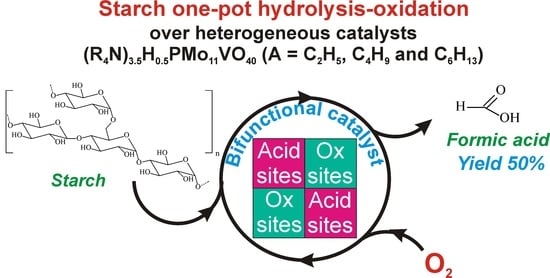

Formic Acid Production via One-Pot Hydrolysis-Oxidation of Starch over Quaternary Ammonium Salts of Vanadium-Containing Keggin-Type Heteropoly Acids

Abstract

:1. Introduction

2. Results and Discussion

2.1. Synthesis and Characterization of Acidic Quaternary Ammonium Salts of HPA

2.2. Catalytic Properties of Acidic Quaternary Ammonium Salts of HPA

2.2.1. Catalytic Properties of Et4N-PMoV

2.2.2. Activity of Solid HPA Catalysts

2.2.3. Investigation of Reaction Mechanism

2.3. Efficiency of Acidic Quaternary Ammonium Salts of HPA

2.3.1. Stability of Et4N-PMoV Catalyst

2.3.2. Efficiency of Acidic Quaternary Ammonium Salts of HPA

3. Materials and Methods

3.1. Synthesis of Acidic Quaternary Ammonium Salts of HPA

3.2. Characterization of Catalysts

3.3. Starch Characterization

3.4. Catalytic Tests

3.5. Reaction Mixture Analysis

3.6. Computation Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deng, W.; Zhang, Q.; Wang, Y. Catalytic transformations of cellulose and cellulose-derived carbohydrates into organic acids. Catal. Today 2014, 234, 31–41. [Google Scholar] [CrossRef]

- Li, J.; Ding, D.-J.; Deng, L.; Guo, Q.-X.; Fu, Y. Catalytic Air Oxidation of Biomass-Derived Carbohydrates to Formic Acid. ChemSusChem 2012, 5, 1313–1318. [Google Scholar] [CrossRef] [PubMed]

- Valentini, F.; Kozell, V.; Petrucci, C.; Marrocchi, A.; Gu, Y.; Gelman, D.; Vaccaro, L. Formic acid, a biomass-derived source of energy and hydrogen for biomass upgrading. Energy Environ. Sci. 2019, 12, 2646–2664. [Google Scholar] [CrossRef]

- Zhang, S.; Metin, Ö.; Su, D.; Sun, S. Monodisperse AgPd Alloy Nanoparticles and Their Superior Catalysis for the Dehydrogenation of Formic Acid. Angew. Chem. Int. Ed. 2013, 52, 3681–3684. [Google Scholar] [CrossRef]

- Deng, L.; Zhao, Y.; Li, J.; Fu, Y.; Liao, B.; Guo, Q.-X. Conversion of Levulinic Acid and Formic Acid into γ-Valerolactone over Heterogeneous Catalysts. ChemSusChem 2010, 3, 1172–1175. [Google Scholar] [CrossRef]

- Albert, J.; Jess, A.; Kern, C.; Pöhlmann, F.; Glowienka, K.; Wasserscheid, P. Formic Acid-Based Fischer–Tropsch Synthesis for Green Fuel Production from Wet Waste Biomass and Renewable Excess Energy. ACS Sustain. Chem. Eng. 2016, 4, 5078–5086. [Google Scholar] [CrossRef]

- Reichert, J.; Albert, J. Detailed Kinetic Investigations on the Selective Oxidation of Biomass to Formic Acid (OxFA Process) Using Model Substrates and Real Biomass. ACS Sustain. Chem. Eng. 2017, 5, 7383–7392. [Google Scholar] [CrossRef]

- Reichert, J.; Brunner, B.; Jess, A.; Wasserscheid, P.; Albert, J. Biomass oxidation to formic acid in aqueous media using polyoxometalate catalysts–boosting FA selectivity by in-situ extraction. Energy Environ. Sci. 2015, 8, 2985–2990. [Google Scholar] [CrossRef]

