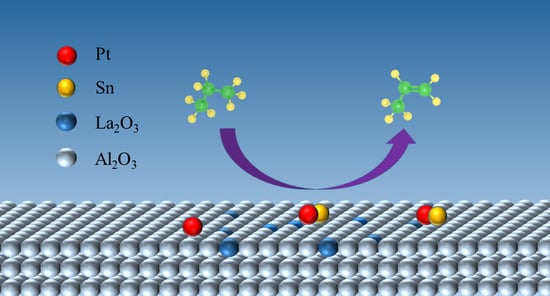

One-Step Fabrication of PtSn/γ-Al2O3 Catalysts with La Post-Modification for Propane Dehydrogenation

Abstract

:1. Introduction

2. Results

2.1. Crystalline Analysis

2.2. Textural Properties of Catalysts

2.3. The Evaluation of Reduction Behavior

2.4. Acidity Analysis

2.5. Propane Dehydrogenation Performance

2.6. The Evaluation of Carbon Deposition over the Spent Catalysts

3. Materials and Methods

3.1. Catalyst Preparation

3.2. Characterization

3.3. Activity Evaluation of Catalysts

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jang, E.J.; Lee, J.; Jeong, H.Y.; Kwak, J.H. Controlling the acid-base properties of alumina for stable PtSn-based propane dehydrogenation catalysts. Appl. Catal. A Gen. 2019, 572, 1–8. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Rong, J.; Liu, C.; Dai, Z.; Bao, J.; Da, Z.; Zheng, H. Defect-driven unique stability of Pt/carbon nanotubes for propane dehydrogenation. Appl. Surf. Sci. 2019, 464, 146–152. [Google Scholar] [CrossRef]

- Saerens, S.; Sabbe, M.K.; Galvita, V.V.; Redekop, E.A.; Reyniers, M.-F.; Marin, G.B. The Positive Role of Hydrogen on the Dehydrogenation of Propane on Pt(111). ACS Catal. 2017, 7, 7495–7508. [Google Scholar] [CrossRef]

- Li, Q.; Yang, G.; Wang, K.; Wang, X. Preparation of carbon-doped alumina beads and their application as the supports of Pt–Sn–K catalysts for the dehydrogenation of propane. React. Kinet. Mech. Catal. 2020, 129, 805–817. [Google Scholar] [CrossRef]

- Dai, Y.; Gu, J.; Tian, S.; Wu, Y.; Chen, J.; Li, F.; Du, Y.; Peng, L.; Ding, W.; Yang, Y. γ-Al2O3 sheet-stabilized isolate Co2+ for catalytic propane dehydrogenation. J. Catal. 2020, 381, 482–492. [Google Scholar] [CrossRef]

- Shan, Y.-L.; Wang, T.; Sui, Z.-J.; Zhu, Y.-A.; Zhou, X.-G. Hierarchical MgAl2O4 supported Pt-Sn as a highly thermostable catalyst for propane dehydrogenation. Catal. Commun. 2016, 84, 85–88. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Zhao, Z.-J.; Wu, T.; Zeng, L.; Gong, J. Nature of the Active Sites of VOx/Al2O3 Catalysts for Propane Dehydrogenation. ACS Catal. 2016, 6, 5207–5214. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, M.-L.; Yu, Y.; Zhu, Y.-A.; Sui, Z.-J.; Zhou, X.-G.; Holmen, A.; Chen, D. Size-Dependent Reaction Mechanism and Kinetics for Propane Dehydrogenation over Pt Catalysts. ACS Catal. 2015, 5, 6310–6319. [Google Scholar] [CrossRef]

- Jiang, F.; Zeng, L.; Li, S.; Liu, G.; Wang, S.; Gong, J. Propane Dehydrogenation over Pt/TiO2-Al2O3 Catalysts. ACS Catal. 2015, 5, 438–447. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Zhao, Z.; Fan, X.; Liu, J.; Wei, Y.; Duan, A.; Xie, Z.; Liu, Q. Size effect of TS-1 supports on the catalytic performance of PtSn/TS-1 catalysts for propane dehydrogenation. J. Catal. 2017, 352, 361–370. [Google Scholar] [CrossRef]

