Solution Combustion Synthesis of Fe2O3-Based Catalyst for Ammonia Synthesis

Abstract

:1. Introduction

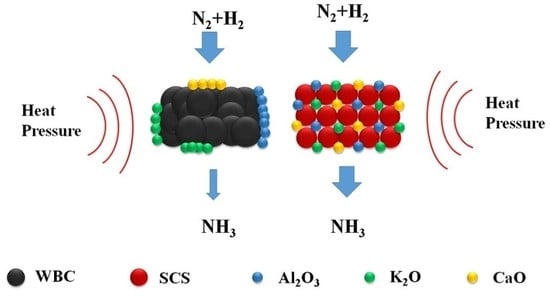

2. Results and Discussion

2.1. Morphology and Phase Structure of Catalysts

2.2. Textural and Microstructural Properties of Catalysts

2.3. TEM Results

2.4. XPS Results

2.5. Catalytic Activity of Catalysts for Ammonia Synthesis

3. Materials and Methods

3.1. Catalysts Preparation

3.2. Catalysts Characterization

3.3. Catalytic Activity Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Liu, H.H. Recent advances in research of catalysts for ammonia synthesis. Chin. J. Catal. 2001, 22, 304–316. [Google Scholar]

- Pernicone, N.; Ferrero, E.; Rossetti, I.; Forni, L.; Canton, P.; Riello, P.; Fagherazzi, G.; Signoretto, M.; Pinna, F. Wustite as a new precursor of industrial ammonia synthesis catalysts. Appl. Catal. A Gen. 2003, 251, 121–129. [Google Scholar] [CrossRef]

- Liu, H.Z. Ammonia synthesis catalyst 100 years: Practice, enlightenment and challenge. Chin. J. Catal. 2014, 35, 1619–1640. [Google Scholar] [CrossRef]

- Liu, H.Z.; Li, X.N.; Hu, Z.N. Development of novel low temperature and low pressure ammonia synthesis catalyst. Appl. Catal. A Gen. 1996, 142, 209–222. [Google Scholar] [CrossRef]

- Han, W.F.; Huang, S.L.; Cheng, T.H.; Tang, H.D.; Li, Y.; Liu, H.Z. Promotion of Nb2O5 on the wustite-based iron catalyst for ammonia synthesis. Appl. Surf. Sci. 2015, 353, 17–23. [Google Scholar] [CrossRef]

- Patil, K.C.; Aruna, S.T.; Mimani, T. Combustion synthesis: An update. Curr. Opin. Solid State Mater. Sci. 2002, 6, 507–512. [Google Scholar] [CrossRef]

- Dinesha, M.L.; Jayanna, H.S.; Mohanty, S.; Ravi, S. Structural, electrical and magnetic properties of Co and Fe co-doped ZnO nanoparticles prepared by solution combustion method. J. Alloys Compd. 2010, 490, 618–623. [Google Scholar] [CrossRef]

- Jin, Y.; Qin, W.P.; Zhang, J.S.; Zhang, M.M.; Wang, Y.; Cao, C.Y. Synthesis of Gd3PO7: Eu3+ nanospheres via a facile combustion method and optical properties. J. Solid State Chem. 2008, 181, 724–729. [Google Scholar] [CrossRef]

- Lou, X.M.; Chen, D.H. Synthesis of CaWO4: Eu3+ phosphor powders via a combustion process and its optical properties. Mater. Lett. 2008, 62, 1681–1684. [Google Scholar] [CrossRef]

- Qiu, Z.F.; Zhou, Y.Y.; Lu, M.K.; Zhang, A.Y.; Ma, Q. Combustion synthesis of three-dimensional reticular-structured luminescence SrAl2O4: Eu, Dy nanocrystals. Solid State Sci. 2008, 10, 629–633. [Google Scholar] [CrossRef]

- Wang, H.; Han, W.; Li, X.; Liu, B.; Tang, H.; Li, Y. Solution Combustion Synthesis of Cr2O3 Nanoparticles and the Catalytic Performance for Dehydrofluorination of 1,1,1,3,3-Pentafluoropropane to 1,3,3,3-Tetrafluoropropene. Molecules 2019, 24, 361. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, Y.F.; Liu, H.Z.; Li, X.N. In situ X-ray Diffraction Investigation on Reduction Process of Ammonia-synthesis Fused-iron Catalysts and the Formation Mechanism of Its Active Phase. Chem. J. Chin. Univ. 2009, 30, 1177–1182. [Google Scholar]

- Gu, B.; Ordomsky, V.V.; Bahri, M.; Ersen, O.; Chemayskii, P.A.; Filimonov, D.; Khodakov, A.Y. Effects of the promotion with bismuth and lead on direct synthesis of light olefins from syngas over carbon nanotube supported iron catalysts. Appl. Catal. B Environ. 2018, 234, 153–166. [Google Scholar] [CrossRef]