- Wölfel, R.; Taccardi, N.; Bösmann, A.; Wasserscheid, P. Selective catalytic conversion of biobased carbohydrates to formic acid using molecular oxygen. Green Chem. 2011, 13, 2759–2763. [Google Scholar] [CrossRef]

- Albert, J.; Wölfel, R.; Bösmann, A.; Wasserscheid, P. Selective oxidation of complex, water-insoluble biomass to formic acid using additives as reaction accelerators. Energy Environ. Sci. 2012, 5, 7956–7962. [Google Scholar] [CrossRef]

- Gromov, N.V.; Taran, O.P.; Delidovich, I.V.; Pestunov, A.V.; Rodikova, Y.A.; Yatsenko, D.A.; Zhizhina, E.G.; Parmon, V.N. Hydrolytic oxidation of cellulose to formic acid in the presence of Mo-V-P heteropoly acid catalysts. Catal. Today 2016, 278, 74–81. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, H.; Zhao, Y.; Yang, Z.; Yu, B.; Xu, H.; Liu, Z. Heteropolyanion-based ionic liquids catalysed conversion of cellulose into formic acid without any additives. Green Chem. 2014, 16, 4931–4935. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, M.; Liu, X.; Han, Y. Catalytic oxidative conversion of cellulosic biomass to formic acid and acetic acid with exceptionally high yields. Catal. Today 2014, 233, 77–82. [Google Scholar] [CrossRef]

- Gromov, N.V.; Medvedeva, T.B.; Rodikova, Y.A.; Pestunov, A.V.; Zhizhina, E.G.; Taran, O.P. The Production of Formic Acid from Polysaccharides and Biomass via One-pot Hydrolysis-Oxidation in the Presence of Mo-V-P Heteropoly Acid Catalyst. J. Sib. Fed. Univ. Chem. 2018, 11, 56–71. [Google Scholar] [CrossRef] [Green Version]

- Brégeault, J.-M. Transition-metal complexes for liquid-phase catalytic oxidation: Some aspects of industrial reactions and of emerging technologies. Dalton Trans. 2003, 3289–3302. [Google Scholar] [CrossRef]

- Rafiee, E.; Jafari, H. A practical and green approach towards synthesis of dihydropyrimidinones: Using heteropoly acids as efficient catalysts. Bioorg. Med. Chem. Lett. 2006, 16, 2463–2466. [Google Scholar] [CrossRef]

- Zhizhina, E.G.; Matveev, K.I.; Russkikh, V.V. Catalytic Synthesis of 1,4-Naphtho- and 9,10-Anthraquinones According to the Diene Synthesis Reaction for Pulp and Paper Industry. Chem. Sustain. Dev. 2004, 12, 47–51. [Google Scholar]

- Gromov, N.V.; Medvedeva, T.B.; Rodikova, Y.A.; Babushkin, D.E.; Panchenko, V.N.; Timofeeva, M.N.; Zhizhina, E.G.; Taran, O.P.; Parmon, V.N. One-pot synthesis of formic acid via hydrolysis–oxidation of potato starch in the presence of cesium salts of heteropoly acid catalysts. RSC Adv. 2020, 10, 28856–28864. [Google Scholar] [CrossRef]

- Tang, Z.; Deng, W.; Wang, Y.; Zhu, E.; Wan, X.; Zhang, Q.; Wang, Y. Transformation of Cellulose and its Derived Carbohydrates into Formic and Lactic Acids Catalyzed by Vanadyl Cations. ChemSusChem 2014, 7, 1557–1567. [Google Scholar] [CrossRef]

- Rocchiccioli-Deltcheff, C.; Fournier, M. Catalysis by polyoxometalates. Part 3—Influence of vanadium(V) on the thermal stability of 12-metallophosphoric acids from in situ infrared studies. J. Chem. Soc. Faraday Trans. 1991, 87, 3913–3920. [Google Scholar] [CrossRef]

- Fournier, M.; Thouvenot, R.; Rocchiccioli-Deltcheff, C. Catalysis by polyoxometalates. Part 1.—Supported polyoxoanions of the Keggin structure: Spectroscopic study (IR, Raman, UV) of solutions used for impregnation. J. Chem. Soc. Faraday Trans. 1991, 87, 349–356. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, L.; Zhang, S.; Yan, R.; Diao, Y. Effect of vanadyl species in Keggin-type heteropoly catalysts in selective oxidation of methacrolein to methacrylic acid. J. Catal. 2015, 329, 431–440. [Google Scholar] [CrossRef]

