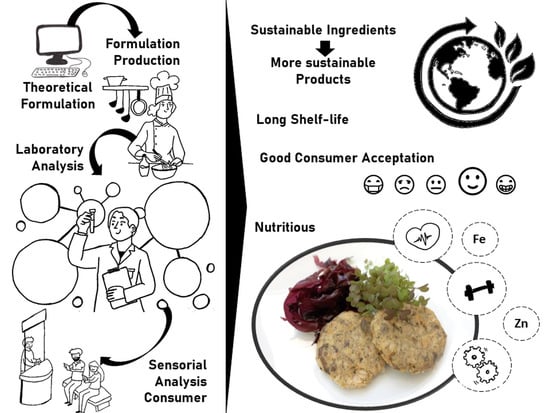

Development, Characterisation, and Consumer Acceptance of an Innovative Vegan Burger with Seaweed

Abstract

:1. Introduction

2. Materials and Methods

2.1. Selection of Ingredients and Formulations

2.2. Production of Vegan Burger

2.3. Chemical/Nutritional Composition

2.3.1. Sample Preparation

2.3.2. pH

2.3.3. Water Activity (aW)

2.3.4. Crude Protein Content

2.3.5. Total Fat Content

2.3.6. Water and Ash Content

2.3.7. Dietary Fibre Content

2.3.8. Sugar Content

2.3.9. Carbohydrate Content

2.3.10. Energy

2.3.11. Mineral Elements Profile

2.3.12. Fatty Acid Profile

2.3.13. Total Phenolic Content (TPC)

2.3.14. DPPH Assay

2.4. Shelf-Life Determination

2.4.1. Thiobarbituric Acid Reactive Substances (TBARS) Assay

2.4.2. Total Volatile Basic Nitrogen (TVB-N) Assay

2.4.3. Microbiological Study

2.4.4. Sensory Evaluation

2.5. Consumer Acceptance

2.6. Statistical Analysis

3. Results

3.1. Raw Material Selection

3.2. Physical and Chemical/Nutritional Composition

3.3. Shelf-Life

3.4. Consumer Acceptance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Reisch, L.; Eberle, U.; Lorek, S. Sustainable food consumption an overview of contemporary issues and policies. Sustain. Sci. Pract. Policy 2017, 9, 7–25. [Google Scholar] [CrossRef]

- Verplanken, B.; Roy, D. Consumer habits and sustainable consumption. In Handbook of Research on Sustainable Consumption; Edward Elgar Publishing: Cheltenham, UK, 2017; pp. 243–253. [Google Scholar]

- Goodland, R. Sustainability: Human, Social, Economic and Environmental. In Encyclopedia of Global Environmental Change; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2002. [Google Scholar]

- Fedema, J.; Freire, J. Soil degradation, global warming and climate impacts. Clim. Res. 2001, 17, 209–216. [Google Scholar] [CrossRef]

- Houghton, J. Global warming. Rep. Prog. Phys. 2005, 68, 1343–1403. [Google Scholar] [CrossRef]

- Rossati, A. Global Warming and Its Health Impact. Int. J. Occup. Environ. Med. 2017, 8, 7–20. [Google Scholar] [CrossRef] [Green Version]

- Froehlich, H.; Afflerbach, J.; Frazier, M.; Halpern, B. Blue Growth Potential to Mitigate Climate Change through Seaweed Offsetting. Curr. Biol. 2019, 29, 3087–3093. [Google Scholar] [CrossRef]

- Jones, A.; Alleway, H.; McAffe, D.; Reis-Santos, P.; Theuerkauf, S.; Jones, R. Climate-Friendly Seafood the Potential for Emissions Reduction and Carbon Capture in Marine Aquaculture. BioScience 2022, 72, 123–143. [Google Scholar] [CrossRef]

- Duarte, C.; Wu, J.; Bruhn, A.; Krause-Jensen, D. Can Seaweed Farming Play a Role in Climate Change Mitigation and Adaptation? Front. Mar. Sci. 2017, 4, 100. [Google Scholar] [CrossRef] [Green Version]

- Peñalver, R.; Lorenzo, J.; Ros, G.; Amarowicz, R.; Pateiro, M.; Nieto, G. Seaweeds as a Functional Ingredient for a Healthy Diet. Mar. Drugs 2020, 18, 301. [Google Scholar] [CrossRef] [PubMed]

