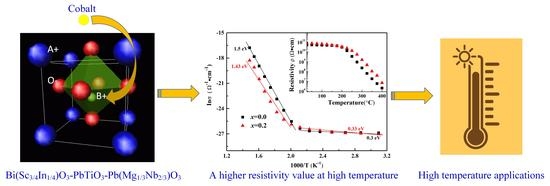

Preparation, Structure, and Electrical Properties of Cobalt-Modified Bi(Sc3/4In1/4)O3–PbTiO3–Pb(Mg1/3Nb2/3)O3 High-Temperature Piezoelectric Ceramics

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jaffe, B.; Roth, R.S.; Marzullo, S. Piezoelectric properties of lead zirconate-lead titanate solid-solution ceramics. J. Appl. Phys. 1954, 25, 809–810. [Google Scholar] [CrossRef]

- Tressler, J.F.; Alkoy, S.; Newnham, R.E. Piezoelectric sensors and sensor materials. J. Electroceram. 1998, 2, 257–272. [Google Scholar] [CrossRef]

- Dong, S.X. Review on piezoelectric, ultrasonic, and magnetoelectric actuators. J. Adv. Dielect. 2012, 2, 1230001. [Google Scholar] [CrossRef]

- Gubinyi, Z.; Batur, C.; Sayir, A.; Dynys, F. Electrical properties of PZT piezoelectric ceramics at high temperature. J. Electroceram. 2008, 20, 95–105. [Google Scholar] [CrossRef]

- Qureshi, A.H.; Shabbir, G.; Hall, D.A. On the synthesis and dielectric studies of (1−x)Bi(Mg1/2Zr1/2)O3−xPbTiO3 piezoelectric ceramic system. Mater. Lett. 2007, 61, 4482–4484. [Google Scholar] [CrossRef]

- Zhang, S.J.; Yu, F.P. Piezoelectric materials for high temperature sensors. J. Am. Ceram. Soc. 2011, 94, 3153–3170. [Google Scholar] [CrossRef]

- Eitel, R.E.; Randall, C.A.; Shrout, T.R.; Rehrig, P.W.; Hackenberger, W.; Park, S.E. New high temperature morphotropic phase boundary piezoelectrics based on Bi(Me)O3-PbTiO3 ceramics. Jpn. J. Appl. Phys. 2001, 40, 5999–6002. [Google Scholar] [CrossRef]

- Eitel, R.E.; Randall, C.A.; Shrout, T.R.; Park, S.E. Preparation and characterization of high temperature perovskite ferroelectrics in the solid-solution (1−x)BiScO3−xPbTiO3. Jpn. J. Appl. Phys. 2002, 41, 2099. [Google Scholar] [CrossRef]

- Iniguez, J.; Vanderbilt, D.; Bellaiche, L. First-principles study of (BiScO3)1−x-(PbTiO3)x piezoelectric alloys. Phys. Rev. B 2003, 67, 224107. [Google Scholar] [CrossRef] [Green Version]

- Inaguma, Y.; Miyaguchi, A.; Yoshida, M.; Katsumata, T.; Shimojo, Y.; Wang, R.; Sekiya, T. High-pressure synthesis and ferroelectric properties in perovskite-type BiScO3-PbTiO3 solid solution. J. Appl. Phys. 2004, 95, 231–235. [Google Scholar] [CrossRef]

- Winotai, P.; Udomkan, N.; Meejoo, S. Piezoelectric properties of Fe2O3-doped (1−x)BiScO3−xPbTiO3 ceramics. Sens. Actuators A 2005, 122, 257–263. [Google Scholar] [CrossRef]

- Chen, J.G.; Shi, H.D.; Liu, G.X.; Cheng, J.R.; Dong, S.X. Temperature dependence of dielectric, piezoelectric and elastic properties of BiScO3-PbTiO3 high temperature ceramics with morphotropic phase boundary (MPB) composition. J. Alloy. Compd. 2012, 537, 280–285. [Google Scholar] [CrossRef]

- Chen, J.G.; Cheng, J.R.; Dong, S.X. Review on high temperature piezoelectric ceramics and actuators based on BiScO3-PbTiO3 solid solutions. J. Adv. Dielect. 2014, 4, 1430002. [Google Scholar] [CrossRef] [Green Version]

- Meng, X.F.; Chen, Q.; Fu, H.; Liu, H.; Zhu, J.G. Influence of PNN on the structure and electronic properties of BSPT ceramics. J. Mater. Sci. Mater. Electron. 2018, 29, 12785–12794. [Google Scholar] [CrossRef]