- Vilanculo, C.B.; da Silva, M.J.; Rodrigues, A.A.; Ferreira, S.O.; da Silva, R.C. Vanadium-doped sodium phosphomolybdate salts as catalysts in the terpene alcohols oxidation with hydrogen peroxide. RSC Adv. 2021, 11, 24072–24085. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, S.; Noh, J.S.; Schwarz, J.A. Determination of the point of zero charge of composite oxides. J. Catal. 1988, 114, 433–439. [Google Scholar] [CrossRef]

- Gromov, N.V.; Taran, O.P.; Aymonier, C.; Parmon, V.N. Kinetic modeling of the multistep hydrolysis-dehydration of cellulose to platform molecules over a solid carbon acid catalyst in pure water. React. Kinet. Mech. Catal. 2020, 130, 669–684. [Google Scholar] [CrossRef]

- Zhang, J.; Hou, B.; Wang, A.; Li, Z.; Wang, H.; Zhang, T. Kinetic study of retro-aldol condensation of glucose to glycolaldehyde with ammonium metatungstate as the catalyst. AIChE J. 2014, 60, 3804–3813. [Google Scholar] [CrossRef]

- Wang, W.; Niu, M.; Hou, Y.; Wu, W.; Liu, Z.; Liu, Q.; Ren, S.; Marsh, K.N. Catalytic conversion of biomass-derived carbohydrates to formic acid using molecular oxygen. Green Chem. 2014, 16, 2614–2618. [Google Scholar] [CrossRef]

- Odyakov, V.F.; Zhizhina, E.G. New Method for Synthesis of Water Solutions of Mo-V-P Heteropoly Acids. Russ. J. Inorg. Chem. 2009, 54, 409–414. [Google Scholar] [CrossRef]

- Semi-Products for Pulp and Paper Manufacture. Methods for Determination of Moisture Content. Available online: https://internet-law.ru/gosts/gost/45007 (accessed on 1 January 2021).

| Textural Properties | pHPZC | |||

|---|---|---|---|---|

| SBET (m2/g) | Vμ (cm3/g) | D (nm) | ||

| Et4N-PMoV | 2 | 0.001 | 13 | 3.5 |

| Bu4N-PMoV | 9 | 0.002 | 32 | 5.0 |

| Hex4N-PMoV | 8 | n.d. | n.d. | 5.2 |

| Bu4N-SiWV | 9 | 0.001 | 34 | 4.5 |

| № | Catalyst | T (°C) | Starch/Catalyst (wt./wt/) | TOF molFA/(mol[V]·h) | X (mol%) | Yield of Products in 7 h (mol%) | Maximum Product Yield b (mol%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gaseous | Water-Soluble c | Glucose | FA | |||||||||||

| CO2 | CO | FA | AA | Other | τ (h) | Ymax (%) | τ (h) | Ymax (%) | ||||||

| 1 | blank | 140 | - | - | - | - | - | 2 | 0 | 8 | 7 | 8 | 7 | 2 |

| 2 | Bu4N-SiWV | 140 | 1:1 | 1.0 | 84 | 37 | 2 | 30 | 9 | <6 | 3 | 25 | 7 | 30 |

| 3 | Bu4N-PMoV | 140 | 1:1 | 2.7 | 100 | 52 | 3 | 30 | 12 | <3 | 0.5 | 2 | 2 | 33 |

| 4 | Et4N-PMoV | 140 | 1:1 | 3.4 | 100 | 46 | 2 | 50 | 1 | <2 | 0.75 | 5 | 2 | 50 |

| 5 | Et4N-PMoV | 120 | 1:1 | 0.7 | 72 | 26 | 2 | 35 | 1 | <7 | 7 | 4 | 7 | 35 |

| 6 | Et4N-PMoV | 170 | 1:1 | 13.5 | 100 | 47 | 3 | 40 | 1 | 0 | 0 | 16 | 0.5 | 50 |

