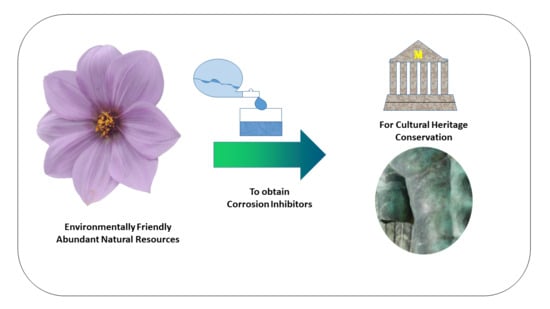

The Use of Plant Extracts as Sustainable Corrosion Inhibitors for Cultural Heritage Alloys: A Mini-Review

Abstract

:1. Introduction

2. Inhibitors

2.1. What Is an Inhibitor?

2.2. Mechanisms of Protection

2.3. Inhibitors for Cultural Heritage Metals

- Vapour Phase Application: Volatile corrosion inhibitors, a type of corrosion inhibitor, can be applied in vapour form by incorporating reactive particles into packaging materials during short- or long-term storage. These chemical compounds vaporise and condense onto the metallic surface in the presence of moisture, providing reliable protection against environmental factors [38,39].

- Immersion: Another method is immersing the item in a solution containing corrosion inhibitors. This can be applied before storage, as part of the stabilization procedures, or as the final step in the conservation treatment. A schematic diagram of this process is shown in Figure 3. As a first step, the corrosion inhibitor molecules are dissolved in a carrier medium, which can be either a polar or non-polar solvent (e.g., water or ethanol). The samples are then immersed in this solution, allowing for the corrosion inhibitor molecules to adsorb onto the metallic surface, thus delivering the desired protective effect. The process of adsorption occurs through various mechanisms, which will be explored further in subsequent sections. After immersion and rinsing, a protective coating is typically applied to enhance corrosion protection by acting as a barrier film. This prevents the access of water molecules to the metallic surface and extends the service life of the corrosion inhibitors [42,43,44].

3. Plant Extracts

4. Features, Advantages, and Disadvantages of Plant Extracts as Corrosion Inhibitors

5. Future Work and Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Joseph, E. Microorganisms in the Deterioration and Preservation of Cultural Heritage; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 9783030694111. [Google Scholar]

- Artesani, A.; Turo, F.D.; Zucchelli, M.; Traviglia, A. Recent Advances in Protective Coatings for Cultural Heritage—An Overview. Coatings 2020, 10, 217. [Google Scholar] [CrossRef]

- Alrefaee, S.H.; Rhee, K.Y.; Verma, C.; Quraishi, M.A.; Ebenso, E.E. Challenges and Advantages of Using Plant Extract as Inhibitors in Modern Corrosion Inhibition Systems: Recent Advancements. J. Mol. Liq. 2021, 321, 114666. [Google Scholar] [CrossRef]

- Rani, B.E.A.; Basu, B.B.J. Green Inhibitors for Corrosion Protection of Metals and Alloys: An Overview. Int. J. Corros. 2012, 2012, 380217. [Google Scholar] [CrossRef]

- Dahmani, K.; Galai, M.; Ouakki, M.; Elgendy, A.; Ez-Zrioulli, R.; Lachhab, R.; Briche, S.; Cherkaoui, M. Corrosion inhibition of copper in sulfuric acid via environmentally friendly inhibitor (Myrtus Communis): Combining experimental and theoretical methods. J. Mol. Liq. 2022, 347, 117982. [Google Scholar] [CrossRef]

- El Shaer, M. Strategies for Saving Our Cultural Heritage. In Proceedings of the International Conference on Strategies for Saving Indoor Metallic Collections with a Satellite Meeting on Legal Issues in the Conservation of Cultural Heritage, Cairo, Egypt, 25 February–1 March 2007; pp. 1–6. [Google Scholar]

- De Silva, M.; Henderson, J. Sustainability in Conservation Practice. J. Inst. Conserv. 2011, 34, 5–15. [Google Scholar] [CrossRef]