- Li, J.B.; Ma, H.F.; Zhang, H.T.; Sun, Q.W.; Ying, W.Y.; Fang, D.Y. Direct production of light olefins from syngas over potassium modified Fe-Mn catalyst. React. Kinet. Mech. Catal. 2014, 112, 409–423. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Pal, S.; Roy, S.K.; Pal, S.K.; Basu, D. Modelling of flame temperature of solution combustion synthesis of nanocrystalline calcium hydroxyapatite material and its parametric optimization. Bull. Mater. Sci. 2010, 33, 339–350. [Google Scholar] [CrossRef]

- Han, W.F.; Wang, Z.K.; Li, X.J.; Tang, H.D.; Xi, M.; Li, Y.; Liu, H.Z. Solution combustion synthesis of nano-chromia as catalyst for the dehydrofluorination of 1,1-difluoroethane. J. Mater. Sci. 2016, 51, 11002–11013. [Google Scholar] [CrossRef]

- Gonzalez-Cortes, S.L.; Imbert, F.E. Fundamentals, properties and applications of solid catalysts prepared by solution combustion synthesis (SCS). Appl. Catal. A Gen. 2013, 452, 117–131. [Google Scholar] [CrossRef]

- Han, W.F.; Liu, B.; Li, X.L.; Yang, L.T.; Wang, J.C.; Tang, H.D.; Liu, W.C. Combustion Synthesis of Amorphous Al and Cr Composite as the Catalyst for Dehydrofluorination of 1,1-Difluoroethane. Ind. Eng. Chem. Res. 2018, 57, 12774–12783. [Google Scholar] [CrossRef]

- Tsuji, Y.; Kitano, M.; Kishida, K.; Sasase, M.; Yokoyama, T.; Hara, M.; Hosono, H. Ammonia synthesis over Co-Mo alloy nanoparticle catalyst prepared via sodium naphthalenide-driven reduction. Chem. Commun. 2016, 52, 14369–14372. [Google Scholar] [CrossRef]

- Gupta, M.; Gupta, R.P. Anomalous surface segregation behaviour of some 3d elements in ferromagnetic iron. J. Phys. Condens. Matter 2013, 25, 8. [Google Scholar] [CrossRef]

- Jafari, A.; Ebadi, A.; Sahebdelfar, S. Effect of iron oxide precursor on the properties and ammonia synthesis activity of fused iron catalysts. React. Kinet. Mech. Catal. 2019, 126, 307–325. [Google Scholar] [CrossRef]

- Lendzion-Bielun, Z.; Jedrzejewski, R. Determination of the content of promoters in magnetite and wustite phases in the fused iron catalyst. Pol. J. Chem. Technol. 2013, 15, 27–29. [Google Scholar] [CrossRef] [Green Version]

- Jedrzejewski, R.; Lendzion-Bielun, Z. Reduction Process of Iron Catalyst Precursors for Ammonia Synthesis Doped with Lithium Oxide. Catalysts 2018, 8, 494. [Google Scholar] [CrossRef] [Green Version]

- Pu, Z.Y.; Zheng, Y.F.; Liu, H.Z.; Li, X.N. Influence of promoter and Fe2+/Fe3+ ratio on microstructure of fused iron catalysts for ammonia synthesis. Indian J. Chem. Sect. A Inorg. Bio-Inorg. Phys. Theor. Anal. Chem. 2011, 50, 156–162. [Google Scholar]

- Powell, C.J. Recommended Auger parameters for 42 elemental solids. J. Electron. Spectrosc. Relat. Phenom. 2012, 185, 1–3. [Google Scholar] [CrossRef]

- Ouyang, M.; Hiraoka, H. Structure and magnetic properties of iron oxide films deposited by excimer laser ablation of a metal-containing polymer. Mater. Res. Bull. 1997, 32, 1099–1107. [Google Scholar] [CrossRef]

- Wu, H.B.; Desai, S.R.; Wang, L.S. Observation and photoelectron spectroscopic study of novel mono- and diiron oxide molecules: FeOy− (y = 1–4) and Fe2Oy− (y = 1–5). J. Am. Chem. Soc. 1996, 118, 5296–5301. [Google Scholar] [CrossRef]

- Hara, M.; Kitano, M.; Hosono, H. Ru-Loaded C12A7:e(-) Electride as a Catalyst for Ammonia Synthesis. ACS Catal. 2017, 7, 2313–2324. [Google Scholar] [CrossRef]

- Kozuch, S.; Shaik, S. Kinetic-quantum chemical model for catalytic cycles: The Haber-Bosch process and the effect of reagent concentration. J. Phys. Chem. A 2008, 112, 6032–6041. [Google Scholar] [CrossRef]

- Spencer, M.S. On the rate-determining step and the role of potassium in the catalytic synthesis of ammonia. Catal. Lett. 1992, 13, 45–54. [Google Scholar] [CrossRef]

- Inoue, Y.; Kitano, M.; Kishida, K.; Abe, H.; Niwa, Y.; Sasase, M.; Fujita, Y.; Ishikawa, H.; Yokoyama, T.; Hara, M.; et al. Efficient and Stable Ammonia Synthesis by Self-Organized Flat Ru Nanoparticles on Calcium Amide. ACS Catal. 2016, 6, 7577–7584. [Google Scholar] [CrossRef]