- Zangeneh, F.T.; Taeb, A.; Gholivand, K.; Sahebdelfar, S. The effect of mixed HCl–KCl competitive adsorbate on Pt adsorption and catalytic properties of Pt–Sn/Al2O3 catalysts in propane dehydrogenation. Appl. Surf. Sci. 2015, 357, 172–178. [Google Scholar] [CrossRef]

- Wang, H.-Z.; Zhang, W.; Jiang, J.-W.; Sui, Z.-J.; Zhu, Y.-A.; Ye, G.-H.; Chen, D.; Zhou, X.-G.; Yuan, W.-K. The role of H2S addition on Pt/Al2O3 catalyzed propane dehydrogenation: A mechanistic study. Catal. Sci. Technol. 2019, 9, 867–876. [Google Scholar] [CrossRef] [Green Version]

- Vu, B.K.; Song, M.B.; Ahn, I.Y.; Suh, Y.-W.; Suh, D.J.; Kim, J.S.; Shin, E.W. Location and structure of coke generated over Pt–Sn/Al2O3 in propane dehydrogenation. J. Ind. Eng. Chem. 2011, 17, 71–76. [Google Scholar] [CrossRef]

- Jung, J.-W.; Kim, W.-I.; Kim, J.-R.; Oh, K.; Koh, H.L. Effect of Direct Reduction Treatment on Pt–Sn/Al2O3 Catalyst for Propane Dehydrogenation. Catalysts 2019, 9, 446. [Google Scholar] [CrossRef] [Green Version]

- Shi, L.; Deng, G.-M.; Li, W.-C.; Miao, S.; Wang, Q.-N.; Zhang, W.-P.; Lu, A.-H. Al2O3 Nanosheets Rich in Pentacoordinate Al3+ Ions Stabilize Pt-Sn Clusters for Propane Dehydrogenation. Angew. Chem. Int. Ed. 2015, 54, 13994–13998. [Google Scholar] [CrossRef] [PubMed]

- Sattler, J.J.H.B.; Ruiz-Martinez, J.; Santillan-Jimenez, E.; Weckhuysen, B.M. Catalytic dehydrogenation of light alkanes on metals and metal oxides. Chem. Rev. 2014, 114, 10613–10653. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Sun, L.; Sui, Z.J.; Zhu, Y.; Ye, G.; Chen, D.; Zhou, X.; Yuan, W. Coke Formation on Pt–Sn/Al2O3 Catalyst for Propane Dehydrogenation. Ind. Eng. Chem. Res. 2018, 57, 8647–8654. [Google Scholar] [CrossRef]

- Wang, G.; Zhu, X.; Li, C. Recent Progress in Commercial and Novel Catalysts for Catalytic Dehydrogenation of Light Alkanes. Chem. Rec. 2020, 20, 604–616. [Google Scholar] [CrossRef]

- Fan, X.; Liu, D.; Sun, X.; Yu, X.; Li, D.; Yang, Y.; Liu, H.; Diao, J.; Xie, Z.; Kong, L.; et al. Mn-doping induced changes in Pt dispersion and PtxMny alloying extent on Pt/Mn-DMSN catalyst with enhanced propane dehydrogenation stability. J. Catal. 2020, 389, 450–460. [Google Scholar] [CrossRef]

- Cesar, L.G.; Yang, C.; Lu, Z.; Ren, Y.; Zhang, G.; Miller, J.T. Identification of a Pt3Co Surface Intermetallic Alloy in Pt–Co Propane Dehydrogenation Catalysts. ACS Catal. 2019, 9, 5231–5244. [Google Scholar] [CrossRef]

- Ren, G.-Q.; Pei, G.-X.; Ren, Y.-J.; Liu, K.-P.; Chen, Z.-Q.; Yang, J.-Y.; Su, Y.; Liu, X.-Y.; Li, W.-Z.; Zhang, T. Effect of group IB metals on the dehydrogenation of propane to propylene over anti-sintering Pt/MgAl2O4. J. Catal. 2018, 366, 115–126. [Google Scholar] [CrossRef]