- Salleh, S.Z.; Yusoff, A.H.; Zakaria, S.K.; Taib, M.A.A.; Abu Seman, A.; Masri, M.N.; Mohamad, M.; Mamat, S.; Ahmad Sobri, S.; Ali, A.; et al. Plant Extracts as Green Corrosion Inhibitor for Ferrous Metal Alloys: A Review. J. Clean. Prod. 2021, 304, 127030. [Google Scholar] [CrossRef]

- Miralrio, A.; Vázquez, A.E. Plant Extracts as Green Corrosion Inhibitors for Different Metal Surfaces and Corrosive Media: A Review. Processes 2020, 8, 942. [Google Scholar] [CrossRef]

- Verma, C.; Ebenso, E.E.; Bahadur, I.; Quraishi, M.A. An Overview on Plant Extracts as Environmental Sustainable and Green Corrosion Inhibitors for Metals and Alloys in Aggressive Corrosive Media. J. Mol. Liq. 2018, 266, 577–590. [Google Scholar] [CrossRef]

- Sastri, V. Green Corrosion Inhibitors: Theory and Practice, 1st ed.; Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 9783131450715. [Google Scholar]

- Gaidis, J.M. Chemistry of Corrosion Inhibitors. Cem. Concr. Compos. 2004, 26, 181–189. [Google Scholar] [CrossRef]

- Hughes, A.; Winkler, D.; Carr, J.; Lee, P.; Yang, Y.; Laleh, M.; Tan, M. Corrosion Inhibition, Inhibitor Environments, and the Role of Machine Learning. Corros. Mater. Degrad. 2022, 3, 672–693. [Google Scholar] [CrossRef]

- Aramaki, K. Historical and Future Perspectives on Corrosion Inhibitor Studies. J-Stage 2004, 53, 348–351. [Google Scholar] [CrossRef]

- Telegdi, J. History of Phosphorus-Containing Corrosion Inhibitors: From the Beginning till the Present Time; Elsevier Inc.: Amsterdam, The Netherlands, 2022; ISBN 9780128228968. [Google Scholar]

- Rahal, C.; Masmoudi, M.; Abdelhedi, R.; Sabot, R.; Jeannin, M.; Bouaziz, M.; Refait, P. Olive Leaf Extract as Natural Corrosion Inhibitor for Pure Copper in 0.5 M NaCl Solution: A Study by Voltammetry around OCP. J. Electroanal. Chem. 2016, 769, 53–61. [Google Scholar] [CrossRef]

- Kokalj, A. Corrosion Inhibitors: Physisorbed or Chemisorbed? Corros. Sci. 2022, 196, 109939. [Google Scholar] [CrossRef]

- Umoren, S.A.; Solomon, M.M.; Obot, I.B.; Suleiman, R.K. A Critical Review on the Recent Studies on Plant Biomaterials as Corrosion Inhibitors for Industrial Metals. J. Ind. Eng. Chem. 2019, 76, 91–115. [Google Scholar] [CrossRef]

- Dillmann, P.; Watkinson, D. (Eds.) Corrosion and Conservation of Cultural Heritage Artefacts; Woodhead Publishing in Materials: Delhi, India, 2013; ISBN 9781782421542. [Google Scholar]

- Letardi, P. Laboratory and Field Tests on Patinas and Protective Coating Systems for Outdoor Bronze Monuments. Proc. Met. 2004, 2004, 379–387. [Google Scholar]

- Joseph, E.; Letardi, P.; Mazzeo, R.; Prati, S.; Vandini, M. Innovative Treatments for the Protection of Outdoor Bronze Monuments. Metal 2007, 7, 71–77. [Google Scholar]

- Biribicchi, C.; Macchia, A.; Favero, G.; Strangis, R.; Gabriele, B.; Mancuso, R.; La Russa, M.F. Sustainable Solutions for Removing Aged Wax-Based Coatings from Cultural Heritage: Exploiting Hydrophobic Deep Eutectic Solvents (DESs). New J. Chem. 2023, 47, 5991–6000. [Google Scholar] [CrossRef]