- Lomartire, S.; Marques, J.; Gonçalves, A. An Overview to the Health Benefits of Seaweeds Consumption. Mar. Drugs 2021, 19, 341. [Google Scholar] [CrossRef]

- Choudhary, B.; Chauhan, O.; Mishra, A. Edible Seaweeds: A Potential Novel Source of Bioactive Metabolites and Nutraceuticals with Human Health Benefits. Front. Mar. Sci. 2021, 8, 740054. [Google Scholar] [CrossRef]

- Stévant, P.; Schemedes, P.; Le Gall, L.; Wegeberg, S.; Dumay, J.; Rebours, C. Concise review of the red macroalga dulse, Palmaria palmata (L.) Weber & Mohr. J. Appl. Phycol. 2023, 35, 523–550. [Google Scholar]

- Schiener, P.; Zhao, S.; Theodoridou, K.; Carey, M.; Mooney-McAuley, K.; Greenwell, C. The nutritional aspects of biorefined Saccharina latissima, Ascophyllum nodosum and Palmaria palmata. Biomass Convers. Biorefinery 2017, 7, 221–235. [Google Scholar] [CrossRef] [Green Version]

- Mouritsen, O.; Dawczynski, C.; Duelund, L.; Jahreis, G.; Vetter, W.; Schröder, M. On the human consumption of the red seaweed dulse (Palmaria palmata (L.) Weber & Mohr). J. Appl. Phycol. 2013, 25, 1777–1791. [Google Scholar]

- Soumare, A.; Diedhiou, A.; Thuita, M.; Hafidi, M.; Ouhdouch, Y.; Gopalakrishnan, S.; Kouisni, L. Exploiting Biological Nitrogen Fixation a Route Towards a Sustainable Agriculture. Plants 2020, 9, 1011. [Google Scholar] [CrossRef] [PubMed]

- Büchi, L.; Gebhard, C.; Liebisch, F.; Sinaj, S.; Ramseier, H.; Charles, R. Accumulation of biologically fixed nitrogen by legumes cultivated as cover crops in Switzerland. Plant Soil 2015, 393, 163–175. [Google Scholar] [CrossRef]

- Howieson, J.; O’Hara, G.; Carr, S. Changing roles for legumes in Mediterranean agriculture developments from an Australian perspective. Field Crops Res. 2000, 65, 107–122. [Google Scholar] [CrossRef]

- Smartt, J. Evolution of Grain Legumes. I. Mediterranean Pulses. Exp. Agric. 1984, 20, 275–296. [Google Scholar] [CrossRef]

- Campbell, C.G. Promoting the Conservation and Use of Underutilized and Neglected Crops; Seeland Bioversity International: Seeland, Germany, 1997; Volume 18. [Google Scholar]

- Lambein, F.; Travella, S.; Kuo, Y.; Van Montagu, M.; Heijde, M. Grass pea (Lathyrus sativus L.) orphan crop, nutraceutical or just plain food? Plants 2019, 250, 821–838. [Google Scholar] [CrossRef] [Green Version]

- Hanbury, C.; White, C.; Mullan, B.; Siddique, K. A review of the potential of Lathyrus sativus L. and L. cicera L. grain for use as animal feed. Anim. Feed Sci. Technol. 2000, 87, 1–27. [Google Scholar] [CrossRef]

- Hillocks, R.; Maruthi, M. Grass pea (Lathyrus sativus) Is there a case for further crop improvement? Euphytica 2012, 186, 647–654. [Google Scholar] [CrossRef]

- Rahman, Q.; Akhtar, N.; Chowdhury, A. Proximate composition of foodstuffs in Bangladesh. Part 1. Cereals and Pulses. J. Sci. Ind. Res. 1974, 9, 129–133. [Google Scholar]

- Santos, R.; Mansidão, A.; Mota, M.; Raymundo, A.; Prista, C. Development and physicochemical characterization of a new grass pea (Lathyrus sativus L.) miso. J. Sci. Food Agric. 2020, 101, 2227–2234. [Google Scholar] [CrossRef] [PubMed]

