Three co-treatment trials were conducted using the mixed liquor from Facility A over the vintage periods of 2017 and 2018. In addition to WWW, the bench-scale bioreactors were fed with primary effluent collected on the day of testing at Facility A. Multiple bench-scale bioreactors were operated in parallel during each trial, varying only in the volumetric loading of WWW in the feed (trial runs). During each trial, one bioreactor was fed with primary effluent alone as a control for the observed treatment performance in the absence of WWW (control run). Trials 1 and 2 investigated the short-term impacts of co-treating WWW (reaction period of 6 h), while Trial 3 investigated the operational and performance impacts over a longer period (72 h). The details associated with each trial are presented in

Table 4, while the concentrations of the key parameters in the WWW are summarized in

Table 1.

3.3.1. Operating Conditions and Effluent Quality

DO and pH were monitored regularly in each bench-scale bioreactor throughout each trial. Because the bioreactor pH remained at or above 7.5 for all runs (above the

pHinhib,obs of 7.1 to 7.4 for Facility A’s mixed liquor,

Table 3), the pH inhibition was not a factor during the co-treatment trials. It can be concluded that the buffering capacity of the mixed liquor and primary effluent was sufficient to maintain a stable pH at the WWW volumetric loadings tested. Despite this, the bioreactor pH should be monitored during full-scale co-treatment since a low pH can significantly reduce the biological oxidation rates (

Section 3.3) and insufficient alkalinity can impact the ability of a WWTP to nitrify [

12].

Air feed rates were equivalent to an aeration rate of 0.63 L/s per m

2 of the bioreactor surface area, which is consistent with the minimum design guideline rate of 0.61 L/m

2·s for fine-bubble aeration systems [

25]. The measured DO concentrations decreased in all bench-scale bioreactors at the outset of each trial, returning to values above 2.0 mg/L for all Trial 1 and 2 runs within 5 min. During the first feed cycle of Trial 3, the DO concentrations remained below 2.0 mg/L for the first 0.5 h for the control and 0.1%

v/

v WWW runs, and for the first 3 h for the 1.0%

v/

v WWW run; during subsequent feed cycles, the DO concentration was only observed to drop below 2.0 mg/L for the bioreactor fed with the 1.0%

v/

v WWW mixture and only during the first hour after addition. Therefore, the co-treatment trials operated under oxygen limited conditions (<2.0 mg/L) only transiently.

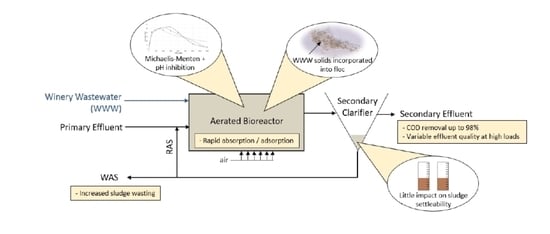

The initial feed (0 h) and simulated secondary effluent COD, TOC, and BOD

5 concentrations over the first 6 h of the reaction for all trials are shown in

Figure 4. Simulated secondary effluent quality at 6 h of reaction time was consistent regardless of the WWW addition rates up to initial feed concentrations of 1550 mg/L, 374 mg/L, and 774 mg/L for COD, TOC, and BOD

5, respectively. The overall observed removal rates at 6 h of reaction time were as high as 89% COD, 84% TOC, and 83% BOD

5 for runs fed with primary effluent only, and up to 98%, 97%, and 99% for runs fed with a mixture of primary effluent and WWW. Given the low BOD

5:COD ratios of the WWW, it can be concluded that the high rates of COD removal are due to sorption with the biological floc rather than biological oxidation. In spite of these high removal rates, elevated secondary effluent concentrations were still observed at high initial organic loading conditions, as illustrated in

Figure 4. Because municipal WWTPs in Ontario and other North American jurisdictions are required to meet effluent concentration limits as part of their approval permits, periods of high loadings could result in effluent non-compliance. Equalization to control the addition of WWW to the liquid treatment train, and to avoid slug loads, could be an effective method to improve the co-treatment performance.

Periods of poor sludge settleability and pin floc as well as poor UV disinfection performance were reported by the Niagara Region staff at co-treating WWTPs. It was hypothesized that the fine and poorly settling particulate solids fraction of the WWW may have contributed to poor sludge settleability and elevated effluent TSS concentrations, and that the complex and often refractory aromatic compounds in the WWW may remain in the treated effluent, resulting in a decrease in the secondary effluent UVT. The trial results suggest that WWW had little to no impact on the simulated secondary effluent turbidity or UVT, as depicted in

Figure 5, and may, conversely, improve the quality of the treated supernatant. After 6 h for all trials, runs fed with WWW had lower supernatant turbidity than the control run, with the exception of the 2.0%

v/

v WWW run from Trial 2 (initial feed COD and TSS concentrations of 5300 mg/L and 776 mg/L, respectively). During Trial 2, improved supernatant quality was observed after 5 h for all runs fed with WWW as compared to the control run (

Figure 5a). During Trial 3, consistent supernatant turbidity and UVT were observed for all three runs (0%

v/

v, 0.1%

v/

v, and 1.0%

v/

v) over the entire 72 h testing period. It can be concluded that the poorly settling solids and aromatic compounds present in the WWW did not increase the turbidity or decrease UVT during the co-treatment trials, suggesting that other mechanisms are responsible for these negative impacts on effluent quality in full-scale WWTPs during the co-treatment of WWW.