- Molina, M.T.; Cano, E.; Ramírez-Barat, B. Protective Coatings for Metallic Heritage Conservation: A Review. J. Cult. Herit. 2023, 62, 99–113. [Google Scholar] [CrossRef]

- Texier, A.; Geffroy, A.; Brocard-Rosa, T. Les Cires Microcristallines Dasn La Protection de La Statuaire En Cuivre et Alliages de Cuivre Exposee En Exterieur. 163–175. Available online: https://www.lrmh.fr/Default/doc/SYRACUSE/71163/les-cires-microcristallines-dans-la-protection-de-la-statuaire-en-cuivre-et-alliages-de-cuivre-expos?_lg=en-US (accessed on 2 January 2024).

- Brinch Madsen, H. A Preliminary Note on the Use of Benzotriazole for Stabilizing Bronze Objects. Stud. Conserv. 1967, 12, 163–167. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Tan, B.; Li, W.; Ji, J.; Yan, M.; Cui, Z. Effect of Corrosion Inhibitor BTA on Silica Particles and Their Adsorption on Copper Surface in Copper Interconnection CMP. ECS J. Solid State Sci. Technol. 2022, 11, 044002. [Google Scholar] [CrossRef]

- Wu, X.; Chou, N.; Lupher, D.; Davis, L.C. Benzotriazoles: Toxicity and Degradation. Conf. Hazard. Waste Res. 1998, 374–382. Available online: https://engg.k-state.edu/HSRC/98Proceed/32Wu/32wu.pdf (accessed on 2 January 2024).

- Pillard, D.A.; Cornell, J.S.; DuFresne, D.L.; Hernandez, M.T. Toxicity of Benzotriazole and Benzotriazole Derivatives to Three Aquatic Species. Water Res. 2001, 35, 557–560. [Google Scholar] [CrossRef]

- Baglioni, M.; Poggi, G.; Chelazzi, D.; Baglioni, P. Advanced Materials in Cultural Heritage Conservation. Molecules 2021, 26, 3967. [Google Scholar] [CrossRef] [PubMed]

- Dermaj, A.; Chebabe, D.; Doubi, M.; Erramli, H.; Hajjaji, N.; Casaletto, M.P.; Ingo, G.M.; Riccucci, C.; de Caro, T. Inhibition of Bronze Corrosion in 3%nacl Media by Novel Non-Toxic 3-Phenyl-1,2, 4-Triazole Thione Formulation. Corros. Eng. Sci. Technol. 2015, 50, 128–136. [Google Scholar] [CrossRef]

- Albini, M.; Letardi, P.; Mathys, L.; Brambilla, L.; Schröter, J.; Junier, P.; Joseph, E. Comparison of a Bio-Based Corrosion Inhibitor versus Benzotriazole on Corroded Copper Surfaces. Corros. Sci. 2018, 143, 84–92. [Google Scholar] [CrossRef]

- Giuliani, C.; Messina, E.; Staccioli, M.P.; Pascucci, M.; Riccucci, C.; Liotta, L.F.; Tortora, L.; Ingo, G.M.; Di Carlo, G. On-Demand Release of Protective Agents Triggered by Environmental Stimuli. Front. Chem. 2020, 8, 304. [Google Scholar] [CrossRef] [PubMed]

- Silva da Conceição, D.K.; Nunes de Almeida, K.; Nhuch, E.; Raucci, M.G.; Santillo, C.; Salzano de Luna, M.; Ambrosio, L.; Lavorgna, M.; Giuliani, C.; Di Carlo, G.; et al. The Synergistic Effect of an Imidazolium Salt and Benzotriazole on the Protection of Bronze Surfaces with Chitosan-Based Coatings. Herit. Sci. 2020, 8, 40. [Google Scholar] [CrossRef]

- Giuliani, C.; Pascucci, M.; Riccucci, C.; Messina, E.; Salzano de Luna, M.; Lavorgna, M.; Ingo, G.M.; Di Carlo, G. Chitosan-Based Coatings for Corrosion Protection of Copper-Based Alloys: A Promising More Sustainable Approach for Cultural Heritage Applications. Prog. Org. Coat. 2018, 122, 138–146. [Google Scholar] [CrossRef]

- Smith, D. The Application of Alloy Analysis to Questions of Attribution: Giovanni Francesco Susini and the Workshop of Giambologna. 2011. Available online: https://core.ac.uk/download/pdf/11341336.pdf#page=257 (accessed on 2 January 2024).

