Effects of Grinding Parameters on the Processing Temperature, Crack Propagation and Residual Stress in Silicon Nitride Ceramics

Abstract

:1. Introduction

2. Materials and Methods

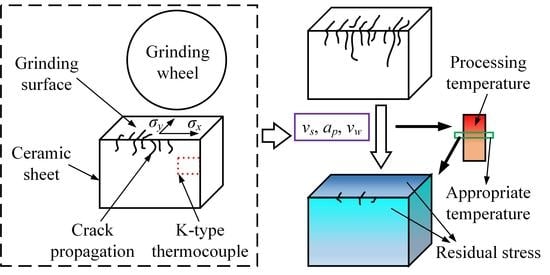

2.1. Experiment for Crack Propagation Analysis

2.2. Experimental Equipment for Residual Stress Analysis

3. Results and Analysis

3.1. Influence of Grinding Parameters on Crack Propagation

3.2. Influence of Grinding Parameters on Residual Stress

3.3. Influence of Grinding Parameters on Grinding Temperature

3.4. Influence of Grinding Temperature on Crack Propagation

4. Discussion

5. Conclusions

- (1)

- Increasing the wheel speed, reducing the grinding depth, and lowering the feed rate are beneficial to decreasing the depth of longitudinal crack propagation in the subsurface of silicon nitride ceramics. After grinding, the cracks in the subsurface of the silicon nitride ceramic workpiece are mainly longitudinal cracks, which gradually extend to the interior of the ceramics in multiple directions, resulting in subsurface damage.

- (2)

- The residual compressive stress on the surface of silicon nitride ceramics increases with the increase in the wheel speed and the decrease in the grinding depth and feed rate. The value of residual compressive stress parallel to the grinding direction is greater than that perpendicular to the grinding direction.

- (3)

- With the increase in the wheel speed and grinding depth and with the decrease in the feed rate, the grinding temperature has a tendency to increase. When the grinding temperature rises from 300 to 1100 °C, the surface residual compressive stress increases first and then decreases, and the crack propagation depth decreases first and then increases. At the temperature of about 600 °C, the surface residual compressive stress has a maximum value, and the crack propagation depth is the smallest. The proper grinding temperature can increase the surface residual compressive stress and inhibit the crack propagation of silicon nitride ceramics.

- (4)

- The residual compressive stress on the ground surface of silicon nitride ceramics decreases with the increase in the crack propagation depth and surface brittle peeling degree. The residual stress at the location of crack propagation is residual tensile stress. It increases with the increase in the crack propagation depth. In addition, the distribution of residual stress alternates between compressive and tensile along the distance into surface, and this is eliminated at a certain depth.

- (5)

- The surface quality of silicon nitride ceramics in grinding can be improved by adjusting the grinding parameters and controlling for an appropriate grinding temperature. The results can provide a useful reference to obtain high-quality machined surface in grinding of silicon nitride ceramics.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, S.J.; Kim, J.D.; Suh, J. Microstructural variations and machining characteristics of silicon nitride ceramics from increasing the temperature in laser assisted machining. Int. J. Precis. Eng. Manuf. 2014, 15, 1269–1274. [Google Scholar] [CrossRef]

- Yan, H.P.; Wu, Y.H.; Sun, J.; Wang, H.; Zhang, L.X. Acoustic model of ceramic angular contact ball bearing based on multi-sound source method. Nonlinear Dyn. 2020, 99, 1155–1177. [Google Scholar] [CrossRef]

- Wu, Y.H.; Yan, H.P.; Li, S.H.; Zhang, K.; Zhang, L.X. Calculation on the radiation noise of ceramic ball bearings based on dynamic model considering nonlinear contact stiffness and damping. J. Sound Vib. 2020, 479, 115374. [Google Scholar] [CrossRef]

- Chen, F.; Yan, K.; Zhu, Y.S.; Hong, J. The modeling and mechanical properties prediction of whisker-reinforced ceramic composites. Ceram. Int. 2022, 48, 28774–28780. [Google Scholar] [CrossRef]

- Choudhary, A.; Paul, S. Surface generation in high-speed grinding of brittle and tough ceramics. Ceram. Int. 2021, 47, 30546–30562. [Google Scholar] [CrossRef]