- Wu, J.G.; Gao, X.Y.; Yu, Y.; Yang, J.K.; Chu, Z.Q.; Bokov, A.A.; Ye, Z.G.; Dong, S.X. Quantitative studies of domain evolution in tetragonal BS-PT ceramics in electric poling and thermal depoling processes. J. Mater. Chem. C 2019, 7, 4517. [Google Scholar] [CrossRef]

- Hu, Z.Q.; Chen, J.G.; Li, M.Y.; Li, X.T.; Liu, G.X.; Dong, S.X. Morphotropic phase boundary and high temperature dielectric, piezoelectric, and ferroelectric properties of (1−x)Bi(Sc3/4In1/4)O3−xPbTiO3 ceramics. J. Appl. Phys. 2011, 110, 064102. [Google Scholar] [CrossRef]

- Ansell, T.Y.; Cann, D.P. High temperature piezoelectric ceramics based on (1−x)[BiScO3+Bi(Ni1/2Ti1/2)O3]−xPbTiO3. Mater. Lett. 2012, 80, 87–90. [Google Scholar] [CrossRef]

- Sehirlioglu, A.; Sayir, A.; Dynys, F. Microstructure-property relationships in liquid phase-sintered high-temperature bismuth scandium oxide-lead titanate piezoceramics. J. Am. Ceram. Soc. 2008, 91, 2910–2916. [Google Scholar] [CrossRef]

- Zhang, S.J.; Eitel, R.E.; Randall, C.A.; Shrout, T.R.; Alberta, E.F. Manganese-modified BiScO3-PbTiO3 piezoelectric ceramic for high-temperature shear mode sensor. Appl. Phys. Lett. 2005, 86, 262904. [Google Scholar] [CrossRef]

- Zhao, T.-L.; Fei, C.; Pu, K.; Dai, X.; Song, J.; Wang, C.-M.; Dong, S. Structure evolution and enhanced electrical performance for BiScO3–Bi(Ni1/2Zr1/2)O3–PbTiO3 solid solutions near the morphotropic phase boundary. J. Alloy. Compd. 2021, 873, 159844. [Google Scholar] [CrossRef]

- Cheng, J.R.; Eitel, R.E.; Li, N.; Cross, L.E. Structural and electrical properties of (1−x)Bi(Ga1/4Sc3/4)O3−xPbTiO3 piezoelectric ceramics. J. Appl. Phys. 2003, 94, 605–609. [Google Scholar] [CrossRef]

- Zhao, T.L.; Wang, C.M.; Wang, C.L.; Wang, Y.M.; Dong, S.X. Enhanced piezoelectric properties and excellent thermal stabilities of cobalt-modified Aurivillius-type calcium bismuth titanate (CaBi4Ti4O15). Mater. Sci. Eng. B 2015, 201, 51–56. [Google Scholar] [CrossRef]

- Ryu, J.; Priya, S.; Sakaki, C.; Uchino, K. High power piezoelectric characteristics of BiScO3-PbTiO3-Pb(Mn1/3Nb2/3)O3. Jpn. J. Appl. Phys. 2002, 41, 6040–6044. [Google Scholar] [CrossRef]

- Stringer, C.J.; Randall, C.A. In situ TEM investigations of the high-temperature relaxor ferroelectric BiScO3-Pb(Mg1/3Nb2/3)O3-PbTiO3 ternary solid solution. J. Am. Ceram. Soc. 2007, 90, 1802–1807. [Google Scholar] [CrossRef]

- Yao, Z.H.; Liu, H.X.; Hao, H.; Cao, M.H. Structure, electrical properties, and depoling mechanism of BiScO3-PbTiO3-Pb(Zn1/3Nb2/3)O3 high-temperature piezoelectric ceramics. J. Appl. Phys. 2011, 109, 014105. [Google Scholar] [CrossRef]

- Chen, J.G.; Zhao, T.L.; Cheng, J.R.; Dong, S.X. Enhanced piezoelectric performance of (0.98-x)Bi(Sc3/4In1/4)O3−xPbTiO3-0.02Pb(Zn1/3Nb2/3)O3 ternary high temperature piezoelectric ceramics. J. Appl. Phys. 2013, 113, 144102. [Google Scholar] [CrossRef]