- Rocca, E.; Bertrand, G.; Rapin, C.; Labrune, J.C. Inhibition of Copper Aqueous Corrosion by Non-Toxic Linear Sodium Heptanoate: Mechanism and Ecafm Study. J. Electroanal. Chem. 2001, 503, 133–140. [Google Scholar] [CrossRef]

- Di Turo, F. Limits and Perspectives of Archaeometric Analysis of Archaeological Metals: A Focus on the Electrochemistry for Studying Ancient Bronze Coins. J. Cult. Herit. 2020, 43, 271–281. [Google Scholar] [CrossRef]

- Rammelt, U.; Koehler, S.; Reinhard, G. Use of Vapour Phase Corrosion Inhibitors in Packages for Protecting Mild Steel against Corrosion. Corros. Sci. 2009, 51, 921–925. [Google Scholar] [CrossRef]

- Pena, L.F.; Veyan, J.F.; Todd, M.A.; Derecskei-Kovacs, A.; Chabal, Y.J. Vapor-Phase Cleaning and Corrosion Inhibition of Copper Films by Ethanol and Heterocyclic Amines. ACS Appl. Mater. Interfaces 2018, 10, 38610–38620. [Google Scholar] [CrossRef] [PubMed]

- Calegari, F.; da Silva, B.C.; Tedim, J.; Ferreira, M.G.S.; Berton, M.A.C.; Marino, C.E.B. Benzotriazole Encapsulation in Spray-Dried Carboxymethylcellulose Microspheres for Active Corrosion Protection of Carbon Steel. Prog. Org. Coat. 2020, 138, 105329. [Google Scholar] [CrossRef]

- Feng, Y.; Cheng, Y.F. An Intelligent Coating Doped with Inhibitor-Encapsulated Nanocontainers for Corrosion Protection of Pipeline Steel. Chem. Eng. J. 2017, 315, 537–551. [Google Scholar] [CrossRef]

- Valdez, B.; Schorr, M.; Cheng, N.; Beltran, E.; Salinas, R. Technological Applications of Volatile Corrosion Inhibitors. Corros. Rev. 2018, 36, 227–238. [Google Scholar] [CrossRef]

- Shin, J.A.; Wi, K.C. A Study on the Applicability of Corrosion Inhibitor for Outdoor Copper Alloy. J. Conserv. Sci. 2018, 34, 259–271. [Google Scholar] [CrossRef]

- Argyropoulos, V.; Boyatzis, S.C.; Giannoulaki, M.; Guilminot, E.; Zacharopoulou, A. Organic Green Corrosion Inhibitors Derived from Natural and/or Biological Sources for Conservation of Metals Cultural Heritage. In Microorganisms in the Deterioration and Preservation of Cultural Heritage; Springer: Berlin/Heidelberg, Germany, 2021; pp. 341–367. [Google Scholar] [CrossRef]

- Pelikan, J.B. Conservation of Iron with Tannin. Stud. Conserv. 1966, 11, 109–116. [Google Scholar] [CrossRef]

- Proença, C.S.; Serrano, B.; Correia, J.; Araújo, M.E.M. Evaluation of Tannins as Potential Green Corrosion Inhibitors of Aluminium Alloy Used in Aeronautical Industry. Metals 2022, 12, 508. [Google Scholar] [CrossRef]

- Iglesias, J.; García de Saldaña, E.; Jaén, J.A. On the Tannic Acid Interaction with Metallic Iron. Hyperfine Interact. 2001, 134, 109–114. [Google Scholar] [CrossRef]

- Church, J.W.; Striegel, M.; Church, J.; Muto, A. Comparative study of rust converters for historic outdoor metalwork comparative study of rust converters for historic outdoor metalwork. Metal 2013, pp. 173–178. Available online: https://www.researchgate.net/profile/Mary-Striegel-2/publication/284157813_COMPARATIVE_STUDY_OF_RUST_CONVERTERS_FOR_HISTORIC_OUTDOOR_METALWORK/links/564ca06608ae7ac727e20192/COMPARATIVE-STUDY-OF-RUST-CONVERTERS-FOR-HISTORIC-OUTDOOR-METALWORK.pdf (accessed on 2 January 2024).

