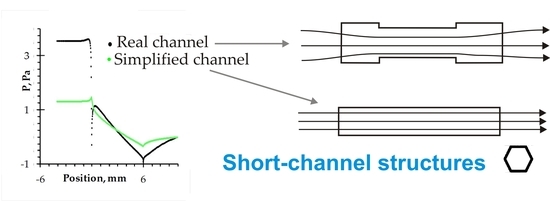

Momentum Transfer in Short-Channel Structures of Hexagonal Channel Cross-Section Shape: Experiments vs. CFD

Abstract

:1. Introduction

2. Theoretical Background

3. Results and Discussion

4. Materials and Methods

4.1. Experimental Set-Up

4.2. Numerical Method

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

List of Symbols

| K | according to [16] or [23] |

| L | sample thickness. m |

| Re | Reynolds number = u0∙Dh∙ρ∙μ−1 ε−1 |

| according to [24] | |

| Sv | specific surface area. m2∙m−3 |

| u0 | superficial fluid velocity. m∙s−1 |

| ΔP | pressure drop. Pa |

| ε | porosity |

| μ | dynamic viscosity, Pa∙s |

| ρ | density. kg∙m−3 |

| Ψ | according to [23] |

| Subscripts | |

| fd | fully developed |

| app | apparent |

References

- Loomis, D.; Grosse, Y.; Lauby-Secretan, B.; El Ghissassi, F.; Bouvard, V.; Benbrahim-Tallaa, L.; Guha, N.; Baan, R.; Mattock, H.; Straif, K. The carcinogenicity of outdoor air pollution. Lancet Oncol. 2013, 14, 1262–1263. [Google Scholar] [CrossRef]

- Hamra, G.B.; Guha, N.; Cohen, A.; Laden, F.; Raaschou-Nielsen, O.; Samet, J.M.; Vineis, P.; Forastiere, F.; Saldiva, P.; Yorifuji, T.; et al. Outdoor Particulate Matter Exposure and Lung Cancer: A Systematic Review and Meta-Analysis. Environ. Health Perspect. 2014, 122, 906–911. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dumesic, J.A.; Huber, G.W.; Boudart, M. Principles of Heterogeneous Catalysis. In Handbook of Heterogeneous Catalysis; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Pardiwala, J.; Patel, F.; Patel, S. Review paper on Catalytic Converter for Automotive Exhaust Emission. In Proceedings of the International Conference on Current Trends in Techology, Ahmedabad, India, 8–10 December 2011. [Google Scholar]

- Williams, J.L. Monolith structures, materials, properties and uses. Catal. Today 2001, 69, 3–9. [Google Scholar] [CrossRef]

- Kołodziej, A.; Łojewska, J. Short-channel structured reactor for catalytic combustion: Design and evaluation. Chem. Eng. Process. Process. Intensif. 2007, 46, 637–648. [Google Scholar] [CrossRef]

- Kołodziej, A.; Łojewska, J.; Ochońska, J.; Łojewski, T. Short-channel structured reactor: Experiments versus previous theoretical design. Chem. Eng. Process. Process. Intensif. 2011, 50, 869–876. [Google Scholar] [CrossRef]

- Shah, R.K.; London, A.L. Laminar Flow Forced Convection in Ducts; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Iwaniszyn, M.; Jodłowski, P.J.; Sindera, K.; Gancarczyk, A.; Korpyś, M.; Jędrzejczyk, R.J.; Kołodziej, A. Entrance effects on forced convective heat transfer in laminar flow through short hexagonal channels: Experimental and CFD study. Chem. Eng. J. 2021, 405, 126635. [Google Scholar] [CrossRef]

- Iwaniszyn, M.; Piątek, M.; Gancarczyk, A.; Jodlowski, P.; Łojewska, J.; Kołodziej, A. Flow resistance and heat transfer in short channels of metallic monoliths: Experiments versus CFD. Int. J. Heat Mass Transf. 2017, 109, 778–785. [Google Scholar] [CrossRef]

- Iwaniszyn, M.; Kryca, J.; Jodłowski, P.J.; Piątek, M.; Gancarczyk, A.; Łojewska, J.; Kołodziej, A. Novel intense metallic monolith for automotive applications: Experimental versus numerical studies. C. R. Chim. 2015, 18, 1030–1035. [Google Scholar] [CrossRef]

- Iwaniszyn, M.; Ochońska, J.; Gancarczyk, A.; Jodlowski, P.; Knapik, A.; Łojewska, J.; Janowska-Renkas, E.; Kołodziej, A. Short-Channel Structured Reactor as a Catalytic Afterburner. Top. Catal. 2013, 56, 273–278. [Google Scholar] [CrossRef] [Green Version]

- Iwaniszyn, M.; Ochońska, J.; Jodlowski, P.; Łojewska, J.; Kolodziej, A. Very short monoliths of triangular cross-sectional channel shape for fast catalytic reactions. Przem. Chem. 2012, 91, 1435–1438. [Google Scholar]