- Zhao, T.L.; Bokov, A.A.; Wu, J.G.; Wang, H.L.; Wang, C.M.; Yu, Y.; Wang, C.L.; Zeng, K.Y.; Ye, Z.G.; Dong, S.X. Giant piezoelectricity of ternary perovskite ceramics at high temperature. Adv. Funct. Mater. 2019, 29, 1807920. [Google Scholar] [CrossRef]

- Kang, H.J.; Chen, J.; Liu, L.J.; Fang, L.; Xing, X.R. Temperature dependences of the ferroelectric and dielectric properties of high Curie temperature PbTiO3-BiScO3-Bi(Zn1/2Zr1/2)O3. Mater. Res. Bull. 2013, 48, 2006–2009. [Google Scholar] [CrossRef]

- Hu, Q.R.; Wang, Y.P.; Wu, L.; Yin, J.; Chen, L.; Yuan, G.L.; Yang, Y. Effects of LiNbO3 doping on the microstructures and electrical properties of BiScO3-PbTiO3 piezoelectric system. J. Mater. Sci. Mater. Electron. 2018, 29, 18036–18044. [Google Scholar] [CrossRef]

- Jiang, Y.H.; Qin, B.Q.; Zhao, Y.; Jiang, Y.Z.; Shi, W.; Li, Q.S.; Xiao, D.Q.; Zhu, J.G. Phase transition, piezoelectric properties, and thermal stability of (1−x−y)BiScO3−yBiGaO3−xPbTiO3 ceramics. J. Am. Ceram. Soc. 2008, 91, 2943–2946. [Google Scholar] [CrossRef]

- Zhao, T.L.; Wang, C.M.; Chen, J.G.; Wang, C.L.; Dong, S.X. Phase transitional behavior and enhanced electrical properties of Bi(Sc3/4In1/4)O3-PbTiO3 by small content Pb(Mg1/3Nb2/3)O3 modification. J. Mater. Sci. Mater. Electron. 2016, 27, 606–612. [Google Scholar] [CrossRef]

- Jaimeewong, P.; Sittinon, S.; Buntham, S.; Bomlai, P.; Namsar, O.; Pojprapai, S.; Watcharapasorn, A. Ferroelectric, piezoelectric and dielectric behaviors of CoO- and Fe2O3-doped BCZT ceramics. Phys. Status Solidi A 2018, 215, 1701023. [Google Scholar] [CrossRef]

- Huang, X.Y.; Gao, C.H.; Huang, M.S.; Yue, Z.X. Influence of Co ion doped amount on property of BCTZ piezoelectric ceramics sintered at low temperature. Ferroelectrics 2015, 481, 146–154. [Google Scholar] [CrossRef]

- Shi, S.F.; Hashimoto, H.; Sekino, T. Enhancing piezoelectric properties of Ba0.88Ca0.12Zr0.12Ti0.88O3 lead-free ceramics by doping Co ions. Ceram. Int. 2021, 47, 3272–3278. [Google Scholar] [CrossRef]

- Koronska, R.B.; Vasylechko, L.; Markiewicz, E.; Nalecz, D.M.; Kalvane, A. X-ray and dielectric characterization of Co doped tetragonal BaTiO3 ceramics. Phase Transit. 2017, 90, 78–85. [Google Scholar] [CrossRef]

- Ma, Y.N.; Chen, H.M.; Pan, F.C.; Chen, Z.P.; Ma, Z.; Lin, X.L.; Zheng, F.; Ma, X.B. Electronic structures and optical properties of Fe/Co–doped cubic BaTiO3 ceramics. Ceram. Int. 2019, 45, 6303–6311. [Google Scholar] [CrossRef]

- Peng, Z.H.; Zheng, D.Y.; Zhou, T.; Yang, L.; Zhang, N.; Fang, C. Effects of Co2O3 doping on electrical properties and dielectric relaxation of PMS-PNN-PZT ceramics. J. Mater. Sci. Mater. Electron. 2018, 29, 5961–5968. [Google Scholar] [CrossRef]

- Guo, Z.L.; Wang, C.M.; Zhao, T.L.; Yu, S.L.; Cao, Z.P. Piezoelectric properties and thermal stabilities of cobalt-modified potassium bismuth titanate. Mater. Chem. Phys. 2013, 140, 260–265. [Google Scholar] [CrossRef]

- Wang, C.-M.; Wang, J.-F.; Zheng, L.-M.; Zhao, M.-L.; Wang, C.-L. Enhancement of the piezoelectric properties of sodium lanthanum bismuth titanate (Na0.5La0.5Bi4Ti4O15) through modification with cobalt. Mat. Sci. Eng. B 2010, 171, 79–85. [Google Scholar] [CrossRef]