- Kobayashi, S.; Kaneko, S.; Ohshima, M.-A.; Kurokawa, H.; Miura, H. Effect of iron oxide on isobutane dehydrogenation over Pt/Fe2O3-Al2O3 catalyst. Appl. Catal. A Gen. 2012, 417–418, 306–312. [Google Scholar] [CrossRef]

- Wang, T.; Jiang, F.; Liu, G.; Zeng, L.; Zhao, Z.-j.; Gong, J. Effects of Ga doping on Pt/CeO2-Al2O3 catalysts for propane dehydrogenation. AIChE J. 2016, 62, 4365–4376. [Google Scholar] [CrossRef]

- Rimaz, S.; Chen, L.; Kawi, S.; Borgna, A. Promoting effect of Ge on Pt-based catalysts for dehydrogenation of propane to propylene. Appl. Catal. A Gen. 2019, 588, 117266. [Google Scholar] [CrossRef]

- Nykänen, L.; Honkala, K. Selectivity in Propene Dehydrogenation on Pt and Pt3Sn Surfaces from First Principles. ACS Catal. 2013, 3, 3026–3030. [Google Scholar] [CrossRef]

- Wu, J.; Peng, Z.; Bell, A.T. Effects of composition and metal particle size on ethane dehydrogenation over PtxSn100−x/Mg(Al)O (70 ⩽ x ⩽ 100). J. Catal. 2014, 311, 161–168. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhou, Y.; Wan, L.; Xue, M.; Duan, Y.; Liu, X. Effect of magnesium addition on catalytic performance of PtSnK/γ-Al2O3 catalyst for isobutane dehydrogenation. Fuel Process. Technol. 2011, 92, 1632–1638. [Google Scholar] [CrossRef]

- Zhao, S.; Xu, B.; Yu, L.; Fan, Y. Catalytic dehydrogenation of propane to propylene over highly active PtSnNa/γ-Al2O3 catalyst. Chin. Chem. Lett. 2018, 29, 475–478. [Google Scholar] [CrossRef]

- Tasbihi, M.; Feyzi, F.; Amlashi, M.A.; Abdullah, A.Z.; Mohamed, A.R. Effect of the addition of potassium and lithium in Pt–Sn/Al2O3 catalysts for the dehydrogenation of isobutane. Fuel Process. Technol. 2007, 88, 883–889. [Google Scholar] [CrossRef]

- De Graaf, E.A.; Rothenberg, G.; Kooyman, P.J.; Andreini, A.; Bliek, A. Pt0.02Sn0.003Mg0.06 on γ-alumina: A stable catalyst for oxidative dehydrogenation of ethane. Appl. Catal. A Gen. 2005, 278, 187–194. [Google Scholar] [CrossRef]

- Naseri, M.; Tahriri Zangeneh, F.; Taeb, A. The effect of Ce, Zn and Co on Pt-based catalysts in propane dehydrogenation. React. Kinet. Mech. Catal. 2018, 126, 477–495. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.; Shi, J.; Zhou, S.; Zhang, Z.; Zhang, S.; Guo, M. Propane dehydrogenation over PtSnNa/La-doped Al2O3 catalyst: Effect of La content. Fuel Process. Technol. 2013, 111, 94–104. [Google Scholar] [CrossRef]

- Del Angel, G.; Bonilla, A.; Peña, Y.; Navarrete, J.; Fierro, J.L.G.; Acosta, D.R. Effect of lanthanum on the catalytic properties of PtSn/γ-Al2O3 bimetallic catalysts prepared by successive impregnation and controlled surface reaction. J. Catal. 2003, 219, 63–73. [Google Scholar] [CrossRef]