| 7 | Et4N-PMoV | 140 | 8:1 | 27.0 | 100 | 46 | 2 | 50 | 1 | <2 | 0.5 | 5 | 2 | 50 |

| 8 | Et4N-PMoV | 140 | 16:1 | 13.0 | 92 | 39 | 2 | 42 | 5 | <4 | 1 | 4 | 7 | 42 |

| 9 | Hex4N-PMoV | 140 | 1:1 | 0.6 | 85 | - | - | 24 | 3 | 12 | 5 | 13 | 7 | 24 |

| Constant | Interaction | k·103 (min−1) |

|---|---|---|

| k1 | Starch hydrolysis to glucose | 84 |

| k2 | Glucose isomerization to fructose | 46 |

| k21 | Fructose isomerization to glucose | 0.1 |

| k3 | Fructose retro-aldol cleavage to C3 intermediates | 114 |

| k4 | Dehydration of C3 intermediates to methylglyoxal (pyruvaldehyde) | 12.8 |

| k5 | Transformation of methylglyoxal to acetic and formic acids | 1.0 |

| k6 | Transformation of C3 intermediates to oxalic acid and formaldehyde | 42.8 |

| k7 | Degradation of C3 intermediates to glycolaldehyde and formic acid | 110 |

| k8 | Oxidation of glycolaldehyde to glycolic acid | 34 |

| k9 | Oxidation of glycolic acid to formic acid and CO2 | 13.1 |

| k10 | Degradation of formic acid to CO2 | ~0 |

| k11 | Oxidation of oxalic acid to CO2 | 7.8 |

| k12 | Transformation of glycolaldehyde to formic acid | 4.82 |

| k13 | Glucose retro-aldol [4+2] cleavage | 1 |

| № | Catalyst | T (°C) | P (MPa) | Time (h) | Starch/V Atom (mmolglucose unit/mmolV) | Starch/V Active Site (mol/mol) | FA Yield (%) | TOF molFA/(mol[V]·h) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Et4N-PMoV | 140 | 5 | 2 | 62/0.57 | 108/1 | 50 | 27.0 | This work |

| 2 | Bu4N-PMoV | 140 | 5 | 2 | 62/0.57 | 108/1 | 33 | 16.3 | This work |

| 3 | Bu4N-SiWV | 140 | 5 | 7 | 62/0.57 | 108/1 | 30 | 4.7 | This work |

| 4 | Co-PMoV2 | 150 | 5 | 1 | 62/20 | 3.1/1 | 50 | 1.5 | Gromov et al. [18] |

| 5 | Cs-PMoV | 150 | 5 | 2 | 62/0.5 | 124/1 | 51 | 32.0 | Gromov et al. [18] |

| 6 | VOSO4 | 140 | 5 | 1.5 | 1/0.1 | 10/1 | 46 | 3.1 | Tang et al. [19] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gromov, N.V.; Medvedeva, T.B.; Lukoyanov, I.A.; Panchenko, V.N.; Timofeeva, M.N.; Taran, O.P.; Parmon, V.N. Formic Acid Production via One-Pot Hydrolysis-Oxidation of Starch over Quaternary Ammonium Salts of Vanadium-Containing Keggin-Type Heteropoly Acids. Catalysts 2022, 12, 1252. https://doi.org/10.3390/catal12101252

Gromov NV, Medvedeva TB, Lukoyanov IA, Panchenko VN, Timofeeva MN, Taran OP, Parmon VN. Formic Acid Production via One-Pot Hydrolysis-Oxidation of Starch over Quaternary Ammonium Salts of Vanadium-Containing Keggin-Type Heteropoly Acids. Catalysts. 2022; 12(10):1252. https://doi.org/10.3390/catal12101252

Chicago/Turabian StyleGromov, Nikolay V., Tatiana B. Medvedeva, Ivan A. Lukoyanov, Valentina N. Panchenko, Maria N. Timofeeva, Oxana P. Taran, and Valentin N. Parmon. 2022. "Formic Acid Production via One-Pot Hydrolysis-Oxidation of Starch over Quaternary Ammonium Salts of Vanadium-Containing Keggin-Type Heteropoly Acids" Catalysts 12, no. 10: 1252. https://doi.org/10.3390/catal12101252