nanoparticles, with a dimension of ~5 nm. The catalytic performance was tested in the Suzuki–Miyaura reactions of an equimolar amount of aryl halides and phenylboronic acid: working with 0.1 mol% of palladium catalyst and 2.0 equiv. of K

2CO

3 as the base in water/ethanol (1:1) at 40 °C, the corresponding coupling products were obtained in excellent yields (90–98% in 0.25–1 h for aryl iodides; 85–96% in 0.5–2 h for aryl bromides; 50–60% in 5–12 h for aryl chlorides) (

Scheme 44).

The use of chitosan-based nanocomposites with inorganic materials does not represent the only approach to improve their chemical, thermal and mechanical features as a support for metal catalysts. In fact, there are several examples of palladium catalysts deposited on composite nanofibers of chitosan (or chemically modified chitosan derivatives) with other organic materials, including synthetic polymers such as poly(ethylene oxide) (PEO), polyvinyl alcohol (PVA), poly(methacrylic acid) (PMAA) or sodium polyacrylate (PAAS) and even other biopolymers (in particular cellulose, starch and agarose).

In this context, Shao and co-workers reported, in 2018, the preparation of composite chitosan/poly(ethylene oxide) (CS/PEO) nanofibers by electrospinning, used as a support for the immobilization of palladium [

121]. In more detail, pristine chitosan was electrospun in the presence of 5 wt% of PEO as co-spinning agent, giving uniform fibers (398 ± 76 nm of diameter) which were then thermally annealed at 200 °C for 2 h. The CS/PEO fibers were then chemically modified by covalent immobilization of 2-pyridylimine or 2-thienylimine ligands, thanks to the condensation reaction of, respectively, 2-pyridinecarboxaldehyde or 2-thenaldehyde with the amino groups of chitosan. The final palladium catalysts were obtained by complexation of a palladium(II) species (Na

2PdCl

4) on CS/PEO-pyridylimine or CS/PEO-thienylimine composite nanofibers; as a comparison, Na

2PdCl

4 was also deposited on the not modified CS/PEO fibers. If chitosan in simple CS/PEO fibers had an abundance of amino and hydroxyl groups, its chemical modification with pyridylimine or thienylimine ligands could provide more metal coordination sites, increasing the composite nanofibers’ affinity with palladium. This point was confirmed by TEM, showing the reduced aggregation of palladium nanoparticles in Pd-CS/PEO-pyridylimine and Pd-CS/PEO-thienylimine compared to Pd-CS/PEO. The performances of these three catalysts were compared in the Mizoroki–Heck reaction of

p-iodoanisole with

n-butyl acrylate: as expected, imine-modified CS/PEO fibers showed higher activity (in terms of product yield and reaction time) and also better recyclability (in particular Pd-CS/PEO-pyridylimine, used in ten consecutive runs with no loss of activity). The Pd-CS/PEO-pyridylimine was then successfully applied for an extended substrate scope: working with 0.79% of palladium loading, the Mizoroki–Heck reactions of aryl iodides and bromides with monosubstituted olefins (

n-butyl acrylate and styrene, 2.0 equiv.), performed in DMA at 110 °C with an excess of Et

3N as the base, afforded the corresponding trans-disubstituted olefins in 35–99% yields (

Scheme 45). In a following study, the same group described the synthesis of a similar palladium catalyst supported on CS/PEO composite nanofibers, based on a slightly modified procedure [

122]. In this case, a cross-linker (the difunctionalized itaconic acid) was electrospun together with chitosan and PEO, in order to give in situ cross-linking during the subsequent thermal annealing step. The resulting nanofibers revealed better solvent resistance, thermal stability and mechanical strength, and at the same time, were able of chelating palladium species without the need of chemical modification with imine ligands. The final Pd-CS/PEO/IA fibers were tested also in this case in the Mizoroki–Heck coupling of iodoarenes with terminal alkenes (

n-butyl acrylate, methyl acrylate and styrene).

Inspired by the two works of Shao and co-workers, in 2020, Zhong proposed a further palladium catalyst supported on CS/PEO composite nanofibers, but applied to Sonogashira reactions (

Scheme 46) [

123].

In this study, a Na

2PdCl

4 aqueous solution and pyridine-2-carboxaldehyde (selected as ligand) were added to an aqueous solution of chitosan, poly(ethylene oxide) (the co-spinning agent) and maleic acid (selected as the cross-linking agent); the resulting mixture was stirred for 12 h in order to allow the formation of imine bonds between aldehyde ligands and chitosan amino groups, followed by the palladium(II) complexation. The final homogeneous mixture was subjected to electrospinning to directly produce the palladium embedded chitosan hybrid nanofibers, which were finally subjected to thermal annealing at 100 °C for 5 h to promote cross-linking of chitosan chains with maleic acid, affording the final catalyst (named Pd@CS/PEO by the author). It was then tested in the copper-free Sonogashira coupling reactions of aryl halides and phenylacetilene (2.0 equiv.), performed with 7.0 mol% of Pd, 4.3 equiv. of K

2CO

3 as the base in DMA at 110 °C; reactions involving aryl iodides were carried out for 5 h, affording disubstituted alkynes in 80–96% yields, while with aryl bromides, low yields (14–38%) were obtained after 24 h (

Scheme 46). If, on the one hand, Pd@CS/PEO revealed excellent recyclability, since it was used for ten consecutive runs with no appreciable loss of catalytic activity, on the other hand, ICP-AES analysis on the recovered Pd@CS/PEO after the 10

th cycle showed that 37% of the Pd initially deposited on the fibers was leached.

If poly(ethylene oxide) is definitely the most common synthetic polymer used for composite nanofibers with chitosan, others have also been successfully used. In 2019, Shao et al. proposed the use of polyvinyl alcohol (PVA) as a co-spinning agent [

124]: its polarity, due to the regular presence of hydroxyl groups on the polymer backbone, makes it highly compatible with the chitosan structure. The preparation of Pd-CS/PVA composite nanofibers was performed by adding a Na

2PdCl

4 solution to an aqueous solution of chitosan, PVA and pyridine-2-carboxaldehyde, followed by electrospinning and thermal annealing. The covalent immobilization of pyridine-2-carboxaldehyde as imine ligands was selected by the authors in order to improve palladium dispersion into composite nanofibers and reduce its leaching from the support during its use as catalyst. Interestingly, a comparison in the XPS analysis of Pd-CS/PVA fibers before and after thermal annealing showed the reduction of divalent palladium(II) cations into palladium(0) species. The catalytic performance of Pd-CS/PVA composite nanofibers was evaluated in the Mizoroki–Heck reactions of aryl iodides and bromides with terminal alkenes (0.5 mol% of Pd, 3.0 equiv. of Et

3N, DMSO, 110 °C): in the case of iodides, the corresponding trans-disubstituted alkenes were obtained in 89–98% yields after 3–9 h (TON: 168–185; TOF: 19–62 h

−1); in the case of bromides, products were obtained in lower yields (23–33%) after 24 h (TON: 44–62; TOF: 2–3 h

−1) (

Scheme 47). Furthermore, compared to other similar palladium catalysts deposited on chitosan-based composite nanofibers, Pd-CS/PVA exhibited an exceptionally high recyclability (18 consecutive runs).

In 2020, Zhong described the first preparation of a palladium catalyst embedded in chitosan/poly(methacrylic acid) composite nanofibers: a homogeneous solution of chitosan, poly(methacrylic acid), pyridine-2-carboxaldehyde and Na

2PdCl