- Kitano, M.; Inoue, Y.; Yamazaki, Y.; Hayashi, F.; Kanbara, S.; Matsuishi, S.; Yokoyama, T.; Kim, S.W.; Hara, M.; Hosono, H. Ammonia synthesis using a stable electride as an electron donor and reversible hydrogen store. Nat. Chem. 2012, 4, 934–940. [Google Scholar] [CrossRef] [PubMed]

- Kitano, M.; Kanbara, S.; Inoue, Y.; Kuganathan, N.; Sushko, P.V.; Yokoyama, T.; Hara, M.; Hosono, H. Electride support boosts nitrogen dissociation over ruthenium catalyst and shifts the bottleneck in ammonia synthesis. Nat. Commun. 2015, 6, 9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, H.Z.; Liu, C.B.; Li, X.N.; Cen, Y.Q. Effect of an iron oxide precursor on the H2 desorption performance for an ammonia synthesis catalyst. Ind. Eng. Chem. Res. 2003, 42, 1347–1349. [Google Scholar] [CrossRef]

- Zheng, Y.-F.; Liu, H.-Z.; Liu, Z.-J.; Li, X.-N. In situ X-ray diffraction study of reduction processes of Fe3O4− and Fe1−xO-based ammonia-synthesis catalysts. J. Solid State Chem. 2009, 182, 2385–2391. [Google Scholar] [CrossRef]

| Catalyst | Crystal Size /nm | |||||

|---|---|---|---|---|---|---|

| D100(FeO) | D110(FeO) | D110(γ-Fe2O3) | D311(γ-Fe2O3) | D104(α-Fe2O3) | D110(α-Fe2O3) | |

| WBC | 28.0 | 25.7 | -- | -- | -- | -- |

| SCS1.7 | -- | -- | 13.9 | 18.4 | -- | -- |

| SCS5 | -- | -- | -- | -- | 18.6 | 14.0 |

| SCS8.3 | -- | -- | -- | -- | 16.2 | 15.8 |

| Catalyst | Crystal Size /nm | Ratios | |||||

|---|---|---|---|---|---|---|---|

| D110 | D200 | D211 | D220 | D310 | D222 | D211/ D110 | |

| WBC | 22.7 | 15.2 | 37.2 | 55.5 | 45.6 | 39.5 | 1.64 |

| SCS1.7 | 33.7 | 27.2 | 28.3 | 32.0 | 29.0 | 40.9 | 0.84 |

| SCS5 | 14.6 | 20.4 | 19.8 | 23.1 | 17.9 | 14.2 | 1.36 |

| Catalysts (Reduced) | SBET (m2.g−1) | Vpore (ccg−1) | PD (nm) |

|---|---|---|---|

| WBC | 4.9 | 0.05 | 30.7 |

| SCS1.7 | 16.2 | 0.10 | 17.3 |

| SCS5 | 16.4 | 0.02 | 59.2 |

| SCS8.3 | 21.9 | 0.02 | 59.7 |

| Catalysts | Fe2p a | Fes/Fe b | |

|---|---|---|---|

| Fe | Fes | ||

| WBC | 13,025 (706.8 eV, 720.2 eV) | 4537 (714.5 eV, 727.7 eV) | 0.35 |

| SCS5 | 6328 (706.2 eV, 719.9 eV) | 2445 (714.5 eV, 727.7 eV) | 0.39 |

| Samples | Weight /g | Activity of Catalyst for Ammonia Synthesis (15 MP, 30,000 h−1) | |||||

|---|---|---|---|---|---|---|---|

| 450 °C | 425 °C | 400 °C | |||||

| vol.% | mmol/g·h | vol.% | mmol/g·h | vol.% | mmol/g·h | ||

| SCS1.7 | 2.27 | 12.26 | 130.30 | 11.24 | 116.93 | 9.22 | 97.69 |

| SCS5 | 2.11 | 12.36 | 126.66 | 11.22 | 129.49 | 9.17 | 109.26 |

| SCS8.3 | 1.94 | 12.36 | 138.52 | 11.48 | 138.95 | 9.44 | 119.21 |

| WBC | 6.06 | 18.60 | 69.32 | 18.82 | 70.01 | 17.35 | 65.35 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, B.; Liu, H.; Han, W. Solution Combustion Synthesis of Fe2O3-Based Catalyst for Ammonia Synthesis. Catalysts 2020, 10, 1027. https://doi.org/10.3390/catal10091027

Cai B, Liu H, Han W. Solution Combustion Synthesis of Fe2O3-Based Catalyst for Ammonia Synthesis. Catalysts. 2020; 10(9):1027. https://doi.org/10.3390/catal10091027

Chicago/Turabian StyleCai, Binxiang, Huazhang Liu, and Wenfeng Han. 2020. "Solution Combustion Synthesis of Fe2O3-Based Catalyst for Ammonia Synthesis" Catalysts 10, no. 9: 1027. https://doi.org/10.3390/catal10091027