- Arenas-Jal, M.; Suñé-Negre, J.; Pérez-Lozano, P.; García-Montoya, E. Trends in the food and sports nutrition industry A review. Crit. Rev. Food Sci. Nutr. 2019, 60, 2405–2421. [Google Scholar] [CrossRef] [PubMed]

- Folch, J.; Lees, M.; Stanley, G. A Simple Method for The Isolation and Purification of Total Lipides from Animal Tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Duarte, A.; Silva, F.; Mendes, S.; Pinto, F.; Barroso, S.; Silva, E.; Neves, A.; Sequeira, V.; Magalhães, M.; Rebelo, R.; et al. Seasonal study of the nutritional composition of unexploited and low commercial value fish species from the Portuguese coast. Food Sci. Nutr. 2020, 10, 3368–3379. [Google Scholar] [CrossRef]

- Dubois, M.; Gilles, A.; Hamilton, J.; Rebers, P.; Smith, F. Colorimetric Method for Determination of Sugars and Related Substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- FAO. Food Energy—Methods of Analysis and Conversion Factors; FAO Food and Nutrition Paper 77; The Food and Agriculture Organization: Rome, Italy, 2003. [Google Scholar]

- Regulation (EU) No. 1169/2011 of the European Parliament and of the Council of 25 October 2011. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2011:304:0018:0063:en:PDF (accessed on 20 November 2022).

- Pinto, F.; Duarte, A.; Silva, F.; Barroso, S.; Mendes, S.; Pinto, E.; Almeida, A.; Squeira, V.; Vieira, A.; Gordo, L.; et al. Annual variations in the mineral element content of five fish species from the Portuguese coast. Food Res. Int. 2022, 158, 111482. [Google Scholar] [CrossRef]

- Pereira, T.; Horta, A.; Barroso, S.; Mendes, S.; Gil, M.M. Study of the Seasonal Variations of the Fatty Acid Profiles of Selected Macroalgae. Molecules 2021, 26, 5807. [Google Scholar] [CrossRef]

- Weihrauch, J.; Posati, L.; Anderson, B.; Exler, J. Lipid Conversion Factors for Calculating Fatty Acid Contents of Foods. J. Am. Oil Chem. Soc. 1977, 54, 36–40. [Google Scholar] [CrossRef]

- USDA. USDA Agriculture Handbook No. 8; USDA: Washington, DC, USA, 1978. [Google Scholar]

- Singleton, V.; Rossi, J. Colorimetry of Total Phenolic Compounds with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Waterhouse, A. Determination of Total Phenolics. Curr. Protoc. Food Anal. Chem. 2003, 6, I1.1.1–I1.1.8. [Google Scholar]

- Pinteus, S.; Silva, J.; Alves, C.; Horta, A.; Fino, N.; Rodrigues, A.; Mendes, S.; Pedrosa, R. Cytoprotective effect of seaweeds with high antioxidant activity from the Peniche coast (Portugal). Food Chem. 2016, 218, 591–599. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.; Berset, C. Use of a free radical method to evaluate antioxidant activity. Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Portuguese Standard NP 3356:2009; Pescado. Determinação do Índice de Ácido Tiobarbitúrico. (T.B.A.). Método Espectrofotométrico. Instituto Português de Qualidade: Lisboa, Portugal, 2009.

- Portuguese Standard NP 2930:2009; Pescado. Determinação do Teor de Azoto Básico Volátil Total (A. B. V. T.). Método de Conway. Instituto Português de Qualidade: Lisboa, Portugal, 2009.

- Rahman, M.; Rahman, R. pH in Food Preservation. In Handbook of Food Preservation; CRC Press: Boca Raton, FL, USA, 2020; pp. 323–332. [Google Scholar]

- Latunde-Dada, G.O.; Kajarabille, N.; Rose, S.; Arafsha, S.M.; Kose, T.; Aslam, M.F.; Hall, W.L.; Sharp, P.A. Content and Availability of Minerals in Plant-Based Burgers Compared with a Meat Burger. Nutrients 2023, 15, 2732. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EC) No. 1924/2006 of the European Parliament and of the Council of 20 December 2006. Available online: https://www.legislation.gov.uk/eur/2006/1924/contents (accessed on 20 November 2022).