- Yan, H.P.; Deng, F.; Niu, H.L.; Zhu, J.D.; Hu, B.B. Effect of grinding parameters on surface quality in internal grinding of silicon nitride ceramics. J. Braz. Soc. Mech. Sci. 2021, 43, 353. [Google Scholar] [CrossRef]

- Inasaki, I. Grinding of hard and brittle materials. CIRP Ann. 1987, 36, 463–471. [Google Scholar] [CrossRef]

- Shamray, S.; Azarhoushang, B.; Paknejad, M.; Buechler, A. Ductile-brittle transition mechanisms in micro-grinding of silicon nitride. Ceram. Int. 2022, 48, 34987–34998. [Google Scholar]

- Wan, L.L.; Liu, Z.J.; Deng, Z.H.; Li, L.; Liu, W. Simulation and experimental research on subsurface damage of silicon nitride grinding. Ceram. Int. 2018, 44, 8290–8296. [Google Scholar]

- Chai, J.L.; Zhu, Y.B.; Gao, X.; Shen, T.L.; Niu, L.J.; Li, S.F.; Jin, P.; Cui, M.H.; Wang, Z.G. Effects of residual stress and intragranular particles on mechanical properties of hot-pressed Al2O3/SiC ceramic composites. Ceram. Int. 2022, 48, 23258–23265. [Google Scholar] [CrossRef]

- Stadelmann, R.; Lugovy, M.; Orlovskaya, N.; Mchaffey, P.; Radovic, M.; Sglavo, V.M.; Grasso, S.; Reece, M.J. Mechanical properties and residual stresses in ZrB2–SiC spark plasma sintered ceramic composites. J. Eur. Ceram. Soc. 2016, 36, 1527–1537. [Google Scholar] [CrossRef] [Green Version]

- Fabris, D.C.N.; Miguel, E.H.; Vargas, R.; Canto, R.B.; Villas-Boas, M.D.O.C.; Peitl, O.; Sglavo, V.M.; Zanotto, E.D. Microstructure, residual stresses, and mechanical performance of surface crystallized translucent glass-ceramics. J. Eur. Ceram. Soc. 2022, 42, 4631–4642. [Google Scholar] [CrossRef]

- Dai, J.B.; Su, H.H.; Wang, Z.B.; Xu, J.H.; Fu, Y.C.; Chen, J.J. Damage formation mechanisms of sintered silicon carbide during single-diamond grinding. Ceram. Int. 2021, 47, 28419–28428. [Google Scholar] [CrossRef]

- Wang, H.; Dong, Z.G.; Yuan, S.; Guo, X.G.; Kang, R.K.; Bao, Y. Effects of tool geometry on tungsten removal behavior during nano-cutting. Int. J. Mech. Sci. 2022, 225, 107384. [Google Scholar] [CrossRef]

- Wang, H.; Guo, X.G.; Dong, Z.G.; Yuan, S.; Bao, Y.; Kang, R.K. Effects of cutting force on formation of subsurface damage during nano-cutting of single-crystal tungsten. J. Manuf. Sci. Eng. 2022, 144, 111008. [Google Scholar] [CrossRef]

- Du, C.Z.; Zhang, G.F.; Wang, H.J. Surface quality and residual stress variation of ceramics after abrasive grinding under pre-compressive stress. Ceram. Int. 2021, 47, 4315–4320. [Google Scholar] [CrossRef]

- Sun, J.; Wu, Y.H.; Zhou, P.; Li, S.H.; Zhang, L.X.; Zhang, K. The effect of grinding parameters on grinding performance and cracks extending mechanism of Si3N4 ceramic based on diamond grains. Rev. Rom. Mater. 2018, 48, 198–203. [Google Scholar]

- Denkena, B.; Krödel, A.; Wippermann, A.; Wolters, P. Grinding of transformation-toughened mixed oxide ceramic. Int. J. Adv. Manuf. Technol. 2020, 109, 1463–1478. [Google Scholar] [CrossRef]

- Ma, Z.L.; Wang, Z.; Wang, X.Z.; Yu, T.B. Effects of laser-assisted grinding on surface integrity of zirconia ceramic. Ceram. Int. 2020, 46, 921–929. [Google Scholar] [CrossRef]