- Argyropoulos, V.; Rameau, J.J.; Dalard, F.; Degrigny, C. Testing Hostacor It as a Corrosion Inhibitor for Iron in Polyethylene Glycol Solutions. Stud. Conserv. 1999, 44, 49–57. [Google Scholar] [CrossRef]

- Benzidia, B.; Hammouch, H.; Dermaj, A.; Benassaoui, H.; Abbout, S.; Hajjaji, N. Investigation of Green Corrosion Inhibitor Based on Aloe vera (L.) Burm. F. for the Protection of Bronze B66 in 3% NaCl. Anal. Bioanal. Electrochem. 2019, 11, 165–177. [Google Scholar]

- Li, M.; Jia, X.; Yang, J.; Deng, J.; Zhao, G. Effect of Tannic Acid on Properties of Soybean (Glycine Max) Seed Ferritin: A Model for Interaction between Naturally-Occurring Components in Foodstuffs. Food Chem. 2012, 133, 410–415. [Google Scholar] [CrossRef]

- Gülçin, I.; Huyut, Z.; Elmastaş, M.; Aboul-Enein, H.Y. Radical Scavenging and Antioxidant Activity of Tannic Acid. Arab. J. Chem. 2010, 3, 43–53. [Google Scholar] [CrossRef]

- Rahman, Z.; Zidan, A.S.; Khan, S.R.; Reddy, I.K.; Khan, M.A. Cholorpheniramine Tannate Complexes: Physicochemical, Chemometric, and Taste Masking Evaluation. Int. J. Pharm. 2012, 436, 582–592. [Google Scholar] [CrossRef] [PubMed]

- Vankar, P.S.; Shanker, R.; Verma, A. Enzymatic Natural Dyeing of Cotton and Silk Fabrics without Metal Mordants. J. Clean. Prod. 2007, 15, 1441–1450. [Google Scholar] [CrossRef]

- Kusmierek, E.; Chrzescijanska, E. Tannic Acid as Corrosion Inhibitor for Metals and Alloys. Mater. Corros. 2015, 66, 169–174. [Google Scholar] [CrossRef]

- Fouda, A.S.; Shalabi, K.; Idress, A.A. Ceratonia Siliqua Extract as a Green Corrosion Inhibitor for Copper and Brass in Nitric Acid Solutions. Green Chem. Lett. Rev. 2015, 8, 17–29. [Google Scholar] [CrossRef]

- Pourzarghan, V.; Fazeli, B. The Use of Robinia Pseudoacacia L Fruit Extract as a Natural Corrosion Inhibitor in the Protection of Copper-Based Objects. Herit. Sci. 2021, 9, 75. [Google Scholar] [CrossRef]

- Gao, Z.; Sun, P.; Du, L.; Zhang, X.; Bai, J.; Xing, H.; Yan, Y. Saccharum Officinarum Leaf Extract as Corrosion Inhibitor of Copper Corrosion in Sulphuric Acid Solution: Experiments and Theoretical Calculations. Int. J. Electrochem. Sci. 2021, 16, 211126. [Google Scholar] [CrossRef]

- Elshahawi, A.; Rifai, M.; Hamid, Z.A. Corrosion Inhibition of Bronze Alloy by Jatropha Extract in Neutral Media for Application on Archaeological Bronze Artifacts. Egypt. J. Chem. 2022, 65, 869–878. [Google Scholar] [CrossRef]

- Tan, B.; Xiang, B.; Zhang, S.; Qiang, Y.; Xu, L.; Chen, S.; He, J. Papaya leaves extracts as a novel eco-fiendly corrosion inhibitor for Cu in H2SO4 medium. J. Colloid Interface Sci. 2021, 582, 918–931. [Google Scholar] [CrossRef] [PubMed]