- Krogdahl, Å.; Jaramillo-Torres, A.; Ahlstrøm, Ø.; Chikwati, E.; Aasen, I.-M.; Kortner, T.M. Protein value and health aspects of the seaweeds Saccharina latissima and Palmaria palmata evaluated with mink as model for monogastric animals. Anim. Feed Sci. Technol. 2021, 276, 114902. [Google Scholar] [CrossRef]

- Greenfield, H.; Southgate, D. Food Composition Data: Production, Management and Use; Food and Agriculture Organization of the United Nation: Quebec City, QC, Canada, 2003; Volume 2, p. 295. [Google Scholar]

- Ramya, K.R.; Tripathi, K.; Pandey, A.; Barpete, S.; Gore, P.G.; Raina, A.P.; Khawar, K.M.; Swain, N.; Sarker, A. Rediscovering the Potential of Multifaceted Orphan Legume Grasspea—A Sustainable Resource with High Nutritional Values. Front. Nutr. 2022, 8, 826208. [Google Scholar] [CrossRef]

- Buttriss, J.; Stokes, C. Dietary fibre and health an overview. Nutr. Bull. 2008, 33, 186–200. [Google Scholar] [CrossRef]

- Siciliano, C.; Belsito, E.; De Marco, R.; Di Gioia, M.; Leggio, A.; Liguori, A. Quantitative determination of fatty acid chain composition in pork meat products by high resolution 1H NMR spectroscopy. Food Chem. 2013, 136, 546–554. [Google Scholar] [CrossRef]

- Smetana, S.; Profeta, A.; Voigt, R.; Kircher, C.; Heinz, V. Meat substitution in burgers Nutritional scoring, sensorial testing, and Life Cycle Assessment. Future Foods 2021, 4, 100042. [Google Scholar] [CrossRef]

- Bird, R.; Eskin, N. Advances in Food and Nutrition Research—The Latest Research and Development of Minerals in Human Nutrition; Academic Press: Cambridge, UK, 2021; Volume 96. [Google Scholar]

- Abbaspour, N.; Hurrel, R.; Kelishadi, R. Review on iron and its importance for human health. J. Res. Med. Sci. 2014, 19, 164–174. [Google Scholar]

- Camaschella, C. Iron deficiency. Blood 2019, 133, 30–39. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cakmak, I. Magnesium in crop production, food quality and human health. Plant Soil 2013, 368, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Araya, M.; Pizarro, M. Copper in human health. Int. J. Environ. Health 2007, 1, 608–620. [Google Scholar] [CrossRef]

- Sousa, C.; Moutinho, C.; Vinha, A.; Matos, C. Trace Minerals in Human Health Iron, Zinc, Copper, Manganese and Fluorine. Int. J. Sci. Res. Methodol. 2019, 13, 57–80. [Google Scholar]

- Grillo, A.; Salvi, L.; Coruzzi, P.; Salvi, P.; Parati, G. Sodium Intake and Hypertension. Nutrients 2019, 11, 1970. [Google Scholar] [CrossRef] [Green Version]

- Heiras-Palazuelos, M.; Ochoa-Lugo, M.; Gutiérrez-Dorado, R.; López-Valenzuela, J.; Mora-Rochín, S.; Milán-Carrillo, J.; Reyes-Moreno, C. Technological properties, antioxidant activity and total phenolic and flavonoid content of pigmented chickpea (Cicer arietinum L.) cultivars. Int. J. Food Sci. Nutr. 2013, 64, 69–76. [Google Scholar] [CrossRef]

- Yuan, Y.; Bone, D.; Carrington, M. Antioxidant activity of dulse (Palmaria palmata) extract evaluated in vitro. Food Chem. 2005, 91, 485–494. [Google Scholar] [CrossRef]

- Segev, A.; Badani, H.; Galili, L.; Hovav, R.; Kapulnik, Y.; Shomer, I.; Galili, S. Total Phenolic Content and Antioxidant Activity of Chickpea (Cicer arietinum L.) as Affected by Soaking and Cooking Conditions. Food Nutr. Sci. 2011, 2, 724–730. [Google Scholar]

- Surh, J.; Koh, E. Effects of four different cooking methods on anthocyanins, total phenolics and antioxidant activity of black rice. J. Sci. Food Agric. 2014, 94, 3296–3304. [Google Scholar] [CrossRef]

- Turkmen, N.; Sari, F.; Velioglu, Y.S. The effect of cooking methods on total phenolics and antioxidant activity of selected green vegetables. Food Chem. 2005, 93, 713–718. [Google Scholar] [CrossRef]

- INSA—Interpretação de Resultados de Ensaios Microbiológicos—Valores-Guia. Available online: https://www.insa.min-saude.pt/interpretacao-de-resultados-de-ensaios-microbiologicos-valores-guia-insa-2019/ (accessed on 23 November 2022).