- Ma, Z.L.; Wang, Q.H.; Chen, H.; Chen, L.Y.; Qu, S.; Wang, Z.X.; Yu, T.B. A grinding force predictive model and experimental validation for the laser-assisted grinding (LAG) process of zirconia ceramic. J. Mater. Process. Technol. 2022, 302, 117492. [Google Scholar] [CrossRef]

- Fergani, O.; Shao, Y.M.; Lazoglu, I.; Liang, S.Y. Temperature effects on grinding residual stress. Procedia CIRP 2014, 14, 2–6. [Google Scholar] [CrossRef] [Green Version]

- Wan, L.L.; Li, L.; Deng, Z.H.; Deng, Z.H.; Liu, W. Thermal-mechanical coupling simulation and experimental research on the grinding of zirconia ceramics. J. Manuf. Process. 2019, 47, 41–51. [Google Scholar] [CrossRef]

- Wu, Y.H.; Yan, H.P.; Sun, J.; Zhang, Z.G. Machining Technology and Noise Characteristics of Full Ceramic Ball Bearings, 1st ed.; Science Press: Beijing, China, 2022. [Google Scholar]

- Azarhoushang, B.; Soltani, B.; Zahedi, A. Laser-assisted grinding of silicon nitride by picosecond laser. Int. J. Adv. Manuf. Technol. 2017, 93, 2517–2529. [Google Scholar]

- Zhang, X.H.; Zhang, Z.C.; Deng, Z.H.; Li, S.; Wu, Q.P.; Kang, Z.X. Precision grinding of silicon nitride ceramic with laser macro-structured diamond wheels. Opt. Laser Technol. 2019, 109, 418–428. [Google Scholar] [CrossRef]

- Ma, Z.L.; Wang, Q.H.; Chen, H.; Chen, L.Y.; Meng, F.W.; Chen, X.; Qu, S.; Wang, Z.X.; Yu, T.B. Surface prediction in laser-assisted grinding process considering temperature-dependent mechanical properties of zirconia ceramic. J. Manuf. Process. 2022, 80, 491–503. [Google Scholar] [CrossRef]

- Baraheni, M.; Amini, S. Predicting subsurface damage in silicon nitride ceramics subjected to rotary ultrasonic assisted face grinding. Ceram. Int. 2019, 45, 10086–10096. [Google Scholar] [CrossRef]

- Romaniv, O.M.; Vasyliv, B.D. Some features of formation of the structural strength of ceramic materials. Mater. Sci. 1998, 34, 149–161. [Google Scholar] [CrossRef]

- Kar, S.; Kumar, S.; Bandyopadhyay, P.P.; Paul, S. Grinding of hard and brittle ceramic coatings: Force analysis. J. Eur. Ceram. Soc. 2020, 40, 1453–1461. [Google Scholar]

- Liu, Y.; Xu, J.Y.; Zhou, K.; Li, S.C.; Huang, Y.; Xiao, G.J. Numerical and experimental investigation on temperature field during belt grinding considering elastic contact. Case Stud. Therm. Eng. 2022, 40, 102555. [Google Scholar]

- Liu, W.; Deng, Z.H.; Shang, Y.Y.; Wan, L.L. Effects of grinding parameters on surface quality in silicon nitride grinding. Ceram. Int. 2017, 43, 1571–1577. [Google Scholar] [CrossRef]

- Deng, X.S.; Zhang, F.L.; Liao, Y.L.; Bai, F.H.; Li, K.J.; Zhou, Y.M.; Wu, S.H.; Wang, C.Y. Effect of grinding parameters on surface integrity and flexural strength of 3Y-TZP ceramic. J. Eur. Ceram. Soc. 2022, 42, 1635–1644. [Google Scholar] [CrossRef]

- Deja, M.; List, M.; Lichtschlag, L.; Uhlmann, E. Thermal and technological aspects of double face grinding of Al2O3 ceramic materials. Ceram. Int. 2019, 45, 19489–19495. [Google Scholar] [CrossRef]