- Zhang, S.J.; Randall, C.A.; Shrout, T.R. High Curie temperature piezocrystals in the BiScO3-PbTiO3 perovskite system. Appl. Phys. Lett. 2003, 83, 3150–3152. [Google Scholar] [CrossRef]

- Kobor, D.; Guiffard, B.; Lebrun, L.; Hajjaji, A.; Guyomar, D. Oxygen vacancies effect on ionic conductivity and relaxation phenomenon in undoped and Mn doped PZN-4.5PT single crystals. J. Phys. D Appl. Phys. 2007, 40, 2920–2926. [Google Scholar] [CrossRef]

- James, A.R.; Priya, S.; Uchino, K.; Srinivas, K.; Kiran, V.V. Investigations of intrinsic defect structure in 0.91Pb(Zn1/3Nb2/3)O3-0.09PbTiO3 single crystal through AC conductivity. Jpn. J. Appl. Phys. 2002, 41, 5272–5276. [Google Scholar] [CrossRef]

- Randall, C.A.; Kim, N.; Kucera, J.P.; Cao, W.W.; Shrout, T.R. Intrinsic and extrinsic size effects in fine-grained morphotropic-phae-boundary lead zirconate titanate ceramics. J. Am. Ceram. Soc. 1998, 81, 677. [Google Scholar] [CrossRef]

| Material | a (Å) | c (Å) | c/a | Relative Density (%) | Grain Size (μm) |

|---|---|---|---|---|---|

| x = 0.0 | 3.920 | 4.005 | 1.022 | 96.2 | 1.94 |

| x = 0.2 | 3.921 | 4.004 | 1.021 | 96.3 | 2.32 |

| x = 0.4 | 3.922 | 4.003 | 1.020 | 97.1 | 2.41 |

| x = 0.6 | 3.922 | 3.998 | 1.019 | 95.3 | 2.53 |

| x = 0.8 | 3.921 | 3.989 | 1.017 | 95.6 | 2.68 |

| Material | Tc (°C) | εr | tanδ | d33 (pC/N) | kp (%) | Ec (kV/cm) | Pr (μC/cm2) | Strain (%) | d33* (pm/V) | h (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| x = 0.0 | 421 | 1685 | 0.055 | 403 | 47.2 | 24.7 | 36.4 | 0.222 | 555 | 17.8 |

| x = 0.2 | 412 | 1450 | 0.051 | 370 | 46.5 | 27.1 | 29.2 | 0.205 | 512.5 | 16.0 |

| x = 0.4 | 408 | 1433 | 0.048 | 360 | 45.7 | 28.6 | 28.4 | 0.198 | 495 | 14.5 |

| x = 0.6 | 403 | 1386 | 0.043 | 350 | 43.8 | 30.4 | 26.3 | 0.188 | 470 | 15.4 |

| x = 0.8 | 398 | 1331 | 0.044 | 330 | 41.6 | 32.3 | 25.1 | 0.182 | 455 | 14.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Lin, N.; Yang, Z.; Zhang, J.; Shi, K.; Sun, X.; Gao, B.; Zhao, T. Preparation, Structure, and Electrical Properties of Cobalt-Modified Bi(Sc3/4In1/4)O3–PbTiO3–Pb(Mg1/3Nb2/3)O3 High-Temperature Piezoelectric Ceramics. Micromachines 2021, 12, 1556. https://doi.org/10.3390/mi12121556

Chen Z, Lin N, Yang Z, Zhang J, Shi K, Sun X, Gao B, Zhao T. Preparation, Structure, and Electrical Properties of Cobalt-Modified Bi(Sc3/4In1/4)O3–PbTiO3–Pb(Mg1/3Nb2/3)O3 High-Temperature Piezoelectric Ceramics. Micromachines. 2021; 12(12):1556. https://doi.org/10.3390/mi12121556

Chicago/Turabian StyleChen, Zhijiang, Na Lin, Zhao Yang, Juan Zhang, Kefei Shi, Xinhao Sun, Bo Gao, and Tianlong Zhao. 2021. "Preparation, Structure, and Electrical Properties of Cobalt-Modified Bi(Sc3/4In1/4)O3–PbTiO3–Pb(Mg1/3Nb2/3)O3 High-Temperature Piezoelectric Ceramics" Micromachines 12, no. 12: 1556. https://doi.org/10.3390/mi12121556