- Danyluk, M.; Parish, M.; Goodrich-Schneider, R.; Worobo, R. Microbial Decontamination in the Food Industry—Novel Methods and Applications; Woodhead Publishing, Swanson: Sawston, UK, 2012. [Google Scholar]

- Peng, J.; Tang, J.; Barrett, D.; Sablani, S.; Anderson, N.; Powers, J. Thermal pasteurization of ready-to-eat foods and vegetables Critical factors forprocess design and effects on quality. Crit. Rev. Food Sci. Nutr. 2017, 57, 2970–2995. [Google Scholar] [CrossRef] [PubMed]

- Hierro, E.; Barroso, E.; de la Hoz, L.; Ordóñez, J.; Manzano, S.; Fernández, M. Efficacy of pulsed light for shelf-life extension and inactivation of Listeria monocytogenes on ready-to-eat cooked meat products. Innov. Food Sci. Emerg. Technol. 2011, 12, 275–281. [Google Scholar] [CrossRef]

| pH | 5.15 ± 0.01 |

| aW | 0.955 ± 0.004 |

| Water content | 60.7 ± 0.6% FW |

| Energy | 798.15 kJ (190.05 kcal) |

| Total fats | 5.35 ± 0.11% FW |

| Saturated fats | 0.87 ± 0.01% FW |

| Carbohydrates | 24.59% FW * |

| Sugars | 1.71 ± 0.03% FW |

| Fibre | 5.75% FW * |

| Total protein | 8.01 ± 0.14% FW |

| TPC | 0.29 ± 0.01 mg GAE/g FW |

| DPPH | below the detection limit |

| C12 | 1.28 ± 0.05 |

| C14 | 0.22 ± 0.01 |

| C15 | 0.22 ± 0.01 |

| C16 | 11.64 ± 0.14 |

| C16:1 | 0.37 ± 0.02 |

| C17 | 0.37 ± 0.01 |

| C18 | 5.89 ± 0.20 |

| C18:1 | 21.01 ± 0.64 |

| C18:2 | 53.65 ± 1.75 |

| C18:3 | 4.82 ± 1.17 |

| C20 | 0.52 ± 0.14 |

| SFA | 20.15 ± 0.31 |

| MUFA | 21.38 ± 0.65 |

| PUFA | 58.47 ± 0.73 |

| Colony Forming Units (CFU/g) | |||

|---|---|---|---|

| Total Aerobic Microorganisms at 30 °C | Psychrophiles | Moulds and Yeasts | |

| Day 1 | <10 | <10 | <10 |

| Day 30 | <10 | <10 | <10 |

| Day 90 | <10 | <10 | <10 |

| Day 180 | <10 | <10 | <10 |

| Criteria | |||

|---|---|---|---|

| Microbiological | Physical and Chemical | Sensory | |

| Estimated shelf life | >180 days | >180 days | 90 days |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, W.D.; Pinto, F.R.; Barroso, S.; Gil, M.M. Development, Characterisation, and Consumer Acceptance of an Innovative Vegan Burger with Seaweed. Sustainability 2023, 15, 10869. https://doi.org/10.3390/su151410869

Fernandes WD, Pinto FR, Barroso S, Gil MM. Development, Characterisation, and Consumer Acceptance of an Innovative Vegan Burger with Seaweed. Sustainability. 2023; 15(14):10869. https://doi.org/10.3390/su151410869

Chicago/Turabian StyleFernandes, Wilson D., Filipa R. Pinto, Sónia Barroso, and Maria M. Gil. 2023. "Development, Characterisation, and Consumer Acceptance of an Innovative Vegan Burger with Seaweed" Sustainability 15, no. 14: 10869. https://doi.org/10.3390/su151410869