3.3.2. Changes in Mixed Liquor Characteristics and Solids Yield

The microscopic characteristics of the solids in the WWW are presented in

Figure 6, along with a microscopic analysis of the mixed liquor from Trial 3 after 56 h of reaction time. Generally, the solids in the WWW are fine and dispersed, ranging in size from 3 to 7 μm, although some larger flocs of agglomerated solids and pieces of grape skin with dimensions of up to approximately 80 μm were also observed, as illustrated in

Figure 6a. The mixed liquor floc from the control run, which was fed with primary effluent alone (

Figure 6b), was smaller and less dense than that from the run fed a mixture of WWW and the primary effluent (

Figure 6c). Given the clarity of the supernatant, as observed microscopically and measured by turbidity levels (

Figure 5), and the microscopic composition of the floc in

Figure 6c, it is clear that the solids present in the WWW are readily incorporated into the activated sludge floc structure.

Furthermore, the incorporation of these solids did not impact the SVI of the mixed liquor in Trials 1 or 3, and it appears to improve settleability at overall WWW solids loadings of 75 mg/L or more; however, a negative impact on SVI was observed during Trial 2, as shown in

Figure 7.

The settling characteristics of the WWW used during Trial 2 differed from that used in Trials 1 and 3 (

Table 4). While the source of the floating solids could not be identified, their presence likely contributed to the increase in SVI during Trial 2. The co-treatment of WWW with floating solids in the liquid treatment train should be avoided; where possible, these WWWs should be co-treated in the WWTP’s anaerobic digester to avoid poor sludge settleability in the liquid treatment train.

In the absence of floating solids, the incorporation of the WWW’s fine solids into the biological floc combined with the nature of the settleable solids in the WWW maintained the sludge settling characteristics (

Figure 7). It is likely that the presence of fining materials, which are added to clarify wine prior to bottling [

26], helps to maintain the settling properties of the mixed liquor during co-treatment.

The co-treatment of WWW significantly and rapidly increases the operating MLSS concentrations (

Table 5). During Trial 3, the addition of 1.0%

v/

v WWW feed caused the MLSS concentration to increase by 790 mg/L at 60 h of reaction time, compared with 250 mg/L with the addition of 0.1%

v/

v WWW feed and 130 mg/L in the control bioreactor. The increase in MLSS concentrations for all runs consisted almost exclusively of VSS, which is consistent with the high VSS:TSS ratio in the WWW and primary effluent, and anticipated biomass generation due to biological oxidation.

Compared to the control run, the observed VSS yield almost doubled with the addition of 1.0% v/v WWW. MLVSS is typically used as a proxy to estimate the concentration of active biomass in the system; however, based on the microscopic analysis of mixed liquor characteristics, it can be concluded that the majority of the increase in the observed yield was due to the incorporation of WWW solids into the floc structure. Therefore, MLVSS concentrations may not provide a representative estimate of the biomass in the co-treating activated sludge system.

The mixed liquor color is also used as a visual indication of biomass health. Visual observations during the co-treatment trials indicate that the bioreactor contents turn dark brown to black at progressively higher WWW loadings. Similar color changes were observed in WWW samples as the pH was increased above approximately 6.5. Dark or black mixed liquor is typically associated with septic or otherwise impaired conditions in the activated sludge; however, color should not be used as a diagnostic criterion during WWW co-treatment. The biomass condition and health should instead be monitored via microscopic analysis.

An increase in WAS rates would be needed during co-treatment to maintain consistent operating MLSS concentrations, which would decrease the operating SRT. To maintain a target SRT, co-treating WWTPs need to be designed to accommodate not only the additional oxygen demands associated with WWW’s organic loadings, but also additional solids inventory during the co-treatment period. This could be accomplished by oversizing bioreactors and/or providing additional secondary clarification capacity to operate at elevated MLSS concentrations.

Due to the generally good settling characteristics of WWW solids, adding this waste upstream of WWTP’s primary clarifiers would reduce solid loading on the downstream bioreactors, reducing the observed yield. However, due to the large fraction of soluble BOD

5 in the WWW (

Table 1), this approach would do little to reduce the oxygen demands in the downstream bioreactors. High solids and organic loadings to the primary clarifiers can promote the generation of septic conditions that result in rising sludge and poor removal rates across primary treatment [

27], which are consistent with issues reported by Niagara Region staff at their co-treating municipal WWTPs.

Ultimately, the results of this study were used as the basis for the development of a novel biological pre-treatment system to improve the co-treatment of high-strength wastewaters, including WWW, at municipal WWTPs [

28].