- Li, P.; Chen, S.Y.; Xiao, H.; Chen, Z.Q.; Qu, M.N.; Dai, H.F.; Jin, T. Effects of local strain rate and temperature on the workpiece subsurface damage in grinding of optical glass. Int. J. Mech. Sci. 2020, 182, 105737. [Google Scholar] [CrossRef]

- Hussainova, I.; Kolesnikova, A.; Hussainov, M.; Romanov, A. Effect of thermo-elastic residual stresses on erosive performance of cermets with core–rim structured ceramic grains. Wear 2009, 267, 177–185. [Google Scholar] [CrossRef]

- Azarhoushang, B.; Daneshi, A.; Lee, D.H. Evaluation of thermal damages and residual stresses in dry grinding by structured wheels. J. Clean. Prod. 2017, 142, 1922–1930. [Google Scholar] [CrossRef]

- Liu, C.B.; Cai, C.Y.; Xie, J.W.; Guo, W.M.; Qin, H.; Gao, P.Z.; Xiao, H.N. Effect of surface brittle-to-ductile transition on high-temperature thermal shock resistance of Al2O3 ceramics. Ceram. Int. 2022, 48, 20627–20638. [Google Scholar] [CrossRef]

- Dong, Z.G.; Wang, H.; Qi, Y.N.; Guo, X.G.; Kang, R.K.; Bao, Y. Effects of minimum uncut chip thickness on tungsten nano-cutting mechanism. Int. J. Mech. Sci. 2023, 237, 107790. [Google Scholar] [CrossRef]

- Yin, H.; Wang, S.; Guo, B.; Zhao, Q.L. Effects of scratch depth on material-removal mechanism of yttrium aluminium garnet ceramic. Ceram. Int. 2022, 48, 27479–27485. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, Y.; Xiao, G.J.; Zhang, Y.D.; Wang, W.X. Analysis of abrasive belt wear effect on residual stress distribution on a grinding surface. Wear 2021, 486–487, 204113. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Material characteristics | HIPSN | Compressive strength (MPa) | 4500 |

| Phase composition | β-Si3N4 | Bending strength (MPa) | 900 |

| Compactness | 98% | Fracture toughness (MPa·m1/2) | 6 |

| Density (kg/m3) | 3240 | Poisson’s ratio | 0.26 |

| Elastic modulus (GPa) | 310 | Hardness (GPa) | 32 |

| Thermal conductivity (W/(m·k)) | 32 | Coefficient of thermal expansion (×10−6/K) | 3.2 |

| Number | vs (m/s) | ap (μm) | vw (mm/min) | σx1 (MPa) | σy1 (MPa) | h (μm) |

|---|---|---|---|---|---|---|

| 1–5 | 25, 30, 35, 40, 45 | 12 | 3500 | 374, 292, 163, 96, 46 | 327, 201, 112, 53, 9 | 22.9, 18.4, 12.5, 7.6, 5.8 |

| 6–10 | 38 | 5, 10, 15, 20, 25 | 3500 | 82, 159, 192, 310, 392 | 35, 108, 129, 225, 351 | 6.5, 12.2, 14.5, 18.9, 23.7 |

| 11–15 | 38 | 12 | 1000, 2500, 4000, 5500, 7000 | 102, 144, 223, 288, 353 | 58, 90, 156, 193, 286 | 7.9, 10.3, 15.2, 18.0, 20.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Deng, F.; Qin, Z.; Zhu, J.; Chang, H.; Niu, H. Effects of Grinding Parameters on the Processing Temperature, Crack Propagation and Residual Stress in Silicon Nitride Ceramics. Micromachines 2023, 14, 666. https://doi.org/10.3390/mi14030666

Yan H, Deng F, Qin Z, Zhu J, Chang H, Niu H. Effects of Grinding Parameters on the Processing Temperature, Crack Propagation and Residual Stress in Silicon Nitride Ceramics. Micromachines. 2023; 14(3):666. https://doi.org/10.3390/mi14030666

Chicago/Turabian StyleYan, Haipeng, Fei Deng, Zhiying Qin, Jinda Zhu, Hongjie Chang, and Huli Niu. 2023. "Effects of Grinding Parameters on the Processing Temperature, Crack Propagation and Residual Stress in Silicon Nitride Ceramics" Micromachines 14, no. 3: 666. https://doi.org/10.3390/mi14030666