- Kolodziej, A.; Lojewska, J.; Iwaniszyn, M.; Jodlowski, P.; Ochonska, J.; Rogulska, A.; Gancarczyk, A.; Matuszek-Chmurowska, A. Mass transfer and flow resistance for sinusoidal short-channel catalytic internals. Przem. Chem. 2012, 91, 2074–2078. [Google Scholar]

- Shah, R. Laminar flow friction and forced convection heat transfer in ducts of arbitrary geometry. Int. J. Heat Mass Transf. 1975, 18, 849–862. [Google Scholar] [CrossRef]

- Asako, Y.; Nakamura, H.; Faghri, M. Developing laminar-flow and heat-transfer in the entrance region of regular polygonal ducts. Int. J. Heat Mass Transf. 1988, 31, 2590–2593. [Google Scholar]

- Turgut, O. Numerical investigation of laminar flow and heat transfer in hexagonal ducts under isothermal and constant heat flux boundary conditions. Iran. J. Sci. Technol. Trans. Mechan. Eng. 2014, 38, 45–56. [Google Scholar]

- Sadasivam, R.; Manglik, R.M.; Jog, M.A. Fully developed forced convection through trapezoidal and hexagonal ducts. Int. J. Heat Mass Transf. 1999, 42, 4321–4331. [Google Scholar] [CrossRef]

- Gu, S.; Lu, T.; Evans, A. On the design of two-dimensional cellular metals for combined heat dissipation and structural load capacity. Int. J. Heat Mass Transf. 2001, 44, 2163–2175. [Google Scholar] [CrossRef]

- Othman, M.Y.H.; Hussain, F.; Sopian, K.; Yatim, B.; Ruslan, H. Performance Study of Air-based Photovoltaic-thermal (PV/T) Collector with Different Designs of Heat Exchanger. Sains Malays. 2013, 42, 1319–1325. [Google Scholar]

- Cornejo, I.; Nikrityuk, P.; Hayes, R.E. The influence of channel geometry on the pressure drop in automotive catalytic converters: Model development and validation. Chem. Eng. Sci. 2020, 212, 115317. [Google Scholar] [CrossRef]

- Hawthorn, R.D. Afterburner Catalysis-Effects of Heat and Mass Transfer between Gas and Catalyst Surface. In Proceedings of the AIChE Symposium Series; American Institute of Chemical Engineers: New York, NY, USA, 1974; pp. 428–438. [Google Scholar]

- Yilmaz, T. General Equations for Pressure Drop for Laminar Flow in Ducts of Arbitrary Cross Sections. J. Energy Resour. Technol. 1990, 112, 220–223. [Google Scholar] [CrossRef]

- Muzychka, Y.S.; Yovanovich, M.M. Laminar Forced Convection Heat Transfer in the Combined Entry Region of Non-Circular Ducts. J. Heat Transf. 2004, 126, 54–61. [Google Scholar] [CrossRef] [Green Version]

| Ref. | Correlation | Notations |

|---|---|---|

| Hawthorn [22] | (f·Re)fd = 15.054 | |

| Asako et al. [16] | (f·Re)fd = 15.065 K = 1.324 | |

| Turgut [17] 1 | (f·Re)fd = 15.077 | |

| Yilmaz [23] | Ψ = 0.94 K = 1.426 | |

| Muzychka and Yovanovich [24] | Є = b/a = 0.885 |

| Model | No Elements | Pin, Pa | ey | |

|---|---|---|---|---|

| Simplified | 1 | 538,720 | 7.2572 | 22.3604788 |

| 2 | 621,600 | 5.9367 | 0.09610521 | |

| 3 | 704,480 | 5.931 | - | |

| Real | 1 | 1,168,090 | 21.926 | 0.19192104 |

| 2 | 1,432,270 | 21.887 | 0.01370865 | |

| 3 | 1,701,770 | 21.884 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sindera, K.; Iwaniszyn, M.; Jodłowski, P.J. Momentum Transfer in Short-Channel Structures of Hexagonal Channel Cross-Section Shape: Experiments vs. CFD. Catalysts 2021, 11, 1036. https://doi.org/10.3390/catal11091036

Sindera K, Iwaniszyn M, Jodłowski PJ. Momentum Transfer in Short-Channel Structures of Hexagonal Channel Cross-Section Shape: Experiments vs. CFD. Catalysts. 2021; 11(9):1036. https://doi.org/10.3390/catal11091036

Chicago/Turabian StyleSindera, Katarzyna, Marzena Iwaniszyn, and Przemysław J. Jodłowski. 2021. "Momentum Transfer in Short-Channel Structures of Hexagonal Channel Cross-Section Shape: Experiments vs. CFD" Catalysts 11, no. 9: 1036. https://doi.org/10.3390/catal11091036