- Tan, B.; Lan, W.; Zhang, S.; Deng, H.; Qiang, Y.; Fu, A.; Ran, Y.; Xiong, J.; Marzouki, R.; Li, W. Passiflora edulia Sims leaves Extract as renewable and degradable inhibitor for copper in sulfuric acid solution. Colloids Surf. A Physicochem. Eng. Asp. 2022, 645, 128892. [Google Scholar] [CrossRef]

- Cao, L. Dimocarpus longan Lour leaf extract as green corrosion inhibitor for copper in sulfuric acid solution. Int. J. Electrochem. Sci. 2022, 17, 2. [Google Scholar] [CrossRef]

- Ben Channouf, R.; Souissi, N.; Bellakhal, N. Juniperus communis Extract Effect on Bronze Corrosion in Natural 0.5M Chloride Medium. J. Mater. Sci. Eng. 2015, 3, 21–29. [Google Scholar] [CrossRef]

- Kokalj, A.; Lozinsek, M.; Kapun, B.; Taheri, P.; Neupane, S.; Losada-Pérez, P.; Xie, C.; Milosev, I. Simplistic correlations between molecular electronic properties and inhibition efficiencies: Do they really exist? Corros. Sci. 2021, 179, 108856. [Google Scholar] [CrossRef]

- Medupin, R.O.; Ukoba, K.O.; Yoro, K.O.; Jen, T.C. Sustainable Approach for Corrosion Control in Mild Steel Using Plant-Based Inhibitors: A Review. Mater. Today Sustain. 2023, 22, 100373. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Jiang, Z.N.; Li, Y.Y.; Wang, X.; Xiong, W.; Liu, H.F.; Zhang, G.A. In-Depth Insight into the Inhibition Mechanism of the Modified and Combined Amino Acids Corrosion Inhibitors: “Intramolecular Synergism” vs. “Intermolecular Synergism”. Chem. Eng. J. 2022, 437, 135439. [Google Scholar] [CrossRef]

- Al Jahdaly, B.A.; Maghraby, Y.R.; Ibrahim, A.H.; Shouier, K.R.; Alturki, A.M.; El-Shabasy, R.M. Role of Green Chemistry in Sustainable Corrosion Inhibition: A Review on Recent Developments. Mater. Today Sustain. 2022, 20, 100242. [Google Scholar] [CrossRef]

- de Souza Morais, W.R.; da Silva, J.S.; Queiroz, N.M.P.; de Paiva e Silva Zanta, C.L.; Ribeiro, A.S.; Tonholo, J. Green Corrosion Inhibitors Based on Plant Extracts for Metals and Alloys in Corrosive Environment: A Technological and Scientific Prospection. Appl. Sci. 2023, 13, 7482. [Google Scholar] [CrossRef]

| Plant Extract | Active Compounds | Reference |

|---|---|---|

| Tannic acid | Tannic acid | Kusmierek et al. [55] |

| Aloe vera mucilage | Acemannan | Benzidia et al. [50] |

| Ceratonia siliqua | Sugar and condensed tannins | Fouda et al. [56] |

| Robinia pseudoacacia L. | Arabinose, ramenoz, galactose, gluconic acid, rubinin, 4 methoxygluconic | Pourzarghan et al. [57] |

| Olive oil | Oleuropein | Rahal et al. [16] |

| Saccharum officiniarum | 3-(-4-hydroxy-3-methoxyphenyl) (HMA), 1-methyl-3-nitrosoguanidine (MND), 3-(3,4-dihydroxyphenyl)acrylic acid (DDA); 5,7-dihydroxy-2-(4-hydroxyphenyl)-4H-chromen-4-one (DHC) | Gao et al. [58] |

| Jatropha | Phytol, stigmasterol, campesterol, sitosterol | Elshahawi et al. [59] |

| Papaya leaves | DL-Ascorbic Acid; 5,7-Dimethoxy-chromen-2-one (DCO); 2-Amino-4-methylsulfanyl-butyric acid (AMB); 3,4-Ditydroxy-benzoic acid (DBA); 2-Hydroxy-succinic acid (HSA); 3-[3-(3,4-Dihydroxy-phenyl)-acryloxyl]-1,4,5-trihydroxy-cyclohexanecarboxylic acid (DTA) | Tan et al. [60] |