- Dong, A.-H.; Wang, K.; Zhu, S.-Z.; Yang, G.-B.; Wang, X.-T. Facile preparation of PtSn-La/Al2O3 catalyst with large pore size and its improved catalytic performance for isobutane dehydrogenation. Fuel Process. Technol. 2017, 158, 218–225. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.; Liu, H.; Wang, Y.; Xu, Y.; Wu, P. Effect of La addition on catalytic performance of PtSnNa/ZSM-5 catalyst for propane dehydrogenation. Appl. Catal. A Gen. 2007, 333, 202–210. [Google Scholar] [CrossRef]

- Vu, B.K.; Song, M.B.; Ahn, I.Y.; Suh, Y.-W.; Suh, D.J.; Kim, W.-I.; Koh, H.-L.; Choi, Y.G.; Shin, E.W. Propane dehydrogenation over Pt–Sn/Rare-earth-doped Al2O3: Influence of La, Ce, or Y on the formation and stability of Pt–Sn alloys. Catal. Today 2011, 164, 214–220. [Google Scholar] [CrossRef]

- Li, Q.; Sui, Z.; Zhou, X.; Zhu, Y.; Zhou, J.; Chen, D. Coke Formation on Pt–Sn/Al2O3 Catalyst in Propane Dehydrogenation: Coke Characterization and Kinetic Study. Top. Catal. 2011, 54, 888–896. [Google Scholar] [CrossRef]

- Natarajan, P.; Khan, H.A.; Yoon, S.; Jung, K.-D. One-pot synthesis of Pt–Sn bimetallic mesoporous alumina catalysts with worm-like pore structure for n-butane dehydrogenation. J. Ind. Eng. Chem. 2018, 63, 380–390. [Google Scholar] [CrossRef]

| Sample | SBET (m2/g) | Vp (cm3/g) | Dave (nm) | Loadings (wt.%) | ||

|---|---|---|---|---|---|---|

| Pt | Sn | La | ||||

| PtSn/γ-Al2O3 | 229 | 0.553 | 9.32 | 0.6 | 0.1 | - |

| PtSn-La1.2 | 208 | 0.542 | 9.17 | 0.6 | 0.1 | 1.2 |

| PtSn-La2.2 | 215 | 0.545 | 9.25 | 0.6 | 0.1 | 2.2 |

| PtSn-La3.2 | 199 | 0.512 | 9.11 | 0.6 | 0.1 | 3.2 |

| Catalysts | T/°C | X1 1 | X2 2 | Reaction Time | Selectivity | References |

|---|---|---|---|---|---|---|

| PtSn-La2.2 | 600 | 47.8 | 34.3 | 800 min | 84.6 | This work |

| PtSnNa/1.0La-Al | 590 | 41.1 | 35.9 | 360 min | 96.2 | [32] |

| PtSnNaLa(1.4%)/ZSM-5 | 590 | ~41.6 | 37.2 | 300 min | ~97.5 | [35] |

| Pt–Sn/La(10%)-Al | 600 | ~52 | ~25 | 180 min | ~97 | [36] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Lu, K.; Yin, C.; Meng, F.; Zhang, Q.; Yan, X.; Bing, L.; Wang, F.; Han, D. One-Step Fabrication of PtSn/γ-Al2O3 Catalysts with La Post-Modification for Propane Dehydrogenation. Catalysts 2020, 10, 1042. https://doi.org/10.3390/catal10091042

Wang G, Lu K, Yin C, Meng F, Zhang Q, Yan X, Bing L, Wang F, Han D. One-Step Fabrication of PtSn/γ-Al2O3 Catalysts with La Post-Modification for Propane Dehydrogenation. Catalysts. 2020; 10(9):1042. https://doi.org/10.3390/catal10091042

Chicago/Turabian StyleWang, Guangjian, Kai Lu, Chaoqun Yin, Fanfei Meng, Qinqin Zhang, Xinlong Yan, Liancheng Bing, Fang Wang, and Dezhi Han. 2020. "One-Step Fabrication of PtSn/γ-Al2O3 Catalysts with La Post-Modification for Propane Dehydrogenation" Catalysts 10, no. 9: 1042. https://doi.org/10.3390/catal10091042