| Pasiflora edulia Sims | (R)-2-Phenyl-2-((2R, 3R,4S, 5S, 6R)-3,4,5-trihydoxy-6-(hydroxymethyl)-tetrahydro-2 H- pyran-2-yloxy)acetonitrile (PTH); 2 R, 3 R,4 R,5 S,6 R)-2-(benzyloxy)- 6-(hydroxymethyl)-tetrahydro-2 H-pyran-3,4,5-triol (BHT); 8-(4,5-dihydroxy-6-methyl-tetrahydro-pyran-2-yl)- 2-(3,4-dihydroxy-phenyl)-5,7-dihydroxy-chromen-4-one (DMT) | Tan et al. [61] |

| Myrtus communis | Myrtenyl acetate | Dahmani et al. [5] |

| Dimocarpus longan Lour | TBE; TDF; PDH | Cao et al. [62] |

| Inhibitory Efficiency (%) | Metal or Alloy | Concentration | Solvent Used for Extraction | Corrosive Testing Solution | Reference |

|---|---|---|---|---|---|

| 89.17 | Cu | 25 mg/dm3 | Methanol | Distilled water | [55] |

| 85.94 | Bronze | 750 ppm | Not provided | 3% NaCl | [50] |

| 84.7 | Brass | 300 ppm | Methanol | 1M HNO3 | [56] |

| 93.5 | Bronze | 1800 ppm | Distilled water | 0.5 M NaCl | [57] |

| 86 | Cu | 0.48 mmol/L | Distilled water | 0.5 M NaCl | [16] |

| 93 | Cu | 500 mg/L | H2SO4 | 0.5 M H2SO4 | [58] |

| 86 | Bronze | 30 ppm | Not provided | 3.5% NaCl | [59] |

| 93 | Cu | 150 mg/L | Ultrapure water | 0.5 M H2SO4 | [60] |

| 96.5 | Cu | 800 ppm | Ultrapure water | 0.5 M H2SO4 | [61] |

| 93.2 | Cu | 2 g/L | Not provided | 0.5 M H2SO4 | [5] |

| 98 | Cu | 400 mg/L | H2SO4 | 0.5 M H2SO4 | [62] |

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Source of inhibitors | Extracted from various plant parts: flower, leaf, root, seed, bark, gum, fruit, and stem [1,64]. | Expensive and time-consuming extraction and purification processes [3]. |

| Corrosion inhibition mechanism | Molecules like polyphenols, flavonoids, or polysaccharides with polar functions and heterocyclic constituents. | Active compound responsible for corrosion inhibition not completely determined; may result from the synergistic effect of several molecules [65,67]. |

| Effectiveness at lower concentrations | Leaf extracts generally exhibit better corrosion inhibition at lower concentrations [3]. | Fundamental aspects unknown, such as the appropriate plant part for extraction and the proper determination of the active compound. |

| Economic and environmental factors | Abundant, low-cost, economically viable, easily renewable, reliable, and biodegradable [18,66]. | - |

| Solubility and toxicity | Easily soluble in water or other polar solvents; less toxic to the environment and human health. | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Parra, J.R.; Di Turo, F. The Use of Plant Extracts as Sustainable Corrosion Inhibitors for Cultural Heritage Alloys: A Mini-Review. Sustainability 2024, 16, 1868. https://doi.org/10.3390/su16051868

González-Parra JR, Di Turo F. The Use of Plant Extracts as Sustainable Corrosion Inhibitors for Cultural Heritage Alloys: A Mini-Review. Sustainability. 2024; 16(5):1868. https://doi.org/10.3390/su16051868

Chicago/Turabian StyleGonzález-Parra, Jesús Rafael, and Francesca Di Turo. 2024. "The Use of Plant Extracts as Sustainable Corrosion Inhibitors for Cultural Heritage Alloys: A Mini-Review" Sustainability 16, no. 5: 1868. https://doi.org/10.3390/su16051868